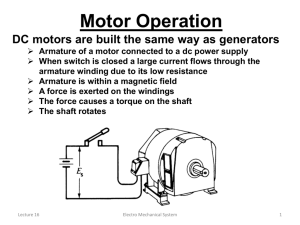

Introduction to Generators and Motors

advertisement