Concrete Anchorage

advertisement

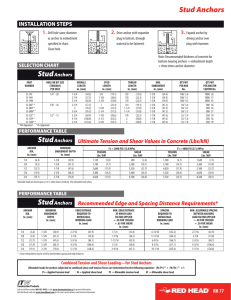

Concrete Anchorage By Jason Oakley, P.E. New Anchorage Design Requirements • • • • • • • Why Cracked Concrete? Structural Requirements (2006 IBC) Anchorage Design Provision (ACI 318 – App. D) Design Example Software that helps Evolution of anchorage Code Reports 1 Why Cracked Concrete? Stress Concentration 2 Studies Show… • Anchors lose capacity when in a crack – Ex: a crack width of 0.4 mm, losses are… are… CIP=25% expansion=40% 1.0 0.75 TC/TUCC 0.50 adhesives=50% 0.25 0.8 0.4 1.2 1.6 Crack Width (mm) When & Where to Use “Cracked Concrete” Anchors • “Tension Zone” Zone” • Any application where seismic forces are considered – Regardless of location (moderate/severe regions) 3 What makes an anchor work in CC? • Tri-segmented clip design – Grabs at least 2 sides of crack – Distributes loads more uniformly • redundancy • 2 Teeth per segment – Creates ledges when installed – Provides ‘secondary’ secondary’ expansion as crack cycles The code has changed • New Codes have adopted new • design provisions The new test standard addresses anchor performance in “cracked concrete” ’07 CBC ’06 IBC ACI 318 - App. D ACI 355.2 AC 193a – mechanical/screw AC 308 – bonded 4 Structural Requirements (2006 IBC) CIP / Post-installed Mech. Anchors • Per IBC 2006, Section 1911 – – – – Allowable Stress Design Approach Applies to castcast-inin-place anchors only Does not apply to postpost-installed anchors Earthquake loads not permitted 5 CIP / Post-installed Mech. Anchors • Per IBC 2006, Section 1912 – – – – Strength Design Approach Covers CIP and postpost-installed mechanical anchor Appendix D referenced Does not cover screw and bonded type anchors STRUCTURAL CIP / Post-installed Mech. Anchors --STRUCTURAL-- • Per 2006 IBC, Section 1908.1.16 – Concrete – Appendix D modified for SDC C/D/E/F: • Anchor steel must have ductile failure mode or • Fixture must yield at anchor nominal strength or • Design strength = 2.5 x factored forces non-ductile overstrength factor STRUCTURAL 6 Steel Failure L Steel Failure L 7 Steel Failure L Fuse L 8 Fuse Plastic Hinge Mp L Use over-strength factor Mu x 2.5 L 9 Anchorage Design Provision (ACI 318 – App. D) Anchorage Design Provision (ACI 318 – App. D) 10 Anchorage Design Provision (ACI 318 – App. D) Appendix D Strength Based Design Approach φNn > Nu φVn > Vu Design Strength > Factored load 11 ACI 318-05, Appendix D • Design equations check 6 different failure modes – Steel capacity • Tension and Shear – Concrete breakout capacity • Tension and Shear – Pullout/Pull-through capacity • Tension only – Concrete Pryout • Shear only. ASD method used safety factors 12 USD considers the spread of the data 13 Concrete Breakout Strength (Tension) Concrete Breakout Strength (Tension) 100000 80000 60000 40000 20000 0 0 2 4 6 8 10 12 14 Concrete Breakout Strength (Tension) What happens when we get close to an edge? Concrete Breakout Strength (Tension) 15 Concrete Breakout Strength (Tension) Not considered suppl. Reinf.!! Concrete Breakout Strength (Tension) Suppl. Reinf. (CIP) Only 7 to 20% increase in CBS! (PI) 16 Concrete Breakout Strength (Shear) Concrete Breakout Strength (Shear) Capacity doubles! 17 Concrete Breakout Strength (Shear) Must use rational engineering judgment: 100” 100” 100” 5” • (1) 5/8” 5/8” x 55-1/8” 1/8” emb. Î Shear = 6,800 lbs • (2) 5/8” 5/8” x 55-1/8” 1/8” emb. Î Shear = 7,025 lbs!! Treat as one anchor if adjacent anchor is greater than 3 x hef away Concrete Breakout Strength (Shear) Flaw of ’05 ACI-318 App. D….. Ψh,V (added in ’08 ACI 318) See: “Shear Toward a Free Edge” paper by Burdette Code fix: Ψh,V = [1.5 x ca1 / ha ]1/2 18 Concrete Breakout Strength (Shear) Ψh,V makes a big difference...... ca1 No Ψh,V Î ca1 = 160” Include Ψh,V Î 37.5” Big difference? Concrete Breakout Strength (Shear) Btw, lightweight concrete factor is not correct….. Should be 0.6…software uses 0.6, not 0.85 19 Simple Design Example Strong Bolt (ESR(ESR-1771) Example (STB) (8d) 5” 1 kip @ 45 deg. hef = 4-1/2” 5/8” Strong-Bolt CC / SDC F / STRUCTURAL 20 Example (Strong-Bolt) TENSION • Steel • • – Ns = 1 x 0.167 x 125,000 = 21 kips Concrete 0.5 1.5 – Nb = 17 x (4,000) 4.5 = 10.3 kips [basic] – Ψed,N = 0.7 + 0.3 x 5 / (1.5 x 4.5) = 0.92 [edge] – Ψc,N = 1.0 [cracked] – Ψcp,N = 1.0 [does not apply to CC] 2 – Anc = (5 + 1.5 x 4.5) x (2 x 1.5 x 4.5) = 159 in [edge] 2 2 – ANno = 9 x 4.5 = 182 in [1 anchor; no edge] – Ncb = 159/182 x 10.3 x 0.92 x 1.0 x 1.0 = 8.3 kips Pullout 0.7 – Npn,cr = 5,200 x (4,000/2,500) = 7.2 kips Example (Strong-Bolt) TENSION • Steel • • – φNs = 0.75 x 21 kips = 16 kips [ductile steel] Concrete – φNcb = 0.65 x 8.3 kips = 5.4 kips [no supplementary reinf.] Pullout – φNp = 0.65 x 7.2 kips = 4.7 kips Pullout governs 21 Anchor Categories Example: • Anchor A: Reference Test = 10000# Reliability Test = 8600# w = 0.012” w = 0.020” φ 8600#/10000# = 0.86 0.65 0.55 0.45 Example (Strong-Bolt) SHEAR • Steel • • – Vsa = 9.7 kips Concrete – Vb = 7(4.5/0.625)0.2(0.625)0.5(4,000)0.5(5)1.5 = 5.8 kips – Ψed,V = 1.0 – Ψc,V = 1.0 [cracked] 2 – AVc = 2 x (1.5 x 5) x (1.5 x 5) = 113 in [edge] 2 2 – AVco = 4.5 x 5 = 113 in – Vcb = 113 /113 x 1.0 x 1.0 x 5.8 = 5.8 kips Pryout – Vcp = 2 x 8.3 = 16.6 kips 22 Example (Strong-Bolt) SHEAR • Steel • • – φVs = 0.65 x 9.7 kips = 6.3 kips [ductile steel] Concrete – φVcb = 0.70 x 5.8 kips = 4.1 kips [no supplementary reinf.] Pryout – φVp = 0.70 x 16.6 kips = 11.6 kips Concrete governs Example (Strong-Bolt) 0.75 x φNcb = 0.75 x 4.7 k = 3.5 kips 0.75 x φVcb = 0.75 x 4.1 k = 3.1 kips NDOF 2.5 x 0.707 x Pmax 2.5 x 0.707 x Pmax + = 1.2 3.5 3.1 Pmax = 1.1 kips > 1 kip …OK Pmax 0.707Pmax 0.707Pmax 23 Reality Check Time • CC/UCC = 0.65 to 0.8, call it 0.70 • Seismic: 0.75 factor (code: SDC C, D, E or F) • Then you apply phi factor: • • – 0.65 (cat. 1) What is left? – 0.7*0.75*0.65 = 0.34 If we assume 15% COV for CC tests N5%=0.49Navg_ult: – 0.34/1.1*0.49 = 0.15*Navg_ult (S.F. = 6.6) – Oh, and if it’s not ductile, divide by 2.5! (S.F. = 16) Ultimate Strength Design (USD) 4” 6” Anchor Software 4” Nua Tension (lbf) Shear (lbf) No Edge 3,000 1,900 4” single edge 3,000 900 4” double edge 3,000 550 Vuay ½” x 3-7/8” emb. STB 24 Evolution of Anchorage Bonded Anchors 25 In the “old” days - ASD ****TENSION**** Dia. Emb. Edge 5/8 5” 7-1/2” 1/2” 6,700 lbs 2,100 lbs Bonded TCA 5/8 5” 4-1/2” 1/2” 1-3/4” 3/4” 2-1/2” 1/2” 3,300 lbs 3,700 lbs 1,400 lbs Bonded anchor was dominant! Bonded anchor evolution (5/8” dia. x 5” emb. in 4 ksi NWC) Old adhesive New adhesive TCA (CC) ** ASD TENSION “prev.” prev.” ESR (UCC) LARR (UCC) New Code/ESR (CC)** Critical Edge 8.9 k @ 7.5” 7.5” 6.4 k @ 7.5” 7.5” 2.1 k @ 12.5” 12.5” 1.3 k @ 9” 9” Min. Edge 4.3 k @ 1.75” 1.75” 3.1 k @ 11-7/8” 7/8” 750 lbs @ 33-1/8” 1/8” 1.3 k @ 5” 5” 50% loss 19-D or 1911.2 **2.5 NDOF included 26 Double anchor example (AC 308) What’s the ASD value for a “dry”, “structural” connection in CC and SDC C – F for (2) ½” ATR x 9” emb.? ASD = 0.65 x [(105 / 74) x 0.98 x 0.95 x 1.0 x 0.19] x 15,200 / 1.1 / 2.5 = 0.65 x 0.25 x 15,200 / 1.1 / 2.5 = 0.059 x 15,200 = 900 lbs [bond strength governs] Cracked Concrete ……compared with single anchor (AC 58) 1.75” Take (1) ½” ATR x 6” emb. @ 1-3/4” – What do we get? Live pull test = 10 to 12 kips (steel fails 90% of the time – witnessed by almost 1,000 eng./arch./plan checkers, contractors, etc.) 18,556 x 0.59 = 11 kips (coincidence?) ASD (old) = 11 / 4 x 1.33 = 3,650 lbs 3650 lbs vs. 900 lbs. @ ½ the edge @ 3” less emb. Cracked Concrete @ ½ the anchors 27 28 Shear walls (ASD / 2006 I.B.C.) 4’ 5/8” dia. 8’ “a” Wood “b” CIP Max Tension 8” emb SETSET-XP 41.5” 8” emb IXP 6-5/8” 5/8” emb **ductile a b Tension 3-3/4” 3/4” 12” 12” 8” 12” 12” 2.7 k 8.9k 1-3/4” 3/4” 10” 10” 8” 10” 10” 1.2k 2.7k 6-5/8” 5/8” 10” 10” 8” 10” 10” 1.7k 2.5k ** Shear walls (ASD / 2006 I.B.C.) 4’ 5/8” dia. 8’ “a” Wood “b” CIP Max Tension 8” emb SETSET-XP 41.5” **ductile 8” emb IXP 6-5/8” 5/8” emb a b shear 3-3/4” 3/4” 12” 12” 8” 12” 12” 290 plf 960 plf 1-3/4” 3/4” 10” 10” 8” 10” 10” 130 plf 295 plf 6-5/8” 5/8” 10” 10” 8” 10” 10” 190 plf 280 plf ** 29 Shear walls (ASD / 2006 I.B.C.) Titen HD 2,500 psi NWC / CC / USD 1-3/4” 567 plf (140 lbs/bolt!) ½” THD x 3-1/4” emb. 5” 3” typ. Wood allowable = 1,040 lbs / bolt 30 2006 IBC Compliant Code Reports • Current – ESR 1771 (Strong(Strong-Bolt) • Concrete / LWCMD – ESR 2138 (pins) • Concrete / Steel / CMU / LWCMD • Pending – SET XP • Concrete – Titen HD • Concrete – Torque Cut – ESR 1772 (SET) • Concrete • CMU / URM – ESR 1056 (Titen HD) • CMU – ESR 1396 (Wedge(Wedge-All) • CMU Questions 31