Project Manager

advertisement

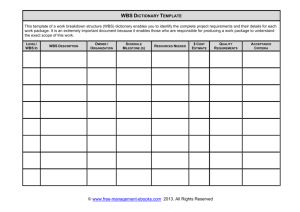

IL PROJECT MANAGEMENT NEI PROGETTI COMPLESSI DI COGENERAZIONE Milano, 11 Luglio 2013 Marcello Laviani Responsabile Costruzioni Enel Ingegneria e Ricerca Engineering, Procurement and Construction Structure ~750 Resources EPC Strong presence in foreign countries (~50% of the resources is involved in foreign projects) Technical Staff Safety Project Control Project Management Quality Assurance EPC Dpt. Engineering Main duties Feasibility studies Process design Machinery and Boiler Effluent treatment Instruments and control Layout & Piping Civil Electrical systems Safety Engineering Procurement Construction Bids management Negotiations Contracts awarding Vendor rating Vendor scouting Expediting Safety Scheduling & Cost Control Construction supervision Commissioning & Start-up Supply follow-up 2 Engineering, Procurement and Construction Main Projects Reftinskaya (3800 MW CFPP): -DARS - Unit 5 (300 MW) - Unit 4 (300 MW) - Unit 7 (500 MW) Great Island CCGT Sredneuralskaya CCGT (430 MW) (450 MW) Marcinelle CCGT Conventional Island- NPP (410 MW) EMO 3&4 (942 MW) Porto Tolle (1.980 MW USC CFPP) Litoral (557 MW) Punta Alcalde CFPP TVN (1980 MW-Ultra Super Critical CFPP) Algeciras (800 MW) (2x370 MW) Bocamina CFPP (350 MW) Brindisi CFPP: - Dome for coal storage - Fabric Filter UNIT 4 EW – LNG Terminal Porto Empedocle - Jetty refurbishment Legenda: NPP: Nuclear Power Plant CFPP : Coal Fired Power Plant CCGT: Combined Cycle Gas Turbine LNG: Liquef. Natural Gas DARS: Dry Ash Removal System Guarantee management Porjects under development Support serrvices 3 Planning methodology and assembly and erection control Principles of project planning WBS – Work Breakdown Structures Breakdown by Geography: Zone, Unit, Area … Breakdown by System: Steam, Water, Auxiliaries, KKS … Breakdown by Discipline: Civil, Mechanical, Engineering, Construction … Breakdown by Commerce commodities: Cables, Valves … Bid Request Contract Award Mechanical Completion PAC FAC WBS by units and systems Specs BASIC DESIGN PFDs P&IDs Specs Info Data Sheets Specs P&IDs Drawings Data Sheets WBS by disciplines WBS by area & disciplines DETAILED DESIGN Drawings Material / Work Requisitions Material / Work Requisitions Info Main Equip. CONSTRUCTION & ERECTION Materials Components Works Info Aux. & Bulk COMMISSIONING & START UP MATERIAL SUPPLY WBS by commerce commodities Offer Preparation Systems & Units Project Implementation TRIAL RUN WBS by systems & units Start Up Warranty Period Hand Over Combination of Breakdown in the same phase of the project; Combination of Breakdown in different phases of the project. 4 Current project challenges Fast Track Projects: projects driven by expected quick returns on investment; Locations: multiple locations with multicultural context, often in all phases of project; Control: strict control on processes, especially those affecting schedule and, therefore, cash flow and praise/penalties Brown fields: EPC Project on existing power plants for fuel conversion, environmental adaptation, refurbishment, revamping… 5 Planning methodology and assembly and erection control Principles of project planning Identification of LLI – Long Lead Items A CCGT power plant GT 18-20 months ST+Gen. 19-21 months HSRG 18-22 months Condenser 16 months FW pumps 14 months Other items Identification of items affecting project schedule 6 EPC Projects Some Numbers A Combined Cycle Power Plant- CCGT 410mw (typical) > 400 t BOP ( BP-HP ) > 225.000 h Engineering > 100.000 h Project Management > 2.300 t steel structures > 3.600 t > 15.000 m3 HRSG concrete > 100 km cables > 1.300.000 h Contractor man-hours > 650 units workforce peak at site > 85.000 h Construction Supervisor 7 Planning methodology and assembly and erection control Principles of project planning Critical Path - 1/2 Critical paths: CCGT Project schedule: o Critical paths (CP): direct and strong impact on project achievement; o Other paths: easy to manage and not requiring specific preliminary actions ESCATRON (Spagna) - CCGT 800 MW CP of HRSG - Heat Recovery Steam Generator: o Constraint: Fast Track Project; o Criticalities – Time Consuming Steps: long bid phase, long fabrication and delivery at site, long and complex erection; o Planning solutions: Limited Notice to Proceed (LNTP) vs Notice to proceed (NTP), early issue of Purchase Technical Specification (PTS), early start of the bid phase 8 Planning methodology and assembly and erection control Principles of project planning Check list of constructability Check of factors influencing the construction in all project phases: Concept and feasibility: o Presence of existing Power Plant – Brown Fields; o Weather conditions. Design and engineering: o Level of prefabrication; o Preliminary works. Procurement and construction: o Heavy lift and transport; o Material availability plan. Check list of constructability 9 Planning methodology and assembly and erection control Contractors - 1/2 Contractors may be: Direct subcontract: o only one subject directly involved and motivated to perform in the project; o contractor may or may not sub-subcontract part of the works (Italian law ….) Joint ventures: o a specific company is created for the scope of the project; o two or more subjects directly involved and motivated to perform in the project; o co-operation of subjects with different backgrounds leads to increase the know-how in technical and managerial fields; Consortia: o community directly involved and interested in building the power plant; o direct involvement of the region in building PP leads to an easy welcome of the project; 10 Planning methodology and assembly and erection control Assembly and erection planning – 2/2 Progress control Contractual target Synthesis of physical progress New target 11 Planning methodology and assembly and erection control Assembly and erection planning – 1/2 Contractual target (green curve): o Acknowledgement of quantities from ENG grouped by WBS activities o Association of standard productivities to ENG quantities and evaluation of manpower required o First contractual planning made according to availability of Engineering and Materials as per contract schedule; Progress control (black and pink curves): o Review of constraints on the schedule and on manpower capacity of the site; o Monthly check of progress and actual manpower consumption; o Delays and low productivity is checked Viz actual workable hours, given by availability of Engineering and Materials (Fault of Erection company or mine?) New target (orange curve): o re-assesment of productivities (actual) and re-forecast o Current target curve is made according to current availability and forecast of Engineering and Materials 12 Supply Chain Management SCM for a General Contractor Supply Chain Management, cradle to grave. For a general Contractor: Engineering Mat.Tak e-Off/ Requisiti on Procur ement Plan Procurement Purch Req/ Req. For Quote Purch ase Order Expediting Inspec tion Plan Transportation Inspec tions and Tests Delive ry Plan Packin g List Site Material Mgmt. Shippi ng Tracki ng Good Receip t Qualit y and Non confor mity Fabrication/Erection Analysis (Forecast and Actual) 13 Site Wareh ouse mgmt. Supply Chain Management Materials Materials may be: LLI = Long Lead Items: o equipments on critical paths (see ex. of CCGT); Other itemized equipments: o pumps, compressors, electrical panels… o equipments not on critical path Bulk materials: o concrete, piping, cables … o not itemized materials and components. 14 Supply Chain Management Monitoring of Bulk quantities during project development Materials Cost Book Work DESIGN CONSTRUCTION Tender, Contracts (works & materials requisitions), Design, Construction…. Safety; Management of Quality; Costs; Time Supply Chain Management Material Tracking and quantity monitoring BoQ = Bill of Quantity BoM = Bill of Material During Project Development … Kg steel, Mc concrete, Km cables, Km pipes…. BoQ BoM Driver Bulk Items items - Work Requisitions - Quantity Monitoring - Cost Control - Subcontract Management - Construction Planning Same objects from different prospectives - Material Requisitions - Material Tracking - Bulk Material Control - Feasibility Analysis - Warehouse Management - Quality issues Supply Chain Management Drivers quantity monitoring Project Manager, Cost Controller, Planner • Control Times and • Give BoQ, BOM • Give Driver Qty by Engineering WBS • Estimate driver quantities forecast to complete • Estimate release dates of documents Costs • Control Progress PrC ENG ENG = Engineering CON = Construction PrC = Project Control • Update Project Control Schedule • Manage and Give the sequences between ENG & COS WBS CON • Supports CPC in Planning construction activities • Manages the Subcontractors, controls adequate resources are provided • Update subcontractor productivity 17 Supply Chain Management Time and costs control Feasibilities curves – 1/3 Feasibility study: o Schedule of Engineering: For Construction (FC) documents o Schedule of Construction: FC documents availability + Delivered materials + manpower capacity 18 Supply Chain Management Time and costs control Feasibilities curves – 2/3 Actual data: o Engineering: Analysis of delay o Construction: Analysis of delay o Project Team: Need of common recovery plan Monitoring with several tools: 3d Model, SmartPlant Material (SPM) … 19 Supply Chain Management Time and costs control Feasibilities curves – 3/3 Recovery plan: o Engineering: Decrease of delay thanks to ENG actions o Construction: Decrease of delay thanks ENG and COS actions New feasibility with several tools: 3d Model, SPM … 20 Supply Chain Management Criticalities – 1/2 Criticalities and consequent preventive actions for supply may be: For LLI: o Long bid, delivery and erection time Pre-contract agreement (see CP of CCGT); o Need to anticipate some civil works Early works (e.g. engineering of boiler and boiler foundations for CFPP or engineering of diaphragm for cryogenic tank for LNG – Liquefied Natural Gas) For bulk materials: o Long time to complete engineering DD Frame agreement or Blanket Orders; o Quantities monitoring to find new object on time Strict material control; o Long delivery time Massive purchase with buy back clauses; o Availability of right material Prefabrication / erection feasibility; 21 Supply Chain Management Criticalities – 2/2 Material managements and erection feasibility The integration of material management information inside 3D Model gives the following benefits : o Extraction of Bill of Quantities; o Check the status of supplies (through interface with SAP); o Check Construction Progress; o Visualization on 3D Model of material and components available in warehouse Lines 100% available BOM, good for construction Lines partly available Lines which cannot be constructed 22