Design Analysis and Review of Stresses at a Point

advertisement

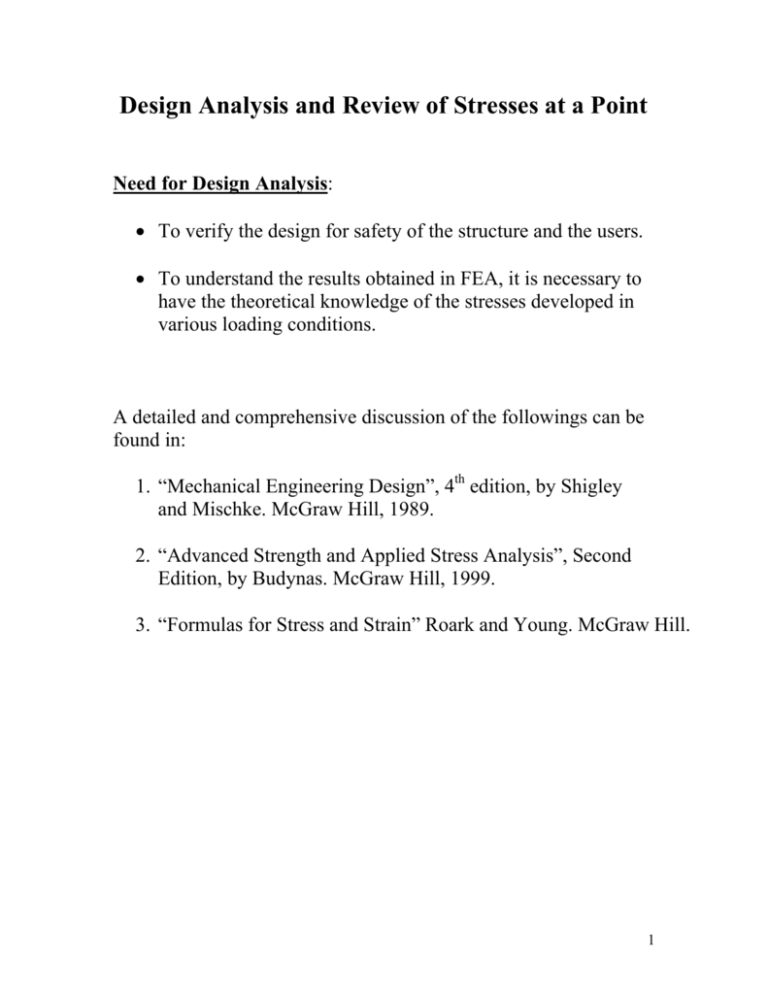

Design Analysis and Review of Stresses at a Point Need for Design Analysis: To verify the design for safety of the structure and the users. To understand the results obtained in FEA, it is necessary to have the theoretical knowledge of the stresses developed in various loading conditions. A detailed and comprehensive discussion of the followings can be found in: 1. “Mechanical Engineering Design”, 4th edition, by Shigley and Mischke. McGraw Hill, 1989. 2. “Advanced Strength and Applied Stress Analysis”, Second Edition, by Budynas. McGraw Hill, 1999. 3. “Formulas for Stress and Strain” Roark and Young. McGraw Hill. 1 Some important terms that frequently occur in Design Analysis Uniaxial stresses Biaxial Stresses 3-D Stresses Torsional Stress Bending Stress Normal Stress Combined Stresses Mohr’s Circle Failure Theories Von-Mises Stress Yield Strength Factor of safety Margin of safety Buckling Fatigue Stresses Modal Analysis Impact Loading Resonance Stresses in Cylinders Rotating Rings 2 Stresses at a Point 3-D Stresses y σy τyz τyx τxy τzy τzx σx τxz x σz z 2-D Stress Distribution σy τyx τxy τxy σx σx τyx σy 3 Principal Stresses In the above figure, the stresses at a point are given in the Cartesian coordinate (x, y, z) directions. Stresses in any direction φ (measured from the x-axis) are given by the following equation, σ = (1/2) (σx + σy) + (1/2) (σx – σy) cos 2φ + τxy sin 2φ Τ = (1/2) (σx – σy) sin 2φ + τxy cos 2φ The normal stress σ and shearing stress Τ vary in magnitude with angle φ. When the shearing stress Τ = 0, the normal stresses become maximum and minimum in magnitude. These stresses are called principal stresses. Mohr’s Circle is used to convert stresses at a point into principal stresses and the relationship is given as, σ1 = (1/2) (σx + σy) + [(1/2) (σx – σy)2 + τ2xy]1/2 σ2 = (1/2) (σx + σy) - [(1/2) (σx – σy)2 + τ2xy]1/2 4 Uniaxial Stress Uniaxial stress occurs when a bar or a plate structure is either stretched or compressed. The resulting stress in the bar is given as, L σ = F/A Where: F is the applied force, and A is the cross-section area of the bar. F Stress-strain relations: σ=Eε F Where: E is the Young’s modulus and ε is the strain. L Strain-deflection relationship: ε = Change in length/original length = ∆L/L 5 Biaxial Stresses When a plate-like structure is loaded in its plane, there are biaxial stresses and strains, Y σx σx X The plate shown is loaded in the x-direction, but the strains will occur in both, x and y-directions. The plate stretches in the x-direction, but due to the poison’s effect, it will shrink in the y-direction, thus creating bidirectional strains. σY σx If loads are applied in both x and y-directions, the plate will have a bi-directional stress distribution. 6 Stress-Strain Relations Assuming that the x and y axes are principal directions, stresses and strains are related by the following equations: σ1 = E (ε1 + νε2)/(1 – ν2) ε1 = σ1/E - νσ2/E σ2 = E (ε2 + νε1)/(1 – ν2) ε2 = σ2/E – νσ1/E σ3 = 0 ε3 = -νσ1/E – νσ2/E Beam in Bending Normal Stress: For a beam in pure bending, the normal stress is given as σ = Mc/I Where, I is the moment of inertia about the axis of beam rotation. Transverse Shear: The transverse shear is given as Τ = VQ/Ib Where, V is the shearing force c Q = ∫ y dA y I = Moment of inertia about the bending axis b = width of the beam 7 If a beam is slender, the transverse shear is negligible and ignored. However, if a beam is not very slender, the transverse shear becomes significant and can’t be ignored. Shear and Bending Moment Diagrams For a beam, the maximum stress occurs at the point where the bending moment is maximum. When the location of the maximum moment is not obvious, we need to draw a shear and bending moment diagram to find the magnitude and location. Sign Convention for Shear and Bending Moment Diagrams Positive Shear and moments Torsion The shearing stress in pure torsion is given as τ = Tr/J where r is the radial distance from the center of the shaft, and J is the polar moment of inertia. r T 8 Stress Concentration In the stress equations for axial, bending, and torsion, it is assumed that the cross section is uniform and no discontinuities exist. If there are holes, notches, fillets, change in cross section, etc., these equations cannot be used. Stresses in the irregular regions are always higher than the uniform sections – as much as by a factor of 3 or more. The stress concentration factor is given as, Kt = σmax/σaverage Where, σmax = Maximum stress at some point σaverage = Stress at the above point, calculated as if there is no stress concentration, and the area is the net area. Uniform cross section Stress concentration The stress concentration factor Kt can be found in engineering handbooks and texts (see the books by Shigley, Martin, Roark and Young, etc.) 9 Deflections Deflection occurs when a static load is applied on a structure at rest (in equilibrium). All deflections are assumed as deformation in the structure. Rigid body motion doesn’t result in stresses, and is not important in FEA, unless it is due to either buckling or warping. Buckling and warping require separate analysis, which is carried out after conduction the static analysis. 10 Elastic Structures All elastic structures follow the Hook’s law, F=kx Most engineering structures are considered as elastic and follow the Hook’s law. Tension, Compression, and Torsion Deflection for tension and compression loading is given as, δ = FL/AE The stiffness can be found by, k = F/x = (F)/ δ = (F)/(FL/AE) = AE/L Torsion Angular deflection in torsion is, θ = TL/JG The stiffness is, k = T/ θ = GJ/L 11 Bending Since there are numerous loading and support conditions that can be applied to a beam, the deflection equation can be found in an engineering textbook or a handbook. Shigley, Norton, and Roark and Young are good source of information. Buckling Buckling occurs in long columns that are loaded by compressive forces. A beam structure, that has several load members, should always be checked for buckling. In buckling, a structure can fail even before reaching the yield stress point, and therefore, the standard failure criteria are not valid. To check for buckling, the critical buckling load should be calculated, which will determine the maximum allowable load magnitude. Euler’s formula gives the critical buckling load equation, PCR = Cπ2EI/L2 C depends on the end-constraint of the part under buckling. It has the following values, 12 Column End Condition Recommended Value Fixed-Free 1/4 Pin-Pin 1 Fixed-Pin 1.2 Fixed-Fixed 1.2 Some textbooks use the term ‘Load Factor’, which is similar to the ‘Factor of Safety’ in stress analysis, and is defined as, LF = Pcr/Papplied For safety, the Load Factor (LF) must be greater than 1. Failure of Engineering Structures Generally, there are two types of engineering materials that are used in FEA: ductile and brittle. 13 Ductile Materials According to the ductile material failure theory, failure occurs when the Von-Mises stress (VMS) in the structure exceeds the yield strength of the material. The VMS is calculated from the principal stresses by the formula, σVM = [(σ1)2 + (σ2)2 - σ1 σ2]1/2 Brittle Materials Brittle materials, such as, cast iron and concrete are governed by Modified Mohr or Coulomb-Mohr theories. In FEA, computer is unable to distinguish between a ductile and a brittle material. Since the expected results are seldom exact answers, FEA software uses the Von-Mises stresses for checking failure in structures, regardless of the applicable theory for the material used. Structure Loads Generally, all loads applied in FEA are static loads. The structure is assumed to be in an equilibrium condition when the loads are applied. For other types of loads, such as, impact, vibrations, and fatigue, there are more advanced FEA software, which can handle these loads. 14