OSHA Presentations

advertisement

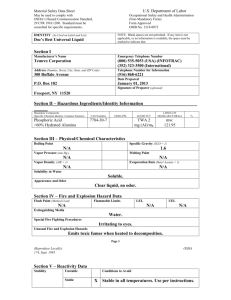

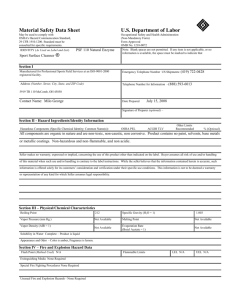

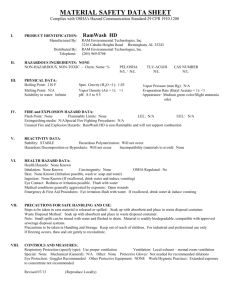

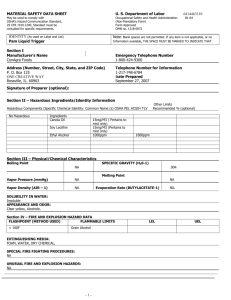

OSHA Update MASWM Conference October 7, 2014 Todd Sieleman Compliance Assistance Specialist Kansas City OSHA Office sieleman.todd@dol.gov Mike Minicky, CSP Compliance Assistance Specialist St. Louis OSHA Office minicky.michael@dol.gov Talking Points OSHA history & mission Safety & health data Employer responsibilities OSHA inspections Common Violations Safety and health resources History of OSHA OSHA stands for the Occupational Safety and Health Administration, an agency of the U.S. Department of Labor OSHA’s responsibility is worker safety and health protection On December 29, 1970, President Nixon signed the OSH Act This Act created OSHA, the agency, which formally came into being on April 28, 1971 3 OSHA’s Mission The mission of OSHA is to save lives, prevent injuries and protect the health of America’s workers. Some of the things OSHA does to carry out its mission are: ◦ developing job safety and health standards and enforcing them through worksite inspections, ◦ maintaining a reporting and recordkeeping system to keep track of job-related injuries and illnesses, and ◦ providing training programs to increase knowledge about occupational safety and health. 4 6 9 11 Topic 2: What Rights Do Employees Have Under OSHA? The right to: ◦ A safe and healthful workplace ◦ Know about hazardous chemicals ◦ Information about injuries and illnesses in your workplace ◦ Complain or request hazard correction from employer ◦ Training ◦ Hazard exposure and medical records ◦ File a complaint with OSHA ◦ Participate in an OSHA inspection ◦ Be free from retaliation for exercising safety and health rights 12 What Are Employer Responsibilities Under OSHA? Provide a workplace free from recognized hazards and comply with OSHA standards Provide training required by OSHA standards Keep records of injuries and illnesses Provide medical exams when required by OSHA standards and provide workers access to their exposure and medical records Not discriminate against workers who exercise their rights under the Act (Section 11(c)) Post OSHA citations and abatement verification notices Provide and pay for PPE 13 FY 2007 – FY 2013 Inspections Conducted 50,000 39,324 40,000 38,667 39,004 40,993 40,648 40,961 37,917 30,000 20,000 10,000 0 FY07 FY08 FY09 FY10 FY11 FY12 FY13 The OSH Act authorizes OSHA compliance safety and health officers (CSHOs) to conduct workplace inspections at reasonable times. OSHA conducts inspections without advance notice, except in rare circumstances (e.g. Imminent Danger) In fact, anyone who tells an employer about an OSHA inspection in advance can receive fines and a jail term. 15 Priority 1st Category of Inspection Imminent Danger: Reasonable certainty an immediate danger exists 2nd Fatality/Catastrophe: Reported to OSHA; inspected ASAP 3rd Complaints/Referrals: Worker or worker representative can file a complaint about a safety or health hazard 4th Programmed Inspections: Cover industries and employers with high injury and illness rates, specific hazards, or other exposures. 16 VIOLATION TYPE PENALTY WILLFUL A violation that the employer intentionally and knowingly commits or a violation that the employer commits with plain indifference to the law. OSHA may propose penalties of up to $70,000 for each willful violation, with a minimum penalty of $5,000 for each willful violation. SERIOUS A violation where there is substantial probability that death or serious physical harm could result and that the employer knew, or should have known, of the hazard. There is a mandatory penalty for serious violations which may be up to $7,000. OTHER-THAN-SERIOUS A violation that has a direct relationship to safety and health, but probably would not cause death or serious physical harm. OSHA may propose a penalty of up to $7,000 for each other-than-serious violation. REPEATED A violation that is the same or similar to a previous violation. OSHA may propose penalties of up to $70,000 for each repeated violation. 17 FY 2007 – FY 2013 Average Current Penalty Per Serious Violation $2,500 $2,133 $2,153 $2,008 $2,000 $1,500 $1,000 $918 $998 $970 $1,053 $500 $0 FY07 FY08 FY09 FY10 Data Source: OIS Insp. Summary Rpt. Dated 9/17/13 FY11 FY12 FY13 St. Louis Area Office Local/Regional/National Emphasis Programs General Industry Amputations Nursing Homes Forktruck Chemical Plants Grain Handling Site-Specific Targeting Program Logging/Sawmills Primary Metals Noise & Respiratory Hexavalent Chromium No Comprehensive 02 Recycling/Scrap Metal Some Common Violations 20 29 CFR Part 1904 Recording and Reporting Occupational Injuries and Illnesses 21 Purpose (of the Rule) To require employers to record and report work-related fatalities, injuries and illnesses – Note: Recording or reporting a work-related injury, illness, or fatality does not mean the the employer or employee was at fault, an OSHA rule has been violated, or that the employee is eligible for workers’ compensation or other benefits. OSHA injury and illness recordkeeping and Workers’ Compensation are independent of each other 22 1904.4 – Recording Criteria Covered employers must record each fatality, injury or illness that: – is work-related, and – is a new case, and – meets one or more of the criteria contained in sections 1904.7 through 1904.11. 23 1904.7 – General Recording Criteria An injury or illness is recordable if it results in one or more of the following: – – – – – – – Death Days away from work Restricted work activity Transfer to another job Medical treatment beyond first aid Loss of consciousness Significant injury or illness diagnosed by a PLHCP 24 25 26 27 1904.32 – Annual Summary Review OSHA Form 300 for completeness and accuracy, correct deficiencies Complete OSHA Form 300A Certify summary Post summary 28 Major Revisions to the Hazard Communication Standard Hazard classification: Provides specific criteria for Labels: Chemical manufacturers and importers will be required to Safety Data Sheets: Will now have a specified 16-section classification of health and physical hazards, as well as classification of mixtures. provide a label that includes a harmonized signal word, pictogram, and hazard statement for each hazard class and category. Precautionary statements must also be provided. format. Information and training: The Revised HCS requires that workers be trained within two years to facilitate recognition and understanding of the new labels and safety data sheets. GHS Pictograms Explosive Flammable Oxidizer Compressed Gas ! Acute Toxicity Corrosive Chronic Health Hazard Irritant A sample GHS compliant label Control – Isolate Electrical Parts Cabinets, Boxes & Fittings Conductors going into them must be protected, and unused openings must be closed OSHA Office of Training & Education 32 Hazard – Improper Grounding • Tools plugged into improperly grounded circuits may become energized • Broken wire or plug on extension cord • Some of the most frequently violated OSHA standards OSHA Office of Training & Education 33 Questions? ALL ABOUT OSHA Missouri Association of Sheltered Workshop Managers October 7, 2014 Todd Sieleman Compliance Assistance Specialist Kansas City Area Office sieleman.todd@dol.gov What to Expect from OSHA Types of inspections Inspection Process (step-by-step) Types of citations Post inspection activity What’s new Reporting fatalities/severe injury requirements GHS - changes in Hazard Communication Standard 3 What’s on the horizon Injury Illness Recordkeeping Proposal Written Programs Hazardous Energy Control (Lockout Tagout) Electrical Safety Hazard Communication Personal Protective Equipment (PPE) Blood-Borne Pathogens Machine Guarding 5 Types of Inspections Accident/Fatality Self Reporting Media referral Law Enforcement Types of Inspections Targeted Enforcement National Emphasis Programs: Hazardous Machinery (reduce workplace hazards likely to cause amputations) Process Safety Management Site-Specific Targeting Types of Inspections Targeted Enforcement Local Emphasis Programs: Falls, Overhead Power Lines Powered Industrial Truck Grain Handling Industries Construction Following a Severe Weather Event Logging and Sawmill Industries Missouri Work Comp Silica u:\ips master templates\best work product\presentation suite\construction presentation suite 2012\proposal presentation.potx u:\ips master templates\best work product\presentation suite\construction presentation suite 2012\proposal presentation.potx u:\ips master templates\best work product\presentation suite\construction presentation suite 2012\proposal presentation.potx u:\ips master templates\best work product\presentation suite\construction presentation suite 2012\proposal presentation.potx u:\ips master templates\best work product\presentation suite\construction presentation suite 2012\proposal presentation.potx Types of Inspections Observed Hazard In Public View: Generally construction activity Types of Inspections Complaint driven Formal Informal Types of Inspections Complaint Driven Formal Current employee (or employee agent) signed complaint Onsite inspection conducted Partial inspection involving listed complaint items only Inspection scope can be enlarged if plain view hazards are noted Types of Inspections Complaint Driven Informal Not an employee (may be any source) No onsite inspection Phone/fax Determination of abatement What to Expect in an Inspection Opening conference: Credentials displayed Union participation (if applicable) Purpose and inspection scope defined Copy of inspection complaint (if applicable) Advisement of employer and employee rights 11c protection Private interviews with employees (union rep may be present if employee desires) Proprietary/confidential information Photography Personal Protective Equipment Request for OSHA Injury and Illness Logs (300 and 300a) What to Expect in an Inspection Examination of Written Programs: All programs if inspection scope is comprehensive Select programs if partial inspection What to Expect in an Inspection Workplace Walk-through: All areas if inspection scope is comprehensive Select areas if partial inspection What to Expect in an Inspection Documentation of Noted Hazards: Photographs Sketches Interviews What to Expect in an Inspection Closing Conference: Noted Hazards Abatement date Citation posting (3 days or until hazard corrected) Employer and employee rights Post Inspection Activity Agreement with citation issuance and payment of assessed penalty Informal conference Contest citation After 15 working days all citations become final order What’s new Reporting fatalities/severe injury requirements (Old) Fatality or hospitalization of 3 or more employees reported within 8 hours (New) Fatality within 8 hours. Any hospitalization, amputation, loss of an eye - 24 hours. Starting in 2015, employers will have to report the following to OSHA: • All work-related fatalities • All work-related inpatient hospitalizations of one or more employees • All work-related amputations • All work-related losses of an eye What’s new Reporting fatalities/severe injury requirements All employers under OSHA jurisdiction must report all work-related fatalities, hospitalizations, amputations and losses of an eye to OSHA, even employers who are exempt from routinely keeping OSHA injury and illness records due to company size or industry. An amputation is defined as the traumatic loss of a limb or other external body part. Amputations include a part, such as a limb or appendage, that has been severed, cut off, amputated (either completely or partially); fingertip amputations with or without bone loss; medical amputations resulting from irreparable damage; and amputations of body parts that have since been reattached. What’s new Globally Harmonized System Aligning HazCom with United Nations’ global chemical labeling system What’s new Globally Harmonized System Employers must train workers on the new label requirements; signal word “Warning” or “Danger”, Pictograms and SDS format by December 1, 2013 Chemical manufacturers, importers, distributors and employees must comply with all modified provisions of the final rule by June 1, 2015. Distributors may ship under old system until December 1, 2015 June 1, 2016, all program elements in place GHS Pictograms Explosive Flammable Oxidizer Compressed Gas ! Acute Toxicity Corrosive Chronic Health Hazard Irritant A sample GHS compliant label What’s on the Horizon What’s on the Horizon Recordkeeping OSHA issued proposed rule (Stage 3) in Nov 2013 to add requirements for electronic submission of injury and illness information employers are already required to keep under existing standards, Part 1904. What’s on the Horizon Recordkeeping The Proposal would require: Employers with more than 250 workers to electronically submit data on a quarterly basis Those with 20 to 250 workers to e-file annually 11 to 20; e-file if notified. Under the proposed new rule, around 440,000 companies will be subject to requirement to report injury and illness rates. Approximately 220,000 currently report All data from the OSHA log would be public information EXCEPT the employee name Stage 1 Making the Decision: Conducting Preliminary Rulemaking Activities Stage 2 Developing the Proposed Rule 12-36 mos 12-36 mos Stage 3 Publishing the Proposed Rule Stage 4 Developing & Analyzing the Rulemaking Record 2-3 mos 6-24 mos Stage 5 Developing the Final Rule 18-36 mos Stage 6 Publishing the Final Rule 2-3 mos Stage 7 Post Promulgation Activities 4-12 mos 12.5 years… Semi Annual Regulatory Agenda June 2014 Written Program Requirements Hazardous Energy Control (Lockout Tagout) Electrical Safety Hazard Communication Personal Protective Equipment (PPE) Blood-Borne Pathogens Machine Guarding Powered Industrial Truck Hazardous Energy Control 1910.147 Hazardous Energy Control Hazardous Energy Control Note: Exception: The employer need not document the required procedure for a particular machine or equipment, when ALL of the following elements exist: (1) The machine or equipment has no potential for stored or residual energy or reaccumulation of stored energy after shut down which could endanger employees; (2) the machine or equipment has a single energy source which can be readily identified and isolated; (3) the isolation and locking out of that energy source will completely deenergize and deactivate the machine or equipment; (4) the machine or equipment is isolated from that energy source and locked out during servicing or maintenance; (5) a single lockout device will achieve a locked-out condition; (6) the lockout device is under the exclusive control of the authorized employee performing the servicing or maintenance; (7) the servicing or maintenance does not create hazards for other employees; and (8) the employer, in utilizing this exception, has had no accidents involving the unexpected activation or reenergization of the machine or equipment during servicing or maintenance. u:\ips master templates\best work product\presentation suite\construction presentation suite 2012\proposal presentation.potx Electrical Safety 1910.333 - 334- 335 Electrical Safety https://www.osha.gov/dte/grant_materials/fy07/sh-16615-07/train-thetrainer_manual2.pdf Electrical Safety Electrical Safety 1910.303(b)(2)Installation and use. Listed or labeled equipment shall be installed and used in accordance with any instructions included in the listing or labeling. 1910.303(b)(6)Deteriorating agents. Unless identified for use in the operating environment, no conductors or equipment shall be located in damp or wet locations; where exposed to gases, fumes, vapors, liquids, or other agents that have a deteriorating effect on the conductors or equipment; or where exposed to excessive temperatures. 1910.303(b)(7)Mechanical execution of work. Electric equipment shall be installed in a neat and workmanlike manner 1910.303(b)(7)(i)Unused openings in boxes, raceways, auxiliary gutters, cabinets, equipment cases, or housings shall be effectively closed to afford protection substantially equivalent to the wall of the equipment Electrical Safety 1910.303(b)(7)(iv)There shall be no damaged parts that may adversely affect safe operation or mechanical strength of the equipment, such as parts that are broken, bent, cut, or deteriorated by corrosion, chemical action, or overheating. 1910.303(b)(8)(i)Electric equipment shall be firmly secured to the surface on which it is mounted 1910.303(g)(1)(ii)Working space required by this standard may not be used for storage. When normally enclosed live parts are exposed for inspection or servicing, the working space, if in a passageway or general open space, shall be suitably guarded. 1910.304(g)(5)Grounding path. The path to ground from circuits, equipment, and enclosures shall be permanent, continuous, and effective 1910.305(b)(1)(i)Conductors entering cutout boxes, cabinets, or fittings shall be protected from abrasion, and openings through which conductors enter shall be effectively closed 1910.305(b)(1)(ii)Unused openings in cabinets, boxes, and fittings shall be effectively closed. Hazard Communication 1910.1200 Hazard Communication Written Plan All workplaces where employees are exposed to hazardous chemicals must have a written plan that describes how the standard will be implemented in that facility. Labels All containers of hazardous chemicals must be labeled, tagged, or marked with the identity of the material and appropriate hazard warnings Safety Data Sheets (SDSs) Chemical manufacturers and importers obtain or develop an SDS for each hazardous chemical they produce or import. Distributors provide their customers copy of these SDSs. Employers must have an SDS for each hazardous chemical they use. Hazard Communication Training Each employee who may be exposed to hazardous chemicals when working must be provided information and trained prior to initial assignment to work with a hazardous chemical, and whenever the hazard changes. Personal Protective Equipment 1910.132 https://www.osha.gov/Publications/osha3151.pdf Personal Protective Equipment Personal Protective Equipment What should employees do? Personal Protective Equipment Personal Protective Equipment Personal Protective Equipment https://www.osha.gov/dcsp/compliance assistance/sampleprograms.html u:\ips master templates\best work product\presentation suite\construction presentation suite 2012\proposal presentation.potx u:\ips master templates\best work product\presentation suite\construction presentation suite 2012\proposal presentation.potx u:\ips master templates\best work product\presentation suite\construction presentation suite 2012\proposal presentation.potx Machine Guarding General Requirements 1910.212 1910.212(a)(1)Types of guarding. One or more methods of machine guarding shall be provided to protect the operator and other employees in the machine area from hazards such as those created by point of operation, ingoing nip points, rotating parts, flying chips and sparks. Examples of guarding methods are-barrier guards, two-hand tripping devices,electronic safety devices, etc. What hazards exist? Crushed by or drawn into equipment Struck by moving parts Struck by failed components or particles Key parts of machines 1. Point of operation: where work is performed on the material, such as cutting, shaping, boring, or forming of stock. 2. Power Transmission Device: transmits energy to the part of the machine performing the work Includes flywheels, pulleys, belts, connecting rods, couplings, cams, spindles, chains, cranks, and gears. Key parts of machines 3. Operation Controls: Control mechanisms 4. Other moving parts: can include reciprocating, rotating, and transverse moving parts, feed mechanisms, and auxiliary parts of the machine Hazards to be Guarded Things to guard include In-running nip points Rotating equipment Flying chips or sparks Belts or gears Parts that impact or shear Rotating Parts Can grip hair or clothing Can force the body into a dangerous position Projecting pieces increase risk In-Running Nip Points Between 2 rotating parts Between rotating and tangential parts Between rotating and fixed parts which shear, crush, or abrade Reciprocating Parts Risk of being struck between stationary and moving part Transverse motion Continuous Worker point straight line motion struck or caught in pinch or shear Cutting action Direct injury from cutting action Flying chips or sparks Saws, drills, lathes, mills Punching action Ram stamps materials Danger at point of operation Shearing action Powered Hazard blade that shears materials at point of operation Bending action Power applied to a slide to stamp/shape materials Hazard at point of operation Guarding Principles Prevent contact between hazardous moving parts and body or clothing Secure Protect guard: not easily removed from objects falling into machinery No new hazards: sharp/rough edges No interference with job/comfort/speed Allow safe lubrication: without removing guards if possible Guarding Methods Location / distance Guards Fixed Interlocked Adjustable Self-adjusting Guarding Methods Devices Presence sensing Pullback Restraint Safety etc.) Gates controls (tripwire cable, two-hand control, Guarding Methods Feeding & ejection methods Automatic and/or semi-automatic feed and ejection Robots Miscellaneous aids Awareness barriers Protective shields Hand-feeding tools Fixed Guard Barrier is a permanent part of machine Preferable over other types Interlocked Guard Stops motion when guard is opened or removed Interlocked guard on revolving drum Adjustable Guard Barrier may be adjusted for variable operations What are the drawbacks? Bandsaw blade adjustable guard Self-Adjusting Guard Adjusts according to size/position of material Circular table saw self-adjusting guard Pullback Device Cables attached to operator’s hands or wrists Removes hands from point of operation during danger period What are the drawbacks? Restraint Device Cables attached to fixed point and wrists or hands Adjustable to let hands travel in predetermined area May be accompanied by hand-feeding tools Safety Tripwire Cable Device located around the perimeter of or near the danger area Operator must be able to reach the cable to stop the machine Two-Hand Control Requires constant pressure on both pads to activate the machine Hands on controls at safe distance while machine is in dangerous cycle Gate Must start close fully to protect user before cycle will Gate Open Gate Closed Safeguarding by Location/Distance Location of hazardous parts that is inaccessible or not a hazard during normal operation Must maintain safe distance Training, warning, communication necessary Protective Shields Protection Do from flying particles or splashing fluids not protect completely from machine hazards 1910.212(a) Machine guarding 1. One or more types of guarding to protect from hazards. Barrier guards Two-hand tripping devices Electronic safety devices Etc. 2. Affixed to machine where possible Guard must not cause its own hazard 1910.212(a) Machine guarding 3. Point of operation guarding: ii. Guarded if exposes employee to injury Keep any part of body out of danger zone iii. Hand tools to permit material handling – in addition to guards, not instead iv. Examples of machines requiring guards on point of operation 1910.212(a) Machine guarding 4. Revolving barrels, drums, containers guarded by interlocked enclosure (cannot turn without guard in place) 5. Exposure to fan blades: guard openings 1/2 inch 1910.212(b) Anchoring fixed machinery Machines designed for fixed location must be anchored to prevent moving This pedestal grinder is designed for anchoring, but is not anchored 1910.215(a) General requirements Abrasive wheels must be guarded, with exceptions Guard design dependent on type of work and type of wheel 1910.215(a) General requirements Work rests: Rigid, clamped in place securely Adjusted to within 1/8 inch of wheel Never adjusted while in motion Work rest is closely adjusted 1910.215(b)(9) Exposure adjustment For type where operator stands in front of opening: Adjustable for decreasing wheel size Adjustable tongue guard must never be more than ¼ inch from wheel 1910.215(d) Mounting Inspect for damage and ring test immediately before mounting Tap with light nonmetallic implement (screwdriver, wooden mallet) If sound is dead, cracked ring may not be used Check spindle speed against maximum for wheel Compliance Assistance State Onsite Consultation Duty Officer Website: www.osha.gov QUESTIONS www.osha.gov Kansas City Area Office 816-374-9572 Confined Space u:\ips master templates\best work product\presentation suite\construction presentation suite 2012\proposal presentation.potx