2.2.3 Phase equilibrium - IFP Energies nouvelles e

5010_ Page 63 Vendredi, 6. avril 2012 2:20 14

> STDI FrameMaker Couleur

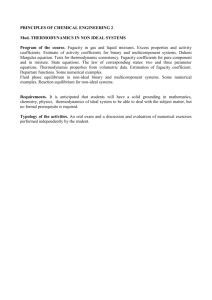

Chapter 2 • From Fundamentals to Properties

V =

U =

H =

A =

G =

S =

Table 2.15 Total properties from an excess approach

Pure component

Real mixture

Ideal mixture

Mixing contribution i

N

∑

= 1

N v

* i

N

∑

= 1

N u

* i

N

∑

= 1

N h

* i

N

∑

= 1

N a

* i

N

∑

= 1

N g

* i

N

∑

= 1

N s

*

+

+

+

+

+

–

RT

RT i i

N

∑

= 1

N

∑

= 1

N

N

0

0

0 i i ln ln

R i

N

∑

= 1

N i ln

( x i

(

( x x

) i i

)

)

+

+

+

+

+

+

Excess property i

N

∑

= 1

( i

− v i

* i

N

∑

= 1

( i

− u i

* i

N

∑

= 1

( i

* i

N

∑

= 1

( i

− a i

* i

N

∑

= 1

( i

− g i

* i

N

∑

= 1

N s

(

− s i

*

)

)

)

)

)

)

(2.104)

(2.105)

(2.106)

(2.107)

(2.108)

(2.109)

63

2.2.3 Phase equilibrium

2.2.3.1 Some basic principles for phase calculations

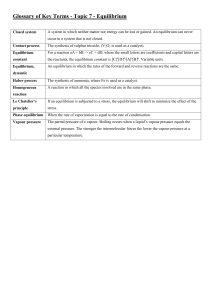

A. The phase equilibrium condition

According to the thermodynamic principles, equilibrium is reached, considering the constraints on the system and at given pressure and temperature, when the Gibbs energy is lowest (see equation (2.19)). It can be shown that this minimum leads to the statement that the chemical potential is identical in all phases, for any component i. For two phases α and

β , this is written as:

μ i

α = μ i

β

(2.110)

For a two-phase equilibrium, equation (2.110) provides as many relationships as components in the mixture ( ). For an equilibrium with φ phases, written.

N N

(

φ − 1

)

relationships can be

Using the definition of the fugacity (2.53), the same rule can be written as: f i

α = f i

β

(2.111)

5010_ Page 64 Vendredi, 6. avril 2012 2:20 14

> STDI FrameMaker Couleur

64 Chapter 2 • From Fundamentals to Properties a. The vapour phase fugacity

The vapour phase fugacity is always expressed using the residual approach.

f i

V = Py ϕ V where

(2.112)

P total pressure; y i

vapour mole fraction of component i ; ϕ i

V vapour phase fugacity coefficient of component i . This property is computed with an equation of state using (2.72). In the limit of low pressure (below 500 kPa), the ideal gas approximation can be used, which states: ϕ i

V = 1.

b. The liquid phase fugacity

The fugacities in the liquid phase can be computed using either the residual or the excess approach (see also the FFF – Famous Fugacity Formulae – of O’Connell [4, 27]).

Using the residual approach , i.e.

with an equation of state, the same expressions can be written as for a vapour phase: f i

L = Px ϕ L (2.113) with x i

liquid mole fraction of component i ; ϕ i

L liquid phase fugacity coefficient of component equation of state using (2.72).

i . This property is computed with an

Using the excess approach , the fugacity is calculated using the definition of the activity coefficient (2.97): f i

L = f i

L *

(

,

)

γ x (2.114)

The most general expression for the liquid phase fugacity is given by: f i

L = f i

L * γ x = P i ϕ i

℘ γ x (2.115) where

• exp

⎝⎜

⎛ 1

RT

∫ P

P i

σ v dP

⎞

⎠⎟

≈ exp

⎜

⎝

⎜⎜

⎛ v i

L

(

− i

σ

)

RT

⎟

⎠

⎟

⎞ is the Poynting correction that uses

• v ϕ i

L i

σ

, the liquid molar volume of component vapour phase (equation (2.72); i at T

is the fugacity coefficient of component

and assumed to be independent of i

P ;

at saturation calculated using the

• γ i

is the activity coefficient of component i in the liquid.

When the vapour pressure of component i , P i

σ is lower than 500 kPa ( i.e.

most often, except for very light components), the pure component liquid fugacity can be approximated as: f i

L * = P i

σ

(2.116)

5010_ Page 65 Vendredi, 6. avril 2012 2:20 14

> STDI FrameMaker Couleur

Chapter 2 • From Fundamentals to Properties 65 c. Excess approach with the asymmetric convention:

The use of expression (2.114) assumes that component i exists as a pure liquid in the pressure and temperature conditions of the mixture (or at least that its properties can be calculated in these conditions). This may be a strong restriction (e.g. supercritical gases or ionic species).

This is why the use of the excess approach is extended by defining a generalised reference state.

f i

L = x f

, γ i

( ref ) (2.117)

This reference state can be the pure component, in which case equation (2.114) is recovered, but it also can be user-defined (often at infinite dilution). The exponent (ref) is added to the activity coefficient in order to indicate that its value depends on the reference state chosen.

Figure 2.14a shows, for the example of a binary mixture, how the fugacity varies with composition. Each component has its own fugacity (in the same way as each component has its own chemical potential). In the limit of zero concentration of component 1 , its fugacity tends to zero, while the fugacity of the other component is f

2

* (and vice-versa). If the plot had been linear between these two end-points, the mixture would have been ideal according to Raoult’s law ( γ i

= 1 in equation (2.114) yielding equation (2.85)).

f = f

1

* Henry's law of solute in solvent f = f

2

*

Fugacity of solvent

Fugacity of solute f = f

2

*

Fugacity of solvent f f f

1

*

Raoult's law for solute

Fugacity of solute

0

Solvent

Raoult's law for solvent x

1

1

Solute

0

Solvent

Raoult's law for solvent x

1 a) Symmetric convention b) Asymmetric convention

Figure 2.14

Fugacities for symmetric and asymmetric conventions, at fixed temperature and pressure, and variable composition for a binary mixture.

1

Solute

In case one of the components is supercritical (say component 1), the right side of the diagram becomes unphysical (figure 2.14b). Only the left side of the diagram has a physical significance: component 2 is a liquid, and is called the solvent . Component 1, that does not exist in the liquid state at the given temperature and pressure conditions, is called the solute .

As a result, it is impossible to determine f

1

L * in equation (2.114). Equation (2.117) needs to be used, and a specific reference state needs to be defined for this solute. An alternative

5010_ Page 66 Vendredi, 6. avril 2012 2:20 14

> STDI FrameMaker Couleur

66 Chapter 2 • From Fundamentals to Properties method, based on the slope at infinite dilution, may be used to calculate its fugacity: the

Henry constant , defined as:

H

σ i s

(

T

)

= x i lim

→ 0 s

σ

⎜

⎛

⎝

⎜ f i

L

(

,

) x i

⎟

⎞

⎠

⎟

(2.118)

In other words, the reference state used for defining the component’s properties is taken at infinite dilution (as shown in table 2.16). Note that the Henry constant is necessarily defined at the solvent’s vapour pressure (this is where the solute concentration is zero) and is therefore not a function of pressure. In order to account for pressure, a Poynting correction must be considered. This is why the liquid fugacity for the solute is now calculated as: f i

L = H ℘ ∞ γ H x i

(2.119) where, in addition to the Henry constant, the following factors are used:

• the dilute Poynting correction:

℘ ∞ i

( )

= exp i

∞

(

RT s

σ

)

(2.120)

•

(

It requires the infinite dilution partial molar volume of component i in the solution v i

∞

). This factor is close to one if the pressure is less than 2 MPa above the solvent vapour pressure ( P s

σ

), the “asymmetric” activity coefficient, γ i

H

(

T , x

)

, that is computed using the same type of models as the symmetric activity coefficient. It is related to the symmetric activity coefficient in such a way that at infinite dilution in the solvent ( asymmetric activity coefficient becomes one: x i

= 0 ), the

γ i

H

(

T , x

)

=

γ ∞

γ

( i

(

T , x

)

, i

= 0

) (2.121)

) i where γ i

∞

(

T x i

= 0 is the activity coefficient of the solute at infinite dilution of component i in the solute given by the symmetric activity convention.

Expression (2.119) is only used for the solutes. For the solvents, equation (2.115) remains valid. This is why, in a solvent + solute mixture, this approach is called asymmetric

convention (the definition of the reference state, as used in (2.117), is different depending on the type of component).

In fact, the use of the asymmetric convention can be extended to all cases where the solutes are in low concentration in a phase:

• gases dissolved in a liquid (they do not exist as pure liquids under the pressure and temperature conditions of the system) [28];

• all solutes (including liquids) in an aqueous phase (their properties are very different from those of the pure component) [29, 30];

• ions in an aqueous phase (they do not exist as ionic species in a pure state).

5010_ Page 67 Vendredi, 6. avril 2012 2:20 14

> STDI FrameMaker Couleur

Chapter 2 • From Fundamentals to Properties 67

Table 2.16 Possible reference states of components

Convention Component Temperature

Symmetric

Pressure Composition Phase

Solute

…………………………

T

System

P

System

Pure

……………………………………

Liquid

…………………

Solvent T

System

P

System

Pure Liquid

Asymmetric

Solvent

…………………………

T

System

P

System

Pure Liquid

…………………

Solute T

System

P Infinite dilution in the solvent

Liquid

It is important to note that as a result of its definition (2.118), the Henry constant is not a pure component property, but rather a binary, as it depends both on the solute (i) and on the solvent (in which i is diluted). This is why in mixed solvents, an exact definition as given by

(2.118) becomes quite difficult, and a mixing rule is required. Carroll [31] suggests the use of ln H = solvents

∑ j x j ln H + solvents

∑ j solvent

∑ ss

(2.122) where H is the Henry constant of solute i in solvent j. The a jk

parameters must be fitted on experimental values. It becomes very simple when a jk

= 0.

A useful summary of the use and mis-use of Henry’s law is given by Carroll [32]. Some additional comments on this issue are provided in section 3.4.3 (p. 189).

d. The solid phase fugacity

Calculating this fugacity requires a specific approach which depends on the phase being looked for. The most general is the excess approach: f i

S = x f i

S * γ i

S (2.123)

In cases where the solid phase is a pure component, no activity coefficient γ i

S is required. However, the solid phase is sometimes a mixture, in which case this coefficient must be taken into account. The models for the solid phase activity coefficient are generally identical to that for the liquid phase (Coutinho [33]).

The pure component solid fugacities are calculated using the fact that at their crystallisation temperature, the phase equilibrium condition holds (2.111): f i

L *

(

T

F i

, P

,

)

= f i

S *

(

T

F i

, P

,

)

(2.124) where the subscript F stands for the crystallisation or fusion conditions. In order to calculate f i

L *

(

T P

)

at the system pressure and temperature, the fundamental equations (2.30) and

(2.36) are used. The derivation can be found in numerous thermodynamics handbooks

(e.g. Vidal [34]). The resulting expression is: ln

⎜

⎝

⎜

⎛ f i

S *

(

, f i

L *

(

T

,

, P

,

)

)

⎟

⎠

⎟

⎞

=

Δ h

RT

F ,, i

⎜

⎛

⎝

⎜

1 −

T

T

⎟

⎞

⎠

⎟

+

Δ c

R

, ,

⎢

⎣

⎢

⎡

T

T

, ln ⎜

⎛

⎝⎝

⎜

T

T ⎥

⎦

⎥

⎤

⎟

⎞

⎠

⎟

+

Δ v

(

−

RT

)

(2.125) where Δ h

,

= h i

L − h i

S is the enthalpy of fusion of component i (taken at T and P );

5010_ Page 68 Vendredi, 6. avril 2012 2:20 14

> STDI FrameMaker Couleur

68 Chapter 2 • From Fundamentals to Properties

Δ c

, ,

= c L

,

− c S

, and the solid phase.

is the difference in molar isobaric heat capacity between the liquid

Δ v

,

= v i

L − v i

S is the molar volume difference upon fusion, taken at T and P

Once again, this property is considered constant with respect to pressure and temperature.

.

This volume is generally small and has little influence on the final result when P P

F,i too large. Often, it is considered independent of temperature.

is not

B. The distribution or partition coefficient

In practice, vapour-liquid phase equilibria are often calculated using the so-called distribution coefficient , “equilibrium coefficient” or “equilibrium ratio”, which describes, for each component i , the ratio of molar fraction in the vapour phase and in the liquid phase:

K i y i x i

(2.126)

According to the phase equilibrium relationship (2.111), the distribution coefficient can be computed using either a similar (residual) approach in both phases, or a different (residual and excess) approach in each phase. The former case is called a homogeneous method (or phi-phi), the latter a heterogeneous method (or gamma-phi). This is summarised in table 2.17.

Approach homogeneous ( ) heterogeneous, symmetric ( heterogeneous, asymmetric (

Table 2.17 Nomenclature of the thermodynamic methods

)

)

Vapour fugacity calculation Liquid fugacity calculation

Residual approach

Residual approach

Excess approach, symmetric convention

Excess approach, asymmetric convention

Using equations (2.112) and (2.113), the homogeneous method results in:

K i

= ϕ i

L ϕ i

V

(

( x y

)

)

(2.127)

In the heterogeneous approach, equation (2.112) is combined with (2.115) (symmetric convention), to yield:

K i

=

( )

℘

P i

( ) ϕ i

σ

( ϕ i

V

( i

σ

)

γ i y

(

))

T , x

)

(2.128)

In cases where the pure component i has no vapour pressure, or when its pure component properties are difficult to find, the asymmetric convention is used for the solutes (equation 2.119) , to yield:

5010_ Page 69 Vendredi, 6. avril 2012 2:20 14

> STDI FrameMaker Couleur

Chapter 2 • From Fundamentals to Properties 69

K i

=

H

σ

,

(

T

)

℘ i

∞ ( )

γ i

H

(

T

)

P ϕ i

V

(

, x y

) (2.129)

It is worth noting that, depending on the mixture and pressure conditions, the heterogeneous approach allows a number of simplifications that are of great use for understanding phase behaviour and identifying trends:

• When the process pressure is low (below 0.5 MPa), all fugacity coefficients may be considered equal to one. In addition, the Poynting corrections may then also be neglected. This considerably simplifies equations (2.128) and (2.129). They become:

=

P

(

(2.130) and

K i

K i

=

H

(

T

P i

H (2.131)

Equation (2.130) is very often used for low pressure non-ideal mixture, and its effect on the phase diagram will be discussed in section 3.4.1 (p. 160).

Equation (2.131) is generally further simplified assuming that the solute is very diluted, and as such that γ i

H

(

T , x

)

is very close to unity:

K i

=

H

σ

,

(

T

)

P

(2.132)

This last equation is sometimes known as the simplified Henry’s law [32].

• When the liquid phase forms an ideal mixture , then the activity coefficient in equation (2.130) becomes unity, and Raoult’s law is found:

K i

=

P

( )

(2.133)

Using (2.126), this law is also written as:

( )

= y P (2.134) where the right hand side of the equation is sometimes called the partial pressure of component i. Since the sum of the partial pressures equals the total pressure, (2.134) leads to:

P = ∑ i

( )

(2.135)

Equation (2.135) clearly shows the consequence of Raoult’s law on the vapour-liquid equilibrium on an isothermal Pxy plot (as shown in figure 2.5 in section 2.1.3.2, p. 30): the bubble pressure is a straight line. This is in fact what is observed for mixtures of like components (e.g. alkanes of similar size). It is important to note that Raoult’s law implies that the composition be given in mole fraction, which is the second reason why molar fractions, rather than weight fractions are used in thermodynamic calculations.

5010_ Page 70 Vendredi, 6. avril 2012 2:20 14

> STDI FrameMaker Couleur

70 Chapter 2 • From Fundamentals to Properties

For liquid-liquid equilibria the distribution coefficient required is defined by:

K i

αβ x x i

α i

β

(2.136)

If the excess approach is used, we obtain from equation (2.115) the expression:

K i

αβ

= f f i i

L *

L * γ

γ i

α i

β

=

γ

γ

( ) i i x

α

( x

α

) (2.137)

The pure component liquid fugacity (the vapour pressure) has no effect on liquid-liquid phase split. The activity coefficient model is often identical in both phases. The only difference between nominator and denominator in equation (2.137) is due to the composition difference between the two phases.

It may be of interest to note that the heterogeneous approach (different model in different phases) can also be used for liquid-liquid phase split (in particular when the phases are very different, as for example an aqueous and an organic phase). The asymmetric convention can then be employed, using a Henry constant for calculating the fugacity of dilute components (e.g. hydrocarbons in the aqueous phase). In this case, equation (2.137) becomes, in the same way as (2.132) (where a specific activity coefficient model is used in each phase):

K i

αβ

=

H

,

(

T

( )

) γ

γ i

H i

α

, β

(

(

T

T

,

, x

β x

α

)

) (2.138)

The ratio of activity coefficients is in this case often neglected, as the concentration in the dilute phase ( β ) is very small, and the other phase ( α ) is considered almost ideal.

C. Flash calculation (the set of equations and unknowns)

The discussion proposed below focuses on the case of two-phase vapour-liquid equilibria.

The same principles are also valid, however, for liquid-liquid, liquid-solid or vapour-solid equilibrium calculations. The equilibrium coefficient must then be defined as the ratio of molar compositions of the two phases present. When more than two phases are present, the number of equations and number of unknowns increases but the basic principles remain the same. More details concerning the algorithmic implementation of the calculations are available elsewhere (Rachford and Rice [35], Michelsen [36, 37]).

In any of the equations (2.127), (2.128) or (2.129), clearly the liquid and vapour compositions ( x and y ) must be known before the distribution coefficient can be calculated. But since the objective of the phase equilibrium calculation is precisely to calculate these compositions, it is clear that an iterative algorithm should be used.

Duhem’s phase rule (section 2.1.4, p. 41) indicates that two state variables are sufficient to calculate the composition and properties of all phases present, provided that the feed composition is known. In the remainder of this document, the feed compositional vector is written as z in order to differentiate it from the liquid ( x ) and the vapour ( y ) compositions.

Consequently, we will call the phase equilibrium calculation (flash) depending on the type of the two state variables given (see also Table 2.7).

5010_ Page 71 Vendredi, 6. avril 2012 2:20 14

> STDI FrameMaker Couleur

Chapter 2 • From Fundamentals to Properties 71 a. PT, T θ or P θ flash

Any phase property can be calculated knowing its composition, pressure and temperature.

The vapour fraction (ratio of mole number in the vapour phase with respect to the total mole number, ( θ = N V N ) must also be known in order to evaluate the material balance. Hence, the basic equations are identical for PT , T θ or P θ flash calculations:

• The iso-fugacity condition (2.111): f i

L = f i

V (2.139) which, using one of equations (2.127), (2.128) or (2.129) for calculating K i as:

, can be written x K = y i

(2.140)

Note that there are two phases in equilibrium, resulting in as many equations as components in the mixture ( N ). If there had been three phases, the iso-fugacity condition would have given rise to 2 N equations, and so on ( N more equations for each additional phase).

• The mass balance equations:

& i

= & i

+ & i z

(

1 θ

) x i

+ θ y i

(2.141)

If more phases had been present, there would have been more terms on the right hand side of the equation, but the number of equations would be the same.

As unknowns, we have the composition vector of the phases (liquid x , and vapour y ), in addition to the vapour fraction θ (in the case of a PT flash). This makes 2 N + 1 unknowns in the case of a two-phase flash. An additional equation is required to solve the problem. It is found by the simple consideration that the sum of all molar fractions must be one. This sum can be applied to the liquid (

N

∑ x i i = 1 equation general, it is replaced by:

= 1 ), or to the vapour (

N

∑ = i = 1 y i

1 ). In order to keep the i

N

∑

= 1 x i

− i

N

∑

= 1 y i

= 0 (2.142)

Rachford and Rice (1952) [35] propose to substitute (2.140) into (2.141) resulting in:

⎧

⎪ x i

⎨

⎪ y i

=

=

1 + θ

( z i

K i

− 1

)

1 + θ

(

K i

− 1

)

(2.143)

These values of x i and y i can now be substituted in (2.142), which yields: i

N

∑

= 1

1 +

(

K i

θ

−

K i

1

) z i

(

− 1

) = 0 (2.144) which is known as the Rachford-Rice equation very often used inside computer algorithms.

5010_ Page 72 Vendredi, 6. avril 2012 2:20 14

> STDI FrameMaker Couleur

72 Chapter 2 • From Fundamentals to Properties

Summing up, the unknowns in a PT flash are K i to be solved are:

and θ ( i.e.

N + 1 unknowns), and the equations

⎧

⎪ K i

⎪

⎪

⎩ i

N

∑

= 1

= ϕ ϕ V i i

L

1 +

(

K i

θ

− 1

K i

) z i

(

− 1

) = 0

(2.145)

One possible procedure to solve the equations (known as successive substitution) is as follows:

1. Estimate the missing piece of information, θ

2. Estimate the distribution coefficients K i

3. Use (2.143) to calculate x i and y i

4. Improve the evaluation of K i

using equations (2.127), (2.128) or (2.129)

5. Evaluate a better θ from (2.144)

a

6. If θ is different from its previous value, return to 3, otherwise the answer is reached.

a A Newton-Raphson method is suitable for this equation [38], [39].

Similarly, a P θ flash (bubble or dew temperature calculation for example), the unknowns are K i and T ( i.e.

N + 1 unknowns), and the equations to be solved are again:

⎧

⎪ K i

⎪

⎪

⎩ i

N

∑

= 1

= ϕ ϕ V i i

L

1 +

(

K i

θ

− 1

K i

) z i

(

− 1

) = 0

Note that, for bubble point calculations, θ = 0, and z i

= x i

; so (2.144) becomes:

(2.146)

N

∑ = i = 1

1

Similarly, for dew point calculations, θ = 1, and z i

= y i

; so (2.144) becomes:

N

∑ i = 1

( y K i

)

= 1

(2.147)

(2.148)

One possible procedure to solve the equations is as follows:

1. Estimate the missing piece of information, T

2. Estimate the distribution coefficients K i

3. Use (2.143) to calculate the unknown phase composition

4. Solve for the temperature using simultaneously equations for K i

(2.128) or (2.129)) and (2.147) or (2.148).

calculations (for example (2.127),

5010_ Page 73 Vendredi, 6. avril 2012 2:20 14

> STDI FrameMaker Couleur

Chapter 2 • From Fundamentals to Properties 73

A T θ flash is conceptually identical to the P θ flash, except that the unknown is the pressure P instead of the temperature T .

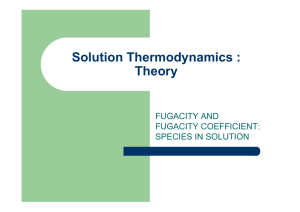

Example 2.7 Distillation column

A mixture of light hydrocarbons is processed in a distillation column (see figure 2.15).

Compositions of distillate obtained from the total condenser and of the residue at the bottom of the column are as follows (see table 2.18):

V n

Stage n L n + 1

D

F

B

Figure 2.15

Sketch of a distillation column.

Component

Propane iso-Butane n -Butane iso-Pentane n -Pentane

Table 2.18 Distillate and residue composition for example 2.7

Distillate

0.23

0.67

0.10

Residue

0.02

0.46

0.15

0.37

a. What is the column pressure to obtain the specified distillate if temperature in the condenser drum is 120 °F? (The pressure drop in column, exchanger and drum will be neglected).

b. What is the temperature in the upper stage and the composition of the liquid pouring off this plate (stage n on the figure)?

c. What is the temperature in the reboiler?

Use the Scheibel and Jenny diagram (figure 2.16) to evaluate the distribution coefficients.

5010_ Page 74 Vendredi, 6. avril 2012 2:20 14

> STDI FrameMaker Couleur

74 Chapter 2 • From Fundamentals to Properties

Analysis: a. In the condenser, the liquid composition is known. Since a liquid in equilibrium with a vapour is at its bubble point, the pressure is the bubble pressure. The pressure is a constant in the column.

b. The overall mass balance around the condenser indicates that all flows have the same composition. Hence, the vapour leaving the top plate of the column has the distillate composition. In addition, this vapour is saturated and is therefore at its dew point. As pressure is known (as calculated in a.), temperature has to be computed (dew temperature) and liquid composition will be part of the answer.

c. The residue from the reboiler is also a liquid phase. Pressure is unchanged, so bubble temperature must be calculated.

Components are all light hydrocarbons and we are told to use the Scheibel and Jenny procedure. This procedure assumes an ideal mixture (equilibrium coefficients are independent of composition) and is more suitable than Raoult’s law at expected working pressure (10 bar).

All calculations are relative to vapour-liquid equilibrium and none of the hydrocarbons in the mixture is at supercritical conditions.

Solution: a. A bubble pressure is calculated using (2.147), the distribution coefficients K i

N

∑

K x = 1 . In order to be able to read i = 1

in the Scheibel & Jenny diagram, both pressure and temperature are needed. A first pressure must be guessed, so distribution coefficients can be read on the nomograph. Raoult’s law can be used as a first approximation:

P = i

N

∑

= 1

P x i

. The estimated pressure is 8.5 atm.

Now a line must be drawn between the points T = 120 °F and P = 8.5 atm. The three K i values are read on the figure. On the first attempt, the sum is not equal to 1 (see table 2.19). A different guess must be made. A basic trick consists in multiplying the old pressure by the sum of the vapour phase compositions ( P = P

( n − 1 )

N

∑

). Due to i = 1 the poor accuracy of the graphical method, the solution can be considered to be reached in the second iteration. The bubble point of the mixture is 8.4 atm.

This procedure is summarised in table 2.19.

Table 2.19 Bubble pressure calculation procedure at 120 °F

Component

Propane iso-Butane n -Butane x i

P i

σ

0.23

16.5

0.67

6.3

0.10

4.6

K i

1.68

0.8

0.6

) y i

= K x

0.387

0.543

0.062

K i

1.7

0.82

0.62

) y i

= K x

0.39

0.55

0.06

Sum/Result 8.5

0.991

1.00

5010_ Page 75 Vendredi, 6. avril 2012 2:20 14

> STDI FrameMaker Couleur

Chapter 2 • From Fundamentals to Properties

15

1

0.9

0.8

10

9

8

7

0.6

0.5

6

0.4

5

0.3

4

500

200

180

160

140

120

400

300

250

100

90

80

70

60

30

20

4

7

6

10

9

8

5

50

3

40

30

25

2

20

3

0.2

-15

5

6

7

8

9

10

0.8

1.2

0.25

1

0.3

0.1

1.5

15

0.3

20

2

0.4

0.8

.03

.02

30

3

40

4

50

60

5

70

1.5

80

90

100

150

2

10

200

300

3

15

400

500

600

700

4

20

5

6

7

30

8

10

40

50

0.5

0.6

0.7

0.8

1

1.5

2

3

100

4

2

1

0.5

0.7

0.8

1.5

3

0.4

0.6

0.6

0.7

0.8

1

0.2

0.3

0.4

0.5

0.15

1

0.5

0.6

0.7

0.8

0.1

.04

0.15

.05

.06

0.2

.07

.08

0.3

0.1

.04

.05

.06

.07

.08

.03

.007

.008

0.01

.015

.02

0.4

0.15

0.1

.03

.003

.004

.005

.006

.007

.008

.002

.003

0.01

.004

0.2

0.3

.04

0.15

0.2

.05

.06

.07

.08

.015

0.02

.005

.006

.008

0.01

0.4

0.3

0.1

0.03

1.5

0.5

15

5

6

4

5

60

70

80

20 6

7

150

200

300

8

9

30 10

2

7

8 3

10

4

40

15

50

20

60

15 6

7

20 8

10

70

30

80

30

100

40

50

150

60

70

200

80

100

5

15

40

20

50

100

1.5

2

3

60

30

70

80

4

5

6

7

3

8 4

10

5

6

15

7

15

30

20

0.6

0.7

0.8

1

1.5

10

20

25

2

0.04

0.4

0.15

0.05

0.06

.02

0.5

0.2

0.6

0.7

0.8

1

0.3

0.4

0.08

0.1

.03

.04

.05

.06

.01

0.04

25

8

20

7

15

6

3

4

5

10

1.5

2

10

13

8

6

7

1.5

4

5

0.8

3

0.5

0.6

0.7

2

1

0.2

.08

.02

0.06

8

7

6

5

4

3

2

1

0.3

0.4

0.5

0.6

0.8

5

6

4

3

2

0.6

0.8

1

0.2

0.3

0.4

0.5

2

3

4

0.1

2

.03

0.01

0.05

ca ne

0.5

0.6

0.8

.4

0.3

0.4

0.2

0.08

0.1

.2

.08

0.1

0.04

0.06

.04

.05

.06

0.03

.03

.04

.02

.02

.02

0.07

0.01

.008

0.01

.006

.008

.01

.004

.006

.06

.03

.08

0.1

0.4

0.5

0.6

.03

.08

.04

.02

0.1

.06

.03

.02

.006

.008

.001

.002

.004

.003

.004

D ode

.002

.001

Tr ide

1

.6

.4

.3

.2

.08

0.1

.05

.07

ca ne

Tetr adeca ne

.5

1

.6

.3

.2

0.1

.8

.4

1

1.5

1

.8

.6

.5

.7

.5

.4

.5

.3

.4

.3

.2

.6

-10

-5

0

10

20

30

40

50

60

70

80

90

100

110

120

130

140

150

160

170

180

190

200

° C °

0

F

10

20

30

40

50

60

70

80

90

100

110

120

220

240

260

280

300

320

340

360

380

400

130

140

150

160

170

180

190

200

220

450

Equilibrium constant for hydrocarbons

(Scheibel and Jenny)

Figure 2.16

Scheibel and Jenny [40] nomograph for light hydrocarbons.

b. Since the pressure drop is neglected, the entire column is assumed to be at 8.4 atm.

We will start the calculation with the distribution coefficients estimates from a. A dew point is calculated and the criteria i n

∑

= 1 y K i

= 1 (equation 2.148) must therefore be satisfied.

75

5010_ Page 76 Vendredi, 6. avril 2012 2:20 14

> STDI FrameMaker Couleur

76 Chapter 2 • From Fundamentals to Properties

At the first iteration (table 2.20), as the composition of the liquid phase is not correct

(sum equals 1.113), the composition is normalised, allowing us to calculate a hypothetical iso-butane distribution coefficient (K iso-butane

= 0.67/0.734 = 0.91). A line is drawn at the same pressure through this point and the other values of K i

are read from the diagram and introduced in the table. Convergence is reached in almost two iterations, with a final temperature of 132 °F, as summarised in table 2.20.

Table 2.20 Dew temperature calculation procedure at 8.4 atm

Component y i

Propane 0.23

iso-Butane 0.67

n -Butane 0.10

K i

( 120 °F ) x i

= y K i

1.7

0.82

0.26

0.135

0.817

0.161

x

' i

= x i

0.121

0.734

0.145

N j

∑

= 1 x j

K i

( 132 °F ) x i

= y K i

1.85

0.91*

0.72

0.124

0.736

0.139

Sum/Result 1.113

0.999

* calculated using K i

= y x ' i

= 0.67/0.734

c. The reboiler is the equipment where liquid at the bottom of the column exits the system while vapour in equilibrium is reinjected. This is a new bubble point problem where the pressure is known, and the temperature is to be calculated. In this case again, convergence is reached when

N

∑ = i = 1

1 .

After the first iteration (table 2.21), the vapour composition is normalised and a K i

(in this case n-butane is used) is estimated. The line is drawn through this value and the pressure of the column. In this case, two iterations are necessary. The distribution coefficients are given in table 2.21 for the two intermediate calculations and the final result.

Table 2.21 Bubble temperature calculation procedure at 8.4 atm, for the residue composition

Component x i

K i

( ) i

= K y iso-Butane 0.02

0.91

n -Butane 0.46

0.72

iso-Pentane 0.15

0.32

n -Pentane 0.37

0.26

0.018

0.331

0.048

0.096

y

' i

= y i

0.037

j

N

∑

= 1 y j

K i

( 207 °F K i

(

0.671

0.097

1.78

1.46

*

0.77

1.70

1.37

0.74

0.195

0.66

0.63

) i

= K y

0.034

0.629

0.111

0.233

Sum/Result 0.493

1.000

* calculated using K i

= y x i

= 0.671/0.46

The temperature of the reboiler is found to be 197 °F.

This example is discussed on the website: http://books.ifpenergiesnouvelles.fr/ebooks/thermodynamics

1.007

5010_ Page 77 Vendredi, 6. avril 2012 2:20 14

> STDI FrameMaker Couleur

Chapter 2 • From Fundamentals to Properties 77 b. Flash where either P, T or θ is provided plus another property

In all cases, if the basic equations (2.144) along with the K i

calculation methods (2.127),

(2.128) or (2.129) are to be used, pressure, temperature and vapour fraction need to be known. In this type of problem, however, only one of the three variables is given. An additional unknown must therefore be taken into account. In order to solve the problem, an additional equation must also be available. This extra equation can be written as a balance equation using the additional property that is given:

If volume is given (isochoric flash):

( 1 − θ ) v

L + θ v

V = v (2.149)

If enthalpy is given (isenthalpic flash):

( 1 − θ ) h

L + θ h

V = h

If entropy is given (isentropic flash):

( 1 − θ ) s

L + θ s

V = s

(2.150)

(2.151)

If internal energy is given (closed system flash):

( 1 − θ ) u

L + θ u

V = u (2.152)

Note that this means that a method must be provided for the calculation of volume, enthalpy or entropy for each phase as a function of pressure, temperature and phase composition (see section 4.1, p. 252).

As an example, if we can illustrate a PH flash (isenthalpic flash as in a distillation column), the unknowns are K i

, T and F ( i.e.

N + 2 unknowns), and the equations to be solved are:

⎧

⎪

⎪

⎪

⎪

⎪

⎪ ( i

K i

∑

= 1

1 −

=

1

(

θ

+

) ϕ ϕ V i i

L

K i

θ h

(

L

−

K i

+

1

)

− z

θ h i

1

)

=

= h

0 (2.153)

One possible procedure to solve the equations is as follows:

1. Estimate the missing piece of information, T and θ

2. Estimate the distribution coefficients K i

3. Use (2.143) to calculate x i and y i

4. Solve for the temperature using the full system (2.153): unknowns.

N + 2 equations with N + 2

The K i

values are calculated as shown with equation (2.127) or with (2.128) or (2.129) depending on the chosen method.

5010_ Page 78 Vendredi, 6. avril 2012 2:20 14

> STDI FrameMaker Couleur

78 Chapter 2 • From Fundamentals to Properties

Example 2.8 Enthalpy balance in a column

An adiabatic distillation column is used to separate a mixture of n-butane (1) and n-heptane (2).

The liquid feed is introduced directly on the third stage as shown on figure 2.17. The column operates at an isobaric pressure of 2.26 atm. Some additional pieces of information concerning the characteristics of the feed and the surrounding stages are also given in table 2.22:

Table 2.22 Data of example 2.8

Position

Temperature (°C)

Vapour molar flow (mol s

–1

)

Liquid molar flow (mol s

–1

)

Vapour molar composition y

1

Liquid molar composition x

1

Feed

47.5

0

100

0.5

Stage 2

43.5

0.46

0.565

0.969

Stage 4

118.2

0.990

For the simplicity of the model, some basic expressions have been selected for enthalpy calculation and for distribution coefficient predictions: the expressions are in °C, and h in cal mol

–1

) for both phases and Ln K = +

(with T

(with T in K). These equations apply to each component and the values of the coefficients are found in table 2.23:

Component n -Butane n -Heptane

Table 2.23 Parameters for example 2.8

Vapour enthalpy

A i

V

23.3

39.7

B i

V

5470

9128

Liquid enthalpy

A i

L

34

54

B

0

0 i

L

Distribution coefficient a i

– 2530.4

– 124.6

b i

8.5426

10.412

a. What is the temperature of stage number 2?

b. What is the temperature of stage number 4?

c. What are the temperature and compositions of stage number 3?

Analysis:

The properties to be evaluated are the temperature of the various equilibria on the three stages around the feed. Pressure is fixed and part of the compositions is given.

a. For the 2 nd stage, the liquid and vapour composition are known, so the distribution coefficients are directly found. The temperature can be calculated using the relationship between K i

and T.

b. For the 4 th stage, composition of the liquid is known, meaning that a bubble point has to be determined.

c. On the 3 rd

stage, all incoming flows are known, so the overall composition and the total enthalpy may be calculated. A PH flash must be solved using the set of equations (2.153).

The fluids are regular light hydrocarbons. All properties are well known. Particular expressions are recommended and no binary interactions are considered (ideal mixture,

5010_ Page 79 Vendredi, 6. avril 2012 2:20 14

> STDI FrameMaker Couleur

Chapter 2 • From Fundamentals to Properties

F

V 3

4

L 4

L 3

V 2

3

2

Figure 2.17

Section of the column with stream and plate nomenclature

Solution: a. Stage number 2 is defined in both phases. So the distribution coefficients of each component can be calculated (it is a binary mixture!).

K

1

= y

1 x

1

= = and K

2

= y x

2

2

= =

Normally, knowledge of T on the 2 nd stage will give both K

1

and equations for one unknown. They lead to:

K

2

, so there are two

T = a

1 ln( ) − b

1

= 316.98 K and T = a

2

(

2

) − b

2

= 315.98 K. The average is 316.48 K.

b. For the 4 th stage, a bubble point calculation has to be undertaken. The iterative procedure must start with an initial value (perhaps the temperature of stage number 2, or any other chosen by the user). If the temperature of stage 2 is used, equation (2.147) yields:

∑

= i exp

⎛

⎝⎜

−

+ .

⎠⎟

.

+ ex pp

⎛

⎝⎜

−

+

⎞

⎠⎟

.

= .

The temperature must be lowered to reduce the sum. After a few iterations, a value of

298.66 K is found for stage number 4.

c. Material and energy balances around the 3 rd

stage must be written.

& F

1

+ & 4 L

1

4

+ & 2 V

1

2

F

2

+

+

4

=

&& 4 L

2

4

+ & 2 V

2

LL L 4

+ &

2

2

=

=

& 3 L

1

3

+ & 3

& 3 L

2

3

+ &

& 3

+

3

&

V

2

V

1

3

3

3

This implies that enthalpies of each flow must be calculated. For example, the enthalpy of the vapour leaving stage 2 is expressed as: h

2

= y h

1

× 2

+ y h

×

2 2

2

= .

× = cal mol – 1

79

5010_ Page 80 Vendredi, 6. avril 2012 2:20 14

> STDI FrameMaker Couleur

80 Chapter 2 • From Fundamentals to Properties

Using this technique, the material and enthalpy content of each of the streams entering the

3 rd

plate ( F &

, L & 4 and V & 2

) can be calculated and summed, as shown in table 2.24.

Table 2.24 Material and enthalpy content of the stream entering plate 3

Component n -Butane (mol s

–1

) n -Heptane (mol s

–1

)

Total nC

4

+ nC

7

(mol s

–1

) h (cal mol

–1

)

H (cal s

–1

)

50

50

100

2090

209000

V

& 2

42.15

1.35

43.5

6605

287336

L

4

109.93

8.27

118.2

903

106740

& + & 4 + V

& 2

202.08

59.62

261.7

2304

603077

Introducing the equilibrium condition in the above material balances (2 first equations), they can be treated as equation (2.141) leading to the Rachford-Rice equation. For a binary mixture, the vapour fraction can be calculated directly:

(

K

1

1 + θ

(

− 1

K

1

)

− z

1

1

) +

(

K

1 + θ

2

(

−

K

2

1

) z

2

− 1

)

(

K

1

(

−− 1

K

1

) z

−

1

1

)

+

(

(

K

K

2

2

−

−

1

1

)

) z

2 where z

1

and z

2

are the global mole fractions on plate 3. They can be found from the global flow rates shown in table 2.24: z

1

= 202.08/261.7 = 0.772 and z

2

= 59.62/261.7 = 0.228.

We are now left with two equations (the enthalpy balance and the above Rachford-Rice equation) with two unknowns ( θ and T). The complete algorithm becomes very simple:

• assume a temperature,

• calculate K

1

and K

2

,

• solve the Rachford-Rice equation to find θ ,

• calculate the enthalpies of streams V

3

and L

3

,

• compare the sum of these two outlet enthalpies with the inlet enthalpy calculated in table 2.24.

A complete iteration is shown in table 2.25:

Table 2.25 Results of one iteration, using an assumed temperature of 40 °C, yielding a vapour fraction θ = 0.4366, and a total enthalphy of 989.444 kcal s

–1

Component & + & 2 + V

& 4 z i

3

K i

3 x i

3 y i

3

L

3 V

& 3 & 3 + V

& 3 n -Butane (mol s

–1

) n -Heptane (mol s

–1

)

202.08

59.62

0.228 0.063 0.385 0.024 56.83

2.79

59.62

Total nC

4

+ nC

7

(mol s

–1

) 261.7

h (cal mol

–1

) 2304

H (cal s

–1

) 603077

0.772 1.587 0.615 0.976 90.62 111.46 202.08

1 1 1 147.45 114.25 261.7

1668 6507

103761 602748

3781

989444

As observed in the results above, calculated at a temperature of 40 °C, the vapour fraction of the flash is 0.4366 and the total enthalpy of value of 602478 cal s –1 for

& &

V

& 2

L

& 3 + V

& 3 is 989444 cal s

–1

, greater than the

. The temperature must therefore be less than

40 °C. A few additional iterations lead to a final value of 34.29 °C with the corresponding compositions and vapour fraction as seen in table 2.26:

5010_ Page 81 Vendredi, 6. avril 2012 2:20 14

> STDI FrameMaker Couleur

Chapter 2 • From Fundamentals to Properties 81

Table 2.26 Final iteration, at 34.29 °C and vapour fraction θ = 0.1904

Component & + & 4 + V

& 2 z i

3

K i

3 x i

3 y i

3

L

3

V

& 3 & 3 + V

& 3 n -Butane (mol s

–1

) n -Heptane (mol s

–1

)

202.08

59.62

Total nC

4

+ nC

7

(mol s

–1

) 261.7

h (cal mol

–1

) 2304

H (cal s

–1

) 603077

0.772 1.367 0.722 0.986 152.93 49.15 202.08

0.228 0.050 0.278 0.014 58.94

1 1 1

0.69

211.87 49.84

1357 6327

103761 602748

59.62

261.7

2304

603077

This example is discussed on the website: http://books.ifpenergiesnouvelles.fr/ebooks/thermodynamics c. Flash where P, T and θ are unknown

When none of the basic variables needed in the basic equations (2.144) along with the K i calculation methods (2.127), (2.128) or (2.129) is available, they all must be calculated, resulting in a total of N + 3 unknowns ( K i

, P , T et θ ). Hence, N + 3 equations are required, or one more compared with (2.

153). Two additional balance equations (from

(2.149) through (2.152)) are therefore required: one for each of the known state variables.

As an example, for solving a flash at fixed volume and internal energy ( UV flash – this case is found when solving pipe transport problems), the unknowns are K i

, T , P and θ ( i.e.

N + 3 unknowns), and the equations to be solved are (provided that (2.127) is used for calculating K i

):

⎪

⎪

⎧

⎪

⎪ i ⎪

⎪

⎪ (

= 1

1 −

1

θ

+

)

(

K i n

∑

1 −

=

(

θ ) ϕ i

L ϕ V i

K i

θ u v

L

(

L

−

K i

+

+

1

)

− z

θ u i

1

)

=

= 0 u

θ v

V = v

(2.154)

One possible procedure to solve the equations is as follows:

1. Estimate the missing pieces of information, T, P and θ

2. Estimate the distribution coefficients K i

3. Use (2.143) to calculate x i and y i

4. Solve for the temperature using the full system (2.154): N + 3 equations with N + 3 unknowns

2.2.3.2 Practical applications of phase equilibrium

In process engineering, phase equilibrium must be calculated in different types of problems.

In this section, we show how the practical applications will lead to the use the concepts developed above.

5010_ Page 82 Vendredi, 6. avril 2012 2:20 14

> STDI FrameMaker Couleur

82 Chapter 2 • From Fundamentals to Properties

A. Distillation or stripping: separation according to volatility (VLE)

When the problem requires separation according to the relative volatility of the components, the most important property to be calculated is the equilibrium coefficient (see (2.127),

(2.128) or (2.129)) of each component. The relative volatility is then defined as:

α ij

=

(

( x x

)

) (2.155)

The concept of relative volatility is essential in distillation processes. When pressure is low, but non-ideal mixtures are considered, equation (2.130) yields:

α ij

=

P i

σ γ i

(

T , x

)

P j

σ γ j

(

T , x

) (2.156)

The activity coefficients can become significant and modify the relative volatility between two components considerably. An example is discussed in example 3.12 (p. 164).

The relative volatility between n -butane and 1-3 butadiene changes significantly upon adding acetonitrile, which is therefore used as an extraction solvent. This solvent has a low volatility, and therefore remains in the liquid phase throughout the distillation column.

While butane and butadiene are almost inseparable by classical distillation (1,3 butadiene is very slightly more volatile than n -butane), they can be separated due to their difference in volatility using a technique known as extractive distillation . Butane is then significantly more volatile than 1,3-butadiene.

For low pressures and ideal mixtures, the relative volatility may be approximated as

(using (2.133)):

α ij

=

P

P i

σ j

σ

(2.157)

B. Extraction: separation according to chemical affinity (LLE)

Liquid-liquid extraction methods are also based on phase separation and as such equations

(2.110) and (2.111) remain valid. Nevertheless, two liquid phases are present simultaneously, and the distribution coefficient now is defined by (2.136). The fugacities are calculated either using the residual approach (2.113), or using the excess approach (2.116). In principle, both methods can be used for calculating a liquid-liquid phase split. Considering the complexity of liquid-liquid phase behaviour (results are very sensitive to small changes in parameters), the excess property models are often more accurate for this type of calculation.

The reason why a liquid phase split appears is not related to the vapour pressure of the pure components, but rather to the chemical affinity among the components. This has been discussed above: the liquid-liquid distribution coefficient defined in equation (2.137). On the condition of having good mixing rules, equations of state can also be used.

Note that, as a consequence of this, the corresponding states principle section 2.2.2.1.C

(p. 57) (which provides a very convenient method to calculate hydrocarbon properties and uses the critical point to describe its volatility) is not adapted to predict liquid-liquid phase

5010_ Page 83 Vendredi, 6. avril 2012 2:20 14

> STDI FrameMaker Couleur

Chapter 2 • From Fundamentals to Properties 83 splits. Consequently, the traditional pseudo-component description is not adapted to the calculation of these types of equilibrium. The liquid phase separation is in fact sensitive to chemical affinity, which is more accurately modelled using the activity coefficient models, further discussed in section 3.4.2 (p. 171).

C. Separation using crystallisation (LSE or VSE)

Crystallisation or solid phase formation is based on another physical phenomenon. When the temperature is sufficiently low, molecular vibrations can no longer keep the molecules apart in the liquid phase. Instead, they start “piling up” in a configuration that depends on the molecular structure. This is why crystallisation temperatures are totally unrelated to the volatilities of the components (except when comparing similar families where the structure remains identical).

The pure component crystallisation properties are further discussed in section 3.1.1 (p. 102).

Crystallisation is a very convenient separation technique as its product is generally very pure: in the solid phase, components do not mix as in a liquid. In section 4.2.1.2 (p. 270), the types of solids that may be encountered are discussed.

Phase equilibrium in the presence of a solid phase uses the same equations as for all phase equilibria, i.e.

the iso-chemical potential (2.110) or iso-fugacity (2.111) condition along with mass balances. The fluid phase fugacity is calculated using either the residual

(equation of state) or the excess (activity coefficient) approach. However, for the solid phase fugacity, the most general approach is the excess approach (2.123) with (2.125), as discussed above. The residual approach can not be used here.

D. Risk of appearance of a new phase

On some occasions, it is essential to know the risk of appearance of an additional, unwanted phase. As an example, the appearance of a liquid phase in a vapour flow can strongly perturb the operation of compressors, turbines, heat exchangers, or, in reservoir conditions, decrease the permeability in porous material. In addition, if this liquid is an aqueous phase, it tends to concentrate corrosive components (acids, etc.) and as a result creates important risks of corrosion. If the incipient phase is solid, the risk of plugging equipment is evident.

From a thermodynamic point of view, this question is investigated looking at the phase diagram boundaries. Phase boundaries or solubilities are essentially two identical ways to envision the very same phenomenon. This can be understood when looking at a Txy diagram

(see figure 2.4 for example). The bubble curve is the boundary between the pure liquid phase and the two phase vapour-liquid region.

The question can be investigated in four different ways:

1. It is useful to draw the full phase diagram to visualise the pressure-temperature (and perhaps composition) path that the system encounters in the process. Specific algorithms for phase diagram calculation exist. An example of such curves is given in figure 2.6 and figure 2.11. If presented in the pressure-temperature plane, they often include a critical point, and as such require the use of a homogeneous method (equation of state). If presented as Txy or Pxy plots, in the absence of a critical point, they can be obtained quite easily for vapour-liquid equilibria. For liquid-liquid or liquid-solid equilibrium, the calculations are more complex and automatic tools are not readily available.

5010_ Page 84 Vendredi, 6. avril 2012 2:20 14

> STDI FrameMaker Couleur

84 Chapter 2 • From Fundamentals to Properties

2. The simplest approach consists in searching the boundary of the phase envelope by performing either T θ (search for the bubble or dew pressure) or P θ (search for the bubble or dew temperature) calculations. The actual system pressure and temperatures are then compared with those resulting from the calculation. If the incipient phase is a second liquid or a solid, bubble or dew calculations cannot be used. If it is a solid phase, the temperature when the first crystal appears is calculated. In the case of paraffinic crudes, the terminology used is the “Wax Appearance Temperature” (WAT).

3. When the incipient phase is assumed to be pure, it is also possible to compare the fugacity of the component in the incipient phase with its fugacity in the bulk system. Whenever the former fugacity drops below the latter, phase separation should occur (in particular for solid phases, but also water condensation).

4. The most elegant approach, when the system composition and two properties corresponding to those listed in table 2.7 are provided (for example pressure and temperature), is to perform a so-called stability calculation. Its purpose is to evaluate whether the single phase is thermodynamically stable. This algorithm (Michelsen [41]) evaluates whether, considering the constraints of the system, a second incipient phase can be formed, which would result in a lower Gibbs energy of the system. It is generally mathematically rather intricate, since being close to a phase boundary, the set of equations to be solved presents several minima that may be close to each other. The true solution is the global minimum, but the solver may stop with a local solution.

Obviously, in all cases, a suitable model is required both for the bulk phase and the incipient phase. As will be discussed in section 3.5.1 (p. 226), this type of calculation is rather sensitive to the correct representation of the components at both ends of the phase behaviour considered:

• For vapour-liquid calculations, these are the lowest volatility and highest volatility components.

• For liquid-liquid calculations, these are the components that most readily separate

(with the lowest affinity for each other). The presence of a third component that acts as a co-solvent may influence the phase behaviour dramatically however.

• For fluid-solid calculations, these are the components with the highest crystallisation temperature on the one hand and the majority component on the other hand.

Example 2.9 Risk of water condensation in a gas stream

A light hydrocarbon mixture (CH

4

: 80%; C

2

H

6

: 15%; C

3

H

8

: 5% in molar percent) is contaminated with water. The mixture is available at 200 kPa but due to severe weather conditions there is a risk of low temperature. Is there a real risk of condensation of water in the line?

Analysis:

Ambient temperature is in all possible cases greater than the critical temperature of methane. Ethane and propane could condense but the vapour pressure, even at 0 °C is greater than 200 kPa, so no hydrocarbons are expected to condense.

The pressure is given and a condensation temperature must be found. It is a dew point calculation.

5010_ Page 85 Vendredi, 6. avril 2012 2:20 14

> STDI FrameMaker Couleur

Chapter 2 • From Fundamentals to Properties

Components are light hydrocarbons and water. Water is known not to mix with hydrocarbons in the liquid phase.

Phases are vapour and liquid. The liquid phase will contain only water.

Solution:

If water condenses the aqueous phase can be considered as pure, so with a composition equal to unity. Pressure is low so the Raoult approximation is valid. Hence, the fugacity of the liquid, incipient phase may be approximated with the vapour pressure of pure water. The fugacity of water in the bulk (vapour) phase is equal to its partial pressure. Hence, if the partial pressure of water reaches the vapour pressure at a given temperature, water will condense:

P partial

H O

= Py = P

σ

H O

T

The form of the DIPPR equation for vapour pressure cannot be solved analytically in T.

A trial and error procedure has to be implemented.

ln

(

P sat

H O

)

= −

T

− ln( ) + .

.

−

T

The maximum water content before liquid drops out is then found as y =

P

σ

H O

.

pressure of water should be used and ice would appear.

Table 2.27 Maximum water content of a gas at the total pressure of 200 kPa

Temperature

(°C)

0

5

10

15

20

45

50

55

60

25

30

35

40

65

70

75

Temperature

(K)

273.15

278.15

283.15

288.15

293.15

298.15

303.15

308.15

313.15

318.15

323.15

328.15

333.15

338.15

343.15

348.15

Vapour pressure of water (Pa)

610

872

1227

1705

2339

3170

4248

5630

7386

9596

12352

15760

19940

25030

31181

38564

This example is discussed on the website: http://books.ifpenergiesnouvelles.fr/ebooks/thermodynamics

Maximum water content (%)

0.31%

0.44%

0.61%

0.85%

1.17%

1.59%

2.12%

2.82%

3.69%

4.80%

6.18%

7.88%

9.97%

12.51%

15.59%

19.28%

85

5010_ Page 86 Vendredi, 6. avril 2012 2:20 14

> STDI FrameMaker Couleur

86 Chapter 2 • From Fundamentals to Properties

E. Relative amounts of the phases

For a number of industrial applications, the composition of the phases is of lesser importance, but the true issue is the relative amount of each phase. An example where this is the true property to be looked for is found in multiple phase flow calculations, whether in pipelines or fluidised bed.

The procedure used to calculate the relative amounts of the phases is identical to that explained above (2.142) for vapour-liquid equilibrium. For liquid-liquid equilibrium the same kind of equation would be used

θ α = N

α

N

α + N i n

∑

= 1 1

(

+

K i

αβ

θ α

(

−

K i

αβ

)

1 z i

−

)

1

= 0 (2.158) where

(

β

)

is the ratio of matter in phase α .

The choice of the correct model will essentially depend on the components and their interactions, as discussed in chapter 4.

• In the case of vapour-liquid equilibrium, the vapour fraction will be more sensitive to the correct solubility calculation of the light components in the liquid than to the description of the volatilisation of the heavy end. Indeed, the vapour phase generally contains only a very small quantity of heavy components, while gases can make up a large fraction of the liquid phase. As a result, the engineer’s attention should focus on the interactions between the gases and the bulk of the liquid.

• In the case of liquid-liquid equilibrium, the same issue should be considered as for the phase boundary calculation (hereabove section D, p. 83): the relative concentrations of the components that show the least affinity should be examined first. The presence of a co-solvent will be the next important issue.

• The calculation of the relative amounts of the solid and fluid phases requires, in addition to the crystallisation properties of the pure components, a good description of the solid phase. Considering that many types of solid phase may exist (see section 4.2.2.3, p. 281), this issue may become complex, in particular when several solid phases coexist. For this issue, we refer to more detailed textbooks [14]).

2.2.4 Chemical equilibrium

In some processes, thermodynamic calculations are needed in order to determine how the equilibrium composition changes with pressure and temperature as a result of one or several chemical reaction(s). This assumes that equilibrium is quickly reached, or that no kinetic limitations exist.

Yet even when the reaction rate is not large, and must therefore be evaluated, it may be useful to describe it as the sum of positive and negative contributions that cancel out at the equilibrium conditions. These conditions must therefore be known.