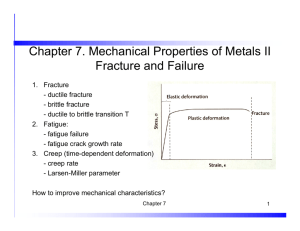

Fracture and fatigue

advertisement

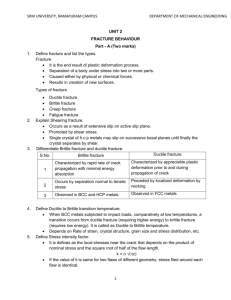

Fracture and fatigue Key point: Preexisting surface flaws and preexisting internal cracks play a central role in the failure of materials. ISSUES TO ADDRESS... • How do flaws in a material initiate failure? • How is fracture resistance quantified; how do different material classes compare? • How do we estimate the stress to fracture? • How do loading rate, loading history, and temperature affect the failure stress? Fracture mechanisms • Ductile fracture – Occurs with plastic deformation and with high energy absorption before fracture • Brittle fracture – Little or no plastic deformation with low energy absorption – Catastrophic 1 An oil tanker that fractured in a brittle manner by crack propagation around its girth Ductile vs Brittle Failure • Classification: Fracture behavior %AR or %EL Very Ductile Moderately Ductile Large Moderate Brittle Small • Ductile fracture is usually desirable! • • Ductile: warning before fracture Brittle: no warning 2 Example: Failure of a Pipe • Ductile failure: --one piece --large deformation • Brittle failure: --many pieces --small deformation Figures from V.J. Colangelo and F.A. Heiser, Analysis of Metallurgical Failures (2nd ed.), Fig. 4.1(a) and (b), p. 66 John Wiley and Sons, Inc., 1987. Used with permission. Moderately Ductile Failure • Evolution to failure: necking s • Resulting fracture surfaces (steel) void nucleation void growth and linkage shearing at surface fracture 50 50mm mm 100 mm particles serve as void nucleation sites. From V.J. Colangelo and F.A. Heiser, Analysis of Metallurgical Failures (2nd ed.), Fig. 11.28, p. 294, John Wiley and Sons, Inc., 1987. (Orig. source: P. Thornton, J. Mater. Sci., Vol. 6, 1971, pp. 347-56.) Fracture surface of tire cord wire loaded in tension. Courtesy of F. Roehrig, CC Technologies, Dublin, OH. Used with permission. 3 Ductile vs. Brittle Failure cup-and-cone fracture brittle fracture Adapted from Fig. 8.3, Callister 7e. Fractured tensile test bars ”Cup and cone” Fractured aluminium alloy I, with a dimpled texture Fractured aluminium alloy II, with a typical cleavage texture 4 Scanning electron micrographs (a) spherical dimples characteristic of ductile fracture, (b) parabolic-shaped dimples characteristic of ductile fracture. Brittle Failure Arrows indicate origin of crack 5 Transgranular fracture Intergranular fracture Brittle Failure Principles of fracture mechanics Flaws are Stress Concentrators or stress raisers Results from crack propagation • Griffith Crack ⎛a s m = 2s o ⎜⎜ ⎝ rt rt 1/ 2 ⎞ ⎟⎟ ⎠ = K t so where rt = radius of curvature of the crack tip so = applied stress sm = stress at crack tip Kt : stress concentration factor 6 Concentration of Stress at Crack Tip Adapted from Fig. 8.8(b), Callister 7e. Engineering Fracture Design ⎛a s m = 2so ⎜⎜ ⎝ rt 1/ 2 ⎞ ⎟⎟ ⎠ = K t so • Avoid sharp corners! s so max Stress Conc. Factor, K t = s w smax r, fillet radius o 2.5 h Adapted from Fig. 8.2W(c), Callister 6e. (Fig. 8.2W(c) is from G.H. Neugebauer, Prod. Eng. (NY), Vol. 14, pp. 82-87 1943.) 2.0 increasing w/h 1.5 1.0 0 0.5 1.0 sharper fillet radius r/h 7 Crack Propagation Cracks propagate due to sharpness of crack tip • A plastic material deforms at the tip, “blunting” the crack. Deformed region bittle plastic Energy balance on the crack • Elastic strain energy • energy stored in material as it is elastically deformed • this energy is released when the crack propagates • creation of new surfaces requires energy When Does a Crack Propagate? • Critical stress for crack propagates in a brittle material i.e., sm > sc or Kt > Kc 1/ 2 ⎛ 2Egs ⎞ sc = ⎜ ⎟ ⎝ pa ⎠ where • • • • • E = modulus of elasticity gs = specific surface energy a = one half length of internal crack Kc = sc/s0 For ductile => replace gs by gs + gp where gp is plastic deformation energy Example problem 8.1, p217 8 Fracture toughness Critical stress for crack propagation (sc) and crack length (a) KC = Ysc ( p a)1/2 1. Y: geometry factor, on the order of 1 2. sc the overall applied stress at failure 3. a: the length of a surface crack (one-half the length of an internal crack) 4. Unit of KIC: MPa • m1/2 a KC: fracture toughness the critical (c) value of the stress intensity factor at a crack tip necessary to produce failure a The three modes of crack surface displacement (a) mode I, opening or tensile mode plane strain fracture toughness p a) KIC = Ysc ( 1/2 (b) mode II, sliding mode (c) mode III, tearing mode 9 Room-temperature mechanical properties for selected engineering materials Fracture Toughness Metals/ Alloys Graphite/ Ceramics/ Semicond Polymers 100 K Ic (MPa · m 0.5 ) 70 60 50 40 30 C-C(|| fibers) 1 Steels Ti alloys Al alloys Mg alloys 20 Al/Al oxide(sf) 2 Y2 O 3 /ZrO 2 (p) 4 C/C( fibers) 1 Al oxid/SiC(w) 3 Si nitr/SiC(w) 5 Al oxid/ZrO 2 (p) 4 Glass/SiC(w) 6 10 7 6 5 4 Diamond Si carbide Al oxide Si nitride PET PP 3 PVC 2 1 0.7 0.6 0.5 Composites/ fibers PC <100> Si crystal <111> Glass -soda Concrete PS Glass 6 Polyester 10 Design Against Crack Growth • Crack growth condition: K ≥ Kc = Ys pa • Largest, most stressed cracks grow first! --Result 2: Design stress --Result 1: Max. flaw size dictates max. flaw size. dictates design stress. Kc < Y pamax sdesign amax 1 ⎛ Kc < ⎜ p ⎜⎝ Ys design ⎞ ⎟ ⎟ ⎠ 2 amax s fracture fracture no fracture no fracture amax s Design Example: Aircraft Wing • Material has Kc = 26 MPa-m0.5 • Two designs to consider... Design A sc = • Use... Design B --use same material --largest flaw is 4 mm --failure stress = ? --largest flaw is 9 mm --failure stress = 112 MPa Kc Y pamax • Key point: Y and Kc are the same in both designs. --Result: 112 MPa 9 mm (s c amax 4 mm )= (s A c amax ) B Answer: ( sc )B = 168 MPa • Reducing flaw size pays off! 11 Loading Rate • Increased loading rate... • Why? An increased rate gives less time for dislocations to move past obstacles. -- increases sy and TS -- decreases %EL s TS sy e larger e smaller TS sy e Impact fracture testing Charpy test of impact energy 1. A notched specimen – stress concentrating 2. Loading applied rapidly 3. impact energy - the energy necessary to fracture the test specimen Charpy test Izod test The swinging pendulum The intial height h The final height h’ 12 Cu: fcc, ductile 1040 carbon steel: Fe-0.4C-0.75 Mn Mg alloy: hcp, relatively brittle J: joule. 1J = 1N • m Toughness obtained in a tensile test Fracture Toughness = ∫ sde , the area under the s - e curve Unit of toughness: N/m2 Or (N/m2) • (mm / mm) = N •m / (mm)3 Toughness: the energy necessary to fracture per unit volume of material 13 Temperature dependence of the Charpy V-notch inpact energy and shear fracture for an A283 steel. Brittle More Ductile Schematic curves for the three general types of impact energyversus-temperature behavior 14 Ductile-to-Brittle Transtion Temperature (DBTT) 1. in bcc alloys 2. an abrupt drop in ductility and toughness as the temperature is lowered Plain-carbon steels with various carbon levels Fe-Mn-0.05C alloys with various manganese levels Design Strategy: Stay Above The DBTT! • Pre-WWII: The Titanic Reprinted w/ permission from R.W. Hertzberg, "Deformation and Fracture Mechanics of Engineering Materials", (4th ed.) Fig. 7.1(a), p. 262, John Wiley and Sons, Inc., 1996. (Orig. source: Dr. Robert D. Ballard, The Discovery of the Titanic.) • WWII: Liberty ships Reprinted w/ permission from R.W. Hertzberg, "Deformation and Fracture Mechanics of Engineering Materials", (4th ed.) Fig. 7.1(b), p. 262, John Wiley and Sons, Inc., 1996. (Orig. source: Earl R. Parker, "Behavior of Engineering Structures", Nat. Acad. Sci., Nat. Res. Council, John Wiley and Sons, Inc., NY, 1957.) • Problem: Used a type of steel with a DBTT ~ Room temp. 15 Fatique • Fatique = failure under cyclic stress • failure after N cycles • load < T.S Fatique-testing apparatusfor making rotating-bending tests 16 • Stress varies with time. -- key parameters are S, sm, and frequency s smax sm S smin time S = stress amplitude, sm= mean stress, sm = (smax + smin)/2 S = (smax – smin)/2 Load ratio R = smin/smax Random stress cycle. • Key points: Fatigue... --can cause part failure, even though smax < sc. --causes ~ 90% of mechanical engineering failures. Typical fatique curve (S-N curve) or fatigue strength 17 Fatigue Design Parameters • Fatigue limit, Sfat: S = stress amplitude --no fatigue if S < Sfat case for steel (typ.) unsafe Sfat safe 10 3 5 7 9 10 10 10 N = Cycles to failure • Sometimes, the fatigue limit is zero! (a material does not display a fatique limit) S = stress amplitude case for Al (typ.) unsafe safe 10 3 5 Adapted from Fig. 8.19(b), Callister 7e. 7 9 10 10 10 N = Cycles to failure Fatique S-N probability of failure curves for a 7075-T6 Al alloy 18 Fatigue Mechanism • Crack grows incrementally da m = (D K ) dN typ. 1 to 6 ~ (Ds ) a increase in crack length per loading cycle • Failed rotating shaft crack origin --crack grew even though Kmax < Kc --crack grows faster as • Ds increases • crack gets longer • loading freq. increases. Texture of the fatigue fracture surface – clamshell or beachmark texture Intrusions and extrusions. SEM. 19 Transmission electron fractograph showing fatique striations in aluminum Each striationis thougth to represent the advance distance of a crack front during a single load cycle, striation width deponds on and incearses with increasing stress range. Improving Fatigue Life 1. Decrease the mean stress level 2. Impose a compressive surface stress (to suppress surface cracks from growing) --Method 1: shot peening --Method 2: carburizing shot C-rich gas put surface into compression 3. Remove stress concentrators. bad better bad better 20 SUMMARY • Engineering materials don't reach theoretical strength. • Flaws produce stress concentrations that cause premature failure. • Sharp corners produce large stress concentrations and premature failure. • Failure type depends on T and stress: - for noncyclic s and T < 0.4Tm, failure stress decreases with: - increased maximum flaw size, - decreased T, - increased rate of loading. - for cyclic s: - cycles to fail decreases as Ds increases. - for higher T (T > 0.4Tm): - time to fail decreases as s or T increases. Homework 8.6 and 8.12, p246 21