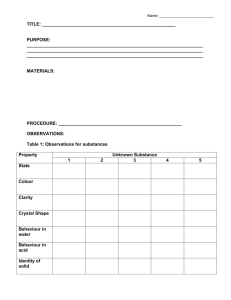

Water and Wastewater Unit Operation Lab Manual

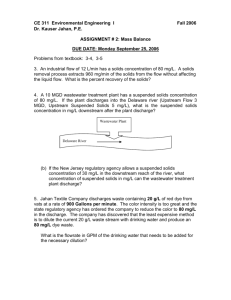

advertisement