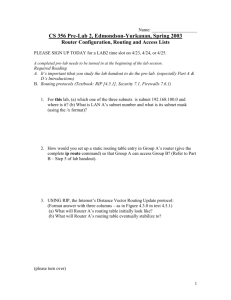

Work Centers, Routings, and WO Subcontracting

advertisement