Elec467 Power Machines & Transformers

advertisement

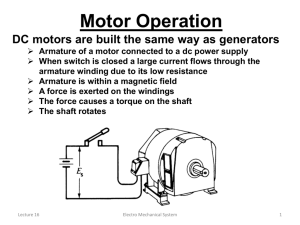

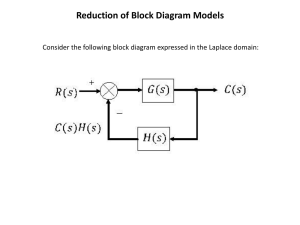

Elec467 Power Machines & Transformers Electric Machines by Hubert, Chapter 10 Topic: DC machines Flux distribution in a DC generator DC machines are powered from a DC source. We will first look at the DC machine as a generator. In Fig. 10.1 we see the flux distribution thru the armature core of a 2-pole DC machine. The interpolar region is the space between the poles. The neutral plane is shown. In the neutral plane there is no flux. Plot of flux passing thru surface A-B In the top diagram a plane labeled A-B is designated at 0° orientated at right angle to the flux between two permanent magnet. The amount of flux flowing is entirely within the surface of the plane. As the rotor rotates, the amount of flux passing thru the plane is diagramed in (b). Adding voltage wave e generated in the armature e Na d dt The Faraday-Lenz formula at the left says that the rate of change of the flux times the number of coils wrapped around the rotor (surface A-B represents one coil) generates a voltage. Since the rate of change is constant, the voltage generated is generally flat. Rectification by commutation Equation 10-8 is more useful: Ea nPNa a (10-8) 30 Ea is the voltage induced in the armature P is the number of field poles n is rotor rpm Фa is maximum pole flux Na is the number of rotor conductor turns Pn f 120 (10-7) f is the frequency of the induced voltage How Commutation Works When a winding is passing thru the neutral plane (a & c) the brushes short circuit the commutator bars but there is no current being generator at that time thus no S/C current will flow. When the winding is cutting thru maximum flux the commutator acts as a rotary switch to polarize the external circuit. With more than one coil on the armature a constant voltage is created at the output. Cutaway view of a DC motor Interlacing of armature wiring Shown is the layout of an eight-slot, eight-coil armature designed for operation with a two pole field. Letter T & B refer to top and bottom conductors in a single slot. Physical layout of winding Here the windings are shown straddling different commutation bars. DC generator equivalent circuit In this schematic the field windings are shown connected to an electrical source. Thus in addition to the prime mover the generator needs a power source for the field windings. Ra and Rf are the DC resistance of the coils. Ea is the output DC voltage fed to the load & controlled by the rheostat on the field current. Putting two and two together z P kG a 60 a Ea n p kG p Ea If Nf If (10-11) (10-12) (10-13) nN f I f kG (10-14) za = # armature conductors…=2*Na a = number of parallel paths in rotor windings kG = motor constant n = rotor rpm n Ea p kG ( alternate form 10-12 used in Lab, aka 10-19 ) If = field current Nf = # turns in field coil R = reluctance of field coil which varies When equation 10-12 is placed into 10-13 we see that Ea is dependant on If Ebat E Rrheo bat R f R f Rrheo If (10-15) Voltage regulation is % change in terminal voltage when loaded: Vnl Vrated 100 Vrated Comparison Generator to Motor When the prime mover is causing the rotor to rotate, the flux bunching created by a wire moving through a magnetic field cause the current to flow in the direction shown When the current in the rotor coil is the prime mover, the flux bunching causes the mechanical rotation. While the rotor is rotating in the same direction in both cases, the current is reversed. You should notice which way the current is flowing in both cases. How a basic DC motor works There are two branches in this circuit: the shunt field and the armature. The Φp created by the flow of current in the field branch (formula 10-13) causes a counter emf in the armature branch that opposes the flow of current Ia. This force also cause the motor to rotate. Basic DC motor formulas VT is the input voltage. When supplied by an infinite bus the value doesn’t change. T D Bp I a kM (10-17) Bp = flux density in air gap produced by shunt field poles Ia = armature current kM = motor constant VT I a Ra Ea (10-19b) Using KVL around the outside loop including the armature branch Ia VT Ea Ra Solving for Ia (10-19c) Dynamic behavior with constant load Speed regulation is the percent change in speed from no load to rated load with respect to rated load: nnl nrated 100 nrated If VT in (3) stays constant the rotor rpms will slow down (1) when the clutch is closed. Ea decreases due to a smaller n in (2) causing the numerator in the equation for Ia to increase and with the increase in Ia the value of TD increases. Rule is TD (will) = Tload No load commutation process (a) Current flow into commutator bar 3 creates a positive value. Armature coils 2 and 3 contribute to the voltage. Coil 3 rotates CCW and coil 2 rotates CW (c) At this point coil 2 has reverse its current flow and both coil 2 & 1 are now sending current into the brush keeping the positive value. (b) With rotation the brush shorts commutator bars 2 & 3 with all the current going into the brush. There is no current flow generated by coil 2 as it’s in the neutral plane. The brush is positive. Commutation when loaded When loaded the increased current takes longer to discharge thus delaying the reversal until a spark occurs. Interpoles An interpole is a small inductor called a choke used to dampen sparking in the brushes. They sit right over the brushes and are basically an inductor used as a low pass filter to lessen high frequency voltage changes on the DC bus. Armature reactance transition Notice that the armature mmf reverses direction when the machine changes from generator to motoring and visa versa but keeps turning in the same direction. Compensation windings corrects armature reactance Equivalent Circuit shunt motor This schematic is nearly the same as Fig. 10-12, can you tell the difference? If we take formula 10-12’s alternate form and substitute in formula 10-25 we get the General Speed Equation for a DC motor: V I R n T a p kG acir (10-26) Armature control = slowing down Base speed is the shaft rpm obtained at rated voltage and load with no extra resistance added. This slide is the similar to Fig. 10-13 where a constant load was added except here the motor was running with a load present when Rs is increased instantaneously. By slowing down n the windage and friction is decrease allowing the motor to adjust Ia so that TD = Tload Field control = speeding up Here resistance is added to the field branch. This decreases Φp (1) which causes the counter emf in the armature branch to decrease. The voltage drop Ea across the armature (2) drops because the field current decreases to a critical point when it begins to adjust to a new constant value. Ia & TD will increase (4) & (5). In (5) Ia is in the numerator and If is in the denominator (Φp = NfIf) but the denominator drops faster than the numerator can rise causing shaft rpms to increase. The motor continues to adjust until TD = Tload Power flow: Motor & Generator Interesting aspect of the power flow diagrams is the rotational power losses switch positions relative to the armature. Ph is the brush contact power loss. The armature doesn’t actually contribute power or lose power; its function is to convert mechanical power to electrical power or visa versa. Technically you never get more out than what you put into the system. The power losses are the cost for converting the energy from one form to another. The efficiency (η) with which this is accomplished is the ratio of Pout divided by Pin Power loss formulas Ploss Pacir Ph Pcore Pf ,w Pstray Pfcl Power losses are subtracted from the input power. The input power for a generator is the Pshaft and the input power for a motor is the electrical power. The voltage across the brush contact used to calculate Ph is either ½ volt for metal-graphic or 2 volts for graphite brushes. In a generator, the Pfcl are usually not included in the losses as the field is separately excited. Pacir I a2 Racir Pfcl I 2f R fcl Pacir is the armature circuit losses (see formula below) Pcore = hysteresis losses & eddy current losses for both armature and field iron Pstray ≈ 1% Pout Pmech VT I a I a2 Racir Ea I a Racir Ra RIP RCW Equivalent Circuit Locked Rotor When you start the motor it behaves like a blocked rotor. Large shortcircuit current flows would result burning out the motor were specialize starters not employed that insert heavy duty resistors into the armature circuit then switch them out as the motor picks up torque spinning the shaft faster and faster. When starting the motors in lab you will notice TD is developed even if the rpm is zero.