Electrical Resistance Test Methods for EMI Coating Processes

advertisement

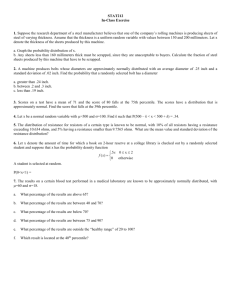

Acheson Colloids Company 1600 Washington Avenue Port Huron, MI 48060 (800) 255-1908 www.achesonindustries.com web.mail@nstarch.com Also: Australia, Brazil, China, France, Italy, Japan, Korea, Mexico, Netherlands, Singapore, Spain, United Kingdom Foreword Measurement of electrical resistance during the processing of EMI coatings can be confusing, especially when comparing numbers to the paint manufacturer’s method. This report describes current industry standards and makes suggestions for proper electrical resistance testing methods. It is essential that coaters monitor film thickness, degree of cure, and conductivity on a daily basis to control costs and ensure optimum coating performance. Current Industry Standards Point-to-Point The most common and easiest resistance measurement is point-to-point testing performed by simply touching ohmmeter probes to the painted surface. Locations of the probes are agreed upon between the OEM and coater. Drawbacks of this method, which affects resistance values, are uncontrolled normal force (pressure applied), sharpness of the probes, distance and location of the probes and oxidation of the probes. While point-to-point is a good and necessary practice, it should be accompanied by film thickness monitoring. Ohm/Square The methods discussed below are erroneously referred to as ohm/square; a distinct square(s) is not actually defined. A convenient “stethoscope” method is to attach an ohm/square jig to the ohmmeter leads. Three ohm/square test jigs became popular in the market over the last ten years: a point-to-point jig, a square block jig, and *Versatronic™ probes held at 1 cm spacing. Ω/Square 1cm Versatronic Probes 1cm 1 Caution: These methods may not be accurate or sensitive enough for the highly conductive coatings and conventional ohmmeter tolerances of today. Readings of 0.01 ohms are common while most conventional ohmmeters have a tolerance of ±0.01 ohms. Indeed, most readings with the square probe jig is < 0.01 ohms, accuracy therefore unknown. The one inch point-to-point jig was useful because it was spring loaded, included only two points of contact and, for higher resistance coatings measured a value close to double the ohm/square value (empirically determined). It can still be useful for comparison measurements. The ohm/square jig is based on two 1 cm square probes spaced at a distance of 1 cm. Drawbacks are uncertain normal force (no springs), uncertain contact area (plastic substrate is typically not flat and, therefore, does not conform to flat probes), and oxidation of the probes. Versatronic™ probes and meters have become popular for its high resolution (±0.001 ohm) and because IBM specified it for measuring conductivity on platings. The probes alleviate the aforementioned drawbacks; normal force is controlled by spring pressure, probes are rounded tip to provide somewhat consistent penetration, and gold plated to reduce oxidation. Versatronic™ readings for conductive paints were originally reported to give ohm/square readings at 1 cm spacing, leading to erroneous ohm/square/mil values reported on paint manufacturers specifications. These errors have been addressed as shown in the section on ohm/square/mil methodology. The most common method in use today for measuring point to point resistivity is the use of an ohmmeter with two leads, which can be placed virtually anywhere on the coated surface. This method allows for readings to be taken from any two points on the coated surface. Versatronic is a registered trademark of Electronic Automation, Inc. 2 Method for Determining Ohms/sq/mil of EMI Coatings SCOPE: To determine the dry film electrical resistivity of conductive coatings. EQUIPMENT: 1. Ohmmeter with low resistance capability that can accept four leads. 2. Special compression contact jig (see Attachment #1, Drawings 1 & 2) for measuring the electrical resistivity of a 1” x 3” area of coated surface. METHOD: 1. A product to be tested for electrical resistance should be applied to a suitable substrate (most commonly a glass plate or GE Lexan® panel) measuring 3” in width and a minimum 4” in length. The coating needs to be properly cured before testing. If the coating is applied onto a glass panel, this same panel can be used to measure dry film thickness after resistivity has been recorded. If the coating is applied onto plastic, a glass slide (typically a 1” x 3” microscope slide) needs to be fixed onto the back of the panel, partially exposed, in the area where resistivity will be measured (see Diagram #1) NOTE: Identification of application method, cure, dilution ratio, if any, and recommended film thickness can be found on the Product Data Sheet. 2. Product application for this test can be by spray or drawdown technique, as specified on the Product Data Sheet. If drawdown technique is used, it must be performed on glass substrate to accurately measure dry film thickness. 3. A one-inch wide section should be scribed into the cured coating. This can be easily done using a 1” x 3” standard microscope slide as a template to measure the 1 inch width of the cut. Be certain that the scribe goes completely through the coating. 4. The electrical resistance of the coating can then be tested using the special jig and the ohmmeter. The ohmmeter must accept four leads to eliminate lead resistance failures. Ensure the leads from the inner probes are wired to the source input on the ohmmeter and the outer probes are wired to the sense input of the ohmmeter. Before performing actual resistance measurements, check the electrical resistance specifications of the product being tested and set the ohmmeter at an appropriate scale. 5. Once the meter has been properly adjusted, insert the coated test panel into the special jig ensuring the scribed area is lined up with the contacts. There is a marked area on the jig for this purpose. 6. Obtain and record the electrical resistance reading from the ohmmeter. This value represents ohms/square inch resistivity of the coating. 3 7. Measure the thickness of the coated glass slide using a micrometer. The measurement must be done in an area where the electrical resistance was made (again, refer to diagram #1). Remove the coating using a razor blade (in the same area the initial thickness measurement was made) and determine the thickness of the glass slide with the micrometer. Subtracting the thickness of the glass slide from the thickness of the glass slide and coating will give the thickness of the coating. 8. The electrical resistance is expressed in units of ohms per square inch at a thickness of 0.001 inch (one mil). The “ohms per square inch” is obtained as the compression contacts on the electrical resistance jigs are one inch apart. This, combined with the one-inch scribe, results in measuring one square inch of coating. 9. To calculate the electrical resistance, multiply the obtained electrical resistance by the film thickness of the coating. This will give an electrical resistance value normalized to a thickness of 0.001 inch, or “ohms/square/mil.” GE Lexan is a registered trademark of General Electric. DIAGRAM #1 4 Attachment #1 – Drawing 1 5 Attachment #1 – Drawing 2 6 1600 Washington Avenue Port Huron, MI 48060 (800) 255-1908 Fax: (810) 984-1446 www.achesonindustries.com web.mail@nstarch.com The information given and the recommendations made herein are based on our research and are believed to be accurate but no guaranty of their accuracy is made. In every case, we urge and recommend that purchasers, before using any product in full scale production, make their own tests to determine to their own satisfaction whether the product is of acceptable quality and is suitable for their particular purposes under their own operating conditions. THE PRODUCTS DISCLOSED HEREIN ARE SOLD WITHOUT ANY WARRANTY AS TO MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OR ANY OTHER WARRANTY, EXPRESS OR IMPLIED. No representative of ours has any authority to waive or change the foregoing provisions but, subject to such provisions, our engineers are available to assist purchasers in adapting our products to their needs and to the circumstances prevailing in their business. Nothing contained herein shall be construed to imply the nonexistence of any relevant patents or to constitute a permission, inducement or recommendation to practice any invention covered by any patent, without authority from the owner of this patent. We also expect purchasers to use our products in accordance with the guiding principles of the American Chemistry Council® program. Printed in U.S.A. 08-752-RV120303 7