The Grignard Reaction

advertisement

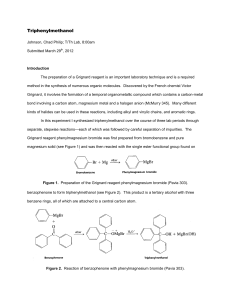

GRIGNARD REACTION: PREPARATION OF TRIPHENYLMETHANOL (12/22/2009) Grignard reagents are among the most versatile organometallic reagents, and they are the easiest organometallic reagent to prepare. Grignard reagents may be readily prepared from alkyl or aryl halides by their reaction with magnesium metal in an ether solvent. The structure of Grignard reagents varies with reaction conditions, but exist as RMgX or ArMgX in dilute (< 1M) solution. We will use these formulas to represent Grignard reagents from hereon. The formation of Grignard RX (or ArX) (CH 3CH2) 2O + Mg RMgX (or ArMgX) or THF reagents is a heterogeneous reaction and occurs on the magnesium metal's surface. Thus it is critical to use a solvent that will dissolve the Grignard reagent as it forms or the magnesium's surface will be coated with the reagent and stop any further reaction. Ethers are about the only solvents that will dissolve Grignard reagents, and the two most commonly used ethers are diethyl ether and tetrahydrofuran (THF). Diethyl ether is usually the preferred solvent because it may be readily obtained in anhydrous form, is less expensive, and is easy to remove after the reagent has been used owing to its low boiling point (36 oC). Grignard reagents are very basic and react readily with water or any compound containing a hydroxyl function. Thus the solvent must be anhydrous, the glassware must be scrupulously dry, and the reaction must be protected from moist air by use of a drying tube. RMgX (or ArMgX) HOR ' + RH (or ArH) + XMgOR ' Grignard reagents also react readily with oxygen and carbon dioxide as shown below. These reactions can be prevented by forming the Grignard reagent under an inert atmosphere such a nitrogen. RMgX + O2 RMgX ROOMgX + CO2 RMgX 2 ROMgX RCO2MgX A side reaction that occurs during the formation of Grignard reagents is the coupling reaction between two alkyl (or aryl) halides as shown below. This side reaction can be minimized if the concentration of the halide is kept low by the slow addition of an ether solution of the halide to a mixture of magnesium and an ether. (CH 3CH2) 2O 2RX (or 2ArX) + Mg RR (or ArAr) or THF + MgX2 Grignard reagents undergo addition to the carbonyl groups of aldehydes, ketones and esters to produce alcohols. By careful combination the appropriate alkyl and/or aryl groups in the Grignard reagent and the carbonyl compound a wide variety of primary, secondary, and tertiary alcohols may be synthesized. Aldehydes and ketones react with one molar equivalent of the Grignard reagent, whereas esters react with two molar equivalents of the reagent. Initially, esters undergo a nucleophilic substitution reaction with one equivalent of Grignard reagent to produce an intermediate ketone, which immediately undergoes an addition reaction with a second equivalent of Grignard reagent to produce a tertiary alcohol. In this experiment, phenylmagnesium bromide will be prepared by the reaction between bromobenzene and magnesium metal and immediately treated with methyl benzoate (prepared in the previous lab period) to produce triphenylmethanol. O O C 6H5 C OCH3 + C 6H5MgBr O C 6H5 C C C 6H5 O C 6H5 + C 6H5MgBr C 6H5 + BrMgOCH3 OH MgBr C 6H5 C C 6H5 C 6H5 H H2O C 6H5 C C 6H5 C 6H5 EXPERIMENTAL PROCEDURES1 Phenylmagnesium Bromide: Before starting, make sure that all glassware to be used, including graduated cylinders, is completely dry, i.e., do not wash any glassware with water just before use in this experiment. Equip a Claisen adapter with a condenser and an addition funnel, attach a drying tube filled with Drierite (anhydrous calcium sulfate) to the top of the condenser, and apply joint lubricant to the bottom joint of the Claisen adapter. Secure a 100-mL round-bottomed flask with a clamp from which the vinyl pads have been removed. Be sure to leave enough room beneath the flask so that a cooling bath or thermowell may be easily placed under it. Place 1.1g of partially ground magnesium turnings (use a mortar and pestle) into the flask. After making sure that no one in the near vicinity is working with diethyl ether or other flammable materials, flame-dry2 the flask containing the magnesium turnings, using a gas burner with a luminous flame3. Immediately attach the Claisen adapter assembly to the flask and allow the flask to cool to room temperature. Extinguish all flames! Make an ice bath ready in case control of the reaction becomes necessary.4 Remove the addition funnel and add 10mL of diethyl ether to the flask. Replace the addition funnel. Prepare a solution of 4.4mL (6.6g, 0.042mol) of bromobenzene in 10mL of diethyl ether and add it to the addition funnel. After making sure that water is flowing through the condenser, add ~2mL of the bromobenzene solution to the flask. To begin the reaction, remove the round bottom flask and hold on a flat surface. Next, crush the turnings with a dry stirring rod very carefully. The appearance of small bubbles at the surface of the magnesium turnings or a slight cloudiness indicates that the reaction has started. When you are certain the reaction is proceeding, return the rbf (flask containing reaction mixture) to the Claissen adapter. Start adding the rest of the bromobenzene solution dropwise at a rate to maintain a gentle reflux. If the reaction becomes too vigorous, briefly cool the flask with the ice bath. The addition should be complete in ~15 min. If the reflux rate slows significantly during addition, increase the rate of addition. If the reflux rate still remains low, heat the mixture with a thermowell to maintain a gentle reflux. The reaction mixture will usually have a brownish color and most of the magnesium will have disappeared. After completion, allow the reaction mixture to cool to room temperature. The next step should be started at once because the Grignard solution will deteriorate on standing. 1. Do not obtain liquid reagents or put on your paper lab coat until instructed to do so! 2. Keep long hair tied back. 3. NO ETHER NEAR OPEN FLAMES! 4. Prepare ice bath before starting to control reaction. Leave space below flask (keep thermowell out of the way). Triphenylmethanol: Prepare a solution of 2.5g (0.018 mol) of methyl benzoate in 10mL of diethyl ether and add it to the addition funnel. If necessary, briefly cool the reaction flask in an ice bath and start the dropwise addition of the methyl benzoate solution with occasional swirling. The reaction rate of the mildly exothermic reaction may be controlled by adjusting the rate of addition and occasional cooling with the ice bath. The addition should be complete in ~5 min. Note any changes in appearance during the addition. Once the addition of the ester is complete and there is at least 1.5 hours remaining in the lab period, heat the reaction mixture at reflux with a thermowell for ~30 min. Next, slowly pour the reaction mixture, with swirling, into a 250-mL Erlenmeyer flask containing 30 mL of 2 M sulfuric acid and ~30 g of ice. Rinse the reaction flask with a few mL of 2 M sulfuric acid and diethyl ether. Swirl the Erlenmeyer flask until no more solid material remains in the mixture. An additional amount of diethyl ether may be required to dissolve all of the organic material. Transfer the mixture to a separatory funnel, rinsing the flask with a few mL of diethyl ether. Carefully shake the funnel, venting to relieve pressure, and drain off the aqueous layer. Wash the organic layer with ~20 mL of 2 M sulfuric acid and then with ~10 mL of saturated salt solution. Dry the organic layer with anhydrous sodium sulfate, and filter or decant the solution into a tared 250-mL round-bottomed flask. Remove the diethyl ether on a rotary evaporator. Add ~5 mL of petroleum ether (TBP 30-60oC) to the residue and mix well. All byproducts in the reaction mixture will dissolve, leaving most of the triphenylmethanol as an insoluble solid. Collect the triphenylmethanol by vacuum filtration, making sure to save the filtrate for column chromatography. Dissolve the product in ethyl acetate (until it just dissolves, with a small amount extra, ≈ 1 ml) on a steam plate. If necessary, filter the solution through a small plug of cotton. Dilute the hot solution with a volume of petroleum ether equal to twice that of the ethyl acetate used and allow to crystallize at room temperature and then in an ice bath. Collect the crystals by vacuum filtration. Determine the melting point and calculate the percent yield. This symbol indicates is a good stopping point for Part I of the experiment. The final isolation and recrystallization steps can easily be completed next week. Preparation of the Column (taken from CH2411 Experiment Manual): Vertically clamp a dry buret, making sure that the stopcock is closed. Push a small plug of polypropylene wool into the bottom of the buret with a wooden dowel rod. Add enough clean, dry sand to form about a 1-cm layer on top of the polypropylene wool, and then add enough petroleum ether (30-60 oC) to half-fill the buret. Open the stopcock and drain out a few milliliters of the solvent to remove air from the sand and the polypropylene wool. Place a funnel in the top of the buret and very slowly add approximately 15 g of dry alumina (no need to weigh 3 rounded tsp = ~15 g). When all of the alumina has been added, rinse the inside of the buret with additional petroleum ether to flush down any alumina that may be adhering to the walls. Add more clean, dry sand to form about a 1-cm layer on top of the alumina. Carefully drain the solvent from the column until the solvent level just reaches the top of the sand. The column is now ready for the addition of the mixture to be separated. solvent sand alumina polypropylene wool sand Column Chromatography Procedure Carefully transfer the petroleum ether filtrate that you saved above to the top of the column with a Pasteur pipet, then slowly drain the column until the liquid level is at the of the layer of sand. Remember that the liquid level must never be allowed to drop below the top layer of the sand from this point on. Begin eluting the column with petroleum ether (30-60 oC) and collect 3 15mL fractions in Erlenmeyer flasks. The first component, biphenyl, should be contained in the first two fractions and the second component, methyl benzoate, should be in the third fraction. Combine the first two fractions, evaporate the combined fractions and the third fraction on a rotary evaporator, and determine the weights of the residues. By switching to a 1:1 mixture of diethyl ether - petroleum ether as the eluting solvent, two more components (additional triphenylmethanol and phenol) could be eluted from the column. However, because of insufficient time remaining in the lab period, they will not be eluted. Name:______________________________________ Section:_________ Date:____________ POSTLAB EXERCISE: GRIGNARD REACTION (12/22/2009) >> Due the lab following the completion of the experimental portion of the notebook (30pts. TOTAL). Please answer questions on this form. Attach sample calculations and copies of any TLC plates, GC tr aces, and/or spectr a which you inter pr et (on the spectra , please!).<< 1. PRODUCT (TRIPHENYLMETHANOL) INFORMATION (15pts) %Yield (5pts): Melting Point (5pts): Appearance (describe) (5pts): 1. (5pts) Why was the tube containing Drierite placed on top of the condenser? 2. (5pts) Even if technical grade diethyl ether is anhydrous, it often contains ethanol. What effect would the use of technical diethyl ether as the solvent have on the preparation of a Grignard reagent? 3. (5pts) Why do Grignard solutions deteriorate when they are exposed to air even though they are protected by a drying tube?