ME 413: System Dynamics & Control

Undamped Vibration

Vibration Absorber

Name:

__________________________________

ID #:

__________________________________

Section #:

__________________________________

Due Date:

__________________________________

Instructor

__________________________________

ME 413: System Dynamics and Control Lab Manual

UNDAMPED VIBRATION

ABSORBER

OBJECTIVES

1. To show the discomfort and dangers that result from the resonance

phenomenon.

2. To study the effect of adding an absorber to a vibratory resonant system.

Part 1:

THEORY

If a single or a multi-degree of freedom system is excited into resonance (the

excitation frequency nearly coincides with the natural frequency of the system), large

amplitudes of vibration result with accompanying high dynamic stresses and noise

and fatigue problems. Excessive vibrations in engineering systems are generally

undesirable and therefore must be avoided for the sake of safety and comfort. If

neither the excitation frequency nor the natural frequency can conveniently be

altered, this resonance condition can often be successfully controlled. It is possible to

reduce the unwanted vibrations by extracting the energy that causes these

vibrations. The extraction of this energy can be established by attaching to the main

vibrating system a dynamic vibration absorber, which is simply a spring-mass

system. The dynamic vibration absorber is designed such that the natural

frequencies of the resulting system are away from the excitation frequency.

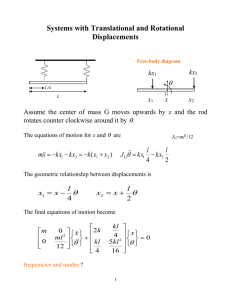

Fο sin ωt

m1

x1 (t )

k1 / 2

Figure 1

Undamped Vibration Absorber

k1 / 2

Idealization of a machine

2

ME 413: System Dynamics and Control Lab Manual

When we attach an auxiliary mass

m2 to a machine of mass m1 through a spring of

k 2 , the resulting two degrees of freedom system will look as shown in

Figure 2. The equations of motion of the masses m1 and m 2 are

stiffness

m1x1 + k 1x 1 + k 2 ( x 1 − x 2 ) = Fο sin ωt

(1)

m 2 x2 + k 2 ( x 2 − x 1 ) = 0

By assuming a harmonic solution,

x j (t ) = X j sin ωt ,

(2)

j=1, 2

We can obtain the steady-state amplitude of the masses

m1 and m2 as we can

obtain

X1 =

(k 2 − m2ω 2 ) Fο

(k1 + k 2 − m1ω 2 )(k 2 − m2ω 2 ) − k 22

(3)

X2 =

k 2 Fο

(k1 + k 2 − m1ω 2 )( k 2 − m2ω 2 ) − k 22

(4)

Fο sin ωt

Machine m1

x1 (t )

vibration absorber

k2

k1 / 2

k1 / 2

m2

x2 (t )

Figure 2

Undamped Vibration Absorber

Dynamic vibration absorber

3

ME 413: System Dynamics and Control Lab Manual

We are primarily interested in reducing the amplitude of the machine

make the amplitude of

X 1 . In order to

m1 zero, the numerator of Eq. (3) should be set equal to zero.

This gives

ω2 =

k2

m2

(5)

if the machine, before the addition of the dynamic vibration absorber, operates near

its resonance,

ω 2 ≈ ω 12 = k1 / m1 . Thus if the absorber is designed such that

ω2 =

k2

k

= 1

m2 m1

(6)

The amplitude of vibration of the machine, while operating at its original resonant

frequency, will be zero. By defining

δ st =

Fο

,

k1

ω1 =

k1

m1

as the natural frequency of the machine or main system, and

ω2 =

k2

m2

(7)

as the natural frequency of the absorber or auxiliary system, equations. (3) and (4)

can be rewritten as

ω

1 −

X1

ω2

=

2

2

δ st k

1 + 2 − ω 1 − ω − k 2

k1 ω 1 ω 2 k1

(8)

And

X2

δ st

=

k ω

1 + 2 −

k1 ω1

2

1

ω 2 k

1 − − 2

ω 2 k1

Figure (3) shows the variation of the amplitude of vibration of the machine

with the machine speed

ω / ω1 .

(9)

X 1 / δ st

The two peaks correspond to the two natural

frequencies of the composite system. As seen before,

X 1 = 0 at ω = ω1 . At this

frequency, equation (9) gives

Undamped Vibration Absorber

4

ME 413: System Dynamics and Control Lab Manual

X2 =−

F

k1

δ st = − ο

k2

k2

(10)

This shows that the force exerted by the auxiliary spring is opposite to the impressed

force (k 2 X 2 = − Fο ) and neutralizes it, thus reducing X 1 to zero. The size of the

dynamic vibration absorber can be found from equations (10) and (6):

k 2 X 2 = m 2ω 2 X 2 = −Fο

Thus the values of

(11)

k 2 and m2 depend on the allowable value of X 2 . It can be seen

from Figure 3 that the dynamic vibration absorber, while eliminating vibration at the

known impressed frequency ω , introduces two resonant frequencies Ω1 and Ω 2 at

which the amplitude of the machine is infinite. In practice, the operating frequency

ω must therefore be kept away from the frequencies Ω1 and Ω 2 .

ω1 = ω 2

m2

1

=

m1 20

X 1 / δ st

Ω1

Ω2

ω / ω1

Figure 3

Effect of undamped vibration absorber on the response of machine

Undamped Vibration Absorber

5

ME 413: System Dynamics and Control Lab Manual

NOTES

1. The primary system possess now the characteristics of a two-degrees of

freedom, it has two natural frequencies

Ω1 and Ω 2 . The new natural

frequencies lie in the neighborhood of the natural frequency

ω1

of the primary

system alone as shown in Figure 3. It can be seen from Figure 3 that

ω1

≤

Ω1 ≤

Ω 2 . Thus the machine must pass through Ω1 during start-up and

stopping leading to large amplitude vibrations during these transient periods.

2. Since the dynamic absorber is tuned to one excitation frequency ω , the

steady-state amplitude of the machine is zero only at that frequency. If the

machine operates at other frequencies or if the force acting on the machine

has several frequencies, then the amplitude of vibration of the machine may

become large.

3

The preceding analysis is valid only for an undamped system. If damping is

present in the absorber it is not possible to eliminate steady state vibrations

of the original mass. The amplitude of vibration can only be reduced.

Part 1:

EXPERIMENT

The above theory is applied to a simply supported beam carrying a motor with mass

unbalance at its mid-span as shown in Figure 4. In this figure, a simply supported

beam carrying a motor with mass unbalance at its mid-span is shown. The motor is

connected to a speed control unit through which the speed of rotation can be varied.

In order to measure the amplitude of vibration an accelerometer can be attached at

the beam mid-span. The output of the accelerometer is connected to a vibration

meter that will provide reading of the amplitude of vibration. Underneath the motor

assembly, the vibration absorber can be fixed.

Figure 4

Setup of the experiment (No vibration absorber attached).

Undamped Vibration Absorber

6

ME 413: System Dynamics and Control Lab Manual

Apparatus

1.

The absorber

Figure 5 shows the vibration absorber clamped below the motor. It comprises two

bodies of equal mass fixed equidistant from the midpoint of the horizontal cantilever.

The distance apart of the bodies varies until the system is ‘tuned’.

l

Figure 5

2.

The vibration absorber clamped below the motor.

Speed Control Unit and Exciter Motor

Figure 6 shows the speed control unit that is used in this experiment. A d.c. motor is

used for all forced vibrations experiments powered by a control unit. This

combination comprises of a control box and d.c. motor, which provides high precision

speed control of the motor up to 3000 rev/min, irrespective of the normal load

fluctuations of the motor.

The front panel of the unit contains a speed control, a fully calibrated speed meter

incorporating an automatic range switching device (there being two ranges: 0 – 1500

and 1500 – 3000 rev/min), and a power socket for:

1. Mains inputs

2. d.c. motor

3. Auxiliary output (either to stroboscope or chart recorder), sometimes

marked drum supply.

Undamped Vibration Absorber

7

ME 413: System Dynamics and Control Lab Manual

Figure 6

3.

Speed control unit front panel layout.

Vibration Meter Type 2511

The Vibration Meter Type 2511 shown in Figure 7 is a wide range instrument that is

used in conjunction with piezo-electric vibration pick-up to measure mechanical

vibration and shock in terms of acceleration, velocity and displacement. It is

completely portable and is built to a high standard of accuracy and stability making it

suitable for laboratory and field conditions. The instrument is fully calibrated in both

metric and British units and has a charge amplifier input that allows the use of long

cables between the pick-up and the meter without any reduction in sensitivity.

Figure 7

Undamped Vibration Absorber

Front panel of the 2511 Type Vibration Meter.

8

ME 413: System Dynamics and Control Lab Manual

Figure 8

4.

Rear panel of the 2511 Type Vibration Meter.

Transducer (Accelerometer)

In general, the transducers employed in vibration analyses convert mechanical

energy into electrical energy; that is, they produce an electrical signal which is a

function of mechanical vibration. See Figure 5.

Figure 9

Undamped Vibration Absorber

Accelerometers.

9

ME 413: System Dynamics and Control Lab Manual

Procedure

For a given frequency, the masses of the vibration absorber are adjusted along their

cantilever leaf spring so that the energy of vibration transmits to the absorber and

the amplitude of the main (primary) system, i.e. the motor and beam, is reduced to

zero.

The aim is to determine the length l , the distance of the center of each of the

bodies from the midpoint of the cantilever so that the natural frequency of transverse

vibration of this sub-system corresponds to the running speed of the main (primary)

system, i.e. the motor and beam.

IMPORTANT

For your safety and the safety of the equipment

WHEN THE SYSTEM VIBRATES AT RESONANCE CONDITIONS

DO NOT LET IT VIBRATE FOR A LONG PERIOD OF TIME

1.

No Absorber

1. Turn the upper right switch of the Vibration Meter Type 2511 on displacement,

velocity or acceleration depending on what you are intending to measure.

2. Turn the lower right switch of the Vibration Meter Type 2511 for the

appropriate range (Range I: metric units and Range II: British units). Notice

that you are reading the amplitude of the quantity to be measured as shown

in Table 1.

Table 1

Reading of the Vibration Meter Type 2511

Quantity

Displacement

Velocity

Acceleration

Equation of Motion

x (t ) = X sin ωt

x (t ) = X ω cos ωt

x(t ) = − X ω 2 sin ωt

Reading Vibration Meter Type

2511

Displacement Amplitude:

X

Xω

2

Acceleration Amplitude: − X ω

Velocity Amplitude:

3. Vary the motor speed and read the vibration amplitudes from the Vibration

Meter Type 2511.

4. For each speed, record your reading (vibration amplitude) in Table 2.

Undamped Vibration Absorber

10

ME 413: System Dynamics and Control Lab Manual

5. Increase the speed gradually until you get the resonance phenomenon that

results in large amplitudes of excessive vibrations. From the tabulated data

plot the response curve and determine the resonant frequency of the system.

2.

With Absorber

1. With the auxiliary system (vibration absorber) attached, vary the motor speed

and record the corresponding frequency and the resulting amplitude of

vibration.

2. Repeat the above (1 to 4) steps of the previous case.

3. With the aid of the experimentally defined resonant frequency, the dynamic

vibration absorber is to be designed such that the frequency of oscillations is

equal to

f =

where

f

ω

1

=

2π 2π

3EI

ml 3

(12)

is natural frequency of the auxiliary system,

of the two bodies, and

beam. The mass

formula.

m is

EI

m

is the mass of each

is the flexural rigidity of the double cantilever

a given constant and

l is

to be found from the above

4. One can easily conclude, that any three parameters of equation (12) can be

fixed, in order to determine the fourth parameter. In this experiment we will

determine the position of the mass m , at which the absorber effect is

verified. Experimentally, one can vary the position of the mass m , and excite

the system at the required excitation frequency until no vibrations of the

primary system are observed, or the position of the mass l can be

determined from equation (12), adjusted accordingly and the absorbing

effect can be verified.

Undamped Vibration Absorber

11

ME 413: System Dynamics and Control Lab Manual

REQUIREMENTS

The report should include the following:

1. Organize your measurements of the vibration amplitudes versus the rotational

speed as shown in Table 2.

2. Plot on the same graph the velocity amplitude X ω versus the rotational

speed for the cases with and without the dynamic vibration absorber. (Use

MATLAB or Excel).

3. Plot on the same graph the displacement amplitude X

versus the

rotational speed for the cases with and without the dynamic vibration

absorber. (Use MATLAB or Excel)

4. Indicate resonant frequencies and the frequency at which the primary system

(no absorber included) has zero vibration

5. Measure the length

l

for which the amplitude of vibration is zero when the

absorber is used. Compare this by solving Equation (12) for the length

Use

E = 200 GPa and I =

l.

1 3

bh .

12

6. Give a brief discussion of your findings.

7. Give conclusions on the effect of the vibration absorber.

Undamped Vibration Absorber

12

ME 413: System Dynamics and Control Lab Manual

Table 2

Readings

With no Absorber

N

(rpm)

Disp.

Ampl.

(mm)

Vel.

Ampl.

(mm/s)

Undamped Vibration Absorber

Acc.

Ampl.

(mm/s2)

With Absorber

N

(rpm)

Disp.

Ampl.

(mm)

Vel.

Ampl.

(mm/s)

Acc.

Ampl.

(mm/s2)

13

ME 413: System Dynamics and Control Lab Manual

References

[1]

[2]

[3]

[4]

[5]

[6]

[7]

[8]

[9]

Experiments in Vibration Using The TM 16 Universal Vibration, TQ Ltd

K. Ogata, System Dynamics, Fourth Edition, Pearson Prentice Hall, 2004.

S. S. Rao, Mechanical vibrations, SI Edition, Pearson Prentice Hall, 2005.

http://ta.twi.tudelft.nl/nw/users/vuik/information/tacoma_eng.html

http://abel.math.harvard.edu/archive/21b_fall_03/tacoma/

http://perso.wanadoo.fr/olivier.granier/meca/accueil.htm

http://www.kettering.edu/~drussell/Demos/absorber/DynamicAbsorber.html

http://www.mfg.mtu.edu/cyberman/machtool/machtool/vibration/absorb.html

http://www.kettering.edu/~drussell/Demos/absorber/DynamicAbsorber.html

Undamped Vibration Absorber

14