23 Fats, Oils, & Soap - faculty at Chemeketa

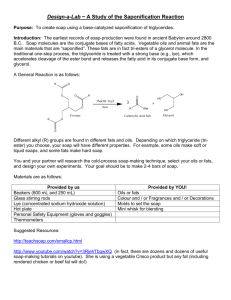

L A B 2 3 : : L I I P I I D S ; ; F A T S , , O I I L S , , & S O A P : :

P R O P E R T I I E S & P

R E P A R A T I I O N

P U R P O S E

: :

To observe physical and chemical properties of fatty acids and triacylglycerols.

To synthesize soap by saponification of vegetable oil.

To compare the physical and chemical properties of soap and detergent.

To isolate essential oils from natural products.

S A F E T Y C O N C E R N S : :

Always wear safety goggles.

Lye (Sodium Hydroxide) is caustic to skin and will dissolve eyes especially the hot concentrated solution used in this experiment. Wash with soap and copious amounts of water if contacted.

Bromine is toxic and irritating to eyes and mucus membranes.

L I P I D S : :

Lipids are a family of compounds that are grouped by similarities in solubility rather than structure. As a group, lipids are nonpolar and so are more soluble in nonpolar solvents such as ether, chloroform, or benzene. Most are not soluble in water.

Natural essential oils can be isolated from plant sources by extraction with nonpolar solvents or by steam distillation whereby the oils are vaporized with steam and then recondensed. Many essential oils from plant extracts are commonly used as flavors and fragrances. Many are structurally terpene compounds made from individual 5 carbon isoprene units.

Examples of Some Common Essential Oils:

Structure

( S )-(+)-Linalool or

licareol

C

10

H

18

O

HO CH

3

( R )-(-)Linalool or coriandrol

C

10

H

18

O

Common Source:

Lavender

Common Source:

Coriander seed

( R )-(+)Limonene or D-Limonene

C

10

H

16

(-)-Menthol

C

10

H

20

O

Common Source:

Orange & Lemon

Rind

Common Source:

Peppermint

Structure

CH

3

OH Vanillin

C

8

H

8

O

3

CH

3

CH

3

OH

Common

Source:

Vanilla

Eugenol

C

10

H

12

O

2

Common

Source:

Cloves

Structure

HO

HO

OCH

3

OCH

3

O

H

( R )-(-)-Carvone

C

10

H

18

O

Common Source:

Spearmint

O

( R )-(-)-Citronellol

C

10

H

20

O

Common Source:

Lemon Geranium

Roses

OH

CH106 Lab 23 Lipids: Fats, Oils, & Soap

(W15)

29

F A T S , ,

A N D O I L S F R O M F A T T Y A C I D S

: :

Fats and fatty oils are mixtures of complex esters. Fat esters are made from long chain carboxylic acids

(called fatty acids ) and an alcohol containing three OH groups (called glycerol ).

A common fat is called a triacylglycerol or triglyceride . The hydrocarbon chain of the fatty acids determines the physical and chemical properties of the compound. Triacylglycerols made from longchain (C-16 to C-18) saturated fatty acids (like palmitic and stearic acids) are solid or semisolid at room temperature. Solid animal fats contain an abundance of long saturated fatty acids.

Common Fatty Acids

Saturated Unsaturated

O O

C 9

12

OH Lauric Acid 16

C

O

OH Palmitoleic Acid

O

14

C

O

OH Myristic Acid

18

9

C

OH

Oleic Acid

12 9

O

16

C

O

OH Palmitic Acid

18

C

OH Linoleic Acid

18

C

OH Stearic Acid

Triacylglycerols made from long-chain unsaturated fatty acids (like oleic or linoleic acids) are liquid oils at room temperature. Liquid vegetable oils contain an abundance of long unsaturated fatty acids.

A few oils owe their characteristic liquid nature to the presence of shorter chain fatty acids (C-6 to C-14).

Coconut oil contains large amounts of lauric (C-12) and myristic (C-14) acids, as well as smaller amounts of C-6, C-8, and C-10 acids.

Synthesis of a Typical Triacylglycerol:

O

O

C

H

HO

H C

H C OH

O

H

+

H C

O

O

C + 3H

2

O

H C OH +

HO

H C O C

O

H C OH H C O

O

H

C

H C

HO

Glycerol

1,2,3-propantriol

Stearic Acids

Glyceryl Tristearate (Tristearin): a typical triacylglycerol

T E S T S F O R U N S A T U R A T I O N : :

Bromine Test: The presence of unsaturation in a fatty acid or a triacylglycerol can be detected by reaction with bromine. If the orange color of a bromine solution added to a lipid fades quickly, an addition reaction has occurred and the oil or fat is unsaturated.

Acrolein Test:

When triacylglycerols are heated with potassium hydrogensulfate, KHSO

4

, (also known as potassium bisulfate or potassium acid sulfate) the glycerol is dehydrated and oxidized to acrolein. As KHSO

4

is a weak acid it can catalyze both the hydrolysis of the triglyceride esters as well as the dehydration/elimination reaction of the glycerol carbohydrate. Acrolein may be detected by its distinctive sharp irritating odor. It can often be present in charcoal broiling of fatty food. It is volatile and will evaporate and be lost with continued heating.

H

H

H

H

H

C C

H

C

C

C

H

H

H

(colorless)

OH

OH

OH

Glycerol

1,2,3-propantriol

+ Br

2

(red-brown)

KHSO

4

O

C

C

C

H

H

H

H

H

Acrolein

Br Br

C C H

H

(colorless)

+

H

H

2

O

30 CH106 Lab 23 Lipids: Fats, Oils, & Soap

(W15)

O X I D A T I V E R A C I D I T Y : :

Oils are more easily digested than fats. They become rancid more easily than fats because of the ease in which their double bonds can be hydrolyzed or oxidized.

O

H

H C O

C

O

H

H

C

C

H

O

O

C

O

C

Oxidation

(rancidity) [O]

O

H

O

H C O

C

O

O

O

OH

O

HO

O O O

O

O O

H

H

C

C

O

O

C

O

C

OH

HO

O

OH

O

HO

O

OH

O

HO

O

OH

O

HO

O

H

OH

HO

Kreis Test:

The most commonly used test to determine oxidative rancidity is the Kreis test. A small quantity of concentrated hydrochloric acid is added to the lipid to be tested, followed by the addition of a 0.1% solution of phloroglucinol (1,3,5-trihydroxybenzene) in ether. The red or pink color indicating rancidity is believed to result from a reaction of epihydrin (an isomer of malonaldehyde) or other oxidation products with the phloroglucinol.

OH

H

HO

O O

H

OH

Malonaldehyde

HO

+

HO

OH

OH

OH

Phloroglucinol

Red colored

complex

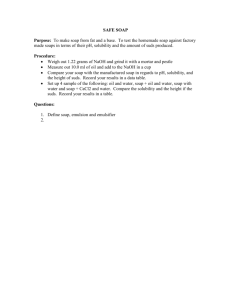

S O A P : :

Hydrolysis of an ester is the reverse of the synthesis of an ester. Hydrolysis of a triacylglycerol into glycerol and fatty acids can be catalyzed by either strong acid or strong base.

The general process of hydrolyzing esters with caustic alkali’s (strong bases such as sodium hydroxide, NaOH or potassium hydroxides, KOH) is called saponification . The products of basic hydrolysis of fats or oils are glycerol and the salts of fatty acids called soaps .

H

H

H

H

C

C

C

H

O

O

O

C

O

C

O

O

C

Glyceryl Tristearate ( A Fat )

H

H

H

C

C

OH

OH

NaOH, H

2

O

H C OH

H

Glycerol

1,2,3-propantriol

+

Na O

O

C

Na O

O

C

O

C

Na O

Sodium Stearate ( A Soap )

Polar hydrophilic end attracts water

Nonpolar lipophilic end attracts grease

M I I C E L L E S : :

Soap owes its cleaning ability to the formation of micelles which can encapsulate grease or oil and make it water soluble. Micelles are destroyed by

“hard” water ions such as Ca 2+

and Mg

2+

. These ions precipitate the fatty acid anions causing a “scum” to form. Synthetic detergents (called “syndets”) have been developed which are less affected by hard water ions since the magnesium and calcium salts are quite a bit more soluble.

O

A Detergent

Na O S

O

CH106 Lab 23 Lipids: Fats, Oils, & Soap

(W15)

A Micelle

O

O

C

O

O

C

O

C

O

O

C

O

O

C

O

O

C O

O

C O

31

H I I S T O R Y O F S O A P : :

According to Roman legend, soap was discovered after a heavy rain fell on the slopes of Mount Sapo (the name means "Mount Soap" in Latin). The hill was the site of an important sacrificial altar, and the rainwater mixed with the mingled ashes and animal fat around the altar's base. As a result of this fortuitous coincidence, the three key components of soap were brought together: water, fat, and lye (potash leached from the ashes). As the mixture trickled down to the banks of the Tiber River, washerwomen at work there noticed that the mysterious substance made their job easier and the wash cleaner. They were so impressed with the cleansing power of this mysterious substance that trickled down from the mountain, they named the mountain in its honor. They knew to name it after

“soap” as there was another substance that they were familiar with that also had exceptional cleansing powers.

Clothes have been cleaned for ages by beating them on rocks near a stream. Near these streams grew certain plants, such as soapworts, whose leaves produced saponins , chemical compounds that give a soapy lather. By mixing these saponins with their wash water, they were getting much cleaner clothes than they got from the water alone. So it was the soapwort plant that gave its name to Mount Sapo. This plant is also known as bouncing bet, a pink-blossomed perennial that grows wild throughout most to the United States.

Over the centuries the basics of soapmaking have remained essentially unchanged from the Roman prescription.

Although we don't sacrifice animals at the altar to obtain our fat and then wait for the next heavy rain, we use the same ingredients. To this day in parts of rural America soap is being made much as it was in ancient Rome: out of potash, rainwater, and animal tallow. The potash is found in wood ashes and, when this ash is extracted with water and the resulting solution evaporated in iron pots, a solid is produced. This solid is called potash. It is known chemically as potassium carbonate and when dissolved in water, it gives us a very basic (caustic) solution. Most people who make soap at home do not go to all the trouble of extracting the potash from wood ashes. They use instead the more caustic substance, sodium hydroxide, which is also known commercially as lye. Animal fat is often substituted by a variety of vegetable oils. Avocado oil, olive oil, coconut oil, palm oil and cinnamon oil are just a few of the many oils that are used in today’s soap formulations. No matter which fat or caustic solution is used, the same basic chemical reaction takes place. The net result of the reaction, called saponification , is the formation of salts from the fatty acids that once were part of the larger fat molecules.

S O A P M A K I I N G : :

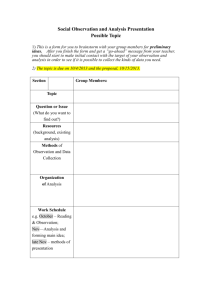

Soap manufacturers use at least two different fats and oils because each one contributes different properties to the finished soap. These properties are defined by the fatty acids that make up the fats and oils and their respective percentage. In this experiment, you will prepare a quality bar of useable soap from three or more fats and oils, like in industry.

The by-product glycerin is both a humectant (attracts moisture from the air) and an emollient (soothes or softens the skin). Due to glycerin’s properties, some manufacturers add more to the prepared soap while others remove it for use in their cosmetic products.

In this experiment, the soap will be made via the cold process. In this method, pre-melted and warmed fats and oils are combined with base. The resultant mixture is stirred until it thickens and subsequently poured into molds; saponification reaches completion within one week.

32 CH106 Lab 23 Lipids: Fats, Oils, & Soap

(W15)

Soap Formulation:

Each fat or oil is composed of varying percentages of different fatty acids (Table 1).

Table 1: Fatty Acid Composition of Common Fats and Oils

Fat or Oil

Almond

Apricot

Avocado

*Canola

*Castor

Cocoa Butter

*Coconut

*Corn

*Lard

Mango Butter

*Olive

Palm

15

*Safflower

Shea Butter

*Sunflower

48

17.3

27

15

20

3.5

2.1

2.5

34.3

6

2.7

4.6

10.3

76

4.3

66.2

1

12

0.3

1.2

4

17.5

1.4

1.3

1.4

77.0

64

70

60

8.6

38.1

6

49.6

48

44.8

84.4

42.7

17

49.0

25.1

4.5

5

10

4

24.4

8.8

10.2

28.3

7.4

6.9

40.1

4.5

5.7

5.6

1

1.5

2.7

85.9

1

2

2

35.4

2

3

11.9

41.8

2.3

5.5

2.5

41

2.2

.79

2.6

3.0

0.37

0.03

0.9

*Available for use in our class preparation of soaps.

The predominant fatty acids provide soap its characteristics (Table 2). For instance, coconut oil contains 48.0% lauric acid, which produces a hard and effective cleanser with fluffy lather.

Table 2: Soap Characteristics Promoted by Common Fatty Acids

Fatty Acid Hard Bar Cleansing Fluffy Lather Conditioning Stable Lather

Lauric

Linoleic

Myristic

Stearic

Yes

No

Yes

Oleic

Palmitic

No

Yes

Ricinoleic

No

Yes

Yes

No

Yes

No

No

No

No

Yes

No

Yes

No

No

Yes

No

No

Yes

No

Yes

No

Yes

No

No

No

No

No

Yes

Yes

Yes

Table 3 gives the percent maximum recommended usage for each fat or oil in saponification, based on price, therapeutic benefits, and soap qualities. A more detailed list can be found at https://www.fromnaturewithlove.com/resources/sapon.asp

Table 3: Percent Maximum Recommended Usage and Saponification Values of Select Fats and Oils

Column A Column B

Fat or Oil % Max Usage SAP Value

(mg KOH/1g fat or oil)

Fat or Oil % Max Usage SAP Value

(mg KOH/1g fat or oil)

*Coconut Oil

10-50

*Lard 10-60

*Olive Oil 10-50

257

198.5

192

*Canola Oil

*Castor Oil

*Safflower Oil

*Sunflower Oil

10-15

10

10-15

10-15

174.7

180.3

192

188.7

*Corn Oil 10-15 190

Most oils in excess of the given percentages will yield an especially soft soap. Beeswax can be used to harden soap. Excesses of coconut or palm oils will give a crumbly bar. Manufacturers use high percentages of coconut and palm oils as they are inexpensive and produce a hard and effective cleanser with fluffy lather. Due to the presence of coconut milk consumers find soap dries the skin. Therefore manufacturers use a 1-7% excess of fats and oils that serve as an emollient. These “superfatted” soaps provide a dense and creamy lather that leaves the skin feeling soft and smooth. All formulations in this experiment use a

5% excess of fats and oils.

The components of the soaps you will make are fats and oils, sodium hydroxide, deionized water, and an essential oil as scent.

CH106 Lab 23 Lipids: Fats, Oils, & Soap

(W15)

33

Sample Soap Recipes:

Following are general instructions and several recipes for preparing usable soap at home:

Safety observations :

Lye (sodium hydroxide) is very corrosive to animal tissue, especially the hot concentrated solution used in making soap. Protective safety goggles and rubber gloves should be worn.

General Procedure :

The basics are the same no matter what kind of soap you wish to make. The three ingredients needed to make soap-fat, water, and lye-are all readily available.

Lye in the form of sodium hydroxide is sold as dry crystals in many supermarkets and hardware stores, while lye in the form of potash can be make at home from wood ash. Because all types of lye are highly caustic substances that react with plastic, aluminum, and tin, soap making utensils should be made of wood, glass, enamel, stainless steel, or ceramic .

Fat for soap making can be almost any pure animal or vegetable oil from reclaimed grease to castor oil. The water should be soft. If you are in a hard water area, treat the water with a commercial softener or add a few tablespoons of borax to it. You can also collect rainwater and use it to make soap.

The following equipment is needed for soapmaking:

1.

A container to hold and pour the lye solution such as a 2-quart juice bottle or glass mason jar.

2.

A 10- to 12-quart pot to hold the fat and lye.

3.

A wooden spoon to stir the lye solution and fat.

4.

A candy or dairy thermometer that is accurate to within 1 o F in the 80 o F to 120 o F range. For convenience you may want to have two such thermometers.

5.

Rubber gloves. Wear as a precautionary measure, since lye will burn if it touches the skin.

6.

Safety goggles. Lye is very caustic and if splashed into the eyes it could cause severe damage.

7.

Molds for the soap. Prepare the molds by lining them with plastic or greasing them with Vaseline. Heavy duty waxed paper also works well.

8.

Insulation to keep the soap warm after it is poured into the molds. Cardboard, Styrofoam, or an ordinary blanket can be used.

9.

Enough newspapers to cover work surfaces and floor areas where you will be working.

Prepare the lye solution before beginning the soap-making process so that it will have a chance to cool. Caution concentrated lye is very caustic. Protect your eyes and skin. You and any helpers must wear goggles and rubber gloves while performing this experiment.

To make the lye solution, pour cold water into an enamelware pot, then add the lye slowly while stirring the solution steadily with a wooden spoon. The reaction between the lye crystals and water is exothermic and will generate temperatures over 200 o F. The container can be placed in a basin of ice cold water to hasten cooling. Once the solution has cooled, pour it carefully into the 2-quart glass container. The type of fat you should use and the relative amounts of fat, lye, and water that should be combined depend on the particular type of soap being made. The standard recipe calls for 6 pounds (2.7 kg) of beef fat, 2 ½ pints (1182 ml) of water, and 13 ounces (369 g) of lye crystals. In order for saponification to take place, the temperature of the lye solution and fat has to be carefully controlled. The simplest method is to bring both the lye and the fat to a temperature of 95 o F to 98 o F before mixing them together. Some experts recommend that the fat be at a higher temperature than the lye: about 125 o F for the fat and 93 o F for the lye when beef tallow is used, 83 o F and 73 o F when lard is used.

Occasionally, saponification does not take place and the soap mixture separates into a top layer of fat and a bottom layer of lye solution. Generally, the mixture can be reclaimed by heating it to about 140 o F while gently stirring with the wooden spoon. Then remove from the heat and keep stirring until the mixture thickens into soap. To test your soap solution, spoon up a bit and let a few drops fall on the surface of the soap; if the surface supports the drops for a moment or two, the soap is ready for the molds.

Option #1: Fast and Cheap

This procedure is much less expensive than others but the soap obtained is not as soft and mild as finer soaps. It is much more like the lye soap our ancestors once made. For a simple trial reduce the quantities to 1/3 of the amounts suggested in the procedural discussion above to make the experiment go faster as well as cost less. DO NOT USE ALUMINUM!!

1. To 400 ml (13 - 14oz) of water slowly add 123 grams (4.3 oz) of sodium hydroxide. A 1-quart Mason jar or plastic drink bottle should work well as a container. Place the container in an ice bath to speed the solution process and to help cool the resulting mixture. If the temperature of the solution drops below 73 o F (23 o C) remove from the ice bath.

2. Warm 2 lbs (908 g) of lard in a 6 quart pot while stirring with a wooden spoon. Once it reaches 83 maintain this temperature. o F (28.3

o C), try to

3.

4.

Pour the 23 o C lye solution into the 28.3

o C fat in a steady stream while continuing to stir with and even, circular motion.

The mixture should turn opaque and brownish, and then lighten. The soap will be ready when its surface can support a drop of mixture for a moment; consistency should be like sour cream.

Add colorants, scents, and other special ingredients at this time. Adding them earlier would hinder the saponification reaction.

34 CH106 Lab 23 Lipids: Fats, Oils, & Soap

(W15)

5. The molds should have been prepared in advance. Rectangular cake pans, cardboard boxes, etc. work well. Line the mold with plastic, wax paper, or Vaseline to allow for easy removal.

6. Pour the liquid into your mold and place in a warm location. Cover with cardboard, Styrofoam, or blanket. Soap should be removed from the molds after 24 hours, and then left uncovered in freely circulating air for two to four weeks .

Option #2: Expensive but high quality

This is a recipe for Lavender soap ; A softer and milder soap. Instead of using only lard or Crisco, it calls for a mixture of oils.

Using these oils also necessitates more careful temperature control. Reduce the quantities to 1/3 of the amounts normally suggested in the commercial recipe for a sample batch. This should make the experiment go faster as well as cost less.

REMEMBER, DO NOT USE ALUMINUM!!

1. To 315 ml (10 - 11 oz) of cold water slowly add 113.5 grams (4 oz) of NaOH. A 1-quart glass bottle should work well as a container but you can also use a glass bowl if necessary. Initially mixing the water and lye in an enamelware pot and then pouring it into the glass container is a good idea. The reaction will heat the lye solution to over 200 o

F so set the container aside in a safe place to cool down to 80 o

F. If you plan to cool the lye overnight, cover the container tightly to avoid evaporation caused weakening of the solution. If you are anxious to do this quickly, place the container in an ice water bath to speed the solution process and to help cool the resulting mixture. If the temperature of the solution drops below 80 o F (27 o C) remove from the ice bath.

2. While the lye is cooling, you can begin mixing the oils. Place 360g (13 oz) of Crisco and 227 grams (8 oz) of coconut oil in a 3 quart pot and heat on a low setting until most of the solid pieces have melted. The few remaining chunks will melt from the heat in the pan. Pour the melted oils into a 6 quart pan that has 227 grams of olive oil in it. (If you want to add a natural preservative, add about 10 grams of grapefruit seed extract.) Let the mixture cool to 80 o

F (27 o

C).

3. You are ready to make soap when the oils and the lye solutions have both cooled to 80 o

F (27 o

C). Wearing goggles and gloves slowly drizzle the lye into the oils, stirring briskly as you pour. Continue to stir, circling the edges of the pan and cutting through the middle of the pan to keep as much of the solution as possible in constant motion. Do not beat or whip the mixture, but stir briskly throughout the entire soap making process. Do not scrape any residue off the sides of the pan.

Once a small amount of soap drizzled across the solution’s surface leaves a faint pattern before sinking back into the mass, the soap is ready for the Lavender. (Consistency should be like sour cream).

4.

5.

Add the Lavender oil (this and other scents can be purchased from Liberty Natural Products in Portland -most craft stores should also carry essences), stirring swiftly and thoroughly with a spatula without beating. (Adding them earlier would hinder the saponification reaction.) Stir for twenty to thirty seconds, or as little time as needed to fully incorporate the essential oils. Too much stirring causes streaking and seizing (a quick setup which makes it hard if not impossible to pour the soap into the frames).

The molds should have been prepared in advance. Rectangular cake pans, cardboard boxes, etc. work well. Line the mold with plastic, wax paper, or Vaseline to allow for easy removal.

6. Quickly pour the soap into the mold without scraping the residue off the sides of the pan. The mixture should be smooth, with no lumps, and the texture and color should be uniform. Watery or oily puddles signal a poorly mixed solution that will result in pockets of solid lye in the final bars. Try to pour evenly from one end of the mold to the other for uniform bars. If you see a change in texture, stop pouring. If the last bit of soap mixture at the bottom of the pan is watery and uneven, the stirring process was not quite complete. Do not pollute the rest of your batch by adding this unsaponified portion.

7.

If you don’t pour the mixture into the mold quickly enough, it may begin to set unevenly. Use a spatula to spread it out to the corners.

Cover the filled frame with another frame, a piece of plywood, or a piece of heavy cardboard; cover with a blanket and place in a warm location. IT MUST BE WELL INSULATED. Soap should be kept in the molds for at least 24-hours then left uncovered in freely circulating air for two to four weeks .

[Soap maker’s note: “I have found that covering the top of the soap with plastic wrap to where it actually touches the surface helps a lot. I have also found that leaving the soap for 5 to 7 days before removing it from the mold produces a better product. If you should decide to do this on a regular basis, experiment with times and other variables and see what gives you the best results.”]

Option #3:

For a recipe that gives excellent results and is preferred by many home soap makers. You’ll get about 40 (4-ounce) bars from this recipe. It is a little spendy, but buying this quality of soap retail would be much more.

Use the above procedures with the following ingredients:

3 pounds (3 pints) cold distilled water (does not need to be refrigerated)

473 grams (1.04 pounds) of sodium hydroxide

4 pounds (1.81 kg) of olive oil

2 pounds 8 ounces (1.13 kg) coconut oil

1 pound 8 ounces (680 g) palm oil

30 grams grapefruit seed extract (natural preservative), optional

45-50 grams (15-18 tsp) pure essential oil, optional

CH106 Lab 23 Lipids: Fats, Oils, & Soap

(W15)

35

P R O C E D U R E S : :

A CTIONS :

I.

S OAP : P REPARATION

1.

From Table 3 choose

2 fats or oils from column A and

2 fats or oils from column B.

Plan that the composition of your soap will be 40% each of the column A fats and 10% each of the column B fats.

2.

On the report sheet show the amounts of chosen fats/oils and sodium hydroxide needed to make a 95% hydrolyzed bar of soap.

1

3.

Into a weighing paper weigh the calculated

1

mass of sodium hydroxide needed.

4.

Into a 250 mL beaker, measure about 20 mLs deionized water.

5.

Slowly and carefully

2

add half of the weighed sodium hydroxide to the water in the beaker stirring constantly with a glass stirring rod.

6.

Once the solid has dissolved, carefully stir in the remaining sodium hydroxide. Dissolve and set aside.

7.

Weigh

3

the fats and oils into a separate 400 mL beaker.

4

8.

Warm the fats and oils mixture gently with stirring on a hot plate.

4

When everything has melted turn the hot plate off.

9.

With stirring, add the NaOH solution from step 4.

Continue stirring with a rubber spatula until “trace” 5

is reached.

10.

Remove a pea sized glob of your soap and place in a large stoppered test tube. Add water and shake to dissolve.

11.

Test the pH of the dissolved soap solution and record the result.

6

12.

To the remaining soap add fragrance or essential oil.

Continue stirring until trace is again reached.

13.

Pour the scented soap into molds

7

or weighing boats and incubate in a cardboard box or insulated chest for at least a week.

8

14.

After a week take the soap on to Part V for evaluation and comparison with detergent.

N OTES :

1

Calculations should be done on the report sheet part I similar to those done in the prelab but on your choice of fat and oils. They must be approved by your instructor before starting lab.

2

Sodium Hydroxide gets very hot with mixed with water. A concentrated NaOH solution is extremely dangerous. Make certain you are wearing eye protection. Do your best to avoid splashes. If skin contact is made wash immediately with soap and lots of water.

3

Zero/Tare the balance between additions and add slowly so you don’t add an excess.

4

If you were using any butters (cocoa, mango, shea butters) or beeswax in your formulation you would need to weigh these together in a separate 100mL beaker and melt them carefully

(avoid smoking) over a hot plate and then add them to your melted fat/oil mixture.

5 To test for “trace”, raise the spatula and drizzle soap onto the surface of the mixture.

The soap has “traced” when a faint pattern is observed on the surface before sinking.

6

This soap solution contains some leftover sodium hydroxide that didn’t react so it will show a very basic pH. The crude basic soap is too harsh to use on your skin so it must be purified or allowed to sit so that the residual

NaOH can either react with remaining triglycerides or react with carbon dioxide in the air.

7

Do not pour clumped or watery soap into molds. As the soap sets in the molds, heat will be generated. This heat, if contained, can aid in hardening the soap. For this reason the soap is enclosed in containers.

8

Any unreacted sodium hydroxide will react with carbon dioxide in the air to become sodium carbonate (washing soda) thus eliminating the need for further purification from the harsh sodium hydroxide.

2NaOH + CO

2

Na

2

CO

3

+ H

2

O

36 CH106 Lab 23 Lipids: Fats, Oils, & Soap

(W15)

II.

I SOLATION OF E SSENTIAL O ILS (Group project)

1.

Place about 100 g of moist

9

ground or chopped plant material

10

around the outside of the central beaker of the OilExTech microwave steam distillation apparatus

11

.

2.

Place the condensation funnel and the lid with ice cone (without the plastic shield) on the apparatus and place in a standard kitchen microwave oven.

3.

Place a mug or beaker of water next to the apparatus in the microwave and microwave on high for about 4-5 minutes. Let sit undisturbed an additional

10-15 minutes.

4.

Remove the center beaker

12

from the apparatus and pour some of the water/oil mix into a small (10 - 50 mL) volumetric flask. Allow the oil to rise to the top within the narrow cone of the flask.

5.

Pipet the oil layer into a vial and save for use as a soap fragrance.

III.

T EST FOR U NSATURATION :

1.

Obtain 3 dry test tubes labeled #1-3.

Keep tube #1 as a control

Stand tube #2 in a beaker on a balance and tare it. Add a match-head sized bit of solid vegetable shortening or lard and record the mass of the fat used.

Stand tube #3 in a beaker on a balance and tare it. Add drops of vegetable oil to reach the same mass as the mass of solid fat used in tube #2.

To each tube add about 10 drops of dichloromethane

13

. Stopper and shake to mix.

2.

Under a fume hood :

14

To tube #1 add 5 drops of 5% bromine in methylene chloride (Br

2

in CH

To tubes #2 and #3 add 5% bromine in methylene chloride (Br

2

Cl

2

in CH

2

)

2

Cl

2

) drop by drop; counting the number of drops until the red-orange color of bromine remains (do not add more than 30 drops).

3.

Record and explain your observations.

4.

Discard the tubes in the “Waste Halogenated Solvent” container.

III.

K REIS T EST FOR O XIDATIVE R ANCIDITY :

1.

Obtain 2 large test tubes or small Erlenmeyer flasks and label them #1(old) and #2( new). Record brands names and date of opening of each sample if available.

2.

Into tube #1 place about 1 g of “old” solid liquid vegetable oil.

16

15

fat or 1 mL (20 drops) of “old”

3.

Into tube #2 place about either 1 g of

“new”

solid shortening or 1 mL (20 drops) of “new” commercial vegetable oil.

4.

To each fat or oil sample add 8 drops of concentrated hydrochloric acid

(12M HCl).

17

Stopper and shake to mix.

5.

Now to each sample add 1 mL (20 drops) of 0.1% phloroglucinol

18 in ether solution. Stopper and gently shake to mix. Let stand for about 10 minutes.

19

6.

Compare the color

20

. Record your results and make conclusions.

9

Add water to moisten the plant material as needed.

10

Many plants will yield oils. Some ideas to try are:

Lavender buds

Grated orange rind

Peppermint leaves

11

For a demonstration see http://oilextech.com

12 The center beaker now contains melted ice water and the essential oil. extracted

13

Also known as methylene chloride

(CH

2

Cl

2

) it is a component of some paint stripper and degreasers.

14

Do not breathe Bromine fumes as they are toxic and irritating to mucus membranes.

15

You do not need to measure 1 g exactly. A gram of a fat is a hunk about the size of the tip of your little finger.

16

The fats tested can be shortening, oils. lard, or other triglyceride containing products.

17

12M HCl is concentrated hydrochloric acid (con HCl). Use with caution.

18

Phloroglucinol is another name for 1,3,5trihydroxybenzene.

19 Ether evaporates rapidly; slight pressure may build up in the stoppered test tube. If too much ether is evaporating add another 1 mL of ether, stopper and gently shake then let stand.

20

A red or pink color indicates rancidity.

CH106 Lab 23 Lipids: Fats, Oils, & Soap

(W15)

37

W EEK 2:

V.

S OAP : E VALUATION

A. Solubility & pH

1.

Remove a thumbnail sized glob of your finished soap and place in a 150 mL beaker with about 50 mLs of deionized water. Heat the mixture, with gentle stirring until all of the solid soap has dissolved in the water.

.21

2.

Test the pH of this soap solution and record the result.

Use this soap solution in each of the following procedures.

B. Purification

3.

Obtain two 50 mL beakers. Into beaker #1 pour 10 mLs of the soap solution you just made and allow it to cool.

4.

Into beaker, #2, pour 10 mLs of a detergent solution.

5.

To each beaker add solid sodium chloride (NaCl) a little at a time with stirring, until no more NaCl dissolves and the bottom of the beaker is covered with NaCl. Record your observations on the report sheet

22

.

6.

Remove the mass of pure soap floating on the surface of beaker #1. This could be done by scraping it off the top with a spatula or piece of filter paper.

7.

Put a small piece of the purified soap into a test tube and dissolve it in deionized water. Stopper the tube and shake the soap to see if it lathers.

23

8.

Test the pH of the purified soap solution in the test tube and also test the pH of the detergent solution in the second beaker. Record the results.

C. Reactivity with Hard Water Ions:

1.

Obtain two test tubes.

Into test tube #1 pour 5 mLs of the soap solution (from step VA1) .

Into test tube #2 pour 5 mLs of detergent solution.

2.

Add 1M Calcium Chloride (CaCl

2

), one drop at a time, to each tube (up to a maximum of 10 drops) until a precipitate forms.

3.

Record the results and complete the equation for the reaction on the report sheet.

24

D. Reactivity with Acid:

4.

Obtain two test tubes.

Into test tube #1 pour 5 mLs of the unpurified soap solution (from step

VA1) .

Into test tube #2 pour 5 mLs of detergent solution.

5.

Add up to 4 drops of 6M HCl (hydrochloric acid), one drop at a time to each test tube and observe if a precipitate forms.

6.

Record the results and complete the equation for the reaction on the report sheet.

25

38 CH106 Lab 23 Lipids: Fats, Oils, & Soap

(W15)

21

If there are clumps that will not dissolve, scoop them out and discard them.

22

Soap can be forced out of solution by dissolving

NaCl in it. Water can only dissolve a limited amount of stuff and since NaCl is more polar than the long hydrocarbon chain of the soap, the water lets go of the soap and dissolves the

NaCl. The soap that has been let go floats to the surface of the water. The

NaOH leftover from the preparation of soap reaction is very polar like sodium chloride so stays dissolved in the water.

Therefore, the soap that comes to the surface of the water is now more pure.

23

You could also test the lathering ability by using the purified soap to wash your hands.

24

The sodium salts of fatty acids, soaps, are soluble in water. When other metal ions like calcium, magnesium, or iron, form salts with fatty acids they are not as soluble in water and tend to precipitate out.

25 A soap is a weak base so it reacts with HCl by taking an H + which turns it into a carboxylic acid. The newly made carboxylic acid is a fatty acid with a long hydrocarbon chain and now that it has no charge it is no longer soluble in water.

L A B 2 3 : : L I I P I I D S : : F A T S , , O I I L S , ,

A N D S O A P : :

N A M E _ _ _ _ _ _ _ _ _ _ _ _ _

P R E L A B E X E R C I S E S

: :

1.___

An unsaturated lipid ____________________than a saturated lipid.

A. is more difficult to digest

D. spoils less easily

B. has a lower melting point

E. more than one of these.

D A T E _ _ _ _ _ _ _ _ _ _ _ _ _ _

C. is more soluble in polar solvents

2.___

If a commercial lipid produced a positive Kreis test, you should

A. return it to the store and demand a refund.

C. use it as a salad dressing.

E. more than one of these.

B. use it regularly for cooking.

D. classify it as a nonsaponifiable lipid.

3.___

Which of the following makes water considered to be “hard” water?

A. Ca

2+

B. Na

1+

C. NH

4

1+

D. More than one of these.

Match each of the following terms with the best structure it represents:

O

4.___

Fatty Acid A.

H H O H H

E.

H

H

H

C

C

O

C

O

O C

5.___

Triacylglycerol H C C C

H H

O C C

H H

H

H C

H

O

O

C

6.___

Detergent

B.

O

C

OH

F.

O

O

C

O

C

O

7.___

Soap

8.___

Micelle

C.

O

C

O Na

O

O

C

O

C O

O

C O

O

C

O

O

C

O 9.___

Ester

D.

O

S

O

O Na

10.

Lab student, Kim Estry, is planning to make soap from the listed fats and oils.

A.

Using the property tables given in the discussion calculate the grams of each fat and grams of KOH needed

Fat or Oil to saponify this mixture.

% Composition

Grams Fat needed to total 50 g’s

SAP Value

(mg KOH/1g fat

X 1 g KOH

1000mg KOH

= g KOH needed

Coconut 40 %

20 g Coconut Oil

1

X 257 mg KOH

1 g Coconut Oil

X 1 g KOH

1000 mg KOH

= 5.14 g KOH

Lard

Castor

50 %

10 %

=

=

100 %

50 g total Fats & Oils

Needed

Total g KOH needed

B.

You calculated the amount of KOH needed to saponify 100% of the fats/oils in Kim’s proposed soap however she only has NaOH available to use. From the mass of KOH required use the molar mass of KOH and NaOH to determine the quantity of NaOH required for 100% saponification. (Show your calculations.) g NaOH

C.

To keep the soap from being too dry Kim only wants to convert 95% of the fats and oils to soap so wants to use just 95% of the NaOH calculated. How much NaOH is needed to saponify only 95% of the fats/oils?

(Show your calculations.) g NaOH needed

D.

What are the expected properties (from Table 2) from your selected combination of fats and oils?

CH106 Lab 23 Lipids: Fats, Oils, & Soap

(W15)

39

40 CH106 Lab 23 Lipids: Fats, Oils, & Soap

(W15)

L A B 2 3 : : F A T S , , O I I L S , ,

A N D S O A P : :

N A M E _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

B.

B.

A.

A.

R E P O R T A : :

I.

S OAP :

Fat or Oil

%

Composition

40 %

40 %

10 %

10 %

Grams Fat needed to total 50 g’s

20 g

1

SAP Value

(mg KOH/1g fat

X ……… mg KOH

1 g

P A R T N E R _ _ _ _ _ _ _ _ _ D A T E _ _ _

X 1 g KOH

1000mg KOH

X 1 g KOH

1000 mg KOH

= g KOH needed

=

=

= g KOH g KOH g KOH g KOH

100 %

50 g total Fats & Oils

Needed

= Total g KOH needed

A.

You calculated the amount of KOH needed to saponify 100% of the fats/oils in your proposed soap however you only have NaOH available to use. From the mass of KOH required use the molar mass of KOH and NaOH to determine the quantity of NaOH required for 100% saponification. (Show your calculations.) g NaOH

B.

To keep the soap from being too dry you only want to convert 95% of the fats and oils to soap so you want to use just 95% of the NaOH calculated. How much NaOH is needed to saponify only 95% of the fats/oils? (Show your calculations.) g NaOH needed

Instructor approval _______

What are the expected properties (from Table 2) from your selected combination of fats and oils?

O BSERVATIONS pH

A. Preparation pH of crude soap dissolved in water:

_________

1. Complete the following: Show Structures

O

H

H

H

C

C

H

H

C

O

C

O

O

C

O

O

C

NaOH

H

2

O

Glyceryl Trioleate

2. Name All of the Products:

CH106 Lab 23 Lipids: Fats, Oils, & Soap

(W15)

41

II.

I SOLATION OF E SSENTIAL O ILS :

Plant Source: Grams Used mLs Oil Obtained Odor and Observations:

III.

U NSATURATION :

Observations

g’s + Drops of Br

2

Used

Solid Shortening or Lard

g's used Drops Br

2

Liquid Vegetable Oil

g's used Drops Br

2

Explanation/Analysis:

Explain the results. Compare the amount of unsaturation in the samples. Explain any anomalies.

3.

Write an equation for the reaction of Bromine with a representative triglyceride that may be present in vegetable oil. Show Structures.

IV.

K REIS T EST FOR R ANCIDITY :

Brand Age

(date)

Observations

Old

Solid/Liquid

(circle which)

Conclusions

Rancid or Not?

New

Solid/Liquid

(circle which)

Explanation/Analysis:

Why were the results this way? Explain any anomalies.

4.

Complete the following showing the products of complete oxidation (rancidity) of the double bonds:

O

H

H

H

C

C

C

O

O

O C

[O] with O

2

or O

3

H C

H

O

O

C

Glyceryl Trioleate

42 CH106 Lab 23 Lipids: Fats, Oils, & Soap

(W15)

R E L A T E D E X E R C I S E S

: : N A M E _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

___1.

Why are some solvents more effective at dissolving grease than others?

A. greases are nonpolar so will dissolve best in nonpolar solvents.

B. greases are nonpolar so will dissolve best in polar solvents.

C. greases are polar so will dissolve best in nonpolar solvents.

D. greases are polar so will dissolve best in polar solvents.

___2.

The odor of acrolein is frequently strong in restaurants that feature charcoal-broiled food. Which of the following best explains the presence of this odor?

A. the proteins in cooked meat decompose to form acrolein.

B. the tracylglycerols in meat decompose in high heat and the resulting fatty acids then dehydrate to form acrolein.

C. the tracylglycerols in meat decompose in high heat and the resulting glycerol dehydrates to form acrolein.

D. the charcoal used to cook food decomposes to form acrolein when the heat is high enough.

___3.

List each of the following that would be expected to produce Acrolein upon heating with KHSO

4

?

A. olive oil B. stearic acid C. glycerol D. palmitic acid

E. oleic acid F. coconut oil

___4.

Soaps and detergents dissolve in both nonpolar oil and in polar water because ____

A. they have a nonpolar ionic end that attracts oil and a polar hydrocarbon end that attracts water.

B. they have a nonpolar ionic end that attracts water and a polar hydrocarbon end that attracts oil.

C. they have a polar ionic end that attracts water and a nonpolar hydrocarbon end that attracts oil.

D. Soaps and detergents are neither polar nor nonpolar so the solvent doesn’t matter.

5.

Label the isoprene units in the essential oil limonene from oranges:

R E F E R E N C E S E A R C H : :

6.

During World War II homemakers were asked to contribute their bacon grease to the war effort for the production of nitroglycerin. Use a source of your choice to find the structure of nitroglycerin and how it is made. Propose a sequence of reactions (using structures) to show the production of nitroglycerin from a fat

( ie bacon grease.)

Reference Source =

CH106 Lab 23 Lipids: Fats, Oils, & Soap

(W15)

43

44 CH106 Lab 23 Lipids: Fats, Oils, & Soap

(W15)

L A B 2 3 : : F A T S , , O I I L S , ,

A N D S O A P : :

N A M E _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

R E P O R T B : :

W EEK 2

I.

S

OAP

: E

VALUATION

P A R T N E R _ _ _ _ _ _ _ _ _ D A T E _ _ _

O BSERVATIONS pH

A.

Solubility & pH

Appearance & qualities of your finished soap: pH of finished soap in water:

_________

B.

Purification

Results of “salting out” the soap:

Describe the “lather” after shaking:

Results of “salting out” detergent: pH of purified soap in water:

_________ pH of detergent solution:

_________

C.

Reaction with Hard

Water Ions

Results of adding CaCl

2 to soap:

Results of adding CaCl

2

to detergent:

Complete and balance the reaction: Show Structures

O

9

Na O

C

18

+ CaCl

2

Sodium Oleate

Name of All Products formed:

D.

Reaction with Acid

Results of adding to HCl soap:

Results of adding HCl to detergent:

Complete the reaction: Show Structures

O

9

Na O

C

18

+ HCl

Sodium Oleate

Name of All Products formed:

CH106 Lab 23 Lipids: Fats, Oils, & Soap

(W15)

45

46 CH106 Lab 23 Lipids: Fats, Oils, & Soap

(W15)