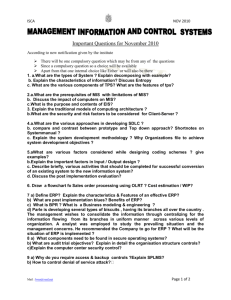

An Overview of Enterprise Resource Planning (ERP)

advertisement