Digital Bangladesh

advertisement

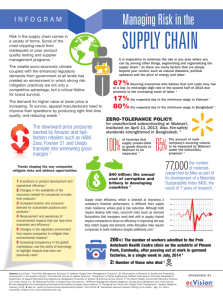

Abstract The success of readymade garment exports from Bangladesh over the past two decades has surpassed the most optimistic expectations. The paper reviews the literature on this industry, presents recent data on the sector's performance, and evaluates future trends in the international and domestic clothing industry. Acknowledgement First thing first it has to be said that completion of this Term Paper was not a very easy task for me. It‟s a very special thank from me to my instructor Mr. „X‟ for his ever kind and intimate assistance and provided freedom for working on it. The effort for this term paper will definitely strengthen my knowledge and sense about the related field of International Business. I strongly believe that I will be able to utilize my knowledge and senses in the practical field. Such type of term paper, I may make some conceptual mistakes. I offer apology for any such unexpected mistake if done. Finally, I wish to mention that here I tried to follow the formal guidelines and it has been casually written all through like usual term papers. It has been done willingly for its uniqueness subject with its field of creative construction. Index PART 1: Introduction -------------------------------------------- #04 1.1 Introduction 1.2 Objective 1.3 Methodology 1.4 Limitations # 04 # 04 # 05 PART 2: Current scenario --------------------------------------- # 06 2.1. An overview of ready made garments of Bangladesh # 06 2.2. Market Access Issues # 07 2.3. Exporters of ready made Garment products; World perspective # 07 2.4. Foreign Demand # 08 Part Three: Prospective Analysis ------------------------------------ # 12 3.1. Prospect of ready made garment industry in Bangladesh # 12 3.2 Current scenario of garment industry in Bangladesh # 16 Part Four: Analysis ------------------------------------------------------ # 19 4.1. SWOT Analysis # 19 4.2. The Future of Garment Exports and the Economy of Bangladesh # 22 Part Five: Conclusion------------------------------------------------------- # 24 Part One: Introduction 1.1 Introduction The tremendous success of readymade garment exports from Bangladesh over the last two decades has surpassed the most optimistic expectations. Today the apparel export sector is a multi-billion-dollar manufacturing and export industry in the country. The overall impact of the readymade garment exports is certainly one of the most significant social and economic developments in contemporary Bangladesh. With over one and a half million women workers employed in semi-skilled and skilled jobs producing clothing for exports, the development of the apparel export industry has had far-reaching implications for the society and economy of Bangladesh. 1.2 Objective: I have tried to show that how much the garments sectors contributed for the betterment of Bangladesh. We earn more than half of the total revenue by exporting RMG products to different countries all over the world. It can be said that the Garments sectors have brought about the revolutionary change for Bangladesh 1.3 Methodology: In order to supplement my theoretical knowledge regarding ready made garments with the field practical exposure, I contacted different buying houses and collected data regarding real life scenario. I make an over view with their income and the necessary conceptual application. I also tried to follow my concern course contents and necessary related materials to utilize for an effective term paper. 1.4 Limitations First of all, the time duration I had for this particular term paper was not appropriate. In fact I faced little bit difficulties to collect the information regarding this particular term paper. There were limited surveys and analysis for the development might have been the other drawback of this report. Part Two: Current Scenario 2.1. An overview of ready made garments of Bangladesh For Bangladesh, the readymade garment export industry has been the proverbial goose that lays the golden eggs for over fifteen years now. The sector now dominates the modern economy in export earnings, secondary impact and employment generated. The events in 1998 serve to highlight the vulnerability of this industry to both internal and external shocks on the demand and supply side. Given the dominance of the sector in the overall modern economy of Bangladesh, this vulnerability should be a matter of some concern to the policymakers in Bangladesh. Although in gross terms the sector‟s contributions to the country‟s export earnings is around 74 percent, in net terms the share would be much less partially because the backward linkages in textile have been slow to develop. The dependence on a single sector, no matter how resilient or sturdy that sector is, is a matter of policy concern. We believe the policymakers in Bangladesh should work to reduce this dependence by moving quickly to develop the other export industries using the lessons learned from the success of apparel exports. Support for the apparel sector should not be reduced. In fact, another way to reduce the vulnerability is to diversify the product and the market mix. It is heartening to observe that the knit products are rapidly gaining share in overall garment exports as these products are sold in quota-free markets and reflect the strength of Bangladeshi producers in the fully competitive global apparel markets. Preliminary data and informal evidence indicate that this sector seems to have weathered the devastating floods relatively well. The floods did create a crisis for the tightly scheduled export industry, but to its credit the firms responded swiftly and creatively to the unexpected dislocation and transportation disruptions. The industry is one hundred percent export-oriented and therefore insulated from domestic demand shocks; however, it remains vulnerable to domestic supply shocks and the smooth functioning of the banking, transportation and other forward and backward linkage sectors of the economy. The Dhaka-Chittagong road remains the main transportation link connecting the production units, mostly situated in and around Dhaka and the port in Chittagong, where the raw material and the finished products are shipped in and out. Despite increased dependence on air transportation, trucks remain the main vehicles for transporting raw materials and finished products for Bangladesh garment exports. 2.2. Market Access Issues: a. Cheap labor cost: Compared to other countries Bangladesh got the advantage of cheap labor that facilitated this particular industry to access in the global market. As it is cheaper to purchase raw materials needed to procure the finished goods that results in the ultimate products to be less costly. b. Infrastructure: as this particular industry has been successfully running for two decades, the related industries have grown quite strongly to make a supportive environment. As a result Bangladesh has a favorable infrastructure for the garment industry to grow. C. Government restriction: government plays an important role to grow this industry by relaxing government taxes and other restrictions to encourage the business to invest and get an access in the garment industry. d. Labor insensitivity: as a labor intensive country Bangladesh naturally gets advantage in manufacturing labor oriented products. 2.3. Exporters of ready made Garment products; World perspective: Along side Bangladesh, there are quite a few countries exporting ready made garments currently to meet up the world demand. Bangladesh is enjoying a healthy position as the market leader in this sector with its comparative advantage of low cost labor resource. But china and India are coming up creating threat for the Bangladesh. Since 2001 with the context of open market and trade system this field has opened up with a challenge for the exporters to grab more and more market share. Hong Kong, Vietnam and Srilanka are the other Asian countries seek to get a chance of export. Recently, news had emanated of the Bangladesh garment industry overtaking India, in exports of apparels to the biggest market in the world; USA. More and more worldwide clothing buyers are heading towards the shores of Bangladesh, since it is able to manufacture apparels, competitive in pricing, than most other countries in Asia. From August 2008 onwards, the exports from the RMG sector from Bangladesh have grown by a remarkable 10 percent, while that of India fell by 3 percent. The biggest advantage Bangladesh clothing manufacturers have vis-à-vis Indian manufacturers are the disparity in wages given to workers, due to which the sector in Bangladesh holds an edge. 2.4. Foreign Demand: Demand for Bangladeshi garments in Sweden is growing gradually as the consumers, facing hardship following the financial downturn in Europe; prefer cheaper goods, businessmen said. “Now-a-days consumers look for cheap garments. Since the Bangladeshi products are cheaper than that of other countries like China, they prefer that,” Ms. Halen Agervi, a manager of the H&M‟s showroom in Stockholm told the FE. Though the flow of customers has recently shrunk due to the financial dip, those who come to the shops usually prefer cheap garments, she said. The Swedish H&M (Hennes & Mauritz AB), Europe‟s second largest buyer of Bangladeshi garments, imports apparel from different countries including China, Mauritius and Turkey for selling those to more than 1000 H&M retail shops in 34 countries across the globe. Bangladesh has so far this year supplied some 120 million pieces of knit products worth about $300 million and 50 million pieces of woven worth about $250 million to the H&M, said Iqbal Khan, a senior executive of the H&M Dhaka office. “Due to financial meltdown our headquarters has asked us to offer fewer prices to the suppliers. But the volume of orders to Bangladesh will not lessen,” Mr. Khan who was visiting their Stockholm headquarters told the FE. H&M pays US$2.5 per unit to the Bangladeshi knitwear products and $4.5 per unit for the woven goods on an average. “The orders from the H&M are increasing day by day even during this global recession,” Amal Poddar, Managing Director of Metro Knitting and Dying Ltd, a major knitwear supplier to the Swedish company told the FE Friday. As the developed world is facing the financial meltdown, they prefer Bangladeshi products for its competitive price than products from China and Turkey, he added. Mr. Poddar said Bangladesh is slowly nudging China as the preferred choice for medium-to-low priced ready-made garments in European markets. “And recession in the wealthiest countries would hasten that process, as the top retailers would desperately hunt for factories, which can offer bargain prices,” he said. The H&M have been giving a lot of orders of knit garments especially sweater for acute cold weather in the Scandinavian countries, Mr. Poddar who supplies about 2 million pieces of garments per month to H&M said. “I don‟t think that our supply volume to the European market will shrink. The H&M has recently shown us that it had a target of 150 per cent business growth during 2008-2013. The projection has made us more bullish,” he said. “Chinese apparels were occupying the H&M retail shops in Stockholm before the global recession. But after the plunge, the consumers now prefer low-valued apparel. It has made a room for the Bangladeshi products again,” said Nahid Hossain, a Bangladeshi born Swedish citizen. H&M Dhaka office‟s Iqbal Khan said they are bullish about Bangladesh as they see the country‟s shipments gain on cheap labor and declining Chinese competitiveness despite its major markets are on the brink of recession. Amal Poddar said: “Bangladesh is the third largest supplier of H&M at this moment. I think it will be able to occupy first position within 2-3 years as our supply volume to the company is growing every month.” He said some 32 per cent of Bangladeshi exportable knit products are imported by the Swedish company — H&M. The US and the EU are the major destinations of Bangladeshi garment exports, accounting for some 90 per cent of the country‟s US$10.7 billion garment shipments last year. Table 2.1. Apparel Exports to Major Markets (1997 - 1998) TOTAL APPAREL EXPORT IN MILLION US$ WOVEN KNIT TOTAL % OF TOTAL 1,443.21 66.89 12.13 228.69 27.88 5.84 1,671.90 94.77 17.97 44.21% 2.51% 0.48% COUNTRY USA CANADA AUSTRIA BELGIUM DENMARK FINLAND FRANCE GERMANY GREECE IRELAND ITALY NETHERLANDS PORTUGAL SPAIN SWEDEN UK OTHERS 78.91 16.69 9.55 206.78 352.78 2.40 5.17 171.42 127.94 1.97 32.26 31.34 226.33 58.66 60.37 23.81 4.23 137.43 130.09 1.41 3.30 46.11 75.47 0.83 10.75 14.63 144.78 21.89 139.28 40.50 13.78 344.21 482.87 3.81 8.47 217.53 203.41 2.80 43.01 45.97 371.11 80.55 3.68% 1.07% 0.36% 9.10% 12.77% 0.10% 0.22% 5.75% 5.38% 0.07% 1.14% 1.22% 9.81% 2.13% TOTAL 2,844.43 937.51 3,781.94 100.00% Source: Export Promotion Bureaus (EPB) Table 2.2: Top Five European Destinations for Bangladesh Apparel (July 1997- May 1998) RANK COUNTRIES VALUE (Millions, $) 1 Germany 434.77 2 United Kingdom 343.89 3 France 305.72 4 Netherlands 183.63 5 Italy 195.82 Source: Export Promotion Bureaus (EPB) Part Three: Prospective Analysis 3.1. Prospect of ready made garment industry in Bangladesh: The apparel exporters of two neighboring countries- Bangladesh and India-have worries of divergent nature. Bangladesh apparel exporters are worried that their export orders have been on the decline for a number of domestic and external reasons. Their counterparts in neighboring India are anguished that Bangladesh is set to beat them in garment exports in the wake of an appreciating rupee. Bangladeshi exporters blame internal political disturbances, reduced demand in their key markets-the USA and the European Union countries-for the decline in export growth in recent months. The Indian apparel manufacturers and exporters, it seems, are ashamed of the fact despite having sufficient backup of raw materials they are lagging behind their Bangladeshi counterparts, who are largely dependent on imported fabrics and other raw materials-- in the international market. A recent Indian newspaper report quoted a number of apparel sector leaders expressing their frustration over the rise of the Bangladesh apparel sector. But the fact remains that with its low cost of labor and sufficient back-up support of raw materials, including fabrics, apparel exporters of India-- a regional economic superpower-- should have competed with China rather than grumbling about RMG export performance by a poor neighbor like Bangladesh. The Indian apparel exporters must have forgotten the issue of value addition while becoming jealous of the success of the Bangladesh RMG. The average value addition in case of woven garment exports by Bangladesh still remains as low as 30 per cent and the same for knitwear exports hovers around 60 to 70 per cent. Since Indian exporters do not have to depend on imported raw materials, the value addition of their exports should be nearly 100 per cent. There is another dark side of such unnecessary moaning by the Indian RMG exporters: It, rightly or wrongly, lends credence to widespread suspicion that the neighbors are involved in conspiracy to cause damage to the emerging Bangladesh garment sector. Such suspicion had become quite strong during a persistent campaign against Bangladesh RMG in the name of child labor, the recent workers unrest in the garment sector and the buyers' insistence on so-called compliance issues. The socio-economic conditions in many Indian cities are almost similar to that of Bangladesh cities where most garment units are located. It is highly unlikely that the working conditions or involvement of child labor in many RMG units have been very different from that of many Bangladeshi RMG units. But has anyone ever heard a word or seen a report in the international electronic and print media or deep concern among US trade union bodies about the situation in apparel units in India? However, Indian apparel exporters should have reasons to be happy to learn that the Bangladesh RMG sector, which proved many doomsday preachers wrong following the total phase-out of the multi-fiber arrangement (MFA) from January 1 2005 and recorded impressive export growth, has for the first time in many years had a poor export performance in recent months. The country's apparel exports recorded a 31.28 per cent growth in the period between the months of July and September of the just concluded financial year. But the average growth at the end of May last stood at only 16.45 per cent. Industry sources have claimed that export orders in recent months have declined by about 30 per cent. Many buyers had withdrawn from Bangladesh markets during political troubles in the last months of 2006 and placed their import orders with apparel manufacturers in China, the world's largest exporter of textile products having control over 70 per cent of the huge US market, and Vietnam, an emerging apparel exporter. The Indian business leaders do need to explore the reasons for buyers not going to India in large numbers. The appreciating rupee may not be the only reason for that. The political troubles that started from the month of October last took a heavy tool on industrial production and exports. The Bangladesh exporters, who have invented their own way of running their business operations amidst frequent shutdowns or blockades, also had become helpless in the face of complete halt of operations at the Chittagong port, enforced by the then opposition political activists led by mayor of Chittagong City Corporation ABM Mohiuddin Chowdhury. That disruption was followed by a slower demand from the buyers in the USA and the EU countries. The intensity of cold being less than previous years during the last winter in most EU countries, the demand for knitwear dropped this time. And in case of the USA, the consumers decided to spend less because of the rising oil prices. The RMG exporters view these developments as temporary and are hopeful about their exports picking up again in coming months. But the researchers on RMG markets are seeing some ominous signs on the horizon. They feel that the buyers, who had withdrawn from the Bangladesh and gone to other markets, may not come back again. However, the exporters, it seems, would have to keep their finger crossed for a major turnaround in demand for apparels in the developed markets. The political troubles have proved more damaging to exports than any other factor. If the same returns to the street-nobody, however, want that-the RMG exporters would find it really hard even to keep their existing buyers satisfied. 3.2 Current scenario of garment industry in Bangladesh In a recent exclusive interview given to fiber 2fashion, Mr Surinder Anand, Executive Secretary of Garment Exporter‟s Association, listing out the advantages the Bangladesh exporters have over India, had said, “First and foremost is the lower manufacturing cost due to cheap labor and simplified labor laws”. “Going further, economies of scale because of bigger and larger manufacturing units; availability of fabric at competitive rates, simplified procedures, labor laws are more flexible and conducive and last but not the least full support and blessings of their Government, while Indian conditions are discouraging to entrepreneurs”, he added by saying. Even in these recessionary periods, most of the garment companies had been humming with winter clothing orders and except for may be a slight dip in orders; the Bangladeshi clothing manufacturers are comfortably placed versus their Asian counterparts and could be among the few countries that could be looking at a flat or marginal negative growth rate in 2009. According to the statistics released by the Bangladesh Export Promotion Bureau, most of the sub-sectors like woven and knitted garment have crossed their targeted figures in the period July- December 2009. Knitted and woven garments grew by 2.16 and 2.45 percent respectively, textile fabrics by 8.16 percent and terry towels by 10.96 percent. Table 3.2.: Apparel Exports from Bangladesh in Value and Volume YEAR TOTAL APPAREL EXPORT (Millions of $) WOVEN Total Mont hly 199 1,240 103. 2-93 .48 37 1993- 1,291 107. 94 .65 64 199495 199596 199697 199798 199899(JUL YAUGU ST) 1,835 .09 1,948 .81 2,237 .95 2,844 .43 152. 92 162. 40 186. 50 237. 04 KNIT TOTAL APPAREL EXPORT (Thousands of dozens) TOTAL Gro wth WOVEN in Mon thly Tota ls Gro wth in Mont hly Total s KNIT TOTAL Total Mont hly 204. 17.0 1,445 120. 36,05 3,004 54 5 .02 42 3.88 .49 264. 22.0 1,555 129. 7.67 34,35 2,862 14 1 .79 65 % 1.00 .58 Total Mont hly 10,66 888.6 3.56 3 10,81 901.2 5.00 5 393. 26 598. 32 763. 30 937. 51 15,30 1.90 23,18 5.45 27,53 6.07 32,60 4.37 Total Mont hly 46,717 3,893 .44 .12 45,166 3,763 .00 .83 3.32 % 62,511 5,209 38.4 .90 .33 0% 72,005 6,000 15.1 .49 .46 9% 80,986 6,748 12.4 .40 .87 7% 98,194 8,182 21.2 .37 .86 5% Tot Mont Total Mon al hly thly 32.7 7 49.8 6 63.6 1 78.1 3 2,228 .35 2,547 .13 3,001 .25 3,781 .94 185. 70 212. 26 250. 10 315. 16 43.2 3% 14.3 1% 17.8 3% 26.0 1% 47,21 0.00 48,82 0.04 53,45 0.33 65,59 0.00 3,934 .17 4,068 .34 4,454 .19 5,465 .83 1,275 .16 1,932 .12 2,294 .67 2,717 .03 561.5 280. 177. 88.6 738.7 369. 17.2 12,18 6,093 6,464. 3,232 18,650 9,325 13.9 4 77 21 1 5 38 0% 6.00 .00 00 .00 .00 .00 6% Source: Bangladesh Exports Promotion Bureau (EPB) RDTI Cell of Bangladesh Garment Manufacturers and Exporters Association (BGMEA) Our own calculations of monthly averages and growth factors Table 3.3. Major Items of Apparel Exportedfrom Bangladesh (Millions of $) YEAR SHIRT T-SHIRT TROUSER JACKET SWEATER S Mont Mont Mon Mont Mont Total hly Tot hly Total thly Tota hly Total hly Aver al Aver Aver l Avera Avera age age age ge ge 1993- 805.3 67.1 225. 18.8 80.56 6.71 126. 10.57 0.00 0.00 94 4 1 90 3 85 1994- 791.2 65.9 232. 19.3 101.2 8.44 146. 12.24 0.00 0.00 95 0 3 24 5 3 83 1995- 807.6 67.3 366. 30.5 112.0 9.34 171. 14.31 70.41 5.87 96 6 1 36 3 2 73 1996- 759.5 63.3 391. 32.6 230.9 19.2 309. 25.77 196.6 16.38 97 7 0 21 0 8 5 21 0 1997- 961.1 80.0 388. 32.3 333.2 27.7 467. 38.93 296.2 24.69 98 3 9 50 8 8 7 19 9 1998- 201.1 100. 49.0 24.5 60.51 30.2 105. 52.63 81.61 40.81 99 2 56 5 3 6 25 (JULAUG) Source: Bangladesh Exports Promotion Bureau (EPB) RDTI Cell of Bangladesh Garment Manufacturers and Exporters Association (BGMEA) Our own calculations of monthly averages and growth factors Part Four: Analysis 4.1. SWOT Analysis SWOT analysis stands for Strength, weakness, opportunities and threats respectively. Here based on our observation we try to find out some aspects of SWOT analysis for the ready made garment industry in Bangladesh. 4.1.1 Strength Considerable Qualified/keen to learn workforce available at low labour charges. The recommended minimum average wages (which include Travelling Allowance, House Rent, Medical Allowance, Maternity Benefit, Festival Bonus and Overtime Benefit) in the units within the Bangladesh Export Processing Zones (BEPZ) are given as below; on the other hand, outside the BEPZ the wages are about 40% lower: Energy at low price Easily accessible infrastructure like sea road, railroad, river and air communication Accessibility of fundamental infrastructure, which is about 3 decade old, mainly established by the Korean, Taiwanese and Hong Kong Chinese industrialists. FDI is legally permitted Moderately open Economy, particularly in the Export Promotion Zones GSP under EBA (Everything But Arms) for Least Developed Country applicable (Duty free to EU) Improved GSP advantages under Regional Cumulative Looking forward to Duty Free Excess to US, talks are on, and appear to be on hopeful track Investment assured under Foreign Private Investment (Promotion and Protection) Act, 1980 which secures all foreign investments in Bangladesh OPIC's (Overseas Private Investment Corporation, USA) insurance and finance agendas operable Bangladesh is a member of Multilateral Investment Guarantee Agency (MIGA) under which protection and safety measures are available Adjudication service of the International Centre for the Settlement of Investment Dispute (ICSID) offered Excellent Tele-communications network of E-mail, Internet, Fax, ISD, NWD & Cellular services Weakness of currency against dollar and the condition will persist to help exporters Bank interest@ 7% for financing exports Convenience of duty free custom bonded w/house Readiness of new units to enhance systems and create infrastructure accordant with product growth and fast reactions to circumstances 4.1.2. Weakness Lack of marketing tactics The country is deficient in creativity Absence of easily on-hand middle management A small number of manufacturing methods Low acquiescence: there is an international pressure group to compel the local producers and the government to implement social acquiescence. The US GSP may be cancelled and purchasing from US & EU may decrease significantly M/c advancement is necessary. The machinery required to assess add on a garment or increase competence are missing in most industries. Lack of training organizations for industrial workers, supervisors and managers. Autocratic approach of nearly all the investors Fewer process units for textiles and garments Sluggish backward or forward blending procedure Incompetent ports, entry/exit complicated and loading/unloading takes much time Speed money culture Time-consuming custom clearance Unreliable dependability regarding Delivery/QA/Product knowledge Communication gap created by incomplete knowledge of English Subject to natural calamities 4.1.3. Opportunity EU is willing to establish industry in a big way as an option to china particularly for knits, including sweaters Bangladesh is included in the Least Developed Countries with which US is committed to enhance export trade Sweaters are very economical even with china and is the prospect for Bangladesh If skilled technicians are available to instruct, prearranged garment is an option because labor and energy cost are inexpensive. Foundation garments for Ladies for the FDI promise is significant because both, the technicians and highly developed machinery are essential for better competence and output Japan to be observed, as conventionally they purchase handloom textiles, home furniture and garments. This section can be encouraged and expanded with continued progress in quality 4.1.4. Threat The exporters have to prepare themselves to harvest the advantages offered by the opportunities. 4.2. The Future of Garment Exports and the Economy of Bangladesh Growth in overall exports from Bangladesh peaked in 1994-1995 at 40 percent a year, but growth has remained strong. In the July 1997-February 1998 period, total export earnings equaled $3.3 billion or 16.4% above the exports over the same period in the previous year.i The garment and knitwear exports accounted for the bulk of these exports. The knitwear sector especially has been highly dynamic in recent years. Given the fact that this market is outside the purview of MFA and not protected by quotas, this bodes well for the post MFA future of the industry. Bangladesh apparel exports can now point to a proven track record of successfully competing in a non-protected global competitive environment. Unfortunately, other potentially promising exports from Bangladesh such as leather, jute goods, and frozen foods have not fared as well over this period. This has accentuated the already narrow export base of the country and is certainly a matter of concern. The excess dependence on foreign exchange earnings and export growth on garments and knitwear calls for policy attempts to diversify the export base of Bangladesh. What can be said about the future performance of the apparel export industry in Bangladesh? What are the downside risks for apparel exports from Bangladesh? Focusing on the most recent disaster, the debilitating floods of 1998 that shaved off several percentage points from the expected GDP growth this year, we have ignored another major crisis the industry seems to have weathered very well. We refer to the East Asian economic debacle of 1997-1998. The financial panic and the following economic meltdown that afflicted scores of dynamic economies neighboring Bangladesh Malaysia, Indonesia, Thailand, Philippine and South Korea- certainly have been a restraining element in the economic performance of this sector. What are the links between the East Asian economies and garment exports from Bangladesh? There are several avenues by which negative economic shocks from these emerging economies have impacted Bangladesh. First, several of these nations are also big apparel exporters to the same markets where Bangladesh sells its apparels. The steep depreciation in their currency has made them more competitive, especially in the quotafree apparel markets. Even in the markets protected by quotas, this would be a deflationary force pulling down the unit prices and the profit margins for Bangladesh exporters. Second, using the time-tested formula, most of these economies are trying to export themselves out of their severe recessions. This has greatly increased competition for Bangladesh exports. Third, to assist them in their time of need, the U.S. and other developed nations have already relaxed quota restrictions on exports from the worst affected economies, making the playing field less level for Bangladeshi exporters. Fourth, prior to this crisis some of these nations were potentially big investors in Bangladesh in the textile and infrastructure projects. Their economic troubles have meant a dramatic scaling back in their direct investments in Bangladesh. Part Five: Conclusion Conclusion: At the starting verge of the twenty first century it is not possible for a country to move ahead grabbing the agriculture based economy. Garment industry in Bangladesh has helped Bangladesh to take it through and has been contributing significantly for the sustainable development. It has created employment for the young women in Bangladesh with the world of hope to be independent. Bangladesh can secure even a far better situation utilizing its advantage of low labor cost to capture more markets across wide world keeping its compotators behind. For that, government has to come forward to build up a stronger infrastructure and communication. References : www.alibaba.com www.tradeindia.com www.countryinformation.org http://www.unescap.org/tid/publication/aptir2456_haider.pdf