The American Heartland: More Definitions Handling Bulk

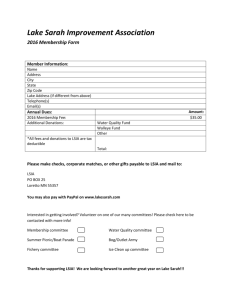

advertisement

4/13/2015 MANUFACTURING: The large-scale transformation of raw materials into finished goods that have higher value . Regional Landscapes of the United States and Canada American Heartland: Industry HEARTLAND overlap area of the AGRICULTURAL and The American Heartland: INDUSTRIAL CORES Agricultural Core stretches from Lake Ontario to the Missouri River Valley and between the Northlands and the South in the area of temperate climate. Overlapping Areas of Agriculture and Manufacturing 2 Manufacturing Core stretches from the Atlantic Ocean to the Mississippi R. and between the Great Lakes and the Ohio River Valley. Prof. Anthony Grande ©AFG 2015 Chapters 7, 8,13 of American Landscape Sub-regions of the Manufacturing Core 2 Manufacturing Needs USA Utica Schenectady Troy New York City Baltimore Patterson Trenton New Haven Springfield Boston Worcester Providence Portsmouth Portland CANADA Windsor London Hamilton Toronto Montreal USA Milwaukee Chicago Peoria Gary Detroit Flint Toledo Cleveland Akron Dayton Cincinnati Wheeling Pittsburgh Erie Philadelphia Scranton Buffalo Rochester Syracuse Includes parts of Megalopolis, the Canadian National Core and Appalachia What is needed for a successful industrial operation – both manufacturing and support? – Space – Raw materials – Energy supply – Water supply – Transportation (accessibility and networks: ports, railroads, highways, canals, airports) – Labor supply (all skill levels) – Financial centers – Markets – Political and legal variables that are favorable (jurisdictions, laws, zoning, regulations) 3 More Definitions 4 Handling Bulk • Comparative Advantage: the area best suited Bulk - a large volume of material Break bulk – to reduce the volume to manageable loads for a task • Agglomeration: clustering for mutual benefit All manufacturing sites have to deal with issues of bulk and storage for both the raw materials and the finished products which requires the room to do so. • On-site Storage: bulk buying; warehousing • Just-in-Time Systems: buy and accept delivery when needed Break-in-bulk Point: • Location Inertia: tendency of an industry to stay in place and at a place. A transfer point on a transport route where the type of carrier changes, and where the volume of shipment is expanded or reduced in size. 5 6 1 4/13/2015 Manufacturing Core Growth of Manufacturing Core The growth and development of the Core was directly related to the: Core region dates from the late-1800s. – Prelude: Early 1800s on the East Coast, there was urban/manufacturing development as the factory system transformed towns. 1. Quantity, quality and location of natural resources (wood, coal, minerals, and water). ORIGINAL CORE IS BOSTON TO BALTIMORE. – Midwest was settled by agriculturalists:1830-1860. 2. Ability to move raw materials and the finished product by water and rail (transportation networks). – Transportation advances were a factor: • Erie Canal and “canal fever” (1820s-1850s). Canals were built to connect the area’s rivers with the Great Lakes. • Railroads (surpassed the canals in 1840s; flexibility). 7 8 Growth of the Railroads Industrial Areas - 1880 (1850-1880) 9 Note the increase of density of lines over the 30 yr period. 10 Railroads and the Heartland Manufacturing Core after the end of the Civil War Railroads’ presence everywhere – tracks, rail In East Coast cities manufacturing grew after the Civil War because of: a) Labor supply, water power, good ports, the siting of railroad terminals and money. b) European immigrants with factory working experience entered the U.S. through these cities. c) The growth of the railroads in the mid1800s, esp. after the invention (1870s) of steel rails, allowed manufacturing to move inland along the tracks expanding the original core. Able to move tons of raw materials, especially coal. Railroad companies sponsored manufacturing along their lines. 11 crossings, stations, yards, depots – have created images in people’s minds that includes them in the mental image of the landscape of the Midwest. 12 2 4/13/2015 Comparison of Core Sub-regions Eastern Cities -- Interior Cities New England Watermills the original factories Undershot water wheel Existed before industrialization Developed near mineral and agricultural resources Developed because of after industrialization commerce and finance Focus: water for transport’n Hearth: New England Specialization: heavy Power source: water wheel industry Specialization: light industry Importance placed on services, esp. finance, educ., culture Sites: Boston, Providence, New Overshot water wheel Used tons of metallic minerals and coal Processing, metal smelting, machinery, milling Small amt of raw materials used High value per unit weight added Sites: Buffalo, Pittsburgh, York, Philadelphia, Baltimore Cleveland, Cincinnati, Detroit, Gary, Chicago, Milwaukee, St. 13 Louis; Toronto, Hamilton Canals of Lowell, MA - 1850 Upstream of the Pawtucket Falls, water from the Merrimack R. was diverted into canals which flowed through factories. The 30 ft. head (drop) turned the waterwheels that transferred energy by gears to the power shaft. 14 Inside a Watermill Gears and shafts for GRINDING action. PULLY SYSTEM with gears and belts to turn drive shafts at different levels Nearly 6 miles of canals operated on 2 levels and powered 10 major mills employing 10,000 workers. WATER-POWERED SAWMILL Cranks and rods for SAWING action 15 Cotton Manufacturing Museum Lowell, MA 16 Mill at Manville, RI Machines (looms) are powered by water turning wheels. 17 18 3 4/13/2015 New England Factory Buildings Great Falls of the Passaic River Salem, MA Manchester, NH Paterson, NJ It is home to the largest and best example of early manufacturing mills in the US. Milton, MA It played a key role in shaping the American Industrial Revolution. Designated a National Historical Park in 2011. Has 18th, 19th and 20th century structures. It contains waterpower remnants from the 1700s, including a 3tiered raceway system. 20 19 DUMBO, Brooklyn, NY New England Factory Buildings Remnants of post-Civil War era factory complex along the Brooklyn waterfront. 21 Proximity within the Heartland of Components for Steel-making 22 Importance of Ports on the Great Lakes • Transfer of iron ore shipped on Great Lakes to rail cars at Great Lakes ports: break-in-bulk. • Return rail cars carrying coal. • Development of steel and other industries at ports. IRON ORE Cleveland •Coal is moved by rail or water. Iron ore is moved by water. •Steel mills are located along the shoreline. •Limestone is trucked in from local sources. •Finished products are moved by water, rail or truck to their next destination. - Largest port city on Lake Erie - Canal linkage to Ohio River COAL Buffalo 23 - Linked to NYC by Erie Canal - Last port on “all American” route from Lake Superior - Extensive rail yards interacted with port facilities 24 4 4/13/2015 Rust Belt Canadian Core Lake Ports 20th century term used to describe the area in industrial decline stretching from western Pennsylvania and central New York State through northern Illinois. Hamilton (iron and steel) Toronto (diversified) Windsor (automobiles) Plus the Welland Canal and access to the sea via the St. Lawrence Seaway. “Golden Horseshoe” of Canada – the area at the west end of Lake Ontario from Toronto to the Niagara River. 25 Lake Michigan Reasons for the “Rusting” Chicago of the Manufacturing Core • Population shifts: movement to new growth • • • • • It is meant to evoke images of rusting manufacturing facilities, especially involving the manufacturing of steel, vehicles, and heavy machinery. 26 Chicago Metro area Dominant city of the Heartland both for agriculture and industry. • Not a great site areas (SE and SW U.S., W. Canada) Labor shortage: young people not wanting to work in factories. Competition: from manufacturers in other U.S. regions and in foreign countries. Aging infrastructure: costly to retro fit or come up to standards; limited space to expand. New technologies: hi tech, especially robotics. Environmental issues: regulations, cost factors. Gary, IN – Swampy, poor-quality drinking water, non-navigable river • But has situational advantages – Transfer point for goods and people from west and southwest – Focus of inland water transportation (Illinois and Michigan Canal, 1848) connecting Lake Michigan to the Mississippi River system – Railroad center – all major rail lines radiate from here. 27 28 Heavy industry on Cleveland’s Cuyahoga River Aerial Photograph of Cleveland Here water is used in processing, for waste disposal and as a means of transportation. Winter 1937 View 29 30 5 4/13/2015 Cuyahoga River Fire Vintage Photos of Pittsburgh June 22, 1969 1930s Pittsburgh steel mill Air pollution from Pittsburgh steel mill 31 PITTSBURGH 32 Detroit: Satellite image • Strategic river junction (where the Monongahela and Allegheny rivers join to form the Ohio River) • Access to raw materials (iron ore and coal) and down-river markets • Steel making center • Today pollution free Detroit, MI USA Lake St. Clair Windsor, ON Canada 33 Lake Erie 34 The Ford Plant at Rouge River Detroit Looking north from Detroit to Lake St. Clair (in • From the French, de troit – “of the narrows” • Located along the Detroit River (a channel) that connects Lake Erie with Lake St. Clair. • Located at a place to cross the river and also to control water traffic between the lakes. • This was a site of colonial forts. south of Detroit Lake St. Clair the distance). Windsor (Canada) is to the right. Major manufacturing plants need a lot of space and are located outside of cities. Assembly line manufacturing is a one level, horizontal production line. 35 (As opposed to the multi-story East Coast factories located within a city.) 36 6 4/13/2015 Automobile Industry A Modern Automobile Assembly Line Henry Ford (1863-1947). Industrialist, automobile manufacturer, and pioneer of the assembly line technique of mass production. He and other auto pioneers happened to live in the area! Some horizontal assemble lines can be over a quarter mile long. 37 Commercial Food Processing 38 Minneapolis Mill Ruins State Park: Once the area of the highest concentration of water powered mills in the world. Kellogg, Battle Creek, MI General Mills, Minneapolis, MN Quaker Oats, St. Louis, MO 39 John Deere Factory Minneapolis and St. Paul, located at the St. Anthony Falls of the Mississippi River, became the focus of grain growers to break bulk before shipping the product east. How? Why? 40 Ethanol Ethanol is a fuel made from processing biomass. Corn is a very good source of biomass. Agricultural need meets industrial ability. 41 Ground corn stored in the manufacture of ethanol. 42 7 4/13/2015 EXAM INFORMATION Exam Two will be Monday, April 20. • Format same as Exam 1. • Multiple choice short answer plus choice of essay topics. • See Study Guide. Missed exam make-up is all essay format . The Extra Credit for Exam Two is due no later than the start of the exam on April 20. Remember to provide examples from all 4 choices for max extra points. All other extra credit is by the end of the semester. 43 8