Advanced Orbital Pipe Welding

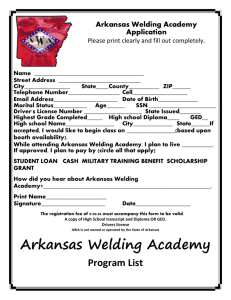

advertisement