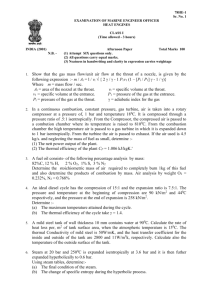

Thermal Power Plants

advertisement