Mech 1

advertisement

As the service technicion,

you need to find onswers to

these questions:

0

How is the broking

system octivoted

O Whot

is

?

o moster

cylinder?

@

Whoi is speciol obout

broke fluid? Why ore

there different types of

broke fluid?

Porking Brokes

flypes

\11 vehicles must have brakes.

' ::e

Although sometimes mistakenly called emergency brakes, parking brakes are brakes that are

of Brqkes

Without brakes,

no way to safely slow or stop a moving vehi. \Iost vehicles have two types of brakes-service

': r.iS and parking brakes.

iS

S,ervice Brqkes

Service brakes are the primary braking system.

,. applied to the service brake pedal is con" . i to hydraulic pressure by the master cylinder.

, :-ressure is transferred through the service

. :--. svstem until it reaches the wheel brakes.

':. orak€ force is applied to the vehicle's wheels,

: ,:-:lg the vehicle to slow or stop.

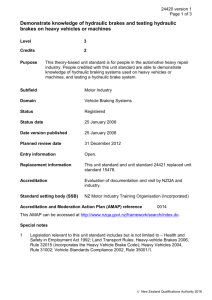

:igure

-

'

'

1-1 shows the major components (parts) of

::-cle's service brake system.

..- master cylinder serves as the brake fluid

,:r\-oir for the service brakes and converts

--=chanical force to hydraulic pressure for the

" .,king system.

- :,e brake hoses/lines can1, brake fluid under pres,-:e from the master cylinder to the wheel brakes.

- -. Cisc brakes include rotors

and disc pads, which

,- ,:=: brake force to the vehicle's wheels.

, ':um brakes include drums and brake shoes,

-* iransfer brake force to the vehicle's wheels.

' ,:

.i iLL'€T bra/u booster supplies the increased forces

.-:d

by the brakes. The booster does this with.

=quiring increased brake pedal pressure.

' : :iake pedal activates the master

cylinder.

used to keep a parked vehicle from moving. They

are usually on the rear wheels and are mechanically

operated.

Friction ond Broking

Friction and braking are closely related in vehicles.

Without friction, there would be no brakins.

Friction

Friction is the resistance to motion between two

objects or surfaces that touch. Friction varies by the

amount of force (often referred to as the load)

between the surfaces. Friction also varies by the

roughness of the surfaces and the materials from

which the objects are made. For instance, there is

more friction between a piece of sandpaper and a

block of wood than between an ice cube and

countertop.

A lubricant between the objects can reduce friction. Water between the melting ice cube and the

countertop allows the ice cube to move with less

friction. Similarly, wet brakes will not stop a vehicle as effectively as dry brakes,

Without friction, no moving object would slow

down or stop. A toy top, once set spinning, would

continue to spin. It is the friction between the top,

the surface it spins on, and the air around it that

slows

it down.

Power Broke Boosler

Reor Brokes

Porkinu Broke Lever

Broke Pedol

w Fig.

a

t-t The moiorcomponents in o iy'picol broking system. Whotarerhedifferences@l

e.b:*:.,',:j'":::!::!:':,::|-::..u:::!*:::i|r*!::o:'^:::-:':::::::.,....-...,...-_.,."-.si

Another example is the space shuttle as it

reenters the earth's atmosphere. Friction between

the shuttle's surface and the atmosphere reduces

the shuttle's speed. The reduction in speed creates

massive amounts of heat. Friction slows the space

shuttle from an orbital speed of about 18,000 mph

[28,800 kph] to a landing speed of about 500 mph

[800 kph].

There are two types of friction-static friction and

kinetic friction. Fig. 1-2.

Friction Stops!

A good driver's braking skills allow the brakes

to stop the vehicle. Unfortunately,lf a driver locks

his wheels and skids, the brakes cannot do their

job. Then the friction between the tires and the

road must stop the vehicle. The stopping distance

is much greater in a skid. The driver also has little

control of steering with locked wheels.

Let's examine an unfortunate situation. Two

older pickup trucks are traveling doum the freeway at 55 mph [BB kph]. The trucks are identical

except that one truck is fully loaded and the other

is empty. Suddenly several deer step onto the road-

way, right into the path of the trucks! The drivers

see the deer immediately and overreact. Each

slams on his brakes at exactly the same instant and

locks the wheels on his truck.

Under nor:rnal braking conditions more energy

will be required to stop the fully loaded truck than

the empty truck. The loaded truck would normally

require a greater stopping distance. The two trucks

with the locked brakes in this example have the

same tire surface area in contact with the road, but

they differ in weight. Under these conditions will

the lighter truck still be able to stop in a shorter distance? Does the weight of the truck make a difference if the truck is skidding?

Experimenting with Friction

Meels NATEF Scienre Slondords

for friction ond decelerolion.

Moteriols cnd Equipment

. Three lorge metol flol woshers

. Smoll piece of double-fored tope

.

O

Ruler or other stroightedge

Tape two of the washers together with the

double-faced tape. No tape should touch the

bottom surface of the stack. This stack represents the heavy, loaded truck. The single

washer represents the lighter, empty truck.

O Place the ruler on a smooth, level surface.

O Put the single washer and the double washer

side-by-side, touching the straight edge of

the ruler. Fig. A.

O Quickly shove and retract the mler to set the

washers in motion. \Arhich one stops first?

Results ond Anolysis As you should have

observed, the stopping distances of the objects

are not dependent on their weight. Why?

Explonotion The force of friction stops the

trucks and washers. The amount of friction is

proportional to the weight of the object. Each

truck's kinetic energ'y of motion is also proportional to its mass. You might expect that the

double washer would take longer to stop

because of its greater kinetic energ'y. However,

twice the mass results in twice the frictional

stopping force. Finally, doubling the amount of

friction causes the double washers to stop in

exactly the same distance as the single washer.

The single washer has half the kinetic energ'y

but also half the frictional stopping force.

Stotic Friction Static means ,,at rest.,,

Static fric_

:on is the resistance between objects that are in

rtact but at rest. Parking brakes ui" un example

of

':ic friction at work. Friction between the Lrake

:.rrg and the brake drum or rotor keeps the wheels

' :.ir moving. Friction between the

vehicle's

-: rhe pavement keeps the vehicle from sliding.tires

{inetic Friction Kinetic means ,,in motion.,, The

:-Sr?ltc€ between objects that are in contact

and

-:lative motion is called kinetic friction.

-

-ike the space shuttle, vehicles on earth use

-=tic friction to change their motion into heat

-:qv. Friction between the moving and nonmov_

- :arts of the service brakes creates heat.

rs the vehicle slows and stops, kinetic energ-y is

-,,rged to heat energy.

The brakes pass this heat

.re air and other wheel parts.

What are service brakes?

\\4rat is friction?

){ame the two types of friction.

(b)

*

*

f,t. t -2 There is more friction between obiects ot rest (o) €

ihon,between obiects in relotive motion (b). Mtre

force is !

needed to move on obfect ot rest thon n [eep

on oU;".t- i

moving. Obiects dt rest have what type oi frictionZ

;

w,:

Give an example of static friction.

Describe how kinetic friction is used to slow

or

stop a vehicle.

sltoes against

Service Broke Sysfem

-:e service brake system is one of the most

_

Fig. 1-3(a).

clamp

the inside of

a

rotating brake drum.

Disc brakes use hydraulic pressure to

brake pads against a

brake rotor. Fig. 1-B(b).

rotating disc called a

_'rtant systems on a vehicle. The engine

may get

ehicle moving, but it is the brakes-that slow

or

it.

- The service brakes are designed to be more

.rfui than the engine. \A4ren uppt"a. braKes can

,- stall the engine.

.

Broke Pods

Coliper

:3"oke Acfion

:=n1ce brakes, those operated by the vehicle's

,... pedal, have two basic parts. The first is the

,, :r cylinder. The

master qlinder

is the part that

.:es hydraulic (fluid) pressure throush ihe

brake

The second is the wheel brake mechaiisms.These

-,,cated at each of the vehicle's wheels. They are

ated by hydraulic pressure.

-

o types of service brakes are used on vehicles.

': brakes use hydraulic pressure to press brake

.'.

Piston

Broking

Pressure

Frictionol

Broke

Contoct

Rolor

Fig. l-3 There ore two types of service brokes: e,l

drum brokes (o) ond disc brokes

bt. why cl;

they have these names? (Robetloxh|;mbi) :

i

,r.i:r:rr.r:i.ii,,:i:!.:,,:ii _.r*...,,.-..,,,r",,.Y

]

Drum brakes have shoes that press against the

inside of the rotating brake drum. Fig. 1-4. Early

bicycle coaster brakes worked this way.

ru

Disc brakes have pads that clamp against a rotating rotor. Fig. 1-5. Hand-operated bicycle brakes

work in a similar way.

Weor Indicolor

Wheel(ylinder

(oliper

Anchor Pin

Secondory Shoe

Broke-Shoe

ond lining

Holddown

Inboord

Pod

Springs

Self.

Piston

Adiu$er

ioble

Porking

Broke

Lever

e rig. t-5

Adiu$er Spring

Adiusling Screw

*

Fig. t-4 Drum brokes hove shoes thot push ogoinst wl

the inside of o rototing drum. Whot fype of friction

t

:,

*w is ai wark here?

tfod l,laror (ompony)

Disc broke

pods clomp oround o

rototing rotor to slow the

vehicle. What is

crealed as a result of

the braking o,ction?

(Deko lltorotne

*:

*

Division

of Genuol

lllotorshrporofon)

Remember-Safety Firstl

Safety is important to both the customer and

the technician. If you, as the technician, are not

careful, you may harm yourself or your customer. And you may do serious damage to your

customer's vehicle.

An action as simple as using old brake fluid

that has been contaminated with water can cause

brakes to fail. Using the wrong fluid or not checking the fluid level properly can also lead to problems. To assure personal safety and proper

service of your customer's car-read!

Technicians must always look for visual clues.

Sometimes a manual will warn you about specific service products. Sometimes, the label on a

can or package will tell all. When you read the

Safety First sections in this chapter, you will be

given specific warnings about brake fluid. Stay

on the alert for safety information about all products and procedures that you use.

Meels NAIEF Communicotions Stondords for rollecting, evoluoting,

und using informolion.

Read the Safety First features later

in

this

chapter.

0

Where could you find this information

and other similar warnings?

O

Make a list of sources that warn or advise

about the products used in servicing a

vehicle.

0

Keep a list of specific warnings that you

find as you service cars. f-Ise this list as an

on-thejob resource.

Pushing the vehicle's service brake pedal forces

:'Luid through the braking system lines and hoses. The

'Jressure of this fluid activates the brakes. The brake

,hoes and brake pads are stationary. The drums and

.'otors are moving. Kinetic friction between the brake

.hoes and drums, or brake pads and rotors, slows and

.ren stops wheel rotation. Friction between the tires

,.rd the road stops the vehicle.

The first dual-braking systems separated the front

brakes from the rear brakes. Fig. 1-6(a). More recent

dual-braking systems are separated diagonally. Each

system on a diagonally split system controls one

front brake and one rear brake. Fig. 1-6 (b).

Primory Reservoir

(Front Broke Sy$em)

Secondory Reservoir

(Reor Broke Sy$em)

The service brakes can be applied hard enough

from rotating). When

::akes are locked, they no longer convert the vehie's motion into heat. Success in stopping a vehicle

'-en depends entirely on the kinetic friction

:tween the tires and the road. If the kinetic fric,rn is not great enough, the tires lose their grip on

. e road and the vehicle begins to skid.

,,, lock the wheels (stop them

The best braking performance occurs just before

tires begin to lose traction. This is the principle

. antilock

(o) Front-Reor Split

Fronl Disc

:

Reor Drum

Brokes

Brokes

brakes.

Wheel

Moster (ylinder

Duql-Brqking Sysfems

Cylinder

Before 1967 most vehicles had a single-piston

-,.ster cylinder. This meant that brakes on all four

,.eels were activated by a single hydraulic system.

' -.nr. part of the hydraulic system failed, the whole

.,king system failed. In 1967, the U.S. Department

Broke Pedol

Secondory Sedion

Transportation (DOT) passed legislation requir. r ehicles to have dual-braking systems.

\

a dual-piston master

-:-Lder, two fluid reservoirs, and two separate

dual-braking system has

Primory Sedion

\Vhat are the two

parts of the

service

brakes?

0

What are the two types of service brakes used

on vehicles?

o \Vhat is the effect of kinetic friction

between

(or

pads

and

brake

the brake shoes and drums

rotors)

?

Reor Drum

Brokes

::'aulic systems. One hydraulic system controls

- rrakes of two wheels. The other hydraulic sys--. controls the remaining two wheels. This

,:rgement provides additional safety. If one sys'-. iaiis, the other system continues to work.

io

{b) Diogonolly Split

Front Disc

Brokes

w Fig. t-6 Duol-broking

'*l

systems ore split eith 'il

front to reor (o) or diogonolly (bl. what is

the benefit of

*

(tord

Alotar

I

a dual-brdking system?

[ompony)

@j

O What kind of pressure do drum brakes use to

press the brake shoes against the inside of a

rotating brake drum?

o

What are the main components of a dualbraking system?

a

Brqke Fluid

a

fluid is used to transfer hydraulic pressure

from the service brake's master cylinder to the

Brake

Brake fluid must:

Be compatible with the metals in the brake system.

Lubricate the moving parts of the braking system.

Brake fluid must not:

too thin or too thick as the temperature

. Become

changes.

wheel brake mechanisms.

Brqke Fluid Properties

Brake fluid must remain stable through a wide

range of temperatures and operating conditions.

a

Evaporate easily.

a

Soften

or damage rubber parts of the braking

system.

. Boil at high temperatures.

Converting lbmperatures

Vapor lock, overheated brakes, boiling radiators, and overheated engines all involve heat and

temperature changes.

The rate of change in Fahrenheit to Celsius is:

Most service manuals show temperatures in

For each increase of 1.8' Fahrenheit (1.8"F),

there is an increase of 1o Celsius (1"C). Note that

both degrees Celsius and degrees Fahrenheit.

However, you will sometimes need to convert

temperature readings from one system to the

other. You could use thermometers that give temperatures both in degrees Celsius ("C) and

degrees Fahrenheit ('F). Fig. A. But it's often

easier to convert a temperature mathematically.

- 32 180

loo-o:loo:t'o

212

OoC equals 32oF.

To convert Celsius temperatures to Fahrenheit

temperatures, use this formula:

F:

+

32

The rate of change in Celsius to Fahrenheit is:

100-0

Refer to Fig. A. Look at the temperature difference between the boiling point and the freezing point of water. The change in Fahrenheit

temperature from 2I2'F to 32'F corresponds to

a change in Celsius from 100"C to 0"C.

1.8 C

100 5

^__^

212-n:lgo:O:u'Jro

For each increase of 5"C there is an increase of

9'F. Note that 32'F corresponds to 0oC.

To convert Fahrenheit temperatures to Celsius

temperatures, you can use this formula:

Boiling Poinl

C:;(F*

of Woler

32)

or C:0.556(F-

32)

i

a

a

Meels NATEF Molhemolics Stondords for using formulos lo converl

meosuremenls between English ond melric systems.

Freezing Point

of Woler

O What is 98.6'F in oC?

O DOT 3 brake fluid boils at 401"F. \Arhat is

the equivalent temperature on the Celsius

scale?

0

What is the Fahrenheit equivalent temperature for 40'C?

a

I

I

C

f

I

n

I

rl

J

...r-,..,c e,,....3.,..,,s_.,e.

e-....J... r..,

Moteriols DOT 3 ond DOT 4 broke fluids

\{4ren brake fluid boils, it becomes a vapor (gas),

much like boiling water turns to steam. A vapor can

compressed.

Pressing on the service brake pedal will compress the

apor in the hydraulic lines instead of transferring the

"

'rressure through the fluid. This can lead to partial or

Broke Fluid Types The Society of Automotive

:ngineers (SAE) and the DOT have standards for

:rake fluid. The DOT specification is typically the

ne referred to. The three currently approved types

.:e DOT 3, DOT 4, and DOT 5. The higher the

.--rmber, the more strict the specifications, especially

'r the boiling point.

Iecl

the

T

monufocturer's specificotions. A vehicle's worif incorrect or incompotible

broke fluids ore used.

ronty moy be voided

DOT 3 and DOT 4 brake fluid types are

1r glycol-based. These are the most commonly

,-d. They are inexpensive and compatible with

. ,st service brake systems.

'

DOT 5 brake fluid is a silicone-based product.

.rcone-based brake fluid is more exDensive than

.r glycol-based brake fluid. It does not readily

.rd with DOT 3 and DOT 4 types, so it must not

: rrixed with them.

I OT 5 brake fluid offers some advantages. It has

.her boiling point than DOT 3 or DOT 4 types.

*.

ore olso sirong point solvents thot con

domoge o vehic'ieis finish. Toke core to ovoid

be compressed; a liquid cannot be

lomplete braking system failure, sometimes called

:,rake pedalfade.Infact, vapor in the hydraulic brakrg system is the primary reason for brake pedal fade.

.

)',

,

Moishrre gets into brake fluid through damaged

seals and loose or faulty connections on the master

cylinder. Moishrre also enters throug'h damaged brake

hoses and seals on wheel cylinders and calipers.

After containers of brake fluid have

been

opened, they must be kept tightly capped when not

in use. Brake fluid should not be stored for a long

period of time. The longer it is stored, the more

moisture it can absorb.

Pour brake fluid directly into the master cylinder

reservoir from a sealed and clean container. This will

decrease the chance of brake fluid contamination. It

is important to keep dust and dirt out of the master

cylinder reservoir.

lnsfolling Broke Fluid

As the disc brakes wear, the fluid level in the

reservoir will drop. If the level gets too low, there is

a possibility that air can get into the hydraulic system. To prevent this, the fluid level must be kept

above the minimum level at all times. Fig. 1-7.

Additionall|, whenever the hydraulic system is

serviced, the brake fluid will have to be replenished.

Mo$er (ylinder

Fluid Reservoir

not damage paint and does not absorb mois'. However, because of its higher cost, it is usuused only in heavy-duty applications. There

,rnly a few applications where silicone-based

.,e fluid is in common use. They are:

i-litary vehicles.

stal vehicles.

.. -,es

Broke Fluid

-rae cars.

i rorcycles.

':ier in Broke Fluid

The major disadvantage

, h glycol-based brake fluid is that it absorbs

,:ure. Because water boils at 212"F [100"C] and

- 3 brake fluid boils at 401'F [205'C], any

,-:re in the brake fluid lowers its boiling point.

.rng the boiling point of brake fluid increases

:ance of having vapor in the braking system.

ir'\

F*

s rig. t-z

I

I

I

I

I

t

Alwoys mointoin the broke fluid level obove€

the MIN mork on the reservoir. Do not overfill. whor

miglli cause ftre ffuid level ta becorne critically

* low?

(Chtlton is

o

registered trodemork

of

W.

6, Nkhlls, ln(.)

r

l

Key Poinfs

Review Gluesfions

Meets the following NATEF Standards for Brakes:

describing brake functions and principles; selecting,

handling, storing, and installing brake fluids.

o The service braking system is activated

hydraulically. The parking brake is activated

mechanically.

o Friction provides braking action in a vehicle.

o Service brakes have two main components:

the master cylinder and the wheel brake

mechanisms.

o The two basic types of service brakes are drum

and disc.

o Dual-braking systems can be identified by the

number of separate fluid reservoirs in the master

cylinder.

o Brake fluids are chosen on the basis of intended

O What

use.

t A vehicle must be safely supported for brake

servicing.

are the two types of braking systems on

most motor vehicles?

O

Explain how friction provides braking action in

a motor vehicle.

O What is the advantage of a dual-braking

system?

O How many

separate fluid reservoirs does a

dual-braking system master cylinder have?

O

FIow is the service braking system activated?

0

Explain the process for selecting and installing

brake fluid.

O

Describe the safe way to support a motor vehicle for brake servicin.q.

o

Explain why you should

avoid "locking up" your service brakes.

o

Is it safe to use brake fluid

from a container that has been opened, capped,

and stored for six months? Whv or whv not?

Applying Essential Knowledge in Apprenticeship Training

Serving an apprenticeship is an ancient, timetested way of learning how to do a job. In an

apprenticeship program affiliated with a training

center, you can learn and earn. Part of the time you

attend class. Another part of the time, you are a

paid employee of a local business. There you

receive on-thejob training.

Apprenticeship training can be a valuable part of

your education. By your work, you earn educational

credit. The employer rotates apprentices through different knowledge areas, such as electrical/electronic

systems, suspension and steering systems, and brake

systems. Apprentices generally find their automotive

course work more meaningful after applying it in a

real job. After graduation, the successful apprentice

finds job-hunting easier because of the knowledge

and experience he or she has gained.

The course work you've already completed will

be very helpful if you start an apprenticeship. Here

are tips on applying the essential knowledge in

automotive services to the work-based learning

experience of apprenticeship training:

. Compare what you learn in class to what you are

taught on the job. Determine what knowledge

from your course work you can apply at work.

. Ask whether there are different ways to look at

the same problem. What more do you want to

learn in class to help you do your job?

Action Actiuity

Ask whether apprenticeship placements in your

community are arranged through the training center or directly with individual businesses. Prepare a

short oral report detailing what a first-year apprentice in automotive services can expect to learn.

Answering the following praclice queslions will help you prepdre for the ASE certification tesls.

l. Two service technicians are discussing a car's pri6. You would expect your car's tires to have betmary braking system. They are talking about its:

ter traction with the road when the road is:

@ Parking brake system.

@ Just wet.

@ Air brake system.

O Wet and icy.

G) Service brake system.

@ Ice covered.

@ Emergency brake system.

Dry.

o

of the following types of wheel brakes

are found in a car's service braking system?

@ Drum and coaster brakes.

2. \Aihich

O

Disc and coaster brakes.

l. Two technicians are working on a can's service

brakes. The technicians determine that the car

has a dual-braking system. This means that the

car has:

@ Coaster and hand brakes.

O Drum and disc brakes.

@ Two hydraulic braking

O

systems.

Two types of brakes.

@ Two sets of brakes.

3.

j

t

,iII

:re

in

mt

are

lgt

L

Technician A and Technician B are talking

about which components in a moving vehicle's

wheel brake system are in relative motion.

Technician A says they are the drums and

rotors. Technician B says they are the brake

shoes and drums. \Arho is correct?

@ Technician A.

0 Technician B.

@ Both Technician A and Technician B.

0 Neither Technician A nor Technician B.

O

A and Technician B are discussing

the dual-braking system of a brand new front

wheel drive car. Technician A says it is more

likely that the brakes will be separated from

front to rear. Technician B says it is more likely

that they will be separated diagonally. \Arho is

8. Technician

correct?

@ Technician A.

0

Technician B.

@ Both Technician A and Technician B.

0 Neither Technician A nor Technician B.

{. \\rhen a vehicle's wheel brakes are locked up

u'here would you expect to find kinetic friction

at work?

@ In the wheel brake system.

O In the parking brake system.

O Where the tires meet the road.

O In the entire service braking system.

9. The most commonly used brake fluids are:

O DOT 3 and DOT b.

O DOT 3 and DOT 4.

O DOT 4 and DOT 5.

O DOT 5 and DOT 6.

iA

rb

Two master cylinders.

Gchnician A and Technician B are discussing at

rrhat instant a vehicle's braking system is most

effective. Technician A says it is just before the

r'-heels lock up. Technician B says it is just after

-,]re brakes have been applied.

Who is correct?

O Technician A.

O

O

O

Technician B.

Both Technician A and Technician B.

Neither Technician A nor Technician B.

10.

DOT 3 and DOT 4 brake fluids are:

@ Water-based.

0

Silicone-based.

@ Polyglycol-based.

O

Water- and polyglycol-based.