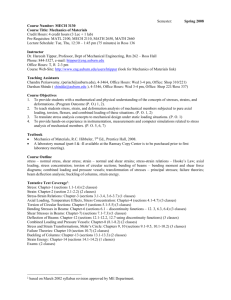

Stress Analysis & Pressure Vessels

advertisement

CET 1:

Stress Analysis &

Pressure Vessels

Lent Term 2005

Dr. Clemens Kaminski

Telephone: +44 1223 763135

E-mail: clemens_kaminski@cheng.cam.ac.uk

URL:

http://www.cheng.cam.ac.uk/research/groups/laser/

Synopsis

1

Introduction to Pressure Vessels and Failure Modes

2

3-D stress and strain

3

Thermal Effects

4

Torsion.

1.1

1.2

1.3

2.1

2.2

2.3

2.4

3.1

3.2

3.3

4.1

4.2

4.3

Stresses in Cylinders and Spheres

Compressive failure. Euler buckling. Vacuum vessels

Tensile failure. Stress Stress Concentration & Cracking

Elasticity and Strains-Young's Modulus and Poisson's Ratio

Bulk and Shear Moduli

Hoop, Longitudinal and Volumetric Strains

Strain Energy. Overfilling of Pressure Vessels

Coefficient of Thermal Expansion

Thermal Effect in cylindrical Pressure Vessels

Two-Material Structures

Shear Stresses in Shafts - τ/r = T/J = Gθ/L

Thin Walled Shafts

Thin Walled Pressure Vessel subject to Torque

5

Two Dimensional Stress Analysis

6

Bulk Failure Criteria

7

Two Dimensional Strain Analysis

5.1

5.2

5.3

5.4

6.1

6.2

7.1

7.2

7.3

7.4

Nomenclature and Sign Convention for Stresses

Mohr's Circle for Stresses

Worked Examples

Application of Mohr's Circle to Three Dimensional Systems

Tresca's Criterion. The Stress Hexagon

Von Mises' Failure Criterion. The Stress Ellipse

Direct and Shear Strains

Mohr's Circle for Strains

Measurement of Strain - Strain Gauges

Hooke’s Law for Shear Stresses

Supporting Materials

There is one Examples paper supporting these lectures.

Two good textbooks for further explanation, worked examples and exercises are

Mechanics of Materials (1997) Gere & Timoshenko, publ. ITP [ISBN 0-534-93429-3]

Mechanics of Solids (1989) Fenner, publ. Blackwell [ISBN 0-632-02018-0]

This material was taught in the CET I (Old Regulations) Structures lecture unit and was examined

in CET I (OR) Paper IV Section 1. There are consequently a large number of old Tripos questions

in existence, which are of the appropriate standard. From 1999 onwards the course was taught in

CET1, paper 5. Chapters 7 and 8 in Gere and Timoshenko contain a large number of example

problems and questions.

Nomenclature

The following symbols will be used as consistently as possible in the lectures.

E

G

I

J

R

t

T

Young’s modulus

Shear modulus

second moment of area

polar moment of area

radius

thickness

α

ε

γ

η

ν

σ

τ

thermal expansivity

linear strain

shear strain

angle

Poisson’s ratio

Normal stress

Shear stress

τορθυε

A pressure vessel near you!

Ongoing Example

We shall refer back to this example of a typical pressure vessel on several

occasions.

Distillation column

2m

P = 7 bara

carbon steel

t = 5 mm

18 m

1. Introduction to Pressure Vessels and Failure Modes

Pressure vessels are very often

• spherical (e.g. LPG storage tanks)

• cylindrical (e.g. liquid storage tanks)

• cylindrical shells with hemispherical ends (e.g. distillation columns)

Such vessels fail when the stress state somewhere in the wall material exceeds some failure criterion. It is thus important to be able to be able to understand and quantify

(resolve) stresses in solids. This unit will concentrate on the application of stress analysis to bulk failure in thin walled

vessels only, where (i) the vessel self weight can be neglected and (ii) the

thickness of the material is much smaller than the dimensions of the vessel

(D » t).

1.1. Stresses in Cylinders and Spheres

Consider a cylindrical pressure vessel

L

External diameter

D

internal gauge pressure P

r

L

h

wall thickness, t

The hydrostatic pressure causes stresses in three dimensions.

1.

Longitudinal stress (axial) σL

2.

Radial stress

σr

3.

Hoop stress

σh

all are normal stresses.

SAPV LT 2005

CFK, MRM

1

σ

r

σ

r

L

L

h

σ

h

a, The longitudinal stress σL

P

σ

L

Force equilibrium

π D2

P = π D t σL

4

if P > 0, then σ L is tensile

σL =

PD

4t

b, The hoop stress σh

P

σ

h

σ

P

h

P

Force balance, D L P = 2 σ h L t

σh =

SAPV LT 2005

CFK, MRM

2

PD

2t

c, Radial stress

σ

σ

r

varies from P on inner surface to 0 on the

outer face

r

σr ≈ o ( P )

D

σh , σL ≈ P (

).

2t

thin walled, so D >> t

so σ h , σ L >> σ r

so neglect σ r

Compare terms

d, The spherical pressure vessel

P

σ

h

SAPV LT 2005

CFK, MRM

π D2

P

= σh π D t

4

PD

σh =

4t

P

3

1.2. Compressive Failure: – Bulk Yielding & Buckling

– Vacuum Vessels

Consider an unpressurised cylindrical column subjected to a single load W.

Bulk failure will occur when the normal compressive stress exceeds a yield

criterion, e.g.

W

σ bulk =

W

= σY

πDt

Compressive stresses can cause failure due to buckling (bending instability).

The critical load for the onset of buckling is given by Euler's analysis. A full

explanation is given in the texts, and the basic results are summarised in the

Structures Tables. A column or strut of length L supported at one end will

buckle if

π 2 EI

W= 2

L

Consider a cylindrical column. I = πR3t so the compressive stress required

to cause buckling is

σ buckle

W

π 2 EπD3t 1

π 2 ED 2

=

=

⋅

=

2

πDt

8L

πDt

8L2

σ buckle

π2 E

=

2

8( L D)

or

SAPV LT 2005

CFK, MRM

4

where L/D is a slenderness ratio. The mode of failure thus depends on the

geometry:

σ

stress

Euler buckling locus

σ

y

Bulk yield

Short

Long

L /D ratio

SAPV LT 2005

CFK, MRM

5

Vacuum vessels.

Cylindrical pressure vessels subject to external pressure are subject to compressive hoop stresses

∆PD

2t

Consider a length L of vessel , the compressive hoop force is given by,

σh =

∆P D L

2

If this force is large enough it will cause buckling.

σh L t =

length

Treat the vessel as an encastered beam of length πD and breadth L

SAPV LT 2005

CFK, MRM

6

Buckling occurs when Force W given by.

4π 2 EI

W=

(π D) 2

I=

∆P D L 4π 2 EI

=

2

(π D )2

b t3 L t3

=

12

12

SAPV LT 2005

CFK, MRM

∆p buckle

7

=

2E ⎛ t ⎞

⎜ ⎟

3 ⎝D⎠

3

1.3. Tensile Failure: Stress Concentration & Cracking

Consider the rod in the Figure below subject to a tensile load. The stress distribution across the rod a long distance away from the change in cross section (XX) will be uniform, but near XX the stress distribution is complex.

D

X

X

d

W

There is a concentration of stress at the rod surface below XX and this value

should thus be considered when we consider failure mechanisms.

The ratio of the maximum local stress to the mean (or apparent) stress is described by a stress concentration factor K

K=

σ max

σ mean

The values of K for many geometries are available in the literature, including

that of cracks. The mechanism of fast fracture involves the concentration of

tensile stresses at a crack root, and gives the failure criterion for a crack of

length a

σ πa = Kc

where Kc is the material fracture toughness. Tensile

stresses can thus cause failure due to bulk yielding or due

to cracking.

SAPV LT 2005

CFK, MRM

8

σ crack =

Kc 1

⋅

√ π √a

stress

failure locus

length of crack. a

SAPV LT 2005

CFK, MRM

9

2.

3-D stress and strain

2.1. Elasticity and Yield

Many materials obey Hooke's law

σ = Eε

σ

E

ε

applied stress (Pa)

Young's modulus (Pa)

strain (-)

σ

failure

Yield

Stress

ε

Elastic

Limit

up to a limit, known as the yield stress (stress axis) or the elastic limit (strain

axis). Below these limits, deformation is reversible and the material eventually

returns to its original shape. Above these limits, the material behaviour depends

on its nature.

Consider a sample of material subjected to a tensile force F.

2

F

F

1

3

An increase in length (axis 1) will be accompanied by a decrease in dimensions

2 and 3.

Hooke's Law

ε1 = (σ1 ≡ F / A ) / E

10

The strain in the perpendicular directions 2,3 are given by

ε2 = −ν

σ1

E

;ε3 = − ν

σ1

E

where ν is the Poisson ratio for that material. These effects are additive, so for

three mutually perpendicular stresses σ1, σ2, σ3;

σ2

σ1

σ3

Giving

ε1 =

σ1

E

ε2 = −

ε3 = −

νσ 2

−

νσ1

E

νσ1

E

E

−

νσ 3

E

+

σ2

−

νσ 2

E

E

−

νσ 3

E

+

σ3

E

Values of the material constants in the Data Book give orders of magnitudes of

these parameters for different materials;

Material

Steel

Aluminum alloy

Brass

E

(x109 N/m2)

210

70

105

11

ν

0.30

0.33

0.35

2.2 Bulk and Shear Moduli

These material properties describe how a material responds to an applied stress

(bulk modulus, K) or shear (shear modulus, G).

The bulk modulus is defined as

Puniform = − Kε v

i.e. the volumetric strain resulting from the application of a uniform pressure. In

the case of a pressure causing expansion

so

σ1 = σ 2 = σ 3 = −P

−P

1

σ1 − νσ 2 − νσ 3 ] =

(1 − 2 ν )

[

E

E

−3P

ε v = ε1 + ε 2 + ε 3 =

(1− 2 ν )

E

E

K=

3(1 − 2 ν )

ε1 = ε 2 = ε 3 =

For steel, E = 210 kN/mm2, ν = 0.3, giving K = 175 kN/mm2

For water, K = 2.2 kN/mm2

For a perfect gas, K = P (1 bara, 10-4 kN/mm2)

Shear Modulus definition

τ = Gγ

γ - shear strain

12

2.3. Hoop, longitudinal and volumetric strains

(micro or millistrain)

Fractional increase in dimension:

ε L – length

ε h – circumference

ε rr – wall thickness

(a)

Cylindrical vessel:

Longitudinal strain

εL =

σL

-

υσ h

-

υσ L

E

E

υσ r

-

E

=

PD

δL

(1 - 2υ ) =

4tE

L

Hoop strain:

εh =

σn

E

E

=

δR

δD

PD

=

(2 - υ ) =

R

D

4tE

radial strain

εr =

δt

3PDυ

1

=

σ r - υσ h - υσ L ] = [

t

4ET

E

[fractional increase in wall thickness is negative!]

13

[ONGOING EXAMPLE]:

εL =

1

(σ L - υσ n )

E

[

=

1

60 x 10 6 - (0.3)120 x 10 6

9

210 x 10

=

1.14 x 10-4 -≡ 0.114 millistrain

ε h = 0.486 millistrain

ε r = -0.257 millistrain

Thus: pressurise the vessel to 6 bar: L and D increase: t decreases

Volume expansion

Cylindrical volume:

⎛ πD 2 ⎞

Vo = ⎜ o ⎟ Lo

⎝ 4 ⎠

New volume

V =

π

(Do

4

(original)

2

+ δD) (Lo + δL)

2

L π Do

2

1 + ε h ] [1 + ε L ]

= o

[

4

δV

Define volumetric strain ε v =

V

V - Vo

2

∴ εv =

= (1 + ε h ) (1 + ε L ) - 1

Vo

(

)

= 1 + 2ε h + ε h2 (1 + ε L ) - 1

ε v = 2 ε h + ε L + ε h2 + 2ε h ε L + ε L ε n2

Magnitude inspection:

14

]

ε max (steel) =

6

σy

190 x 10

−3

=

∴ small

9 = 0.905 x 10

210 x 10

E

Ignoring second order terms,

εv = 2ε h + ε L

(b)

Spherical volume:

εh =

so

1

[σ h - υσ L - υσ r ] = PD (1 - υ )

4Et

E

{

π (Do + δD )3 - Do3

εv =

6

πD 3o 6

}

= (1 + εh)3 – 1 ≈ 3εh + 0(ε2)

(c)

General result

εv = ε1 + ε2 + ε3

εii are the strains in any three mutually perpendicular directions.

εL = 0.114 mstrain

{Continued example} – cylinder

εn = 0.486 mstrain

εrr = -0.257 mstrain

εv = 2εn + ε L

∴ new volume = Vo (1 + εv)

Increase in volume =

π D2 L

4

ε v = 56.55 x 1.086 x 10-3

= 61 Litres

Volume of steelo = πDLt = 0.377 m3

εv for steel = εL + εh + εrr = 0.343 mstrains

increase in volume of steel

= 0.129 L

Strain energy – measure of work done

Consider an elastic material for which F = k x

15

Work done in expanding δx

dW = Fδx

F

A=area

work done

L0

x

Work done in extending to x1

2

kx1

1

x1

x1

w = ∫o Fdx = ∫o k x dx =

=

Fx

2

2 1 1

Sample subject to stress σ increased from 0 to σ1:

Extension Force:

x1 = Lo ε1 ⎫

AL oε 1σ1

⎬ W =

F1 = Aσ 1 ⎭

2

(no direction here)

Strain energy, U = work done per unit volume of material, U =

⇒ U =

Al o ⎛ 1 ⎞

⎟ ε σ

⎜

2 ⎝ Al o ⎠ 1 1

U =

ε1σ 1

2

ALo ε1σ 1

2(ALo )

σ 12

=

2E

1

[ε1σ1 + ε2σ2 + ε3σ3]

2

υσ 3

υσ 2

σ

etc

Now ε1 = 1 E

E

E

In a 3-D system, U =

So U =

[

]

1

σ 12 + σ 2 2 + σ 32 - 2ν (σ 1σ 2 + σ 2σ 3 + σ 3σ 1)

2E

Consider a uniform pressure applied: σ1 = σ2 = σ3 = P

2

2

3P

P

∴U =

(1 - 2 υ) =

2E

2K

energy stored in system (per unit vol.

16

For a given P, U stored is proportional to 1/K → so pressure test using liquids

rather than gases.

{Ongoing Example}

P – 6 barg

.

δV = 61 x 10-3 m3

increase in volume of pressure vessel

Increasing the pressure compresses the contents – normally test with water.

5

6 x 10

∆P

= - 0.273 mstrains

= −

∆V water? ε v (water ) = −

K

2.2 x 109

∴ decrease in volume of water = -Vo (0.273) = -15.4 x 10 –3 m3

Thus we can add more water:

Extra space = 61 + 15.4 (L)

= 76.4 L water

extra space

p=0

p=6

17

3. Thermal Effects

3.1. Coefficient of Thermal Expansion

ε = αL∆T Linear

Definition: coefficient of thermal expansion

Coefficient of thermal volume expansion εv = αT

Steel: αL = 11 x 10-6 K-1

reactor

Volume

∆T = 10oC

∴ εL = 11 10-5

∆T = 500oC

εL = 5.5 millistrains (!)

Consider a steel bar mounted between rigid supports which exert stress σ

Heat

σ

σ

ε = α∆T -

σ

E

If rigid: ε = 0 ⇒

so

σ = Eα∆T

(i.e., non buckling)

steel:

σ = 210 x 109 x 11 x 10-6 ∆T = 2.3 x 106 ∆T

σy = 190 MPa:

failure if ∆T > 82.6 K

18

{Example}: steam main, installed at 10oC, to contain 6 bar steam (140oC)

if ends are rigid, σ = 300 MPa→ failure.

∴ must install expansion bends.

3.2. Temperature effects in cylindrical pressure vessels

.

steel construction

L = 3 m . full of water t = 3 mm

D=1m

Initially un pressurised – full of water: increase temp. by ∆T: pressure rises

to Vessel P.

The Vessel

Wall stresses (tensile)

σL =

PD

= 83.3 P

4t

σn = 2σL = 166.7 P

19

Strain (volume)

εL =

υ

=

E

α

= 210 x 10 ⎬

= 11 x 10 −6 ⎪⎭

0.3

σ L νσ h

+ α l ∆T

E

E

⎫

9⎪

εL = 1.585 x 10-10 P + 11 x 10-6 ∆ T

Similarly

→

εh = 6.75 x 10-10 P + 11 10 –6 ∆T

εv = εL + 2εn = 15.08 x 10-10 P + 33 x 10-6 ∆T = vessel vol. Strain

vessel expands due to temp and pressure change.

The Contents, (water)

Expands

due to T

increase

Contracts

due to P

increase:

εv, H2O = αv∆T – P/K

∴

H2O = αv = 60 x 10-6 K-1

εv = 60 x 10-6 ∆T – 4.55 x 10-10 P

Since vessel remains full on increasing ∆T:

εv (H20) = εv (vessel)

Equating

→

P = 13750 ∆T

pressure, rise of 1.37 bar

Now

per 10°C increase in temp.

σn = 166.7 P = 2.29 x 106 ∆T

∆σn = 22.9 Mpa per 10°C rise in Temperature

20

∴

Failure does not need a large temperature increase.

Very large stress changes due to temperature fluctuations.

MORAL: Always leave a space in a liquid vessel.

(εv, gas = αv∆T – P/K)

21

3.3. Two material structures

Beware, different materials with different thermal expansivities

can cause difficulties.

{Example} Where there is benefit. The Bimetallic strip -

temperature

controllers

a=

4 mm (2 + 2 mm)

b=

10 mm

a

d

Cu

Fe

L = 100mm

Heat by ∆T:

b

Cu expands more than Fe so the strip will bend: it will

bend in an arc as all sections are identical.

22

Cu

Fe

The different thermal expansions, set up shearing forces

in the strip, which create a bending moment. If we apply a sagging bending

moment of equal [: opposite] magnitude, we will obtain a straight beam and

F

Cu

Fe

F

can then calculate the shearing forces [and hence the BM].

Shearing force F

compressive in Cu

Tensile

in Fe

F

F

= α Fe ∆T +

bdE cu

bdE Fe

Equating strains:

α cu ∆T -

So

1 ⎫

F ⎧ 1

+

⎨

⎬ = (α cu - α Fe ) ∆T

bd ⎩ E cu E Fe ⎭

23

bd = 2 x 10-5 m2

Ecu = 109 GPa

αcu 17 x 10-6 k-1

∆T = 30°C

EFe = 210 GPa

αFe = 11 x 10-6 K-1

F = 387 N

(significant force)

F acts through the centroid of each section so BM = F./(d/2) = 0.774 Nm

Use data book to work out deflection.

ML2

δ=

2 EI

This is the principle of the bimetallic strip.

24

Consider a steel rod mounted in a upper tube – spacer

Analysis – relevant to Heat Exchangers

Cu

Fe

assembled at room temperature

.

increase ∆T

Data: αcu > αFe

:

copper expands more than steel, so will generate

a TENSILE stress in the steel and a compressive

stress in the copper.

Balance forces:

Tensile force in steel

|FFe| = |Fcu| = F

Stress in steel

= F/AFe = σFe

“

= F/Acu = σcu

“ copper

Steel strain:

εFE = αFe ∆T + σFe/EFe

= αFe∆T + F/EFeAFe

copper strain

εcu = αcu∆T – F/EcuAcu

25

(no transvere forces)

Strains EQUAL:

⎡ 1

1 ⎤

⇒ F⎢

+

=

Acu Ecu ⎥⎦

Fe E Fe

⎣1A4

442444

3

(α cu - α Fe ) ∆T

∆d

sum of strengths

So you can work out stresses and strains in a system.

26

4. Torsion – Twisting – Shear stresses

4.1. Shear stresses in shafts –τ/r = T/J = G θ/L

Consider a rod subject to twisting:

Definition : shear strain γ ≡ change in angle that was originally Π/2

Consider three points that define a right angle and more then:

Shear strain

γ = γ1 + γ2

[RADIANS]

γ1

A

B

Hooke’s Law

C

τ=Gγ

B

A

γ

2 C

G – shear modulus =

27

E

2(1 + υ)

Now consider a rod subject to an applied torque, T.

T

2r

Hold one end and rotate other by angle θ

.

B

B

θ

γ

B

B

L

Plane ABO was originally to the X-X axis

Plane ABO is now inclined at angle γ to the axis: tan γ ≈ γ =

Shear stress involved τ = Gγ =

Grθ

L

28

rθ

L

Torque required to cause twisting:

τ

τ

r

dr

.δT = τ 2Π r.δr r

T = ∫ τ 2Π r 2 dr

or

A

T

cf

∫ τ r.dA

A

=

Gθ

L

=

Gθ

{J}

L

∫r

2

dA

so

T Gθ τ

=

=

J

L

r

M E σ

= =

I R y

DEFN: J ≡ polar second moment of area

29

Grθ ⎫

⎧

⎨τ =

⎬

⎩

L ⎭

Consider a rod of circular section:

R

π

o

2

J = ∫ 2π .r r 2 dr =

R4

y

r

x

J=

πD 4

32

Now

r2 = x2 + y2

It can be shown that J = Ixx + Iyy

[perpendicular axis than]→ see Fenner

this gives an easy way to evaluate Ixx or Iyy in symmetrical geometrics:

Ixx = Iyy = πD4/64 (rod)

30

Rectangular rod:

d

b

I xx

I yy

bd 3 ⎫

=

⎪

12 ⎪

⎬

3⎪

db

=

⎪

12 ⎭

J=

[

bd 2

b +d2

12

31

]

Example: steel rod as a drive shaft

D = 25 mm

L = 1.5 m

Failure when τ = τy = 95 MPa

G = 81 GPa

τ max

rmax

Now

J=

πD 4

32

T 95 x 10 6 ⎫

= =

⎪

J

0.0125 ⎪

⎪

⎬ so T = 291 Nm

= 383 x 10 −8 m 4 ⎪

⎪

⎪⎭

(

)

Gθ T

81 x 109 θ

9

= ⇒ 7.6 x 10 =

⇒

From

L

J

1.5

Say shaft rotates at 1450 rpm: power

32

θ = 0.141 rad = 8.1°

=

Tω

=

291 x

=

45 kW

2π

x 1450

60

4.2. Thin walled shafts

(same Eqns apply)

Consider a bracket joining two Ex. Shafts:

T = 291

Nm

D

min

0.025m

What is the minimum value of D for connector?

rmax = D/2

J = (π/32){D4 – 0.0254}

τy

rmax

6

32

⎛ T ⎞ 95 x 10 x 2 291

=⎜ ⎟⇒

=

4

D

π D - 0.0254

⎝J⎠

D4 – 0.0254 = 6.24 x 10-5 D

(

)

D ≥ 4.15 cm

33

4.3. Thin walled pressure vessel subject to torque

τ T

=

r J

now cylinder

J=

=

≈

so

τ2

D

τ=

=

[(D + 2t )

32

π

4

- D4

[8D t + 24 D t

32

π

π

4

3

D 3t

4T

πD 3 t

2T

πD 2 t

34

]

2 2

]

+ ...

CET 1, SAPV

5. Components of Stress/ Mohr’s Circle

5.1 Definitions

Scalars

tensor of rank 0

Vectors

tensors of rank 1

r

r

F = ma

hence :

F1 = ma1

F2 = ma2

F3 = ma3

or :

Fi = mai

Tensors of rank 2

3

pi = ∑ Tij q j

i, j = 1,2,3

j =1

or :

p1 = T11q1 + T12 q2 + T13 q3

p2 = T21q1 + T22 q2 + T23 q3

p3 = T31q1 + T32 q2 + T33 q3

Axis transformations

The choice of axes in the description of an engineering problem is

arbitrary (as long as you choose orthogonal sets of axes!). Obviously the

physics of the problem must not depend on the choice of axis. For

example, whether a pressure vessel will explode can not depend on how

we set up our co-ordinate axes to describe the stresses acting on the

34

CET 1, SAPV

vessel. However it is clear that the components of the stress tensor will

be different going from one set of coordinates xi to another xi’.

How do we transform one set of co-ordinate axes onto another, keeping

the same origin?

x1

x2

x3

a11

a12

a13

x2 ' a21

x3 ' a31

a22

a32

a23

a33

x1 '

... where aij are the direction cosines

Forward transformation:

3

xi ' = ∑ aij x j

“New in terms of Old”

j =1

Reverse transformation:

3

xi = ∑ a ji x j

“Old in terms of New”

j =1

We always have to do summations in co-ordinate transformation and it is

conventional to drop the summation signs and therefore these equations

are simply written as:

xi ' = aij x j

xi = a ji x j

35

CET 1, SAPV

Tensor transformation

How will the components of a tensor change when we go from one coordinate system to another? I.e. if we have a situation where

pi = ∑ Tij q j = Tij q j (in short form)

j

where Tij is the tensor in the old co-ordinate frame xi, how do we find the

corresponding tensor Tij’ in the new co-ordinate frame xi’, such that:

pi ' = ∑ Tij ' q j ' = Tij ' q j ' (in short form)

j

We can find this from a series of sequential co-ordinate transformations:

p' ← p ← q ← q'

Hence:

pi ' = aik pk

pk = Tkl ql

ql = a jl q j '

Thus we have:

36

CET 1, SAPV

pi ' = aik Tkl a jl q j '

= aik a jl Tkl q j '

= Tij ' q j '

For example:

Tij ' = ai1 a jl T1l

+ ai 2 a jl T2l

+ ai 3 a jl T3l

= ai1 a j1 T11 + ai1 a j 2 T12 + ai1 a j 3 T13

+ ai 2 a j1 T21 + ai 2 a j 2 T22 + ai 2 a j 3 T23

+ ai 3 a j1 T31 + ai 3 a j 2 T32 + ai 3 a j 3 T33

Note that there is a difference between a transformation matrix and a 2nd

rank tensor: They are both matrices containing 9 elements (constants)

but:

Symmetrical Tensors:

Tij=Tji

37

CET 1, SAPV

38

CET 1, SAPV

We can always transform a second rank tensor which is symmetrical:

Tij

→

Tij '

such that :

⎡T1 0

Tij ' = ⎢ 0 T2

⎢

⎢⎣ 0 0

0⎤

0⎥

⎥

T3 ⎥⎦

Consequence? Consider:

pi = Tij q j

then

p1 = T1 q1 ,

p2 = T2 q2 , p3 = T3 q3

The diagonal T1, T2, T3 is called the PRINCIPAL AXIS.

If T1, T2, T3 are stresses, then these are called PRINCIPAL STRESSES.

39

CET 1, SAPV

Mohr’s circle

Consider an elementary cuboid with edges parallel to the coordinate

directions x,y,z.

y

Fxy

y face

Fx

x

z face

Fxz

Fxx

z

x face

The faces on this cuboid are named according to the directions of their

normals.

There are thus two x-faces, one facing greater values of x, as shown in

Figure 1 and one facing lesser values of x (not shown in the Figure).

On the x-face there will be some force Fx. Since the cuboid is of

infinitesimal size, the force on the opposite side will not differ

significantly.

The force Fx can be divided into its components parallel to the coordinate

directions, Fxx, Fxy, Fxz. Dividing by the area of the x-face gives the

stresses on the x-plane:

σ xx

τ xy

τ xz

It is traditional to write normal stresses as σ and shear stresses as τ.

Similarly, on the y-face:

τ yx , σ yy , τ yz

40

CET 1, SAPV

and on the z-face we have:

τ zx , τ zy , σ zz

There are therefore 9 components of stress;

⎡σ xx τ xy

⎢

σ ij = ⎢τ yx σ yy

⎢ τ zx τ zy

⎣

τ xz ⎤

⎥

τ yz ⎥

σ zz ⎥⎦

Note that the first subscript refers to the face on which the stress acts and

the second subscript refers to the direction in which the associated force

acts.

σ yy

y

x

τyx

τ xy

σ xx

σ xx

τ xy

τ yx

σ yy

But for non accelerating bodies (or infinitesimally small cuboids):

and therefore:

⎡σ xx τ xy τ xz ⎤ ⎡σ xx τ xy τ xz ⎤

⎢

⎥ ⎢

⎥

σ ij = ⎢τ yx σ yy τ yz ⎥ = ⎢τ xy σ yy τ yz ⎥

⎢ τ zx τ zy σ zz ⎥ ⎢ τ xz τ yz σ zz ⎥

⎣

⎦ ⎣

⎦

Hence σij is symmetric!

41

CET 1, SAPV

This means that there must be some magic co-ordinate frame in which all

the stresses are normal stresses (principal stresses) and in which the off

diagonal stresses (=shear stresses) are 0. So if, in a given situation we

find this frame we can apply all our stress strain relations that we have set

up in the previous lectures (which assumed there were only normal

stresses acting).

Consider a cylindrical vessel subject to shear, and normal stresses (σh, σl,

σr). We are usually interested in shears and stresses which lie in the

plane defined by the vessel walls.

Is there a transformation about zz which will result in a shear

Would really like to transform into a co-ordinate frame such that all

components in the xi’ :

σ ij

→

σ ij '

So stress tensor is symmetric 2nd rank tensor. Imagine we are in the coordinate frame xi where we only have principal stresses:

0⎤

⎡σ 1 0

σ ij = ⎢⎢ 0 σ 2 0 ⎥⎥

⎢⎣ 0 0 σ 3 ⎥⎦

Transform to a new co-ordinate frame xi’ by rotatoin about the x3 axis in

the original co-ordinate frame (this would be, in our example, z-axis)

42

CET 1, SAPV

The transformation matrix is then:

⎛ a11

⎜

aij = ⎜ a21

⎜a

⎝ 31

a13 ⎞ ⎛ cos θ

⎟ ⎜

a23 ⎟ = ⎜ − sin θ

a33 ⎟⎠ ⎜⎝ 0

a12

a22

a32

sin θ

cosθ

0⎞

⎟

0⎟

1 ⎟⎠

0

Then:

σ ij ' = aik a jl σ kl

⎛ cos θ

⎜

= ⎜ − sin θ

⎜ 0

⎝

sin θ

cosθ

0

0 ⎞⎛ cos θ

⎟⎜

0 ⎟⎜ sin θ

1 ⎟⎠⎜⎝ 0

− sin θ

cosθ

0

⎡

σ 1 cos 2 θ + σ 2 sin 2 θ

⎢

= ⎢− σ 1 cosθ sin θ + σ 2 cosθ sin θ

⎢

0

⎣

43

0 ⎞ ⎡σ 1 0

0⎤

⎟⎢

0⎟ 0 σ 2 0 ⎥

⎢

⎥

⎟

1 ⎠ ⎢⎣ 0

0 σ 3 ⎥⎦

σ 1 cosθ sin θ + σ 2 cosθ sin θ

σ 1 cos 2 θ + σ 2 sin 2 θ

0

0⎤

⎥

0⎥

σ 3 ⎥⎦

CET 1, SAPV

Hence:

σ 11 ' = σ 1 cos 2 θ + σ 2 sin 2 θ

1

1

= (σ 1 + σ 1 ) − (σ 2 − σ 1 ) cos 2θ

2

2

σ 22 ' = σ 1 sin 2 θ + σ 2 cos 2 θ

=

1

1

(σ 1 + σ 1 ) + (σ 2 − σ 1 ) cos 2θ

2

2

σ 12 ' = −σ 1 cosθ sin θ + σ 2 cosθ sin θ

=

1

(σ 2 − σ 1 ) sin 2θ

2

44

Yield conditions. Tresca and Von Mises

Mohrs circle in three dimensions.

y

z

x

Shear stresses τ

y,z plane

x, y plane

normal

stresses

σ

x,z plane

1

We can draw Mohrs circles for each principal plane.

6. BULK FAILURE CRITERIA

Materials fail when the largest stress exceeds a critical value. Normally we

test a material in simple tension:

P

P

σy =

Pyield

A

τ

σ

σ = σ

σ=σ

This material fails under the stress combination (σy, 0, 0)

τmax = 0.5 σ y = 95 Mpa

for steel

We wish to establish if a material will fail if it is subject to a stress

combination (σ1, σ2, σ3) or (σn, σL, τ)

2

Failure depends on the nature of the material:

Two important criteria

(i)

Tresca’s failure criterion: brittle materials

Cast iron: concrete: ceramics

(ii)

Von Mises’ criterion: ductile materials

Mild steel + copper

6.1. Tresca’s Failure Criterion; The Stress Hexagon (Brittle)

A material fails when the largest shear stress reaches a critical value, the

yield shear stress τy.

Case (i)

Material subject to simple compression:

σ1

σ1

Principal stresses (-σ1, 0, 0)

τ

-σ

3

M.C: mc passes through (σ1,0), (σ1,0) , ( 0,0)

σ1

τ max

σ1

τmax = σ1/2

occurs along plane at 45° to σ1

Similarly for tensile test.

Case (ii)

σ2 < 0 < σ1

τ

-σ

σ

σ2

σ

1

σ1 - σ2

M.C.

2

Fails when

= τ max

= τy =

σy

2

σ1 - σ2 = σy

i.e., when

material will not fail.

4

Lets do an easy example.

5

6.2 Von Mises’ Failure Criterion; The stress ellipse

(ductile materials)

Tresca’s criterion does not work well for ductile materials. Early hypothesis

– material fails when its strain energy exceeds a critical value (can’t be true

as no failure occurs under uniform compression).

Von Mises’: failure when strain energy due to distortion, UD, exceeds a

critical value.

UD = difference in strain energy (U) due of a compressive stress C equal to

the mean of the principal stresses.

C =

1

[σ + σ2 + σ 3 ]

3 1

UD =

1 ⎧ 2

⎨σ +

2E ⎩ 1

1

=

(σ1

12G

{

[

]

1

⎫

σ 22 + σ 32 + 2υ (σ1σ 2 + σ 2 σ 3 + σ 3σ 1 ) 3C 2 + 6υC 2 ⎬

⎭

2E

2

2

2

- σ 2 ) + (σ 2 - σ 3 ) + (σ 3 - σ1 )

}

M.C.

τ

σ3

σ

σ

σ

2

1

6

Tresca → failure when max (τI) ≥ τy)

Von Mises → failure when root mean

square of {τa, τb, τc} ≥ critical value

τ

σ

σ

y

Compare with (σy, σ, σ) . simple tensile test – failure

Failure if

{

}

{

1

(σ1 - σ2 )2 + (σ2 + σ3 )2 + (σ3 - σ1 )2 > 1 σ2y + 02 + σ2y

12G

12G

{(σ - σ )

2

1

2

}

+ (σ 2 + σ3 ) + (σ3 - σ1 ) > 2σ 2y

2

2

7

}

8

Lets do a simple example.

9

Example Tresca's Failure Criterion

The same pipe as in the first example (D = 0.2 m, t' = 0.005 m) is subject to

an internal pressure of 50 barg. What torque can it support?

PD

= 50 N / mm 2

4t'

PD

σh =

= 100 N / mm 2

2t'

σL =

Calculate stresses

and σ3 = σr ≈0

Mohr's Circle

(100,τ)

τ

50

100

σ

s

(50,−τ)

Circle construction

s = 75 N/mm2

t = √(252+τ2)

The principal stresses

σ1,2 = s ± t

Thus σ2 may be positive (case A) or negative (case B). Case A occurs if τ is

small.

10

Case A

(100,τ)

τ

100 σ1

σ2 50

σ3

s

(50,−τ)

Case B

τ

(100,τ)

2β

σ2

σ3

100

50

σ1

σ

s

(50,−τ)

We do not know whether the Mohr's circle for this case follows Case A or

B; determine which case applies by trial and error.

Case A; 'minor' principal stress is positive (σ2 > 0)

Thus failure when

τ max = 12 σ y = 105N / mm 2

11

For Case A;

τ max =

⇒

σ1

2

=

1

2

[75 +

(252 + τ 2 )]

τ 2 = 135 − 252

τ = 132.7N / mm 2

σ1 = 210 N / mm2 ; σ 2 = −60 N / mm2

⇒

Giving

Case B;

We now have τmax as the radius of the original Mohr's circle linking our

stress data.

Thus

τ max = 252 + τ 2 = 105 ⇒

τ = 101.98N / mm2

Principal stresses

σ1,2 = 75 ± 105

⇒ σ 1 = 180N / mm2 ; σ 2 = −30N / mm 2

Thus Case B applies and the yield stress is 101.98 N/mm2. The torque

required to cause failure is

T = πD2 t' τ / 2 = 32kNm

Failure will occur along a plane at angle β anticlockwise from the y (hoop)

direction;

102

⇒ 2 λ = 76.23° ;

75

2β = 90 - 2λ ⇒ β = 6.9°

tan(2 λ ) =

12

Example

More of Von Mises Failure Criterion

From our second Tresca Example

σ h = 100N / mm 2

σ L = 50 N / mm 2

σ r ≈ 0 N / mm2

What torque will cause failure if the yield stress for steel is 210 N/mm2?

Mohr's Circle

(100,τ)

τ

50

100

σ

s

(50,−τ)

Giving

σ1 = s + t = 75 + 252 + τ 2

At failure

UD =

σ 2 = s − t = 75 − 252 + τ 2

σ3 = 0

1

(σ 1 − σ 2 ) 2 + ( σ 2 − σ 3 ) 2 + ( σ 3 − σ 1 ) 2 }

{

12G

13

Or

(σ1 − σ 2 ) 2 + ( σ 2 − σ 3 ) 2 + ( σ 3 − σ1 ) 2 = ( σ y )2 + (0)2 + (0 − σ y ) 2

4t 2 + (s − t)2 + (s + t) 2 = 2σ 2y

2s2 + 6t 2 = 2 σ y2

s 2 + 3t 2 = σ 2y

⇒ 752 + 3(252 + τ 2 ) = 210 2

τ = 110 N / mm 2

The tube can thus support a torque of

πD2 t' τ

T=

= 35kNm

2

which is larger than the value of 32 kNm given by Tresca's criterion - in this

case, Tresca is more conservative.

14

7. Strains

7.1. Direct and Shear Strains

Consider a vector of length lx lying along the x-axis as shown in Figure

1. Let it be subjected to a small strain, so that, if the left hand end is fixed

the right hand end will undergo a small displacement δx. This need not be

in the x-direction and so will have components δxx in the x-direction and

δxy in the y-direction.

δx

γ1

δxy

δxx

lx

Figure 1

We can define strains εxx and εxy by,

ε xx =

δ xx

;

lx

ε xy =

δ xy

lx

εxx is the direct strain, i.e. the fractional increase in length in the direction

of the original vector. εxy represents rotation of the vector through the

small angle γ1 where,

γ1 ≅ tan γ1 =

δ xy

l x + δ xx

≅

δ xy

lx

= ε xy

Thus in the limit as δx→ 0, γ1 → εxy.

Similarly we can define strains εyy and εyx = γ2 by,

ε yy =

δ yy

ly

;

ε yx =

δ yx

ly

1

δ yx

Figure 2

δ

yy

δy

ly

γ

2

γ1

as in Figure 2.

lx

Or, in general terms:

ε ij =

δ ij

li

where i, j = 1,2,3

;

The ENGINEERING SHEAR STRAIN is defined as the change in an

angle relative to a set of axes originally at 90°. In particular γxy is the

change in the angle between lines which were originally in the x- and ydirections. Thus, in our example (Figure 2 above):

γ xy = ( γ 1 + γ 2 ) = ε xy + ε yx or

γ xy = −(γ 1 + γ 2 )

depending on sign convention.

τ yx

A'

A

τ

B

xy

C

B'

C'

Figure 3b

Figure 3a

Positive values of the shear stresses τxy and τyx act on an element as

shown in Figure 3a and these cause distortion as in Figure 3b. Thus it is

sensible to take γxy as +ve when the angle ABC decreases. Thus

2

γ xy = +( γ 1 + γ 2 )

Or, in general terms:

γ ij = (ε ij + ε ji )

and since

τij = τji,

we have

γij = γji.

Note that the TENSOR SHEAR STRAINS are given by the averaged

sum of shear strains:

1

1

1

1

γ ij = (ε ij + ε ji ) = (γ 1 + γ 2 ) = γ ji

2

2

2

2

7.2 Mohr’s Circle for Strains

The strain tensor can now be written as:

⎡

⎢ ε 11

⎢1

ε ij = ⎢ y 21

⎢2

⎢1 y

⎢⎣ 2 31

1

y12

2

ε 22

1

y32

2

1 ⎤ ⎡

y13

ε 11

2 ⎥ ⎢

⎥ ⎢1

1

y 23 ⎥ = ⎢ y12

2

⎥ ⎢2

1

ε 33 ⎥ ⎢ y13

⎥⎦ ⎣⎢ 2

1

y12

2

ε 22

1

y 23

2

1 ⎤

y13

2 ⎥

⎥

1

y 23 ⎥

2

⎥

ε 33 ⎥

⎥⎦

where the diagonal elements are the stretches or tensile strains and the

off diagonal elements are the tensor shear strains.

Thus our strain tensor is symmetrical, and:

3

ε ij = ε ji

This means there must be a co-ordinate transformation, such that:

ε ij '

→

ε ij

such that :

⎡ε 1 0

ε ij = ⎢⎢ 0 ε 2

⎢⎣ 0 0

0⎤

0⎥

⎥

ε 3 ⎥⎦

we only have principal (=longitudinal) strains!

Exactly analogous to our discussion for the transformation of the stress

tensor we find this from:

ε ij ' = aik a jl ε kl

⎛ cos θ

⎜

= ⎜ − sin θ

⎜ 0

⎝

sin θ

cosθ

0

0 ⎞⎛ cos θ

⎟⎜

0 ⎟⎜ sin θ

1 ⎟⎠⎜⎝ 0

− sin θ

cosθ

0

⎡

ε 1 cos 2 θ + ε 2 sin 2 θ

⎢

= ⎢− ε 1 cosθ sin θ + ε 2 cosθ sin θ

⎢

0

⎣

And hence:

4

0 ⎞ ⎡ε1 0

⎟

0 ⎟⎢ 0 ε 2

⎢

1 ⎟⎠ ⎢⎣ 0 0

0⎤

0⎥

⎥

ε 3 ⎥⎦

ε 1 cosθ sin θ + ε 2 cosθ sin θ

ε 1 cos 2 θ + ε 2 sin 2 θ

0

0⎤

⎥

0⎥

ε 3 ⎥⎦

ε11 ' = ε1 cos 2 θ + ε 2 sin 2 θ

1

1

= (ε1 + ε1 ) − (ε 2 − ε1 ) cos 2θ

2

2

ε 22 ' = ε1 sin 2 θ + ε 2 cos 2 θ

=

1

1

(ε1 + ε1 ) + (ε 2 − ε1 ) cos 2θ

2

2

1

2

ε12 ' = γ 12 ' = −ε1 cos θ sin θ + ε 2 cos θ sin θ

=

1

(ε 2 − ε1 ) sin 2θ

2

For which we can draw a Mohr’s circle in the usual manner:

5

Note, however, that on this occasion we plot half the shear strain against

the direct strain. This stems from the fact that the engineering shear

strains differs from the tensorial shear strains by a factor of 2 as as

discussed.

7.3 Measurement of Stress and Strain - Strain Gauges

It is difficult to measure internal stresses. Strains, at least those on a

surface, are easy to measure.

•

Glue a piece of wire on to a surface

•

Strain in wire = strain in material

•

As the length of the wire increases, its radius decreases so its

electrical resistance

increases and can be readily measured.

In practice, multiple wire assemblies are used in strain gauges, to

measure direct strains.

strain gauge

_

_

_

45°

Strain rosettes are employed to obtain three measurements:

7.3.1 45° Strain Rosette

Three direct strains are measured

ε

C

εB

θ

Mohr’s circle for strains gives

6

εA

ε1

principal strain

120°

A

γ/2

B

ε

2θ

εB

εA

εC

C

radius t

so we can write

circle, centre s,

ε A = s + t cos(2θ )

ε B = s + t cos(2θ + 90) = s − t sin( 2θ )

ε C = s − t cos(2θ )

3 equations in 3 unknowns

Using strain gauges we can find the directions of Principal strains

γ/2

ε

7

7.4 Hooke’s Law for Shear Stresses

St. Venant’s Principle states that the principal axes of stress and strain are

co-incident. Consider a 2-D element subject to pure shear (τxy = τyx =

τo).

τo

y

Y

The Mohr’s circle for stresses is

τo

Q

τo

P

τo

X

x

where P and Q are principal stress axes and

σ pp = σ1 = τ o

σ qq = σ 2 = − τ o

τ pq = τ qp = 0

Since the principal stress and strain axes are coincident,

ε pp = ε1 =

=

τo

E

σ1

E

−

νσ 2

E

(1+ ν )

ε qq = ε 2 =

σ2

E

−

νσ1

E

=

−τ o

(1+ ν )

E

and the Mohr’s circle for strain is thus

γ/2

the Mohr’s circle shows that

Y

Q

P

εqq

εpp

ε

ε xx = 0

− γ xy

2

X (0,−γ )

xy

8

=−

τo

E

(1 + ν )

So pure shear causes the shear strain γ

τo

τo

γ/2

γ=

γ/2

and

2τ o

(1+ ν )

E

But by definition τo = Gγ

so

G=

τo

E

=

γ 2(1+ ν )

Use St Venants principal to work out principal stress values from a

knowledge of principal strains.

Two Mohrs circles, strain and stress.

ε1 =

σ1

E

ε2 = −

ε3 = −

−

νσ 2

νσ1

E

νσ1

E

E

−

νσ 3

E

+

σ2

−

νσ 2

E

E

−

νσ 3

E

+

σ3

E

9

So using strain gauges you can work out magnitudes of principal strains.

You can then work out magnitudes of principal stresses.

Using Tresca or Von Mises you can then work out whether your

vessel is safe to operate. ie below the yield criteria

10