indagine di mercato macchine tessili _maggio 2014

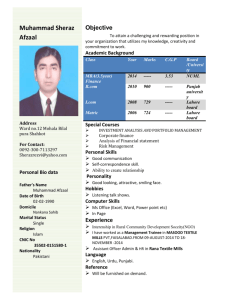

advertisement

Italian Trade Commission – Jakarta Trade Promotion Office of the Italian Embassy Indonesian Textile Industry and Machinery Market Report and Statistics 2012 and 2013 Country Reference period : Indonesia : January 2012 – December 2013 1. The General Economic Situation in the Country for 2012 and 2013 In 2012, despite the global economic downturn suppressing the trade lines, by public domestic consumption and high investment, Indonesia’s economy in 2012 maintained its growth momentum amid a slowdown and uncertainty in the global economy. Indonesia’s GDP reached Rp 8,241.86 trillion or US$ 862.5 billion, registering a growth rate of 6.2%, down from 6.5% in 2011, with inflation remaining relatively low at 4.3%. The biggest contributor to Indonesia’s overall GDP is the manufacturing sector, accounting for 23.94% in 2012. Amid weaker exports performance, the national economic expansion was driven mainly by strong domestic demand, buttressed by favorable macroeconomic and financial conditions. Total exports in 2012 reached US$ 190.04 billion, representing a decrease of 6.61% over 2011 which reached US$ 203.50 billion. Non-oil and gas exports dropped from US$ 162.02 billion to US$ 153.05 billion, registering a growth rate of - 5.54%. Total imports rose by 8.04% to US$ 191.67 billion from US$ 177.43 billion, with non-oil and gas imports increasing by 9.06% from US$ 136.73 billion to US$ 149.13 billion, resulting in a trade deficit of US$ 1,659.2 billion. Indonesia’s economic growth in 2013 was lower than in 2012, down to 5.8% from 6.2% in the previous year, reaching Rp 9,083.97 trillion or US$ 912.5 billion. The global economy, especially in developed countries, was slowing, followed by corrections to economic growth in emerging markets, including Indonesia. In terms of domestic demand, investment growth, particularly non-construction investments, was also slowing. The uncertainty of the global financial situation has increased sharply in line with negative sentiment to the reduction of the monetary stimulus in the US. The average exchange rate in 2013 weakened to Rp 10,562.7 per US Dollar. Total exports in 2013 dropped further to US$ 182.55 billion, representing a decrease of 3.94% year-on-year over 2012. Total imports decreased by 2.63% to US$ 186.63 billion from US$ 191.67 billion, resulting in a trade deficit of - US$ 4.08 billion. Entering the year 2014, there are still many challenges to be faced by the country. Indonesia’s economic growth is still going to be affected by the global economic outlook. Volatility in global commodity prices and demands is expected to continue to affect Indonesia’s trade balance. In the context of regional economic outlook, uncertainty of the global economic recovery will also affect exports and imports and investments in regions. Indonesia’s economy is expected to grow moderately in 2014 due to the impact of the economic tightening policy. The moderation in domestic demand is expected to continue, while export performance will improve with the continuing global economic recovery to drive improvements in Indonesia’s economic structure, with economic growth in 2014 expected to reach 5.6%. Inflation will likely normalize to 5.5% in 2014 after fuel price hike in 2013. In the medium term, inflation is expected to converge to its regional average of 3.5-4.0%. 2 Italian Trade Commission – Jakarta Trade Promotion Office of the Italian Embassy 2. Summary of the Economic Trend in the Textile Sector for 2012 and 2013 According to data from the Ministry of Trade, exports of textile and textile articles (including garments) rose from US$ 12.46 billion in 2012 to US$ 13.30 billion in 2013, representing an increase of 6.74%. Textiles and apparel account for 8.69 % of total non-oil exports from Indonesia. Out of the total textile and textile articles exports, garments made up for a share of approximately 60.0%. Imports rose by 5.66% from US$ 5.3 billion to US$ 5.6 billion, resulting in a surplus of US$ 7.7 billion. As a result in the influx of garment imports, the domestic sales of textile and textile products dropped from US 7.6 billion in 2012 to US$ 6.8 billion, registering a negative growth of 10.52%. According to the Indonesian Textile Association (API), backed by good demand from countries like the US and Japan, Indonesia’s textile exports are expected to reach $14.4 billion in 2014 and the country’s textile sector is expected to attract investments of about US$ 165 million. 3. Imports of Textile Machines, 2012 as against 2013 (in 1000 of US$) Machines Jan-Dec 2012 Jan-Dec 2013 Spinning 79,136.49 86,448.38 Weaving 119,948.71 107,675.10 Knitting 17,719.30 14,149.37 64,856.49 35,353.25 Finishing & Others Accessories 29,491.16 48,935.39 311,152.15 292,561.50 Total Source: Central Statistics Agency, processed Growth (%) 9.24 (10.23) (20.15) (45.49) 65.93 (5.97) 4. Origin of Imported Machines, January-December 2012 (in 1000 of US$) Country Spinning Weaving Knitting Finishing & Others 2,671.60 5,630.23 4,772.74 36,581.94 5,443.08 1,964.84 5,465.64 210.93 64.14 32.60 2,018.74 64,856.49 Accessories Japan 17,791.45 26,888.19 920.36 1,758.05 China 12,497.84 48,469.71 1,362.75 6,669.25 Taiwan 3,022.15 10,408.09 2,952.91 2,278.62 Germany 15,722.96 8,520.94 10,522.39 8,642.03 Korea 3,259.27 2,065.03 751.08 574.74 United States 161.22 141.33 102.23 43.93 Italy 2,516.93 4,938.88 99.54 311.44 United Kingdom 313.28 313.47 22.33 110.06 Switzerland 7,108.84 382.82 164.79 1,569.34 India 10,063.04 1,294.28 264.02 790.15 Others 6,679.53 16,526.00 556.91 6,743.55 TOTAL 79,136.49 119,948.71 17,719.30 29,491.16 Source: Central Statistics Agency, processed Origin of Imported Machines, January - June 2013 (in 1000 of US$) Total 50,029.64 74,629.78 23,434.50 79,990.26 12,093.20 2,413.55 13,332.44 970.07 9,289.93 12,444.08 32,524.72 311,152.14 3 Italian Trade Commission – Jakarta Trade Promotion Office of the Italian Embassy Country Spinning Weaving Knitting Japan 15,076.73 36,817.24 1,214.90 China 21,405.99 28,719.21 1,083.30 Taiwan 2,016.34 7,563.49 367.76 Germany 15,383.20 6,489.08 4,233.51 Korea 3,176.17 894.50 813.92 United States 414.17 209.69 36.02 Italy 2,442.48 2,192.61 248.53 United Kingdom 459.44 2.99 73.30 Switzerland 7,041.91 2,266.16 278.98 India 11,572.38 2,387.47 1,304.64 Others 7,459.58 20,132.69 4,494.51 TOTAL 86,448.38 107,675.10 14,149.37 Source: Central Statistics Agency, processed Finishing & Others 7,761.68 7,068.34 4,848.34 3,594.42 3,376.59 1,814.34 1,231.38 810.96 699.31 56.51 4,091.40 35,353.25 Accessories 3,568.47 16,435.89 3,354.33 4,074.91 780.00 44.67 10,075.85 22.28 2,487.40 1,939.43 6,152.17 48,935.39 Total 64,439.02 74,712.71 18,150.25 33,775.13 9,041.18 2,518.88 16,190.84 1,368.97 12,773.76 17,260.42 42,330.35 292,561.49 5. Positive Quality Image of Italian Textile Machinery Production and Trade Italian textile machinery has a high-quality image in Indonesia and is recognized for their technological innovation, creativity, sophistication, flexibility, durability and reliability, and is acknowledged to be among the best in the market. 6. Shortcomings of Italian Textile Machinery Production and Trade Interviews with numerous end-users of Italian textile machinery indicated that the main weakness does not lie in the machines themselves but rather in the weak distribution network and lack of promotion on the part of the local agents and distributors. One of the most important key criteria is the credit/ payment terms. In general, Japanese textile machinery suppliers are known to offer the best payment terms, better than European competitors. Chinese equipment on the other hand offer machines at the lowest prices and are known to have improved their quality and technology. 7. Investments in the Textile Industry Planned for the Near Future (5 years) ok Year Foreign Investment (PMA) Domestic Investment (PMDN) Number & Total Value Number & Total Value 2009 66 investments (US$ 251.4 million) 23 investments (Rp 2,645.7 billion) 2010 8 investments (US$ 154.8 million) 8 investments (Rp 431.7 billion) 2011 166 investments (US$ 497.3 million) 51 investments (Rp 999.2 billion) 2012 149 investments (US$ 473.1 million) 22 investments (Rp 4,450.9 billion) 2013 241 investments (US$ 759.7 million) 88 investments (Rp 1,686.3 billion) Source: Investment Coordinating Board, processed Note: The above data is based on investment approvals by the Investment Coordinating Board (BKPM) and hence does not necessarily represent the actual investments to take place in the forthcoming five years. 4 Italian Trade Commission – Jakarta Trade Promotion Office of the Italian Embassy 8. Production of Various Textile Products: January - December 2010 (code PRODCOM) Description Code Volume (in kg) Value (in US$) Man-made fibres yarn (17.10.51 to 17.10.55) 22,520,841,201 4,668,140,512 Man-made fibres fabrics (17.20.31 to 17.20.33) 1,818,005,297 3,007,378,979 Cotton yarns (17.10.43) 4,677,626,949 700,601,844 Cotton fabrics (17.20.20) 286,848,296 742,575,786 Wool yarns (17.10.42) 1,080,000 4,877,790 Wool fabrics (17.20.10.22) 29,317,480 2,318,685 Silk yarns (17.10.41) 115,321 8,235,048 Silk fabrics (17.20.10.10) 126,559,511 Knitwear (17.72) 10,471,816 (77,910,309 m) 164,706,509 pcs Socks and Stockings (17.71) 46,906,534 pcs 98,989,389 478,150,669 Source: Central Statistics Agency, Large and Medium Industrial Production Statistics, processed. Year 2010 constitutes the latest production data available. 9. Exports of Various Textile Products: January - December 2012 (code NACE/CLIO) Description Man-made fibres yarn HS – Code Volume (in Kg) Value (in US$) 312,385,971 888,088,117 150,493,857 959,852,730 Cotton yarns (54.01 to 54.06 55.09 to 55.11) (54.07 to 54.08 55.12 to 55.16) (52.04 to 52.07) 116,688,393 380,501,353 Cotton fabrics (52.08 to 52.12) 33,464,712 210,548,986 Wool yarns (51.07 to 51.10) - - Wool fabrics 10,388 150,742 Silk yarns (51.11 - 51.12 51.13) (50.04 to 50.06) 965 1,790 Silk fabrics (50.07) - - Kneatwear (61.09 to 61.10) 97,640,102 1,388,829,574 Socks and stockings (61.15) 9,585,480 114,254,775 Man-made fibres fabrics Source: Central Statistics Agency, processed Exports of Various Textile Products: January – December 2013 (code NACE/CLIO) 5 Italian Trade Commission – Jakarta Trade Promotion Office of the Italian Embassy Description Man-made fibres yarn HS – Code Volume (in Kg) Value (in US$) 355,176,939 952,054,531 146,021,282 863,853,853 Cotton yarns (54.01 to 54.06 55.09 to 55.11) (54.07 to 54.08 55.12 to 55.16) (52.04 to 52.07) 184,982,909 478,933,444 Cotton fabrics (52.08 to 52.12) 35,446,481 212,673,136 Wool yarns (51.07 to 51.10) - - Wool fabrics 4,483 82,144 Silk yarns (51.11 - 51.12 51.13) (50.04 to 50.06) 1,182 377 Silk fabrics (50.07) - - Kneatwear (61.09 to 61.10) 105,639,959 1,288,028,960 Socks and stockings (61.15) 10,158,077 117,523,966 Man-made fibres fabrics Source: Central Statistics Agency, processed 10. Imports of Various Textile Products: January - December 2012 (code NACE/CLIO) Description Man-made fibres yarn HS – Code Volume (in Kg) Value (in US$) 128,847,516 405,174,034 111,289,320 859,066,762 Cotton yarns (54.01 to 54.06 55.09 to 55.11) (54.07 to 54.08 55.12 to 55.16) (52.04 to 52.07) 26,475,829 106,793,526 Cotton fabrics (52.08 to 52.12) 104,181,467 1,038,323,665 Wool yarns (51.07 to 51.10) - - Wool fabrics 986,079 20,621,748 Silk yarns (51.11 - 51.12 51.13) (50.04 to 50.06) 240,671 903,084 Silk fabrics (50.07) - - Kneatwear (61.09 to 61.10) 2,995,655 41,749,683 Socks and stockings (61.15) 465,684 4,179,392 Man-made fibres fabrics Source: Central Statistics Agency, processed Imports of Various Textile Products: January – December 2013 (code NACE/CLIO) 6 Italian Trade Commission – Jakarta Trade Promotion Office of the Italian Embassy Description Man-made fibres yarn HS – Code Volume (in Kg) Value (in US$) 134,190,318 429,463,659 109,458,003 863,289,575 Cotton yarns (54.01 to 54.06 55.09 to 55.11) (54.07 to 54.08 55.12 to 55.16) (52.04 to 52.07) 33,140,468 130,280,678 Cotton fabrics (52.08 to 52.12) 101,069,434 1,048,876,525 Wool yarns (51.07 to 51.10) - - Wool fabrics 928,312 20,150,630 Silk yarns (51.11 - 51.12 51.13) (50.04 to 50.06) 245,181 745,655 Silk fabrics (50.07) - - Kneatwear (61.09 to 61.10) 5,246,580 59,202,890 Socks and stockings (61.15) 509,826 4,570,255 Man-made fibres fabrics Source: Central Statistics Agency, processed 11. Value of Production: January – December 2010 and 2011 2010 2011 Growth (%) Textile sector* 3,428,388 3,706,895** 8.12 Clothing sector 8,662,997 10,555,834** 21.85 Value (in 1000 US$) Note: * Excl. Fiber and Spinning/ yarn ** Preliminary Figure based on production index from the Central Statistics Agency 12. Production Structure Change in 2012 - 2013 (Number of Mills and Annual Production Capacity) The data is no longer available from the Investment Coordinating Board (BKPM). As of 2008, the BKPM no longer published the details of approved investment permits, but only presents aggregate data for the entire textile sector (as presented in section 7 above). The total number of companies in operation is as follows: 7 Italian Trade Commission – Jakarta Trade Promotion Office of the Italian Embassy Sector Industry Description/ Sub-Sector Fiber Preparation of Textile Fibers Yarn Manufacture of Yarn Spinning Spinning of Sewing Yarn Manufacture of Finished Yarn Fabrics Manufacture of Ikat Woven Fabrics Manufacture of Finished Textiles Manufacture of Printed Textiles Manufacture of Batik Textiles Manufacture of Knitted Textiles Manufacture of Crochetted Fabrics Manufacture of Made-up Textile Articles Manufacture of Finished Textile Embroidery Manufacture of Crocheted Fabrics & Embroidery Manufacture of Other Made-Up Textiles Manufacture of Narrow Fabrics Manufacture of Pruduced Fabrics for Industrial Uses Manufacture of NonWoven fabric Items Garments Manufacture of Other Textiles N.E.C. (Garments) Manufacture of Wearing Apparel Made of Textile Manufacture of Clothing Accessories of Textile Manufacture of Crochetted Apparel ISIC Code 13111 No. of Mills as of 2010 16 Annual Production (in ‘000 IDR) Rp 651,182,883 13112 121 Rp 17,626,978,797 13113 23 Rp 6,433,170,137 13131 61 Rp 32,311,277,158 13122 39 Rp 68,213,628 13132 154 Rp 10,044,113,451 13133 92 Rp 8,929,356,963 13134 418 Rp 1,223,931,640 13911 96 Rp 2,804,321,449 13912 43 Rp 58,400,400 13921 153 Rp 12,950,809,738 13922 50 Rp 19,423,511 13924 20 Rp 74,826,934 13929 22 Rp 626,361,218 13991 23 Rp 616,195,270 13992 4 Rp 68,875,589 13993 6 Rp 139,273,939 13999 1674 14111 22 Rp 277,984,821 14131 25 Rp 467,576,760 14302 77 Rp 39,243,344 Rp 38,892,160,004 8 Italian Trade Commission – Jakarta Trade Promotion Office of the Italian Embassy Manufacture of Knitted Apparel Souce: Central Statistics Agency 13. Other Events 14301 27 Rp 764,350,742 Indonesia’s Textile Machinery Restructuring Program Continues In 2012 and 2013, the Indonesian government through the Ministry of Industry has continued to offer stimulus funds to textile entrepreneurs in the country to upgrade their textile machines in a bid to raise the competitiveness of country’s textile and textile products industry. Under the program, rebates and interest subsidy is given to textile companies for upgrading of machinery and equipment. From 2007 to 2012, Rp. 9.9 trillion investment was injected into the textile industry, as a result of which the production increased by 15-34%, energy consumption was reduced by 5-9 %, and productivity rose by 6-10 %. In 2012 alone, the Ministry of Industry has sanctioned a sum of Rp 145.5 billion for revitalizing machines in textiles, leather and footwear industries. According to the Indonesian Textile Association (API), in 2013 local textile makers have spent Rp 1.5 trillion (US$154.84 million) to buy machinery, excluding land and buildings. Most of the investments come from domestic firms, as investment by foreign firms stands at 20%. The figure is down 34.7% from the Rp 2.3 trillion textile makers spent on machinery in 2012, including Rp 500 billion in foreign investments. The Industry Ministry stated that the textile sector faced two major problems in 2013. Firstly, a 15% increase in electricity rates. Secondly, local textile makers said that the existing customs regulations have hindered their growth. Indonesian textile makers also continue to face fierce competition from imported goods. Over the past few years, there has been a major rise in Indonesia’s textile imports from China. The prices of a wide range of textile and textile goods have risen by 10 - 15%, as most of the textile firms in the country are concentrated in the areas like Banten and West Java, which have been hit by sharp rises in minimum wages. Some 500 Indonesian Textile Mills need Machinery Revitalization According to the Ministry of Industry, about 500 textile mills in Indonesia need revitalization in order to enhance their competitiveness in the domestic and export markets. Some 500 of the 1,500 textile and apparel factories in Indonesia are currently using machines that are 25 years old and are producing using outdated technology. Indonesia is dependent on imports for textile machinery, which are mostly imported from China, a major competitor of Indonesian textiles in the domestic and global markets. The textile and clothing sector is a major contributor to Indonesia’s non-oil export earnings, and hence the Government is seeking to invite opening of textile machinery factory in Indonesia. The Indonesian Government would extend several benefits, including a 10-year tax holiday, to the company investing in textile machinery production in the country. Currently, the Government is studying the possibility of investment in textile machinery by Taiwanese and Japanese companies. 9 Italian Trade Commission – Jakarta Trade Promotion Office of the Italian Embassy Indonesia Opened Dumping Probe on SDY from Four Nations The Government of Indonesia has initiated anti-dumping investigation on import of spin draw yarn (SDY), also called fully drawn yarn (FDY), from China, Malaysia, South Korea and Taiwan. The probe is in response to a request made by two Indonesian manufacturers - PT Indorama Ventures Indonesia and PT Asia Pacific Fibers. After an initial analysis by the Indonesian Anti-Dumping Committee (KADI), there were strong indications that SDY was sold at dumping prices, and thereby, causing injury to domestic producers. The investigation was carried out on imports of SDY with tariff heading 5402.47.00.00, originating from China, Malaysia, South Korea and Taiwan. In 2012, China exported SDY worth US$ 19.355 million to Indonesia, showing an increase of 418 percent year-on-year in value, and 559 percent year-on-year in terms of volume, according to the Chinese Customs statistics. Around 40 Chinese firms export SDY to Indonesia. TUV SUD Opens Textile Testing & Certification in Indonesia PT TÜV SÜD PSB, an internationally recognized testing body, in collaboration with PT Qualis Indonesia and Nissenken has begun providing testing and certification facility for international standards to the Indonesian textile and clothing industry. The new facility offers comprehensive test services, including chemical, performance and regulatory testing, to support softlines (textiles and apparels) manufacturers in complying with international quality and safety requirements for their products. PT TÜV SÜD PSB sees a huge potential in the textile industry in Indonesia and offering this services enables businesses to achieve higher standards or gain quicker access to foreign markets. In terms of certification, there are also many international standards that apply to textiles & clothing manufacturers, specific to social compliance such as SA8000 and BSCI. Factory and supplier audits are also necessary to ensure that quality is maintained at the sourcing and manufacturing stages. By working with an independent third party testing and certification body, textile manufacturers can be assured of end-to-end quality assurance. PT South Pacific Viscose has become the World’s largest Viscose Fiber Plant In late October 2013, trial operations of the fifth production line started successfully at Lenzing’s Indonesian subsidiary PT South Pacific Viscose. With an additional nominal capacity of 80,000 tons of viscose fibers p.a., the annual total capacity of SPV has increased to 320,000 tons once Line 5 has been launched. SPV will thus exceed the capacity of the parent plant in Lenzing/Upper Austria (250,000 tons p.a.) for the first time and therefore has become the world’s largest viscose fiber plant. Asia constitutes the most important market for the Lenzing Group, where more than half of its fiber revenues are generated. Therefore more than half of its fiber production capacity is now located in Asia. Anhui to Set Up Textile Machinery Plant in Indonesia 10 Italian Trade Commission – Jakarta Trade Promotion Office of the Italian Embassy Anhui Conch Group Company Ltd. has expressed interest to invest in textile machinery plant in Indonesia. The Anhui Conch Group has sought allotment of 150 hectares of land to build a textile industrial park in the country, where a number of textile and textile machinery industries can be set up. The new investment would help domestic textile manufacturers to better take advantage of the restructuring scheme for textile machinery launched by the Ministry of Industry. The setting up of new textile machinery plant would help in modernizing textile machinery at various plants across Indonesia, he said. 14. Expected Changes Indonesia’s Machinery/ Equipment Restructuring Program of Textile and Textile Product (TPT) Industry and Footwear Industry for the 2014 Budget Year The Indonesian Industry Ministry has also pledged to raise the competitiveness of the country’s textiles and apparels through the refurbishment of machinery and equipment, which is already more than 20 years old must be rejuvenated or restructured by machinery/ equipment with more modern technology. The Government, through the Ministry of Industry, considers it necessary to give stimulants through the activities of Machinery/ Equipment Restructuring of Textile and Textile Product Industry as well as Footwear Industry in relation to boosting the industry for better competitiveness through the investment in more modern machinery/ equipment. The Machinery/ Equipment Restructuring Program of Textile and Textile Product Industry which was launched by the Ministry of Industry in 2007 and the Machinery/ Equipment Restructuring Program of Footwear Industry in 2009 have always been welcomed by the industry. For 2014, the Government has decided to continue the programs with a budget allocation of Rp. 106.5 billion and they are expected to give positive impacts in form of the following: 1. Investment funding from Banking and Textile and Textile Product Industry as well as Footwear Industry and Leather Processing Industry of Rp. 1.065 Trillion (US$ 90.25 million), 2. Employment creation for at least 8,000 people for Textile and Textile Product Industry, Footwear Industry and Leather Processing Industry, 3. Efficiency improvement of energy use and production cost as well as producing higher quality and more competitive products. The legal basis, requirements, criteria, and registration procedures are as follows: • Technical Guidelines of Revitalization Program of Industrial Growth through Machinery/ Equipment Restructuring of Textile and Textile Product Industry and Footwear Industry. • Regulations of the Minister of Industry No. 01 Year 2014 on The Second Amendment of the Regulations of the Minister of Industry No. 123/M-IND/PER/11/2010 on the Revitalization Program of Industrial Growth through Machinery/ Equipment Restructuring of Textile and Textile Product Industry and Footwear Industry. 11 Italian Trade Commission – Jakarta Trade Promotion Office of the Italian Embassy • Regulations of Directorate General of Manufacturing Base Industry No. 01/BIM/PER/1/2014 on the Revitalization Program of Industrial Growth through Machinery/ Equipment Restructuring of Textile and Textile Product Industry and Footwear Industry. Rise in Power Tariff will Push Up Textile and Garment Prices According to the Indonesian Synthetic Fiber Producers Association (Asosiasi Produsen Synthetic Fiber Indonesia - APSyFI), the planned increase in electricity tariff will push the prices of Indonesian garments by up to 50 %, making the industry less competitive in both domestic and export markets, which would in turn will affect the garment sector. The government of Indonesia is planning to raise the electricity tariff, ranging between 38.9% - 64.7 %, for large-scale industries from May 1, 2014, which is to be implemented in stages over a period of 2 - 4 months. APSyFI pointed out that with the rising electricity tariffs of I-3 and I-4 classes of industries by 38.9% and 64.7%, the cost of industrial production in the polyester industry would also jump automatically, which would be passed on in a domino effect on the weaving, knitting and garment industries, and the price of final product to consumers would rise by about 50%. In addition to the rising prices of raw material, the spinning industry would also be affected by the increase in electricity tariff. This affect would also spillover to the garment manufacturing sector, causing the price of the finished product to go up by about 50%. This condition would negatively impact the performance of the Indonesian textile and garment industry, both in the domestic and export markets. The loss of competitiveness would mean either shutdown or reduction in production, which in turn would impact the livelihood of workers. In 2013, exports of Indonesian polyester sector dipped 9% to US$ 464 million from US$507 million in the previous year. On the other hand, polyester imports grew 8% to US$416 million from US$386 million worth of imports in 2012. Even the polyester industry’s share in the domestic market fell from 83% to 79%, according to the data from the Central Statistics Agency. Additional Information Regarding the Upstream Textile Raw Material Sector Indonesia is on Way to Self-Sufficiency in Petrochemicals Currently, several petrochemical projects in Indonesia are under construction or expansion and is on its way to become self-sufficient in the production of olefins such as ethylene and propylene, aromatics and other petrochemical products by 2020. According to the Indonesian Olefin, Aromatic and Plastic Industry Association (INAplas), the construction of new petrochemical plants and the ongoing expansion projects would raise Indonesia’s 12 Italian Trade Commission – Jakarta Trade Promotion Office of the Italian Embassy current production capacity of 3.9 million tons per annum by 30-40% over the next 3-5 years. It is hoped that Indonesia would not need to import petrochemical products after 2020. Expansion is being carried out at five existing plants, all of which are located in Banten, West Java. These include Japan-based Nippon Shokubai, which will raise its acrylic acid production capacity; PT Polychem Indonesia, which has plans to increase mono ethylene glycol (MEG) production; and PT Chandra Asri Petrochemical (CAP), which plans to increase its naphtha cracker production capacity. Additionally, there are seven new projects coming up in Indonesia, which include South Korean Honam Petrochemical Corporation’s naphtha cracker facility in Banten. German petrochemical company Ferrostaal Industrial Projects will work together with Chandra Asri to build a methanol-to-olefin (MTO) plant in Papua. Most of the seven new projects, being built at the cost of US$ 39 billion, are likely to be completed between 2017 and 2020. At present, Indonesia has a petrochemical production capacity of 3.9 million tons, compared to the national demand of 4.3 million tons. Pertamina and PTTGC Public Company Limited Sign for Petrochemical Complex PT Pertamina (Persero) and PTT Global Chemical Public Company Limited (PTTGC) have signed the Manufacturing Joint Venture to pursuing the final investment decision of the world-scale Petrochemical Complex in Indonesia targeting for commercial operation by 2018. Pertamina, the Indonesian State-Owned energy company, and PTTGC, the leading Thai Petrochemical producer, have advanced its partnership and collaboration by entering into the Manufacturing JV - HOA to proceed further with the feasibility study of the worldscale petrochemical complex. This collaboration advancement comes after the completion of the extensive project preliminary feasibility study - a part of the partnership HOA signed in April 2013. This Manufacturing JV - HOA is aimed to further materialize the agreed joint venture principles and investment scope, as well as enable both parties to finalize the project details by early 2014 prior to conducting the detail bankable feasibility study and Front End Engineering Design (FEED). Pertamina and PTTGC have reached the project definition understanding, including a common goal and objective, a competitive investment model and appropriate site specification, as well as each party’s strength to be leveraged for building JV’s competitiveness. This will move forward for final investment decision, anticipated in 2015. In addition the exhaustive Indonesia polymer market survey has been jointly conducted through the distribution and marketing activities of both parties, where the initial complex configuration has been defined and technical study of such investment scope has been assessed, assuring the parties aspiration in being part of an Indonesian self-sufficient society. Meanwhile, the domestic demand for petrochemical products is expected to increase, due to the positive trend of manufacturing sector. Indonesian petrochemical market value is expected to reach US$ 30 billion in 2018 and the JV Company is targeting to control 30% of market share after the Petrochemical Complex commercially operates in 2018. Currently, the production of petrochemical in Indonesia is still insufficient to meet the downstream industry needs, creating large import to the amount of US$ 5 billion per year. 13 Italian Trade Commission – Jakarta Trade Promotion Office of the Italian Embassy Titan plans Naphtha Cracker Project in Indonesia Aiming to expand presence in the petrochemical space, Indonesia’s biggest polyethylene producer, PT Titan Kimia Nusantara Tbk plans to construct a naphtha cracker complex near its industrial plant in Merak, Banten. The firm intends to spend around US$ 3-5 billion on the construction of the new facility with a projected ethylene production capacity of 700 kilo tons per annum (KTA) and propylene production capacity of 500 KTA. Originally the construction was to be launched in 2014, however due to problems in acquisition of land for setting up the plant, this has now been pushed back to 2017, while the date for launching operations has been pushed back from early 2016 to early 2018. The firm plans to obtain around 60% of the equity for the new facility from South Korea’s official export credit agency - Korea Eximbank (KEXIM) and the rest from its holding firm Lotte Chemical Titan International Sdn. Bhd. Lotte Chemical Titan International Sdn. Bhd. holds a 95.31% stake in Titan Kimia, while the rest of 4.69% is held by the public. In 2013, Titan Kimia achieved 352 kilo metric tons (KMT) polyethylene production levels, which is the highest level attained since launch of operations by the company. However, this could not save the firm from incurring a net loss of US$ 16 million. The firm has been posting negative results since 2010, when it last booked a profit of US$ 23 million on account of enhanced sales and consumer base. PT Chandra Asri and Ferrostaal Sign Deal for PP and Ethylene Plant Indonesia’s largest petrochemical firm PT Chandra Asri and German company Ferrostaal Industrial Projects GmbH have signed an agreement to set up a methanol-based olefin production complex in Indonesian province of West Papua. The complex, to be set up in Teluk Bintuni region will have an annual capacity to produce up to 400,000 tons of polypropylene (PP) and 175,000 tons of ethylene. The construction work for the US$ 1.89 billion project would start after completion of the feasibility studies as well as the decision on gas prices and allocation from the Ministry of Energy and Mineral Resources. The Tangguh liquefied natural gas (LNG) plant in West Papua is expected to supply gas for the petrochemical complex, which however is expected to be completed by 2019. The Indonesian Government is currently focusing on development of the petrochemicals sector, along with other sectors, for industrial growth. The growth of petrochemical sector is expected to decrease the country’s dependence on imports of propylene, ethylene, polypropylene and methanol. In 2012, Indonesia imported petrochemicals worth US$ 8.5 billion from several countries, including Singapore and Thailand. BP fully Acquired PTA Producer PT AMI 14 Italian Trade Commission – Jakarta Trade Promotion Office of the Italian Embassy BP completed the purchase of all interests previously held by Japan’s Mitsui Chemicals, Inc. (MCI) and Mitsui & Co. Ltd. (MBK) in PT Amoco Mitsui PTA Indonesia (AMI). For over fifteen years, AMI was a 50/50 joint venture between BP and its partners, producing and marketing purified terephthalic acid (PTA) in Indonesia, where domestic demand for PTA has been growing at around 6% over the last few years. Effectively as of 1 March 2014, AMI has become a wholly owned subsidiary of the BP group. AMI has its head office in Jakarta, and a manufacturing site at Merak, Cilegon, Banten Province in Indonesia. 15. New Laws and Regulations for the Textile Industry Enacted in the Period Taken into Consideration From 2012 - 2014, three new regulations for the textile industry were enacted: • Regulations of the Minister of Industry No. 01 Year 2014 on the Second Amendment of the Regulations of the Minister of Industry No. 123/M-IND/PER/11/2010 on the Revitalization Program of Industrial Growth through Machinery/ Equipment Restructuring of Textile and Textile Product Industry and Footwear Industry. • Regulations of Directorate General of Manufacturing Base Industry No. 01/BIM/PER/1/2014 on the Revitalization Program of Industrial Growth through Machinery/ Equipment Restructuring of Textile and Textile Product Industry and Footwear Industry. • Decree of the Ministry of Industry of the Republic of Indonesia Number: 15/M-IND/ PER/2/2012 on the amendment of the Decree Number 123/M-IND/PER/11/2010 on Revitalization program and Industrial acceleration through textile machinery restructurization/textile industrial equipment and textile product and Footwear Industry. 16. Tenders in the Period Considered, Indicating Details of the Tender and a Brief Illustration of the Object) In the publicly announced tenders in the period of 2012 and 2013, none covered in the textile industry. 17. New Joint Ventures between Textile Producers or Textile Machinery Manufacturer, if any (specify Partners and Object) Based on data from the Data Center of the Ministry of Industry, in 2012 and 2013 no new textile machinery component manufacturers were established. With regard to new textile manufacturers, as of 2008, the BKPM no longer publishes the details of approved investments permits, but only presents aggregate data for the entire textile sector. The Manufacturing Directory of the Ministry of Trade lists the following 15 textile machinery manufacturers: 15 Italian Trade Commission – Jakarta Trade Promotion Office of the Italian Embassy No. Company Name and Address 1. AROUND STAR, PT Address: Jl Cilampeni No 12 A Rt 02/05, Bandung, Jawa Barat Phone. 022-5891677 2. ARUKINDO, CV Address: Krajan Ii Rt 06/rw 04, Karawang, Jawa Barat 3. ASAHI CIPTA PRIMA, PT Address: Ki Jababeka Blok Oo No.3d, Bekasi, Jawa Barat Phone. 8937311 4. BENGKEL MESIN GARUDA Address: Jl.komud Supardio No3, Bandung, Jawa Barat Phone. 022-6031303 5. HORIGUCHI ENGINEERING INDONESIA Address: Kawasan Industri K11c Lot D- Ia, Karawang, Jawa Barat Phone. 8901612 6. INTEX MESIN INDONESIA, PT Address: Kawasan Dwipapuri Kav M-11, Sumedang, Jawa Barat Phone. 022-7792158 7. MITRA LESTARI SEJATI, PT Address: Jl. Bojong Buah Raya No.15, Bandung, Jawa Barat Phone. 5892419 8. PRAKARSA SETIA GEMILANG PT Address: Jl Moh Toha No 382, Bandung, Jawa Barat Phone. 022523091 9. SAHABAT KERJA, CV Address: Ds. Tegal Rejo Rt 01 Rw 08, Klaten, Jawa Tengah Phone. 0272-551233 10. SETIA ABADI LOGAM, PD Address: Jl. Griya Buaran Indah, Kradenan III No.1 A, Pekalongan, Jawa Tengah Phone. 0285-425058 11. SIMPLETEX MCHINERY IND, PT Address: Jl. Cibaligo No 169, Kota Cimahi, Jawa Barat Phone. 0226033735 12. SPARTA Address: Jl.Raya Dayeuhkolot No.170, Bandung, Jawa Barat Phone. 022-5205044 Products Manufactured Knitting Machines Parts of Weaving Machines Textile Machinery Components Auxilliary Textils Machines and Lathe Machines Textile Machinery Repair Dyeing & Finishing Equipment Rotary Screens Textile Machines Spare Parts of Textile Machinery Weaving Machines Textile Machines Repair of Textile Machines 16 Italian Trade Commission – Jakarta Trade Promotion Office of the Italian Embassy 13. SUGIH MUKTI,PT Address: Jl.cigending No.679, Bandung, Jawa Barat Phone. 7800008 14. TAUFIK JAYA TEKNIK, CV Address: Jl. M. Bisri 88 Gedebage Wetan, Bandung, Jawa Barat Phone. 022-7561814 15. TRIMUDA PUTRAMA, PT Address: Jl Cibaligo 167 Km 1,7, Kota Cimahi, Jawa Barat Phone. 022-6032650 Spare Parts of Textile Machinery Spare Parts of Textile Machinery Textile Machinery Up to now, Indonesia only has one integrated producer of textile machinery, i.e. PT Texmaco Perkasa Engineering of the Texmaco Group. The company produces air-jet and water-jet weaving machines, rapier shuttle-less looms, seizing machines, printing machines, stenter machines, dobby machines, steamers and spare parts, mainly for the group’s own operations and partly for exports. The machines are produced with the technology of MS Machinery from Italy, ICBT from France and Draper Inc. of the US. PT Texmaco Perkasa Engineering Head Office: Jl. H.R. Rasuna Said Kav. X.6 Phone: 002-12520656, Fax: 002-15225738 Factory Address 1: Kiara Payung Klari, Klari 41300 – West Java Phone: 0267-431645, Fax: 0267-432312 Factory Address 2: Jl. Raya Kaliwungu Km 19, Kaliwungu – Central Java Phone: 0294-81253, Fax: 0294-81861 Headcount: 2247 Contact Person: Anang Sukantono (HRD Manager) Email: mustofa@perkasa.co.id Perkasa Heavyndo Engineering, PT (Subsidiary) Product: Weaving Machines Office Address: Jl. H.R. Rasuna Said – Jakarta Factory Address: Jl. Raya Kaliwungu Km.19 – Kaliwungu 51372 – Central Java Phone: 024-660055, Fax: 024-6600271 Headcount: 337 Contact Person: Nurcholis Habib (HRD Manager) 18. New Textile Machines Agencies Records at the Ministry of Trade indicate that no new textile machine agencies were established in 2012 and 2013. Information was obtained that in many cases existing textile machinery agencies have broadened their variety to include more brands. 19. New Trading Companies 17 Italian Trade Commission – Jakarta Trade Promotion Office of the Italian Embassy The data is no longer available from the Investment Coordinating Board. As of 2008, the BKPM no longer publishes the details of approved investments permits, but only presents aggregate data for the entire textile sector. The Ministry of Trade publishes directories of trading companies in operation, but do not provide lists of new textile trading companies. 20. New Engineering Companies Data from the Ministry of Industry, Ministry of Trade, and the Indonesian Investment Coordinating Board indicate that no new engineering companies in the field of textiles were established in 2012 and 2013.