EMS+Lecture+16

advertisement

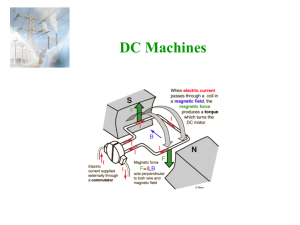

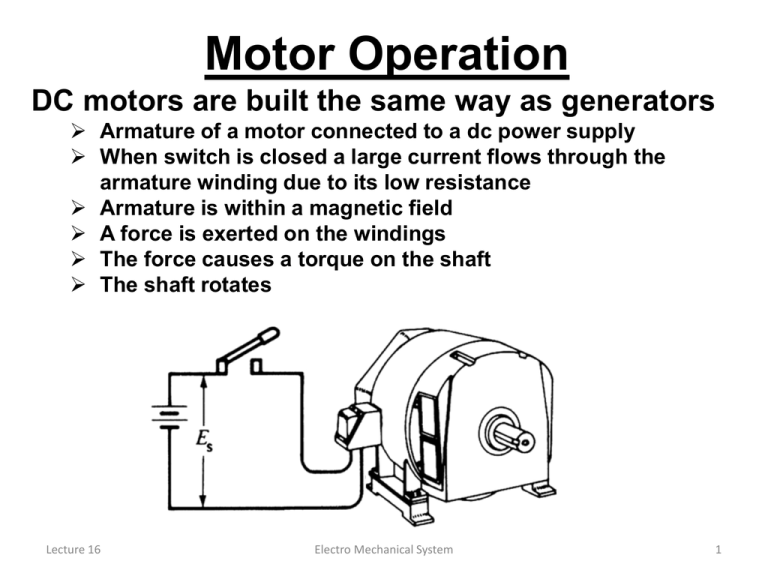

Motor Operation DC motors are built the same way as generators Armature of a motor connected to a dc power supply When switch is closed a large current flows through the armature winding due to its low resistance Armature is within a magnetic field A force is exerted on the windings The force causes a torque on the shaft The shaft rotates Lecture 16 Electro Mechanical System 1 Counter EMF Rotating armature cuts through the magnetic field Voltage is induced in the armature windings E = B l v Zn EO 60 This induced voltage is called counter-electromotive force (cemf), its polarity acts against source voltage ES Power is taken from the electrical system Lecture 16 Electro Mechanical System 2 Acceleration of the Motor The net voltage acting on the armature circuit is: ES – EO The resulting armature current I is limited only by the armature resistance: I = (ES – EO) / R At rest, the induced voltage is zero: EO,rest = 0 V Starting Current is 20 to 30 times greater The large current produces a large torque I = ES / R As speed increases, the counter emf increases and the voltage difference diminishes Resulting in a reduced current Lecture 16 Electro Mechanical System 3 Example Armature of a permanent magnet dc generator has a resistance of 1 ohm and generates 50V at a speed of 500 rpm. If the armature is connected to a 150V supply, find: a) The starting current b) The counter-emf when the motor runs at 1000 rpm. At 1460 rpm c) The armature current at 1000 rpm. At 1460 rpm a) At start-up EO,rest = 0 V so starting current is: I = ES / R = 150V / 1Ω = 150A b) Generator voltage at 500 rpm is 50 V, so counter-emf of the motor at 1000 rpm will be 100V and at 1460 rpm will be 146V c) Armature current at 1000 rpm is I = (ES – EO) / R = (150 – 100)/1 = 50A Armature current at 1460 rpm is I = (ES – EO) / R = (150 – 146)/1 = 4A Lecture 16 Electro Mechanical System 4 Machine Power and Torque Power and torque characteristics can be determined over various shaft speeds Counter emf: EO = Zn/60 Power supplied: Pin = Pa = ESI Voltage drop (IR losses): ES = EO + IR Separating power and losses Pa = ESI = (EO + IR)I = EO I+ I2R The mechanical power : Pm = P = EOI The developed torque: nT Zn Pm P EO I since EO so 9.55 60 nT Zn ZI I T 9.55 60 6.28 Home Work Page 99 Example 5-2 Lecture 16 Electro Mechanical System 5 Speed of Rotation We know that EO = Zn/60 The voltage drop across the armature resistance is always small compared to the supply voltage Even as the load varies from no-load to fullload EO is approximately equal to ES EO = Zn/60 n = 60EO /Z ≈ 60ES /Z Lecture 16 Electro Mechanical System 6 Armature speed control ES can be varied by connecting motor armature to a separately excited variable voltage dc generator G Field excitation of the motor is kept constant, but the generator excitation current IX varies from zero to maximum or reverse which in turn vary the ES and motor speed This method is known as Ward-Leonard system and is found in steel mills, high rise elevators and paper mills etc. ES is adjusted slightly higher than EO, the armature will absorb power because I flows into the positive terminal Let us reduce ES, now EO current I reverses as a result motor torque reverses and dc motor suddenly becomes generator Lecture 16 Electro Mechanical System 7 Armature Speed Control Speed is controlled by varying the armature voltage ES 60 ES n Z Motor speed changes proportionally to the armature voltage The armature voltage is controlled by an external variable power supply The field winding is separately excited by a constant voltage source Lecture 16 Electro Mechanical System 8