Static and Kinetic Friction (One or two weights)

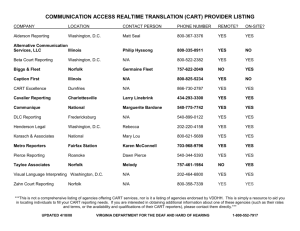

advertisement

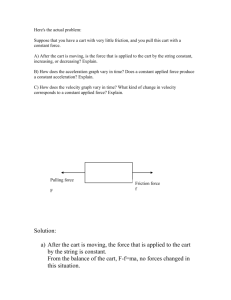

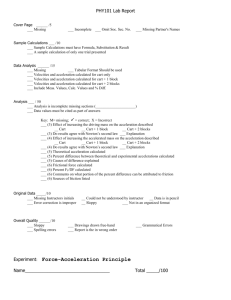

1 Static and Kinetic Friction (One or two weights) Part I is worth one weight. Part II adds one weight more. Recommended reading: R.A.Serway and J.W.Jewett, Jr. Physics for Scientists and Engineers 8th ed. (Thomson, 2010). Chapter 5.8. Preparatory Questions: 1. B C Force A D E Time 2. 3. 4. 5. 6. 7. The graph above is representative of the force applied to an object as it is pulled across a horizontal surface. Draw a free-body diagram for each of the positions labeled in the graph above. Describe the motion of the object for the positions labeled in the graph. Write the relationship between the static frictional force and the normal force on an object. Draw a diagram for the Force of Friction vs. Force for the same time interval as in the diagram above. Assume that at an instant of time corresponding to point E on the given graph the applied force begins steadily decreasing. On two diagrams with graphs Force vs. Time and Frictional Force vs. Force, draw a dashed line representing this process. An object is at rest on the ramp with the angle of inclination θ. The object starts moving down the ramp being just slightly pushed. What is the coefficient of static friction between the object and the surface of the ramp? An object is moving down the ramp with constant acceleration. What is the coefficient of kinetic friction between the object and the surface of the ramp if the angle of inclination is θ? Why do anti-lock brakes help to avoid automobile accidents? EXPERIMENT PART 1: LEVEL TRACK Part 1 (a): Preparing DataStudio for the experiment, Part 1(c)* 1. Open DataStudio, click on “Create Experiment”, click on the interface to connect the PASCO Force Sensor Cl-6746 to Channel A. Set the sample rate to 500Hz. 2 2. In the “Data” window on the left panel, drag Force, Ch A (N) into Graph in the “Display” window. Rename it as Force vs Time. 3. From menu, click on “Experiment”; select “New Empty Data Table”. Label it appropriately with the type of cart in both Data and Display. Double clicking on Editable Data will open up a new window. Change X to Normal Force and Y to Static Friction, and write N as the unit. 4. Repeat Step 3, with Y as Kinetic Friction. 5. Note that Step 3 and 4 are for only one type of a cart. Since we will be using 3 different types of carts, steps 3 and 4 should be repeated another 2 times. 6. From the menu, click on “Experiment”, select “Add Display” and choose “Graph”. Rename it as Friction vs Normal. 7. Drag the two data tables created in step 3 and 4 from the “Data” window into the “Graph” created in Step 5. You should see that the graph is plotting from two different sets of data. 8. In graph settings, uncheck “Connected Lines” to create a scatter plot. Part 1 (b): Some training and verifying that µs ≥ µk 1. Open a new experiment in DataStudio, and drag the measurement Force, Ch A(N) into Graph to create a plot of Force vs. Time. 2. Use a bubble level to level the track in both directions. As the track is quite long and may experience a small midspan deflection, it is advisable to use a measuring tape or ruler to measure the height of the track on both ends. 3. Cut a string of about 10 cm; tie a knot to the cart and a loop to attach it to the force sensor. 4. Put any combination of masses in one of the carts and secure them to the base of the cart using masking tape. This is to ensure that the mass and the cart are acting as a single object. The tape can be obtained outside of the Resource Center. 5. Take this part as training for part 2. You will need practice pulling the cart very slowly and steadily to maintain a constant velocity, as extra force applied to accelerate the carts will give a result that may be up to 100% larger than the expected result. 6. Click on START on DataStudio and press the TARE button on the force sensor (make sure that no force is applied when pressing the TARE button, and the string attached to the force sensor is not experiencing any tension) 7. Start pulling the cart horizontally to ensure no vertical component of the force is applied which might influence the normal force. (Note: slowly apply tension to the string by gradually increasing the force applied until the cart starts moving. Applying a sudden and abrupt force will result in a spike in the Force-Time graph which does not accurately reflect the maximum static friction). Once the cart is moving, pull it at an approximately constant velocity. Pull it in a straight line, using the groove on the sides of the track for guidance. Stop moving the cart after a distance of about 15-20 cm. 8. ASTM Standard D-1894 (Standard Test Method for Static and Kinetic Coefficients of Friction) states that the speed of the specimen should be 150mm/min. Although this speed is practically too slow for this experiment, it suggests that the accuracy of the results can be improved by moving the object slowly. 9. Repeat steps 3 to 6 for different combinations of mass (at least 3 different runs, one using each cart). Label the runs appropriately in DataStudio. (Suggestion: It would be easier to 3 begin with cork cart with 300g mass added, felt cart with 300g mass added, and plastic cart with 500g mass added). 10. Show that constant force is needed to maintain constant velocity of the cart by highlighting the data points when the cart is moving and performing a linear fit. You should get a slope value close to 0. If that is not the case, repeat from step 5. 11. Verify that µs ≥ µk by showing that the force needed to start moving the cart is greater than (or equal to) the force needed to move the cart at constant velocity. Part 1 (c): Estimating the coefficient of static friction and kinetic friction 1. Use the DataStudio file prepared earlier in the experiment in part 1(a). 2. Put one (or more) 100g masses into the plastic cart. Measure the mass of the cart with mass(es) in it. Calculate the normal force and record it in the Data Table created earlier as “Normal force”. 3. Start pulling the cart gently and carefully (as suggested in part 1(b)) while pressing START on DataStudio (Don’t forget to press the TARE button). Stop it after moving a distance of about 15-20 cm, but keep allowing force sensor to record the data. Start moving it again from the stopped position. Repeat this for at least 5 times to collect data at different locations of the track. After doing this, return the cart to the starting position on the track. (We suggest repeating this for at least 3 times, for a total of 15 runs per data point to get more accurate result). 4. Each run has a peak that corresponds to the maximum static friction and a near-to-constant force that corresponds to the kinetic friction. Calculate the average of the maximum static friction for this specific mass and specific type of cart and record it into the Data Table with variable Y as Static Friction. Also average the kinetic friction and record it into the Data Table with variable Y as Kinetic Friction. 5. Repeat step 2 to 4 for different combinations of mass in the plastic cart. Then repeat for the other two types of cart. Take at least 3 different mass combinations for each type of cart for a total of 9 runs. 6. For each type of cart, create a linear plot in the graph Friction vs Normal by dragging the data from the tables into the graph. The slopes of Static Friction vs Normal and Kinetic Friction vs Normal represent the coefficients of static friction and kinetic friction respectively. 7. In addition to DataStudio plot, try Microsoft Excel to perform error analysis for a graph with error bars in it. EXPERIMENT PART 2: INCLINED TRACK Part 2 (a): Measuring static friction 1. This part will only involve the use of the plastic cart. 2. Use two PASCO large table clamps ME-9472 that come with metal rods to mount the track at one end using the track rod clamps. Care is needed to prevent damaging the long track. The end that is not mounted to the stand must be cushioned by PASCO Dynamics Track Feet ME-8972. 4 3. This experiment will only use the plastic cart. Using results for the coefficient of static friction from the previous part of the experiment, calculate the estimated height required for each cart to begin sliding and explain why only the plastic cart can be used. 4. Set the track at a low inclination and put the plastic cart on the track. Add mass into the cart and measure the total mass. Record this mass. 5. Loosen the screws on the track rod clamps and slowly adjust the angle of inclination by increasing the height of the track. This process should be smooth and produce no vibrations if the track is mounted properly. The track should be supported from the bottom using both hands. Any vibrations will cause the cart to temporarily leave the track surface and start moving, even if the critical angle has not been reached. 6. When the cart starts sliding down the track, stop adjusting the height and tighten the screws on the rod clamps to secure the track in place. 7. Using a ruler, determine the height at which the cart starts to move. Extra care should be taken to measure the height that gives the angle of inclination, as a small change in height will produce a significant difference in the coefficient of static friction. 8. Repeat this step at least three more times, by having different masses in the cart. Remember to reset the height of the inclined ramp and start from step 4. 9. Calculate the coefficient of static friction by using the formula that you have derived answering question 5 of the Preparatory Questions. Part 2 (b) Measuring kinetic friction l h1 h0 1. This part is performed with the plastic cart only. 2. From the critical height determined in part 2(a), raise the track to a slightly higher inclination. Use a bubble level to make sure the track is not slanted to either side. Measure the angle of inclination as in the previous part. 3. Using the scale on the side of the track, determine the starting point of the cart. 4. Add mass into the cart and measure the total mass. A good mass to start with is 200g or above; otherwise it will be difficult to keep the cart moving in a straight line. 5. Place the cart on the track and allow it to move down the track while starting the stopwatch simultaneously. Do not give the cart an initial push so that the initial velocity is zero. Make sure the cart starts at the middle of the track and is moving down the track in a straight line. The result will be affected significantly if the cart collides with the scale on the track or with the sides of the track. If the cart is colliding into the sides of the track, repeat the trial. It 5 may take a few trials to get well acquainted with the technique of making the cart moving in a straight line. 6. Stop the stopwatch when the cart reaches the destination, i.e. the end of the track. Cushion the cart before it hits the table to prevent damage to both the table and the cart. Measure the distance traveled by the cart. 7. Repeat the experiment 3 times for at least 3 different masses in the cart. 8. Calculate the coefficient of kinetic friction using the formula that you have derived 2s 1 + tan 2 θ . t2 Present results of all measurements in the table, calculate uncertainties and give the value of coefficient of static friction for the pair of surfaces “cork – aluminum” and “felt-aluminum” with their uncertainties. Using the results of measurements of friction for the plastic cart, show the coefficient of static friction and coefficient of kinetic friction for the plastic cart. Which method – of Part 1 or of Part 2 – gives more precise result? answering question 6 of the Preparatory Questions. µ k = tan θ − Additional Exercise. Design an experiment and perform measurements to prove or disprove your predictions for the behavior of functions Force vs. Time and Frictional Force vs. Force, drawn in dashed lines in your answer to question 4 of the Preparatory Question. Compare the graphs of theoretically predicted functions and experimentally obtained data. Developed and first tested in May - June 2012 by Mr.Yih Tang Yeo (1 year EngSci) and Ms. Jody Chan (PHY152), SURF students of the Department of Physics supervised by Dr. Natalia Krasnopolskaia Revised and updated by Natalia Krasnopolskaia in October 2012 st