8. Failure - MSE 235- Materials Science for Electronics Engineers

advertisement

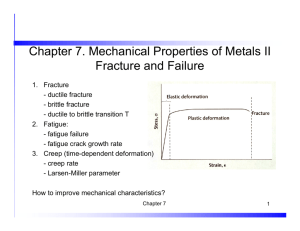

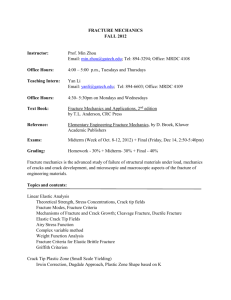

‘’FAILURE’’ Part 1 IE-114 Materials Science and General Chemistry Lecture-8 OUTLINE - Mechanisms of crack propogation for both ductile and brittle modes of fracture - Impact fracture testing techniques - Strengths of Brittle Materials - Fracture toughness and Plain Strain Fracture Toughness Failure The inability of a material to; (1) Perform the intended function (2) Meet performance criteria although it may still be operational (3) Perform safely and reliably even after deterioration Examples of Failure: Yielding, wear, buckling, corrosion and fracture Fracture: The seperation of solid under stress into two or more parts. Ductile Brittle Mixture of ductile and brittle fracture may also be seen Most of the metal alloys are ductile, but ceramics are brittle. Polymers exhibits the two types of fracture. (1) Ductile Fracture Ductile fracture of a metal occurs after extensive plastic deformation. Fracture point Characterized by slow crack propogation (a) For extremely soft metals: There is about 100% reduction in area. (b) Most common tensile fracture profile: Necking is followed by frature. Pure gold or lead at RT or some metals Polymers and inorganic glasses at high T. A typical fracture process has two steps: 1) Crack formation 2) Propagation (this is the step determining the mode of the fracture) Stages of cup-and-cone DUCTILE fracture Initial necking Small cavity formation Coalescence of cavities to form a crack Crack propagation Final shear fracture at a 45o angle relative to tensile direction Ductile fracture proceeds slowly as the crack length is extended. This type of crack is called stable. Cup-and-cone fracture of an aluminum alloy Characteristic Features of Ductile Fracture Surfaces Dimples are characteristics features of ductile failure Each dimple is one half of a microvoid formed and then seperated during the fracture process Equiaxed dimples formed during microvoid coalescence Shear dimples resulting from shear loading (2) Brittle Fracture Ceramics fracture in a brittle manner with little or no plastic deformation at room temperature Many metals with the HCP crystal structure (i.e. Zn) fractures in a brittle manner (limited number of slip systems) BCC metals such as -iron, Mo, W fracture in brittle manner at low temperatures and high strain rates Fracture Point Cracks spread rapidly with very little accompanying plastic deformation. This type of cracks are called unstable. The motion of the crack is perpendicular to applied stress. Characteristic Features of Brittle Fracture Surfaces Brittle crystalline materials have successive and repeated breaking of atomic bonds along specific crystallographic planes (cleavage planes) and fracture cracks pass through grains. The process is called cleavage and type of fracture is called transgranular. Transgranular: Intergranular: Most brittle fractures in polycrystalline metals are transgranular When grain boundary contains brittle film or segregated detrimental particles Cracks propagate across the matrix of grains Cracks propogates along the grain boundaries Brittle Fracture in Metals In many cases, brittle fracture in metals occurs due to existance of defects, low operating temperatures, or high strain rates Defects may be formed either in manufacturing stage or develop during service Manufacturing ( forging, rolling, extrusion and casting) defects; - Large inclusions - Poor microstructure - Porosity - Tears - Cracks - Voids - Sharp corners Brittle fracture initiates at the defect location (stress risers) - The fracture of a metal starts at a place where the stress-concentration is highest (which may be at the top of a crack) Brittle Fracture Surfaces seen in Steels Fracture surfaces of materials that failed in a brittle manner will have their own characteristics Cracks initiated at sharp corner V-shaped ‘chevron’ marking Cracks initiated at surface crack Radial fan shaped ridges Very Moderately Brittle • B is most common mode. • Ductile fracture is desired Why? Soft metals at RT (Au, Pb) Metals, polymers, inorganic glasses at high T. A B crack + plastic Note: Remnant of microvoid formation and coalescence. C Brittle: crack failure Plastic region Brittle fracture: no warning. Cup-cone fracture in Al Brittle fracture: mild Steel Toughness and Impact Testing The test is used to measure the impact energy (amount of energy a material can absorb before fracturing) , which is also called notch toughness. Standardized tests: Charpy Izod - Used to measure the impact energy (or notch toughness) - Standart V-notch specimens are used Standart test specimen Impact Testing IZOD CHARPY IZOD The load is applied as an impact blow from a weighted pendulum hammer. It is released from a fixed height (h). Pendulum strikes and fractures the specimen at the notch. The pendulum continues its swing rising to maximum height h’. The energy absorption, computed from the difference between h and h’ is a measure of the impact energy. initial height final height IMPACT TESTING APPARATUS Ductile to Brittle Transition Temperature(DBT) Low temperatures, high stress values, and fast loading rates may all cause a ductile material to behave in a brittle manner Important in material selection for components that operate in cold environment Impact Energy Ductile-to-brittle trasnsition temperature is determined by conducting Charpy or Izod test at various temperatures FCC metals (e.g., Cu, Ni) BCC metals (e.g., iron at T < 914°C) polymers Brittle More Ductile High strength materials ( y > E/150) Temperature Ductile-to-brittle transition temperature Ductile to brittle transition temperature of Steel used in Titanic was 32oC, the seawater temperature at the time of accident was -2oC This temperature is often defined as: -The temperature at which the absorbed energy assumes some value (e.g. 20 J) or - The temperature corresponding to some given fracture appearance (e.g. %50 fibrous) Fracture surfaces of V-notched charpy impact specimens brittle (shiny) ductile (fibrous) Metal alloys with FCC structures (Al and Cu) remain ductile even at extremely low T BCC and HCP alloys experience this transition. Factors that influence the ductile to brittle transition: Composition Heat treatment Processing Decreasing the grain size lowers the transition T and increasing C content raises the CVN transition of the steels. Fracture Mechanics This research area is about the relationships between material properties, stress level, the presence of crack producing flaws and crack propagation mechanisms. The measured fracture strengths for brittle materials are lower than those predicted by theoretical calculations. Microscopic flaws or cracks already existing within the material. SURFACE CRACK INTERNAL CRACK The flaws are sometimes called stress raisers due to their ability to amplify the applied stress in their locale. The fracture of a material starts at a place where the stress (or stress concentration) is maximum Maximum Stress at the crack tip, m If the crack has an elliptical shape and is oriented perpendicular to the applied stress; m = 2o(a/t)1/2 σm σ0 ρt a : maximum stress at the crack tip : magnitude of the nominal applied tensile stress : radius of curvature of the crack tip : length of a surface crack or half of the length of an internal crac Stress concentration factor, Kt The ratio of maximum stress at the crack tip to nominal applied stress:σm/ σno Kt = m/ o = 2(a/t)1/2 This factor shows the degree to which an external stress is amplified at the tip of a crack. * The effect of stress raiser in brittle fracture is more significant than in ductile fracture of the materials. In ductile material, the plastic deformation indicates the point when maximum stress exceeds the yield strength. This causes a more uniform distribution of stress in the vicinity of the stress raiser. But this does not occur in brittle materials. The critical stress (σc) required for crack propagation in a brittle material: c=(2Es/a)1/2 E: Modulus of elasticity s : specific surface energy a : one half of the length of an internal crack Griffith Theory of Brittle Fracture Energy balance between release of elastic strain energy during propogation of crack and surface energy Condition for Crack Propogation in brittle material If the magnitude of a tensile stress at the tip of a flaw exceeds the value of this critical stress, then a crack forms and then propagates, which results in fracture. (m> c) Above equation applies only to completely brittle materials. But, some metals which fail in a brittle manner will experience some plastic deformation. So, s in above equation is replaced by p + s p : plastic deformation energy associated with crack extension Fracture Toughness, Kc Fracture Toughness (Kc) is a measure of materials resistance to brittle fracture when a crack is present. Fracture of a metarial starts at a place where the stress concentration is highest (e.g. at the top of a sharp crack) The critical value of stress concentration is Kc and depends on applied load and width of the crack SURFACE CRACK INTERNAL CRACK Kc = Yca σc : critical stress for crack propagation a : crack length Y : dimensionless parameter and its value depends on both crack and specimen sizes and geometries, and load application. Y=1 for aplate of infinite width having a throughthickness crack Y= 1.1 for aplate of semi-infinite width having an edge crack lentgh of a. Plain Strain Fracture Toughness, KIc For relatively thin specimens, the value of Kc depends on the thickness. Plain Strain Condition: KIc = Ya B 2.5 (KIC/y)2 B: specimen thickness KIC: plain strain fracture toughness If the thickness is much greater than the crack dimensions, Kc becomes independent of thickness and plain strain conditions exists. This means that when a load operates on a crack in the manner shown in there is no strain component perpendicular to the front and back faces. KIc is a fundamental material property and depends on: Temperature Strain rate Microstructure The magnitude of KIC decreases with increasing strain rate and decreasing temperature KIC decreases as yield strength is improved by solid solution or dispersion additions or by strain hardening. KIC increases with reduction in grain size. Room Temperature Yield Strength and Plane Strain Fracture Toughness Data for Some Materials Brittle materials have relatively low fracture tougnhness (Kıc) Ductile materials have high Kıc values