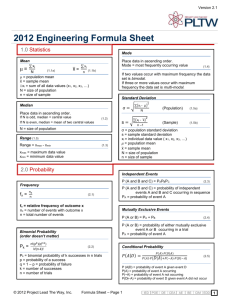

PLTW Engineering Formula Sheet 2014

advertisement

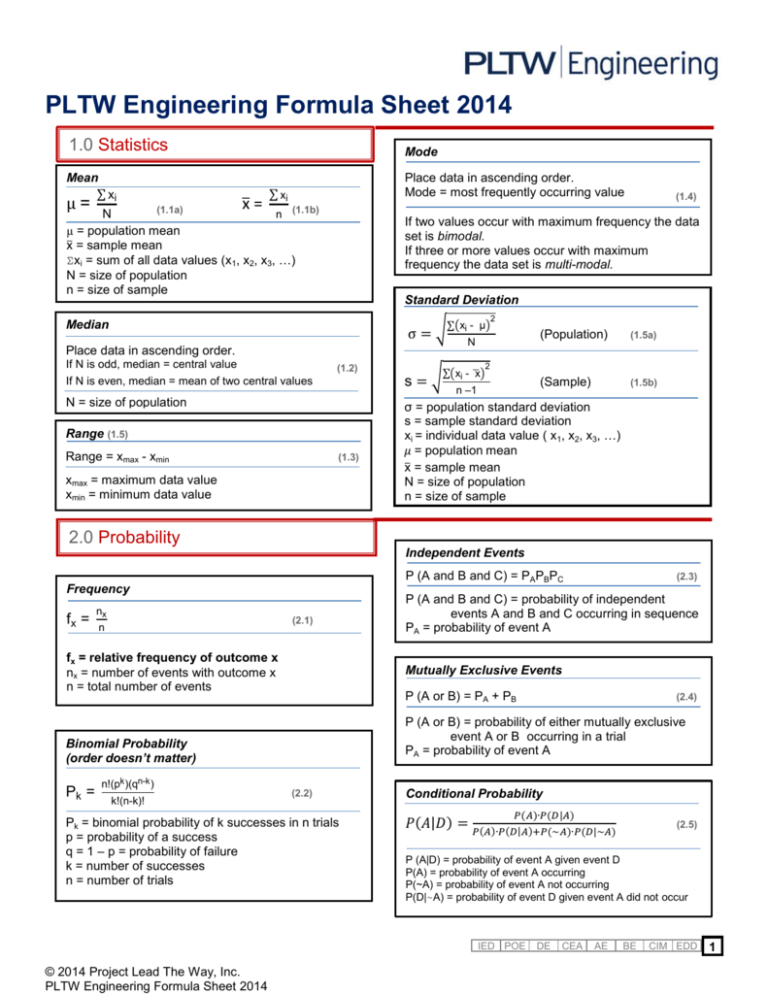

PLTW Engineering Formula Sheet 2014 1.0 Statistics Mode Mean xi μ= (1.1a) x= Place data in ascending order. Mode = most frequently occurring value xi (1.4) (1.1b) N n µ = population mean x = sample mean Σxi = sum of all data values (x1, x2, x3, …) N = size of population n = size of sample If two values occur with maximum frequency the data set is bimodal. If three or more values occur with maximum frequency the data set is multi-modal. Standard Deviation Median σ= Place data in ascending order. If N is odd, median = central value If N is even, median = mean of two central values (1.2) N = size of population Range (1.5) Range = xmax - xmin (1.3) xmax = maximum data value xmin = minimum data value s= xi - μ 2 N xi - x (Population) (1.5a) (Sample) (1.5b) 2 n ‒1 σ = population standard deviation s = sample standard deviation xi = individual data value ( x1, x2, x3, …) 𝜇 = population mean x = sample mean N = size of population n = size of sample 2.0 Probability Independent Events P (A and B and C) = PAPBPC Frequency fx = nx (2.1) n fx = relative frequency of outcome x nx = number of events with outcome x n = total number of events n!(pk )(qn-k ) k!(n-k)! P (A and B and C) = probability of independent events A and B and C occurring in sequence PA = probability of event A Mutually Exclusive Events P (A or B) = PA + PB (2.2) Pk = binomial probability of k successes in n trials p = probability of a success q = 1 – p = probability of failure k = number of successes n = number of trials Conditional Probability 𝑃 𝐴𝐷 =𝑃 𝑃 𝐴 ∙𝑃 𝐷 𝐴 (2.5) 𝐴 ∙𝑃 𝐷 𝐴 +𝑃 ~𝐴 ∙𝑃 𝐷 ~𝐴 P (A|D) = probability of event A given event D P(A) = probability of event A occurring P(~A) = probability of event A not occurring P(D|~A) = probability of event D given event A did not occur IED POE © 2014 Project Lead The Way, Inc. PLTW Engineering Formula Sheet 2014 (2.4) P (A or B) = probability of either mutually exclusive event A or B occurring in a trial PA = probability of event A Binomial Probability (order doesn’t matter) Pk = (2.3) DE CEA AE BE CIM EDD 1 3.0 Plane Geometry Ellipse Circle Rectangle 2b Perimeter = 2a + 2b (3.9) 2a Area = π a b (3.8) Area = ab (3.10) Circumference =2 π r (3.1) Area = π r2 (3.2) B Triangle (3.6) Parallelogram Area = ½ bh h Area = bh a = b + c – 2bc·cos∠A 2 2 2 b = a + c – 2ac·cos∠B 2 2 2 c = a + b – 2ab·cos∠C 2 (3.3) b 2 2 c =a +b sin θ = tan θ = Area = n (3.4) a 2 b c h (3.12) (3.13) A C b (3.14) c 2 = ns2 tan( 1 n (3.15) ) n = number of sides θ (3.6) a b s(12 f) c a (3.5) c cos θ = 2 a Regular Polygons Right Triangle 2 (3.11) b (3.7) a h Trapezoid Area = ½(a + b)h h h (3.16) b h 4.0 Solid Geometry Cube Sphere Volume = s 3 Surface Area = 6s s (4.1) 2 Volume = π r (4.2) s s 3 Surface Area = 4 π r (4.8) 2 (4.9) Rectangular Prism Cylinder Volume = wdh r h (4.3) Surface Area = 2(wd + wh + dh) (4.4) d w 2 Volume = π r h h (4.10) Surface Area = 2 π r h+2 π r 2 (4.11) Right Circular Cone Volume = h πr2 h Irregular Prism (4.5) 3 Surface Area = π r r2 +h2 r (4.6) Volume = Ah h (4.12) A = area of base Pyramid Volume = Ah 3 (4.7) A = area of base © 2014 Project Lead The Way, Inc. PLTW Engineering Formula Sheet 2014 h 5.0 Constants 2 g = 9.8 m/s = 32.27 ft/s -11 3 2 G = 6.67 x 10 m /kg·s π = 3.14159 IED POE DE 2 CEA AE BE CIM EDD 2 6.0 Conversions Mass/Weight (6.1) 1 kg 1 slug 1 ton 1 lb Area (6.4) 2 1 acre = 4047 m 2 = 43,560 ft 2 = 0.00156 mi = 2.205 lbm = 32.2 lbm = 2000 lb = 16 oz 1N 1 kip 1J 1 atm Volume (6.5) 1L = 3.28 ft = 0.621 mi = 2.54 cm = 5280 ft = 3 ft 1mL = 0.264 gal 3 = 0.0353 ft = 33.8 fl oz 3 = 1 cm = 1 cc 1psi Time (6.3) 1d 1h 1 min 1 yr Energy (6.10) = 0.225 lb = 1,000 lb = 0.239 cal -4 = 9.48 x 10 Btu = 0.7376 ft·lbf 1kW h = 3,600,000 J Pressure (6.8) Length (6.2) 1m 1 km 1 in. 1 mi 1 yd Force (6.7) = 24 h = 60 min = 60 s = 365 d = 1.01325 bar = 33.9 ft H2O = 29.92 in. Hg = 760 mm Hg = 101,325 Pa = 14.7 psi = 2.31 ft of H2O Temperature Unit Equivalents (6.6) Power (6.9) 1K 1W = 1 ºC = 1.8 ºF = 1.8 ºR See below for temperature calculation 1 hp 7.0 Defined Units 1J 1N 1 Pa 1V 1W 1W 1 Hz 1F 1H = 3.412 Btu/h = 0.00134 hp = 14.34 cal/min = 0.7376 ft·lbf/s = 55 ft∙lb/sec = 1 N·m = 1 kg·m / s2 = 1 N / m2 =1W/A =1J/s =1V/A = 1 s-1 = 1 A·s / V = 1 V·s / V 8.0 SI Prefixes Numbers Less Than One Power of 10 Prefix Abbreviation 10-1 10-2 10-3 10-6 10-9 10-12 10-15 10-18 10-21 10-24 decicentimillimicronanopicofemtoattozeptoyocto- 9.0 Equations Numbers Greater Than One Power of 10 Prefix Abbreviation 101 102 103 106 109 1012 1015 1018 1021 1024 d c m µ n p f a z y decahectokiloMegaGigaTeraPetaExaZettaYottaForce and Moment Temperature F = ma Mass and Weight TK = TC + 273 (9.4) m = VDm (9.1) TR = TF + 460 (9.5) W = mg (9.2) TF = (9.6) W = VDw (9.3) V = volume Dm = mass density m = mass Dw = weight density W = weight g = acceleration due to gravity © 2014 Project Lead The Way, Inc. PLTW Engineering Formula Sheet 2014 Tc + 32 da h k M G T P E Z Y TK = temperature in Kelvin TC = temperature in Celsius TR = temperature in Rankin TF = temperature in Fahrenheit M = Fd (9.7b) (9.7a) F = force m = mass a = acceleration M = moment d= perpendicular distance Equations of Static Equilibrium ΣFx = 0 ΣFy = 0 ΣMP = 0 (9.8) Fx = force in the x-direction Fy = force in the y-direction MP = moment about point P IED POE DE CEA AE BE CIM EDD 3 9.0 Equations (Continued) = F∥ ∙ d (9.9) W = work F∥ = force parallel to direction of displacement d = displacement t = p= V1 T1 p1 T1 F (9.16) A V = T2 (Charles’ Law) 2 (9.17) p = T2 (Gay-Lussanc’s Law) 2 p1V1 = p2V2 (Boyle’s Law) Power P= Ohm’s Law Fluid Mechanics Energy: Work E Electricity (9.10) t P=τω (9.11) P = power E = energy W = work t = time τ = torque ω = angular velocity Efficiency (%) = Pout Pin ∙1 % (9.12) Pout = useful power output Pin = total power input (9.13) U = potential energy m =mass g = acceleration due to gravity h = height A1v1 = A2v2 P = Qp (9.22) K = kinetic energy m = mass v = velocity Energy: Thermal ∆Q = mc∆T (9.15) ∆Q = change in thermal energy m = mass c = specific heat ∆T = change in temperature © 2014 Project Lead The Way, Inc. PLTW Engineering Formula Sheet 2014 1 1 1 1 + + ∙∙∙ + R1 R2 Rn IT = I1 + I2 + ··· + In n or IT = k=1 Ik VT = V1 + V2 + ··· + Vn n or VT = k=1 Vk V = voltage VT = total voltage I = current IT = total current R = resistance RT = total resistance P = power Mechanics Thermodynamics s= d v= ∆d a= X= (9.24) t P = Q′ = AU∆T P=Q = (9.25) ∆t vf − vi (9.36) t (9.27) -g v = vi + at (9.28) (9.29) v = vi + 2a(d – di) (9.30) τ = dFsinθ (9.31) s = average speed v = average velocity v = velocity vi = initial velocity (t =0) a = acceleration X = range t = time ∆d = change in displacement d = distance di = initial distance (t=0) g = acceleration due to gravity θ = angle τ = torque F = force 1 (9.39) k =L R P= kA∆T (9.37) (9.38) ∆Q ∆t U= (9.26) vi 2 sin(2θ) 2 (9.35) Kirchhoff’s Voltage Law p = absolute pressure F = force A = area V = volume T = absolute temperature Q = flow rate v = flow velocity P = power 2 (9.14) RT (series) = R1 + R2+ ··· + Rn (9.34) Kirchhoff’s Current Law (9.21) 2 K = 12 mv2 (9.33) (9.19) (9.20) d = di + vit + ½at Energy: Kinetic P = IV RT (parallel) = Q = Av Energy: Potential U = mgh (9.32) (9.18) absolute pressure = gauge pressure + atmospheric pressure (9.23) Efficiency V = IR (9.40) (9.41) L A1v1 = A2v2 (9.42) Pnet = Ae(T2 -T1 ) (9.43) k= PL (9.44) A∆T P = rate of heat transfer Q = thermal energy A = area of thermal conductivity U = coefficient of heat conductivity (U-factor) ∆T = change in temperature ∆t = change in time R = resistance to heat flow ( R-value) k = thermal conductivity v = velocity Pnet = net power radiated = 5.6696 x 10 -8 m2 ∙K e = emissivity constant L = thickness T1, T2 = temperature at time 1, time 2 POE 4 DE 4 AE 4 CIM 4 10.0 Section Properties y Moment of Inertia Ixx = h bh3 x x= (10.1) 12 x= Ai and y = 2 h and y = (10.3) 2 x b 3 and y = h y (10.4) 3 x y Semi-circle Centroid Complex Shapes Centroid x= b Right Triangle Centroid b Ixx = moment of inertia of a rectangular section about x axis xi Ai y Rectangle Centroid x=r yi Ai d y= (10.2) Ai x = x-distance to the centroid y = y-distance to the centroid xi = x distance to centroid of shape i yi = y distance to centroid of shape i Ai = Area of shape i r 3 (10.5) x x = x-distance to the centroid y = y-distance to the centroid 12.0 Structural Analysis 11.0 Material Properties Beam Formulas Reaction Stress (axial) F σ= A Moment (11.1) Deflection = stress F = axial force A = cross-sectional area Reaction Strain (axial) ε= δ L ε = strain L0 = original length δ = change in length E= ε (F2 -F1 )L 𝛿2 −𝛿1 )A max ωL 2 (12.3) (12.4) 2 ωL (12.2) = (at center) (12.5) Deflection max = 35ωLEI (at center) (12.6) RA = RB = P (12.7) =P Moment max Deflection max Moment (11.3) E = modulus of elasticity = stress ε = strain A = cross-sectional area F = axial force δ = deformation (at point of load) EI RA = RB = RA = max (12.8) = 2PEI(3L2 Pb L 2) = (at Deformation: Axial δ= FL AE (12.9) P b L L (12.10) (at Point of Load) (12.11) 2 2 = P a a+ 2 (12.12) when a b ) Truss Analysis (12.13) δ = deformation F = axial force L0 = original length A = cross-sectional area E = modulus of elasticity © 2014 Project Lead The Way, Inc. PLTW Engineering Formula Sheet 2014 and RB = = Deflection (11.4) = (at point of load) PL3 (at center) Modulus of Elasticity E= = max Reaction σ max (12.1) 2 PL Moment Reaction (11.2) P RA = RB = 2J = M + R (12.14) J = number of joints M =number of members R = number of reaction forces POE 5 AE 5 CEA 4 13.0 Simple Machines Inclined Plane Mechanical Advantage (MA) I A= DE (13.1) DR % Efficiency= ( A A I A )1 A A= FR FE (13.2) L I A= H (13.6) (13.3) Wedge IMA = ideal mechanical advantage AMA = actual mechanical advantage DE = effort distance DR = resistance distance FE = effort force FR = resistance force L I A= H (13.7) Lever Screw 1st Class IMA = C Pitch Pitch = 2nd Class (13.8) 1 (13.9) TPI C = circumference r = radius Pitch = distance between threads TPI = threads per inch 3rd Class Compound Machines MATOTAL = (MA1) (MA2) (MA3) . . . (13.10) Gears; Sprockets with Chains; and Pulleys with Belts Ratios Wheel and Axle GR = Effort at Axle dout din = Nout Nin = dout = τout ωin ωout din τin = ωin ωout = (pulleys) τout τin (13.11) (13.12) Compound Gears B GRTOTAL = ( Effort at Wheel Pulley Systems IMA = total number of strands of a single string supporting the resistance (13.4) IMA = DE (string pulled) DR (resistance lifted) © 2014 Project Lead The Way, Inc. PLTW Engineering Formula Sheet 2014 (13.5) D ) (C) A (13.13) GR = gear ratio ωin = angular velocity - driver ωout = angular velocity - driven Nin = number of teeth - driver Nout = number of teeth - driven din = diameter - driver dout = diameter - driven 𝜏in = torque - driver 𝜏out = torque - driven POE 6 14.0 Structural Design Steel Beam Design: Moment Steel Beam Design: Shear Va ≤ Vn (14.1) Ωv Vn = 0.6FyAw a n b Mn = FyZx (14.2) (14.3) Spread Footing Design qnet = qallowable - pfooting pfooting = tfooting ∙15 (14.4) q= Ma = internal bending moment Mn = nominal moment strength Ωb = 1.67 = factor of safety for bending moment Fy = yield stress Zx = plastic section modulus about neutral axis = allowable bending strength Va = internal shear force Vn = nominal shear strength Ωv = 1.5 = factor of safety for shear Fy = yield stress Aw = area of web 𝑉𝑛 = allowable shear strength 𝛺 𝑣 15.0 Storm Water Runoff Storm Water Drainage Q = CfCiA Cc = C1 A1 + C2 A2 + ∙∙∙ A1 + A2 + ∙∙∙ (15.1) (15.2) 3 Q = peak storm water runoff rate (ft /s) Cf = runoff coefficient adjustment factor C = runoff coefficient i = rainfall intensity (in./h) A = drainage area (acres) Runoff Coefficient Adjustment Factor Return Period Cf 1, 2, 5, 10 1.0 25 1.1 50 1.2 100 1.25 © 2014 Project Lead The Way, Inc. PLTW Engineering Formula Sheet 2014 Rational Method Runoff Coefficients Categorized by Surface Forested 0.059—0.2 Asphalt 0.7—0.95 Brick 0.7—0.85 Concrete 0.8—0.95 Shingle roof 0.75—0.95 Lawns, well drained (sandy soil) Up to 2% slope 0.05—0.1 2% to 7% slope 0.10—0.15 Over 7% slope 0.15—0.2 Lawns, poor drainage (clay soil) Up to 2% slope 0.13—0.17 2% to 7% slope 0.18—0.22 Over 7% slope 0.25—0.35 Driveways, 0.75—0.85 walkways Categorized by Use Farmland 0.05—0.3 Pasture 0.05—0.3 Unimproved 0.1—0.3 Parks 0.1—0.25 Cemeteries 0.1—0.25 Railroad yard 0.2—0.40 Playgrounds 0.2—0.35 (except asphalt or Business Districts concrete) Neighborhood 0.5—0.7 City (downtown) 0.7—0.95 Residential Single-family 0.3—0.5 Multi-plexes, 0.4—0.6 detached Multi-plexes, 0.6—0.75 attached Suburban 0.25—0.4 Apartments, 0.5—0.7 condominiumsIndustrial Light 0.5—0.8 Heavy 0.6—0.9 P A lb ft (14.5) (14.6) (14.7) qnet = net allowable soil bearing pressure qallowable = total allowable soil bearing pressure pfooting = soil bearing pressure due to footing weight tfooting = thickness of footing q = soil bearing pressure P = column load applied A = area of footing 16.0 Water Supply Hazen-Williams Formula hf = 1 . 1. 5 C 1. 5 LQ d . 655 (16.1) hf = head loss due to friction (ft of H2O) L = length of pipe (ft) Q = water flow rate (gpm) C = Hazen-Williams constant d = diameter of pipe (in.) Dynamic Head dynamic head = static head – head loss (16.2) static head = change in elevation between source and discharge (16.3) 17.0 Heat Loss/Gain Heat Loss/Gain Q′ = AU∆T U= 1 R (17.1) (17.2) Q = thermal energy A = area of thermal conductivity U = coefficient of heat conductivity (U-factor) ∆T = change in temperature R = resistance to heat flow (Rvalue) CEA 5 18.0 Hazen-Williams Constants 19.0 Equivalent Length of (Generic) Fittings Pipe Size Screwed Fittings 1/4 3/8 1/2 3/4 1 1¼ 1½ 2 2½ 3 4 Elbows Regular 90 degree Long radius 90 degree Regular 45 degree 2.3 1.5 0.3 3.1 2.0 0.5 3.6 2.2 0.7 4.4 2.3 0.9 5.2 2.7 1.3 6.6 3.2 1.7 7.4 3.4 2.1 8.5 3.6 2.7 9.3 3.6 3.2 11.0 4.0 4.0 13.0 4.6 5.5 Tees Line Flow Branch Flow 0.8 2.4 1.2 3.5 1.7 4.2 2.4 5.3 3.2 6.6 4.6 8.7 5.6 9.9 7.7 12.0 9.3 13.0 12.0 17.0 17.0 21.0 Return Bends Regular 180 degree 2.3 3.1 3.6 4.4 5.2 6.6 7.4 8.5 9.3 11.0 13.0 Valves Globe Gate Angle Swing Check 21.0 0.3 12.8 7.2 22.0 0.5 15.0 7.3 22.0 0.6 15.0 8.0 24.0 0.7 15.0 8.8 29.0 0.8 17.0 11.0 37.0 1.1 18.0 13.0 42.0 1.2 18.0 15.0 54.0 1.5 18.0 19.0 62.0 1.7 18.0 22.0 79.0 1.9 18.0 27.0 110.0 2.5 18.0 38.0 4.6 5.0 6.6 7.7 18.0 20.0 27.0 29.0 34.0 42.0 Strainer Flanged Fittings Elbows Tees Return Bends Valves Pipe Size 1/2 3/4 1 1¼ 1½ 2 2½ 3 4 5 6 8 10 12 14 16 18 Regular 90 degree Long radius 90 degree Regular 45 degree Line Flow Branch Flow Regular 180 degree 0.9 1.1 0.5 0.7 2.0 0.9 1.2 1.3 0.6 0.8 2.6 1.2 1.6 1.6 0.8 1.0 3.3 1.6 2.1 2.0 1.1 1.3 4.4 2.1 2.4 2.3 1.3 1.5 5.2 2.4 3.1 2.7 1.7 1.8 6.6 3.1 3.6 2.7 2.0 1.9 7.5 3.6 4.4 3.4 2.5 2.2 9.4 4.4 5.9 4.2 3.5 2.8 12.0 5.9 7.3 5.0 4.5 3.3 15.0 7.3 8.9 5.7 5.6 3.8 18.0 8.9 12.0 7.0 7.7 4.7 24.0 12.0 14.0 8.0 9.0 5.2 30.0 14.0 17.0 9.0 11.0 6.0 34.0 17.0 18.0 9.4 13.0 6.4 37.0 18.0 21.0 10.0 15.0 7.2 43.0 21.0 23.0 11.0 16.0 7.6 47.0 23.0 Long radius 180 degree Globe Gate Angle Swing Check 1.1 38.0 1.3 40.0 1.6 45.0 2.0 54.0 2.3 59.0 18.0 10.0 18.0 12.0 4.2 120.0 2.9 38.0 38.0 5.0 150.0 3.1 50.0 50.0 5.7 190.0. 3.2 63.0 63.0 7.0 260.0 3.2 90.0 90.0 8.0 310.0 3.2 120.0 120.0 9.0 390.0 3.2 140.0 140.0 11.0 17.0 7.2 3.4 94.0 2.8 285.0 27.0 10.0 15.0 5.3 2.9 77.0 2.7 22.0 21.0 9.4 15.0 3.8 2.7 70.0 2.6 21.0 17.0 3.2 160.0 3.2 190.0 3.2 210.0 © 2014 Project Lead The Way, Inc. PLTW Engineering Formula Sheet 2014 20.0 555 Timer Design quaons T = 0.693 (RA + 2RB)C f = (20.1) 1 (20.2) T duty-cycle = (RA+ RB) ∙1 (RA+2RB) % (20.3) T = period f = frequency RA = resistance A RB = resistance B C = capacitance 21.0 Boolean Algebra Boolean Theorems Commutative Law Consensus Theorems X• 0 = 0 (21.1) X•Y = Y•X (21.10) X + XY = X + Y (21.16) X•1 = X (21.2) X+Y = Y+X (21.11) X + XY = X + Y (21.17) X• X =X (21.3) X + XY = X + Y (21.18) X • X= (21.4) X + XY = X + Y (21.19) X+0=X (21.5) X+1=1 (21.6) X+X=X (21.7) Distributive Law X+X=1 (21.8) X(Y+Z) = XY + XZ (21.14) X=X (21.9) (X+Y)(W+Z) = XW+XZ+YW+YZ (21.15) Associative Law X(YZ) = (XY)Z (21.12) X + (Y + Z) = (X + Y) + Z (21.13) DeMorgan’s Theorems XY = X + Y (21.20) X+Y = X • Y (21.21) 22.0 Speeds and Feeds N= CS(12in. ) ft πd fm = ft·nt·N (22.1) (22.2) Plunge Rate = ½·fm N = spindle speed (rpm) CS = cutting speed (in./min) d = diameter (in.) fm = feed rate (in./min) ft = feed (in./tooth/rev) nt = number of teeth © 2014 Project Lead The Way, Inc. PLTW Engineering Formula Sheet 2014 DE 5 CIM 5 23.0 Aerospace Equations Propulsion F N= Forces of Flight CD = 2D Aρv2 R e= ρvl CL = 2L μ Aρv2 = Fd (23.1) (23.2) (23.3) (23.4) CL = coefficient of lift CD = coefficient of drag L = lift D = drag A = wing area ρ = density Re = Reynolds number v = velocity l = length of fluid travel μ = fluid viscosity F = force m = mass g = acceleration due to gravity M = moment d = moment arm (distance from datum perpendicular to F) Orbital Mechanics vj - vo (23.5) I = Fave ∆t (23.6) Fnet = Favg - Fg (23.7) a= 𝑣𝑓 T = 2π (23.8) ∆t F= FN = net thrust W = air mass flow vo = flight velocity vj = jet velocity I = total impulse Fave = average thrust force t = change in time (thrust duration) Fnet = net force Favg = average force Fg = force of gravity vf = final velocity a = acceleration t = change in time (thrust duration) (23.9) G m (23.11) 2R m G = 6.67 × 10−11 kg × 𝑠2 (23.14) G (23.15) r2 ρv2 ) = 2 1 (Ps + ρv2 ) 2 2 (23.16) PS = static pressure v = velocity ρ = density Atmosphere Parameters T = 15. - . (23.12) K = kinetic energy m =mass v = velocity U = gravitational potential energy G = universal gravitation constant M =mass of central body m = mass of orbiting object R = Distance center main body to center of orbiting object E = Total Energy of an orbit © 2014 Project Lead The Way, Inc. PLTW Engineering Formula Sheet 2014 a2 (23.10) R E=U+K=− μ = 2π Ber oulli’s L w Energy −G m a2 G m (Ps + U= (23.13) a2 𝑒 = eccentricity b = semi-minor axis a =semi-major axis T = orbital period a = semi-major axis μ = gravitational parameter F = force of gravity between two bodies G = universal gravitation constant M =mass of central body m = mass of orbiting object r = distance between center of two objects NOTE: Fave and Favg are easily confused. K = 12 mv2 b2 𝑒= 1- h T + 273.1 5.256 p = 1 1.2 ρ= 6 2 . p .2 6 T + 273.1 (23.17) (23.18) (23.19) T = temperature h = height p = pressure ρ = density AE 6