Issue 7 - Tata Steel in Europe

advertisement

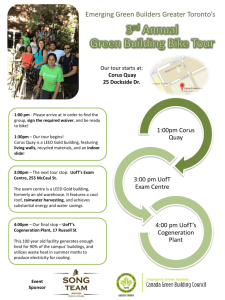

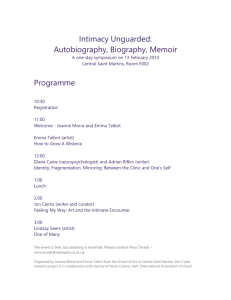

SA13 Issue 7 • December 2009 News for the community Going, going, gone... Drugs are for mugs Page 4 Page 7 2010 Richard Burton tribute 10km OK! Winterland wordsearch Page 11 Page 9 LETTERS Dear resident So here we are at the end of 2009, and with 2010 just around the corner I’m sure many of us will be glad to welcome the New Year. The beginning of 2009 was challenging for us, as we had to commit to minimise manpower reductions across our South Wales sites. However, as we look to 2010 there are signs of development in the market. Blast Furnace number 4 at Port Talbot has returned to operations following nine months out of production and our energy recovery project is an exciting development for us and the community. Our work in the community has remained and we have had the pleasure of being involved in many great projects throughout the year despite the economic climate. The year started with the ever-popular Richard Burton Run in Cwmafan, with the event attracting many hundreds of spectators. Spring saw the beginnings of our employee volunteering programme and employees from both Port Talbot and Llanwern helped their local communities develop outdoor spaces. Apprentices from Port Talbot joined forces with the Welsh Wildlife Trust and Communities First to revamp a tired and overgrown Church Hall garden in Briton Ferry into a plot that the whole community could be proud of! During autumn, we launched a drug and alcohol competition in Port Talbot primary and secondary schools, linked children from Taibach with counterparts in India and delved into the world of F1 with the F1 in Schools initiative. And as we lead up to Christmas, Corus is delighted to be sponsoring the Christmas lights and Santa’s Parade in Port Talbot, Neath and Pontardawe for another year. A Christmas message Once again, I am very pleased to have the opportunity to make my contribution to this special edition of SA13. In my work as Works Chaplain, I greatly value the connection with the community of which we are a part. All year round, I work within the community, and to be able to share some thoughts at Christmas is very special. I know from many years of experience that as Christmas approaches, many people pause and reflect on what has happened during the last twelve months; recalling the highs and lows, and reflecting perhaps on members of the family who will be no longer around for the Christmas celebration. To lose a close member of the family is always hard, especially when we see the empty chair at the table, and again from long experience, I know that the first Christmas after the death of a loved one is often the hardest thing. This applies even more so when it involves a younger person, and again, the loss is felt even greater when it is perhaps a person who has lost their life serving in the armed forces in Afghanistan. Some people reading this will have experienced such a tragedy in their family. Perhaps the rest of us could just pause, reflect, and remember such families as we plan our own celebration. “Hark! The herald angels sing, Glory to the new born King.” May I wish you all a very happy and joyful Christmas. Until the next edition, be safe and enjoy the festive period! As you get together with your family this Christmas, take a moment to remember what the season is all about – the birth of our Saviour. The hope that comes into the world with the coming of Jesus is incalculable, and it still means so much to so many. Let us hope that this joy and peace does not become swamped by the commercial aspect of Christmas. I pray that you and yours will know that peace, and feel that joy and hope this season, and that perhaps you will once again see the wonder of His birth, bringing that glorious hope into a waiting world. Keith Farron, Editor SA13 Contents Responding to residents’ complaints 3 Going, going, gone... - Demolition of the Transhipment Bunker 4 General news from Corus 5 Corus in the Community 2 6-10 Winterland wordsearch 11 What’s on with Corus 12 Corus SA13 News for the community The Rev. Peter H. Lolley, Works Chaplain at Corus, Port Talbot, and Minister in the Presbyterian Church of Wales in the Neath area. ENVIRONMENT A BioMassive debate The proposed construction of a biomass energy plant on land adjacent the steelworks is arousing considerable interest – and some outspoken opposition in the local community. Is Corus involved? No, there is no connection – but it still doesn’t stop the gossip. View of the biomass plant looking towards Port Talbot Works. The project needs no introduction for local people who have followed the issue in the local press. This particular power station will generate a massive 350MW of energy – more than ten times the capacity of the recently opened Western Log biomass plant. Biomass plants generate energy from incinerating wood chippings, old industrial pallets and ‘brash’ (tree off-cuts and prunings), offsetting the need to burn fossil fuels and reducing waste to landfill. In this ‘sustainable’ age, biomass plants are ‘up there’ with wind-farms, tidal power and energy recovery from waste. This autumn the First Minister for Wales formally opened the Western Log biomass plant with a capacity of 14MW. Costing £33 million, the plant benefited from considerable Government backing. Again, despite its proximity to the steelworks, there is no connection with Corus. Formal Government approval has recently been given for the proposed £400 million ‘Prenergy’ biomass plant. The plant would be located on land perceived to be within the steelworks site, but actually owned by Associated British Ports (ABP). Likewise, the deepwater harbour, also owned and managed by ABP, but used by Corus, will receive bulk imports of wood chip products from Canada. Thus, it would be quite understandable if residents perceived the biomass plant to be just another part of the steelworks horizon. That steelmaking is a highly energy intensive business is well known. However, Corus’ sustained presence is partly due to its investment in ‘energy optimisation’ – saving, re-using and recycling existing energy sources. The steelworks currently generates 61MW of energy – soon to be 76MW (upon commissioning of the Steel Plant’s energy recovery project). However, the business still needs to draw some energy from the Grid. Coinciding with the ‘Prenergy’ biomass plant, the local authority here in Port Talbot has approved an application by National Grid for a large electricity transmission sub-station to be built near the steelworks site. This will serve the proposed biomass plant, and just as importantly, replace two aging transformers serving the steelworks. This investment is vital for the area’s energy infrastructure, and although Corus is not part of the biomass proposals, its future competitiveness will be influenced by the availability and cost of energy sourced via the Grid. The Western Log biomass plant was formerly opened by the First Minister for Wales. Costing £33 million, the plant will have a capacity of 14MW. Despite its proximity to the steelworks, there is no connection with Corus. Responding to residents’ complaints A recent incident aroused complaints from local residents about damage done to vehicles and property caused by a mysterious dust. SA13 interviewed CSP UK’s Environment Manager, Richard Leonard, to find out what this was – and what has been done. “The company received a total of 15 complaints on two separate occasions in August and September,” said Richard. “The Environment Agency received two complaints, and we acted on these to find out what the problem was, if we were responsible, and what we could do.” The bleeder valve sits right at the top of the furnace. Fine particles of iron were found, which had reacted with some vehicles’ paintwork. The source was identified as Blast Furnace number 5. “It was pure iron,” explained Richard. “In itself, it is not hazardous, but we could see evidence that the particles had caused damage.” “It happens very rarely indeed.” Richard continued: “It is caused as a result of a release of pressure through bleeder valves situated on top of the furnace.” “The damage – and fixing it – has been assessed by our insurers and a company which specialises in dealing with the problem has provided a successful solution.” Richard concluded: “We don’t want it to happen again, and we are looking into ways of dealing with it.” Corus SA13 News for the community 3 ENVIRONMENT Going, going, gone… The countdown began… there was a loud explosion as the charges were detonated, and the large Transhipment Bunker gracefully fell forwards before crashing onto scrubland. The decision to demolish this redundant, but once vital, structure was one of safety, environmental and commercial benefit to the business. Over the next six weeks, the 2,000 tonnes of reclaimed metal will be cut up and prepared for recycling at our BOS plant. SA13 visited the bunker a day before its demise to learn about what it once did, and exactly how a facility of this size is prepared for demolition. The Llanwern Transhipment Bunker was used to fill trains with raw materials destined for Llanwern’s Heavy End. In simple terms, it comprised four large hoppers, fed by conveyors transporting raw materials straight from vessels docked in the harbour. Trains would then draw underneath the hoppers ready for loading before making the 50-mile journey East to Llanwern. The rail network supporting this operation was specially strengthened to cope with the increased weight of constant raw-material transit. When the Heavy End at Llanwern closed in 2001 the facility become redundant. Prior to the demolition, a specialist contractor doctored the supporting legs of the structure to ensure it fell as planned when the explosives were detonated. The idea was to focus the charges on one set of supporting legs, resulting in a clean fall in the intended direction. On the chosen side of the building, the legs were pre-cut using oxyacetylene burners and small shims inserted to stop gravity taking its course. When the moment came, the charges, which were detonated in succession, blew these legs clean away. Bob Fradd, manager for the project, commented, “This demolition went exactly as planned. Credit must go to the team involved for ensuring all stakeholders, including nearby local residents, were kept abreast of our intentions. It is important that we deal with our redundant structures for ongoing health and safety reasons, but this also gives us an opportunity to recycle the resulting scrap through the BOS plant and avoid purchasing on the open market.” Lignite ignites optimism The 135m-high sinter stack is the most visible emission on the steelworks. The emission is generated as the various raw material ingredients of coal, coke, iron ore and iron fines are blended and heated to combine into sinter. The resulting exhaust gas is then filtered and treated before being released into the atmosphere via the stack. For some time the visible plume from the sinter stack has been under the spotlight. Readers who have been following developments throughout the year may recall that we are trialling ways to reduce its environmental impact, firstly by cutting down emissions from the stack and secondly by reducing the visibility of the plume. The trials are taking longer than expected because of fluctuating volumes in sinter production, often because ironmaking schedules during the last six months have been relatively inconsistent. To assess the different options we need test conditions to be consistent and strictly controlled. The testing is being carried out in waves – each lasting a week – and the results are currently being scrutinised by Corus’ research and development team in Rotherham. So far the results are encouraging. It has been found that introducing lignite (brown coal) into the sinter ‘cake’ mix provides a more balanced control in the emissions – but it is a delicate balance. However, assessing the plume content for the most environmentally harmful materials is like looking for the equivalent of a grain of salt in a swimming pool. Easterly view of the sinter plant and stack. 4 Corus SA13 News for the community GENERAL A blast furnace is just ‘ore-some’ In this edition we take a look at the next stage in the steelmaking process. The blast furnace is an integral part of a typical steelworks, and is the focal point for many preparatory operations on the site. As described in previous editions of SA13, ironmaking relies on the harbour for incoming raw materials, their storage and blending, cokemaking, sinter production and energy. Without any of these commodities and processes, ironmaking cannot take place. Corus operates two blast furnaces at Port Talbot: Blast Furnace number 4 (BF4) and Blast Furnace number 5 (BF5). The carbon monoxide and exhaust gases rising through the furnace are drawn off through the downcomer and cleaned (scrubbed) and filtered to extract dust particles, before being recycled. The hot gas is circulated through the stoves to assist the speed of heating, and then used as a source of energy elsewhere on site. ‘Tapping’ through the clay bung. A blast furnace performs the specific role of converting iron ore into liquid iron. To do this, iron ore, coke, sinter and fluxes are carried to the top of the blast furnace by a conveyor, or in a skip and pulley system, and tipped, or charged, into a double sealed chamber at the top of the furnace. The chamber holds up to sixty tonnes of feedstock at a time and releases each charge into the lower chamber. When opening to drop the materials into the furnace, the lower chamber is sealed to prevent any loss of pressure and emissions to the atmosphere. At the same time the upper chamber is being refilled. Reducing the iron ore into liquid form cannot happen without heat. A series of three stoves supply super-heated air under pressure at temperatures above 900°C. Each one provides hot air in sequence. As one stove supplies the furnace, the other two are in various stages of reheating. As the hot air is forced into the furnace, the oxygen in the hot air combusts with the coke (carbon) to form carbon monoxide gas. This in turn generates more heat and, as it rises to the furnace top, reacts to remove oxygen from the melting iron ores, which are slowly sinking downwards under the weight of new material being added from the top. The liquid iron drops and collects in the hearth in the bottom of the furnace. The hot air ‘blast’ has another important purpose: as it is forced into the furnace, the pressure helps support the material from collapsing under its own weight into the hearth. The liquid iron (or ‘hot metal’ as it is called in the industry) is tapped at regular intervals by alternately drilling through clay bungs seated on each of two ‘tap’ holes in the hearth. The molten iron is then channelled and received in specially constructed railway containers, called torpedo ladles, for onward transport to the Steel Plant for further processing. The interaction of limestone in the furnace draws out the impurities to form slag, which floats on top of the liquid iron and is ‘tapped’ off separately at regular intervals. The whole operation works around the clock, 24 hours a day, 365 days a year. Every blast furnace operates on the basis of a ‘campaign life’, which can last as long as 12 years by maintaining continuous production. Operationally, a furnace can be ‘damped down’, i.e. its temperature reduced to levels that allow maintenance and repairs to take place under controlled conditions. However, should a furnace be allowed to cool for any length of time, then damage could be caused to the refractory brick lining which naturally contracts under cooling. Eventually, all furnace refractory brick linings wear away. At that stage, ironmaking ceases, and the furnace is relined with new bricks ready to Torpedo ladle. begin a new campaign. Iron making heritage The first multi-furnace ironworks built in Wales was situated in Blaenavon and began production in 1789. In its time, it was the equivalent of today’s ‘cutting edge technology’, with its purpose-built coke-fired furnaces and the air blast provided by a steam engine. Blaenavon is one of the best preserved 18th-century ironworks in Blaenavon Ironworks. Europe – complete with furnaces, cast houses, water balance tower, calcining kilns and ironworkers cottages. Blast Furnace Number 5. Control Centre for BF5. In November 2000, Blaenavon Industrial Landscape, in which the ironworks is situated, was awarded World Heritage Status. The site has been featured in several television programmes including the BBC’s ‘Coal House’ and ‘Coal House at War’, and Channel 4’s Time Team excavations. It is well worth a visit. Information is available on the following websites: www.world-heritage-blaenavon.org.uk, www.blaenavontic.com Corus SA13 News for the community 5 COMMUNITY Fast and Furious F1 racing hits the region Teams setting up in the Museum Foyer. F1 in Schools is regarded by the Formula One GP fraternity as a platform for introducing youngsters to the world of engineering and computer design. The student challenge, which attracts pupils as young as 10 years old, right up to Sixth Form students, is helping Formula One to shed its image as an elitist sport, accessible only through multi-million pound budgets. Not so. The F1 in Schools challenge competition is open to any school with access to a computer. The competition challenges teams of students to use CAD/CAM software to design, test and manufacture miniature CO2-powered balsa wood F1 cars. A purpose-built 20-metre track is used to test the speed of the model F1™ cars. In addition, the teams are judged their marketing and presentational skills, project management, car design, engineering development and team working. Presentation display by Cynfig Comprehensive School. The South Wales Regional Finals took place in late November at the National Waterfront Museum, Swansea. Sixteen teams were lined up for the Finals, sponsored locally by Corus, and category sponsors, IET, Jaguar and Denford. The challenge was introduced to the UK in 2000 and has since expanded to include 26 countries around the world, with over 7.5 million students having taken part. Mr Bernie Ecclestone, President and CEO of Formula One Management, gave his support to F1 in Schools by granting the challenge a world-wide protected trademark and a new logo in 2005. Since this time the initiative has built close links with teams and personalities within Formula One. For the second year running no entries were received from schools in Neath Port Talbot, so Corus will be looking to develop a mentoring scheme utilising its Graduate Engineers to adopt up to six school teams interested in competing in next year’s Finals. St Joseph’s RC School won the Innovative Team Award. There are several category prizes on offer at each of the UK’s regional events, including overall winners of each age group, the Fastest Car, the Best Engineered Car, the Best Team Marketing & Sponsorship, Best Team Merchandise Award and Overall Regional Winners. The winners from each age group go on to compete for the UK F1 in Schools title, held each January at the Autosport International Show in the NEC, Birmingham. ...ready 6 ...steady Corus SA13 News for the community Overall winners, Barry School for Boys, display their racing car. ...go COMMUNITY Get the (anti-drugs) message As many as 2,000 children across Neath Port Talbot were educated on the dangers of alcohol and drugs as part of a Corus-sponsored campaign in schools and on local radio. Pupils getting the anti-drugs message from Corus' in-house D&A counsellor, Holly Gallagher. The initiative saw police, drugs misuse counsellors and officers from child welfare agencies going into schools to give pupils advice. And a month-long competition gave the children the opportunity to enter either literary or artistic work about their own or family and friends’ experience of drugs misuse. The campaign also featured the production of a short video about a local teenager, Daniel Chapman, who has had a pretty hard upbringing, but who turned it around and is now a Commonwealth Games boxing gold medallist. The 19-year-old from Blaengwynfi won gold at the Commonwealth Youth Games in India. “Daniel Chapman has spent much of his upbringing in foster care and the influence by his peers to take drugs or alcohol has always been present. Boxing was a release for him,” said Corus Community Spokesman Keith Farron. “Daniel is now in full-time training with the GB squad and believes it has changed his life – making him a fantastic role model for these pupils.” Daniel, who has been awarded £300 by Corus to support his training, attended launch events at two of the schools taking part in the initiative. A radio advertising campaign on The Wave and Swansea Sound supported the project, with trailers leading up to the launch outlining the statistics in Wales for alcohol misuse, as well as giving out contact details for the Welsh Drug and Alcohol Helpline. Keith Farron, Steve Wiltshire, Daniel Chapman, Dr Brian Gibbons AM and PC Wozencroft. Keith Farron said: “The company is part of the community and takes its corporate responsibilities seriously. We hope this initiative will dissuade the pupils from getting caught up in drink and drugs, and help them to lead normal, healthy and happy lives.” Pupils learning to spot different types of illegal substances. Corus SA13 News for the community 7 COMMUNITY Prelude Theatre Arts School. i t t Pu k r l a e p s i n e t l o t t C i l h a r ist g n Trehore Snowmen by Irish Dance. Academy of Nothing superstitious occurred on this Friday the 13th, as Port Talbot’s Christmas lights were the first of several to be switched on in the Borough. The evening’s entertainment, led by Swansea Sound Radio, included a brass band and local Rhosafan Primary School Choir in the countdown to the big ‘switch on’. Despite the inclement weather, several hundred ‘hardy souls’ turned out to see the spectacle. As the clock chimed six o’clock the Mayor, Councillor Pam Thomas, pulled the lever – and the Christmas lights were on. 8 Corus SA13 News for the community mas Showtime C armen Miran da. Even the weather on the following day could not dampen the enthusiasm of the crowd. Arriving on his sleigh with his trusty reindeer Rudolf, Father Christmas and his Santa Parade wound slowly through the streets of Port Talbot to his Grotto in the Aberavon Shopping Centre. In view of the weather it was extremely heartening to see so many residents turn up for the switching on of the Christmas lights and Santa’s Parade on the following day. Corus says a big thank you to Swansea Sound Radio, and to the Neath Port Talbot Council’s Special Events Team for organising the events so well. COMMUNITY 2010 Richard Burton tribute 10km OK! Entries are coming in thick and fast for the next annual Richard Burton 10km Run, which takes place on Sunday 10 January at the Cwmafan Community Centre. Sponsored by Corus, the event attracts athletes from all over Wales and South West England. Starting runners in the Richard Burton 10km Run. The 10km course is quite demanding as it winds its way up and downhill through the streets of Cwmafan. Supported by Welsh Athletics, this event is unusual because it attracts serious runners who find the course a particular challenge, and because there is prize money on offer. The course record currently stands at 29 minutes, 23 seconds. New for the 2010 event is the one-mile fun run, which the organisers are hoping will attract a large number of local children. Each child will receive a goody bag upon completiton of the run. Unbelievably, the Richard Burton 10km Run, held each year on the streets of Cwmafan, had its origins some 27 years ago. The event was originally started as a means of raising funds for a local family who had lost loved ones in a car crash. Two years later, local celebrity and actor Richard Burton, gave his permission to use his name to raise the profile of the event. Sadly, just six months later, Richard Burton died, but his widow Sally, who now lives in Australia, gave her permission to continue using Richard's name to promote the race event. Sally Burton remains the event president and continues to take an active interest in the event, along with Richard’s brother, Graham Jenkins, who still lives in Pontrhydyfen. For more information and application forms please go to: www.richardburton10k.squarespace.com Intent on indenture success Students at Port Talbot marked the completion of their first-year apprenticeships with an official ‘indenture signing’ ceremony in late August. Each apprentice signs an ‘indenture’ – a document acknowledging they have completed their first year of formal college training – before spending a further three years in the workplace, learning practical skills in their chosen discipline. Guilds and Trades developed indentures in the Middle Ages. History of the indenture Port Talbot Works’ 1st Year Apprentices. An indenture represents a contract with the company, and providing a final trade test is completed, each apprentice will be offered employment. It also proves that the apprentice has recognisable skills that can be transferred to any industry. Many Corus Works Engineers and Directors started as apprentices, proving that a successful completion of an apprenticeship can be the first step to a long-term career. Each year Corus enrols a number of students on its Modern Apprenticeship scheme at each of its manufacturing sites throughout the UK. The indenture dates back to the late Middle Ages, when contracts were entered into with master craftsmen, such as cobblers, blacksmiths, tailors and weavers. The craftsmen benefited from cheap labour by taking on an apprentice, who was usually a child in their early teens. In return they were offered training, board and lodgings. The term comes from the medieval English ‘indenture of retainer’. The indenture was originally written on one piece of paper and cut (in a saw-tooth pattern) in half, so that when the apprenticeship was completed, and both pieces married up, it proved an apprentice’s legitimacy. Being a legally bound document, the indenture could only be broken by the Justices of the Peace, in circumstances such as ill treatment or abuse. Many apprentices, however, failed to complete their training. With the introduction of mass manufacturing and factory work in the 19th century, this early form of indenture eventually died out. Corus SA13 News for the community 9 COMMUNITY Corus golfers’ putt for charity Corus steelworkers have again demonstrated their mettle by helping another deserving local charity through their annual fundraising golf event. ‘Bacc’ to the future Children from a local Port Talbot school are studying towards the new Welsh Baccalaureate with the partnership of CSP UK. The new qualification develops both technical and communication skills as students study elements of science and engineering in the steel industry and also develop their writing and verbal dexterity. Six years on from their first golf day, Hot Rolled Products at Corus’ Port Talbot Works have held another successful charity golf event. The day was held at the Grove Golf Club in Cornelly with over £1,000 raised so far for charity – and the money is still coming in! Pupils from Duffryn Comprehensive prepare for Works tour. Designed by the Welsh Assembly Government to be unique in Wales, the Welsh Bacc has been created to add new dimensions to qualifications for 14 to 19-year-olds. It combines personal development factors with elements of existing qualifications like GCSEs or NVQs to make one wide award, which is endorsed by employers and further education establishments. Eleven 15-year-old students from Duffryn Comprehensive School have been inducted at Corus with a Works tour and a presentation about the business. Over the next 18 months, they will be supported by CSP UK engineering graduates, Gareth Morgan, Gareth Cross, Marc Davies and Jamal Bari, in carrying out studies which earn them points towards the ‘Welsh Bacc’ qualification. The day’s players. This year, the charity was CISS (Cancer Information and Support Services). Since its formation in 1993, CISS has become one of the leading cancer support organisations in Wales, helping over 13,000 families come to terms with cancer and its repercussions on family life. Overall winner Anthony Rogers with Keith Hampton and Andrew Stanley, Works Manager. Keith Hampton, a team leader at the re-heat furnaces, who has organised the event every year since 2003, said: “I would like to thank all involved in Hot Rolled Products for being so generous in their donations and especially to the people and businesses outside of Corus who have donated prizes for the raffle, who have once again come up trumps despite the current tough economic situation.” Johanna Challinor, CSP UK Learning and Development Advisor, says: “We can support teachers by showing young people how the theory they learn in the classroom is applied in real life. Young people can come to understand our technical processes, how the organisation works and furthermore how individuals carry out their work. Students can take away a positive view of the Works as a dynamic organisation and part of the life-blood of the community.” “Looking further ahead, it would be great to see Welsh Bacc students return to the Works as apprentices, functional trainees, graduates or as ‘expert’ recruits.” Board meets with Special Needs approval Learning just got easier and more fun for schoolchildren in Neath Port Talbot thanks to a donation from Corus towards a specialist interactive whiteboard at Ysgol Maes-Y-Coed. The whiteboard is different to those used in other schools in the county as it is specially designed to aid learning for children with special needs. Conventional interactive boards, which are front-lit, can be difficult for children with vision impairment to use, as shadows are often cast across the screen. Corus awarded Ysgol Maes-Y-Coed with a community award donation towards a back-lit board so that all the children in the school can enjoy using the learning tool. The interactive whiteboard enables IT to be used as an integral part of the children’s curriculum, giving them the opportunity to enhance literary and artistic skills, access the Internet and communicate with others. Mrs Helen Glover, Headmistress at Ysgol Maes-Y-Coed, commented: “The school is extremely grateful to Corus for supporting us with the purchase of the whiteboard. Its installation has already made a big difference to the children’s learning.” Pupils learn how to use their new whiteboard. 10 Corus Community Spokesman Keith Farron said: “Despite the current economic climate, it is important we continue to support activities in the community, particularly with schools.” Corus SA13 News for the community COMMUNITY Christmas wordsearch competition Once again we have teamed up with greengrocer Margaret Gammonds, to provide five fruit and vegetable hampers as prizes. All you have to do is correctly find and mark the nine words hidden in the wordsearch.The competition is open to all ages and the first five correct entries picked at random will win one of the five hampers. Closing date for entries is Friday 15 January 2010. Robin redbreast The robin first appeared on a Christmas card in the 1860s, pictured delivering a card. In those days postmen wore red tunics and were known as redbreasts. Hence its affectionate name – robin redbreast. Robins are not shy birds. They can be heard singing all through the winter months. How often have you been digging in the garden only to find a robin watching you, and then darting in to pick up a wriggling worm or insect from the freshly turned earth? Robins are very territorial birds, aggressively defending their individual areas for breeding. Despite being territorial, robins are also known to travel huge distances. One robin was recorded as travelling 1,500 miles – from Shetland to Southern Spain. In the UK, the oldest robin on record was a bird from the Blackpool area, which reached eight years and four months old. However, it is a German robin that holds the European record at 13 years and three months old. Want to find out more? Visit: www.bto.org or www.wildlifetrustswales.org Photo: Steve Waterhouse, WTW. Name Age Address Phone number Winners of our last competition (Summer edition): Mrs C Aston, Port Talbot; Mrs S Callister, Baglan; Mrs Evans, Aberavon; Mr E Jones, Port Talbot; BF Williams, Baglan. Corus SA13 News for the community 11 What’s on with Corus For information on forthcoming Corus-sponsored events in the Neath Port Talbot area, please visit: www.corussouthwales.co.uk All year round. National Waterfront Museum, Sunday 17 January. Cardiff Cross-Country Swansea Marina. Challenge UK 2010. Blackweir Field, Cardiff. A must visit for enquiring minds and 'hands on' activities. Incorporating a range of men's, women's and young Why not view the ‘Ghosts in Armour’ exhibition currently person's races, the event is open to all comers. touring Wales, Spain and Germany. Further information is obtainable on: Visit www.museumwales.ac.uk/en/swansea www.cardiffxchallenge.co.uk Sunday 10 January. 2010 Corus Richard Burton 10km Run, Cwmafan Community Centre. One year ago... Go on, blow the Christmas cobwebs away and enter the run. There's even a one-mile fun run for children. Every child that finishes the run will receive a Corus goody bag. Entry details available on: www.welshathletics.org Visit www.richardburton10k.squarespace.com dot com... for dot community You can browse SA13 on our website, and also see the latest ‘What’s on @ Corus’ events and sponsorships. Visit www.corussouthwales.co.uk and it will take you directly to the community page of the Corus website. Remember the ‘Big Freeze’ last Christmas? This picture of the Sgwd Gwladus Falls in the Neath Valley was taken by Peter Knowles. How to contact us Correspondence to the Editor The Editor will be pleased to receive your thoughts and opinions on any article you have read in this issue of SA13 Corus community newspaper. We would like to hear your views and opinions, whether on environmental issues, community activities, etc. Address: The Editor, Corus Strip Products UK, Business Headquarters, PO Box 42, Port Talbot, South Wales, SA13 2NG. Fax: 01639 603 179 Email: cspuk.community@corusgroup.com Community Award applications for Neath and Port Talbot Applications for community awards, community sponsorships/partnerships and ‘community assist’ projects for consideration must be submitted in writing to the following address: Community Liaison Manager, Corus Strip Products UK, Business Headquarters, PO Box 42, Port Talbot, South Wales, SA13 2NG. Email: cspuk.community@corusgroup.com Environmental complaints 01639 871111 (24 hours) For calls concerning environmental issues such as noise and air quality (during normal office hours the telephone exchange will re-direct your call. Calls received out of office hours will be directed by the Security Department). For written enquiries please address to: Environment Manager, Corus Strip Products UK, Business Headquarters, PO Box 42, Port Talbot, South Wales, SA13 2NG or fax: 01639 872 159. Careers information and general vacancies For further information regarding career opportunities and current job vacancies with Corus, go to www.corusgroupcareers.com or write to us at: Recruitment, Human Resources, Corus Strip Products UK, Business Headquarters, PO Box 42, Port Talbot, South Wales, SA13 2NG. All email correspondence should be addressed to: cspuk.recruitment@corusgroup.com Your community newspaper SA13 SA13 is written and produced by Communications, Corus Strip Products UK for the residents in Port Talbot and surrounding area. FSC labelled products are made with consideration for people, wildlife and the environment. The FSC label guarantees that the trees that are harvested are replaced or allowed to regenerate naturally. 12 Corus SA13 News for the community