530.327 - Introduction to Fluid Mechanics

advertisement

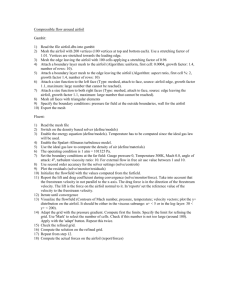

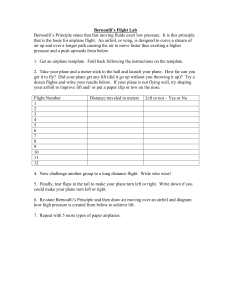

530.327 - Introduction to Fluid Mechanics - Su Third experiment: Lift and drag The individual reports for this lab will be due Monday, December 7. The reports should conform to the guidelines used for the previous two reports. 1 Background and objectives. In this experiment we will consider external flow around objects by making surface pressure measurements on models placed in a wind tunnel. The wind tunnel is located in Krieger B-2, and is a virtual duplicate of the wind tunnel we used for the first lab in the course. The models we will work with are a circular cylinder, a symmetric airfoil (‘symmetric’ meaning the curvature of the upper surface mirrors that of the lower surface), and an asymmetric airfoil, for which the upper surface has greater curvature than the lower surface. We have discussed in class (or will soon, anyway) how drag and lift on bodies can be explained in terms of surface pressure forces, and we noted that drag, both friction drag and pressure drag, on bodies arises only by consideration of viscous effects in fluids. In particular, viscous fluids develop boundary layers at the surfaces of immersed bodies. The development of these boundary layers as fluids move over the bodies can strongly affect the drag and lift forces. In class we saw that pressure drag on a sphere is a direct result of the separation of the boundary layers from the sphere’s surface. Lift forces, in contrast to drag forces, can exist even in inviscid fluids. However, the phenomenon of stall, where the lift generated by an airfoil suddenly plummets as the angle of attack of the airfoil increases, can only be understood in the context of viscous fluids and boundary layer separation. We will be looking at three model shapes: (1) a circular cylinder, (2) a symmetric airfoil, and (3) an asymmetric airfoil. The airfoil shapes are among the many standard forms defined years ago by NACA, the National Advisory Committee on Aeronautics (which became NASA in 1958). The symmetric airfoil is the NACA 0012 form, and the asymmetric airfoil is the NACA 4412 form.1 Each of the models is equipped with pressure taps that allow us to measure pressures at different points on the surfaces of the models when the models are placed in the wind tunnel flow. For the airfoils, we will measure these surface pressure distributions at different angles of attack, to get an idea of the relative performance of the two airfoil shapes. Our goal is to develop an intuitive feel for the flow field around different body shapes, and, through analysis of the data acquired, how these flow fields are manifested in terms of drag and lift forces. This lab also affords us the opportunity to do realistic engineering work (wind tunnel testing is still highly relevant both in industry and for research), so we can get some practice in thinking from a design standpoint. 2 Experimental apparatus. The experiment will use the wind tunnel in Krieger B-2 whose test section is configured to allow for the placement of the models. Figure 1 shows the model cylinder, symmetric airfoil, and asymmetric airfoil. Each model is mounted on a plexiglas disk that fits in a circular cutout in the side wall of the test section. The cylinder model has a tiny hole (a ‘pressure tap’) on its surface that connects to a pressure port on the plexiglas disk, through which we can measure surface pressures on the cylinder. The symmetric airfoil model has seven pressure taps on one side for pressure measurements, while the asymmetric airfoil has seven pressure taps on each side, which all connect to individual pressure ports on the respective plexiglas disks. Figure 2 shows the asymmetric airfoil model mounted in 1 NACA performed extensive wind tunnel studies of the aerodynamic properties of different wing shapes, which was very valuable to the early aerospace industry. This sort of work is pretty easily done nowadays with computers. 1 asymmetric airfoil cylinder symmetric airfoil Figure 1: The model cylinder, symmetric airfoil, and asymmetric airfoil. flow direction airfoil tubes for pressure measurement Figure 2: Close-up view of the tunnel test section, with the asymmmetric airfoil in place. The pressure measurement tubes connect to the pressure ports visible on the end of the airfoil. the tunnel test section. The tunnel airflow is from left to right in the figure. The bundle of pressure measurement tubes is used to connect the pressure ports on the plexiglas disk to the pressure measurement apparatus described below. Each model is easily rotated by hand about its long axis, allowing us to vary the angular position of the single hole on the surface of the cylinder model, as well as the angle of attack, α, of the airfoil models. A scale on the tunnel wall indicates the angular position of the models. Figure 3 shows an overview of the tunnel and pressure measurement apparatus. This equipment is located on the opposite side of the tunnel from the view shown in Fig. 2, so the airflow moves from right to left in Fig. 3. The pressure measurement tubes shown in Fig. 2 connect to the box shown on the table in the foreground. The dial on the box selects the specific tube from which the pressure will be read. The actual pressure readouts are given on the computer shown on the right. 3 Experimental procedure. Preliminary measurements. (Target time: 10 minutes.) As usual, distribute these tasks among group members to save time. 1. Record the temperature and pressure in the room, for eventual determination of the air density. 2. For each of the model shapes, measure all relevant geometric parameters: these are the span 2 computer for pressure readouts tunnel test section pressure tube selector Figure 3: Overview of the experiment. The figure shows a model airfoil fitted with surface pressure taps, and the box used for pressure and force measurements. The tunnel flow is from right to left. and diameter for the cylinder, and the span and chord (the front-to-back length) for the airfoils. For consistency, use metric units throughout the lab. 3. For the airfoil models that are equipped with pressure taps, record the positions of the taps in terms of their distances from the leading edge of the airfoil. In the case of the asymmetric airfoil, be sure to distinguish between the seven taps on the top surface and the seven taps on the bottom surface (there is one tap on the very front of the airfoil that we count as being on the bottom surface). 4. Turn on the tunnel. Using the slant-tube manometer and pitot-static probe from the first lab, record the dynamic pressure in the tunnel with the fan set at 50, 70, and 90. Insert the pitot-static probe through the slot on top of the tunnel. You need this dynamic pressure information to determine the free-stream flow velocity in the tunnel. Turn the tunnel back off afterwards. Pressure measurements. (Target time: 45 minutes.) 1. Begin with the circular cylinder. Connect the single pressure port on the cylinder to the small tube numbered ‘1’ from the bundle of seven tubes coming from the measurement box. 2. Set the dial on the measurement box to read the pressure from tube 1. 3. Record the gage pressure reading from the computer when the cylinder is outside of the tunnel. This will be the standard offset that needs to be subtracted from all other readings. 4. Place the cylinder in the tunnel. Set the tunnel speed to 50. Record the gage pressures for port positions of 0 to 180 degrees, in increments of 15 degrees. If the readout fluctuates, get a quick estimate of the mean value. Don’t spend too much time on each measurement. 5. Repeat 4] for tunnel speeds of 70 and 90. Return the tunnel speed to zero. 6. Connect the seven pressure ports for the symmetric airfoil to the box, so that tube 1 connects to the port on the front, and the rest of the tubes are in order. Record the pressure offset value with the airfoil outside of the tunnel. (You can just measure the offset for one of the tubes – each of the pressure ports will have the same offset value.) 3 7. Place the airfoil in the tunnel. The front of the airfoil is the blunt end. Set the tunnel speed to 50. 8. Set the airfoil angle of attack, α, to 0. Record the gage pressures for each port. Repeat for tunnel speeds of 70 and 90. 9. Leave the tunnel speed at 90. Record the gage pressures for α = 5◦ , −5◦ , 10◦ , −10◦ , 15◦ , −15◦ , 20◦ , and −20◦ . You will need to hold the airfoil to prevent it from pitching up or down. 10. Connect the seven pressure ports on the upper surface of the asymmetric airfoil to the box. (Recall that the port on the very front of the airfoil is treated as being on the bottom surface.) Record the pressure offset value. 11. Place the airfoil in the tunnel and set the tunnel speed to 90. 12. Record the gage pressure readings for α = 0, 5◦ , 10◦ , 15◦ , and 20◦ . 13. Return the tunnel speed to zero. Repeat steps 10–12 for the pressure ports on the lower surface of the airfoil. 14. Return the tunnel speed to zero, and remove the model from the tunnel. 4 Airfoil data. The plots on the last two pages present data for the lift and drag coefficients, CL and CD , for our two airfoils, the symmetric NACA 0012 airfoil and the asymmetric NACA 4412 airfoil. (The plots are taken from Theory of Wing Sections, by Abbott and von Doenhoff.) Some notes on interpreting the plots: • The lift and drag coefficients, CL and CD , are conventionally defined in terms of the lift and drag forces, FL and FD , as CL = FL , 1 2 2 ρV A CD = FD 1 2 2 ρV A where ρ is the fluid density, V is the fluid velocity, and A is the planform area of the wing, i.e. the span times the chord for a rectangular wing. • The lift coefficient in the following plots is given as a function of the wing’s angle of attack, α, but the drag coefficient is given as a function not of α, but of CL . • The R in the plots is the Reynolds number, defined in terms of the wing chord. The symbols in the plots represent Reynolds numbers of 3.0 · 106 , 6.0 · 106 and 9.0 · 106 (the exponent ‘6’ is somewhat hard to read on the NACA 4412 plots). 5 Report. Your report should include the following observations and data analyses. (i) Compute the air density in the room using the ideal gas law, and compute the tunnel flow speeds for the three settings (50, 70 and 90) using your dynamic pressure measurements. 4 x p (q = 60 ) q 15 Figure 4: Geometry for discrete integration of Eq. 1. (ii) Plot the pressure data for the cylinder as a function of pressure tap angular position. Put the pressure distributions for the different tunnel speeds on the same plot. Comment on the change in the pressure field with flow velocity. (iii) Now consider the drag coefficient for the cylinder. Ignoring friction drag, the drag on the cylinder arises strictly because of the pressure differences between the front and back. Specifically, the net pressure force on the cylinder in the direction of the flow (call this the x-direction) is − → (1) Fx = − p(î · dA) S where the integration is over the full surface of the cylinder, S, and p is the pressure, î is the − → unit vector in the x-direction, and dA is the area element vector, which by the usual definition points out from the surface. You can estimate this net pressure force on the cylinder using your pressure measurements through a discrete integration. Specifically, you have pressure data for angular positions θ = θ1 , θ2 , . . . = 0◦ , 15◦ , . . . . To perform the discrete integration of Eq. 1, take your 24 measurement locations (assuming that the results are symmetric between the top and bottom of the cylinder), and make each one the midpoint of one side of a regular, 24-sided polygon (as shown in Fig. 4). You can compute the pressure force on each face of the polygon by assuming that the pressure is constant on each face. Then, find the x-component of the pressure force on each face, and finally sum up all of these to complete the integral. Do this to find the drag force, and the coefficient of drag, for the cylinder at the three flow speeds. Compare your results to the tabulated values for the cylinder drag coefficient in the text, and comment on possible sources of error (beyond the proverbial ‘measurement error’ or ‘faulty equipment’). (iv) Plot the pressure data for the symmetric airfoil at α = 0, again as a function of pressure tap position (in units of x/c, where x is the distance of the pressure tap from the leading edge, and c is the wing chord). Again, put the data for the different tunnel speeds on the same plot. How does the pressure field vary with tunnel speed? It turns out that the cylinder has significantly more drag than the airfoil does – can you explain why, on the basis of your pressure measurements? (v) Plot the pressure data for the symmetric airfoil for the cases where the tunnel speed was set to 90. Put the data for the positive angles of attack on one plot and for the negative angles of attack (representing the pressures on the bottom surface of the airfoil when the angle of attack is positive) on another plot. What happens to the pressure field as α increases? Can 5 p3,top x top bottom Figure 5: Geometry for discrete integration of Eq. 2. you guess what might be happening to lift and drag? Which surface, lower or upper, seems to be most responsible for lift? (vi) Repeat the previous step for the asymmetric airfoil, generating one plot for the pressures on the top surface and one for the bottom surface. Also, comment on any notable differences between the symmetric and asymmetric airfoils. (vii) Now use discrete integration to estimate the lift coefficients for the two airfoils at the different angles of attack at tunnel speed 90. If the y-direction is vertically upward, the net lift force is given by − → (2) Fy = − p(ĵ · dA) S where the integration is over the full surface of the given airfoil and ĵ is the unit vector in the ydirection. To estimate Fy using your pressure measurement data through discrete integration, we will start by assuming that the airfoil surfaces are flat, as shown in Fig. 5. Then, divide each airfoil surface into segments, where each segment corresponds to one of your pressure measurements. (Define the boundary between two segments as the point halfway between the associated pressure measurement locations.) For the asymmetric airfoil, don’t use the pressure measurement from the very front of the airfoil. Assume that the pressure is constant on each segment, and, accounting for the angle of attack of the airfoil, determine the y-component of the pressure force on each segment. Finally, add up these individual forces to determine the net lift force on the given airfoil, and also the associated lift coefficient. Do these calculations for both airfoils at tunnel speed 90 and each of the angles of attack, α. Present a single plot that gives CL versus α for both airfoils. Comment on the results and compare to the published results. Can you identify a stall point for each airfoil? (viii) Adopt the viewpoint of a aircraft designer for a moment. Why does it make sense to plot CD as a function of CL , as in the published plots, instead of α? Based on your answer to this question, and using the published CD and CL curves for the two airfoils, which of the airfoils seems like it would be a better performer on a realistic airplane, and why? 6 Figure 6: Plots of the lift and drag coefficients of the NACA 0012 airfoil. Note carefully the axes. 7 Figure 7: Plots of the lift and drag coefficients of the NACA 4412 airfoil. 8