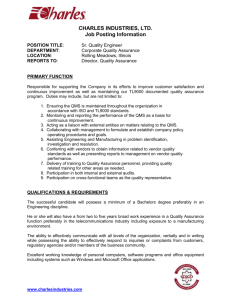

Implement and monitor quality assurance

advertisement