Influence of Guar Gum on the Distribution of Some Flavor

advertisement

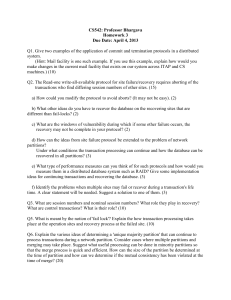

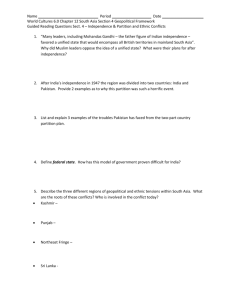

DAIRY FOODS Influence of Guar Gum on the Distribution of Some Flavor Compounds in Acidified Milk Products C. G. LO,*gl K. D. LEE,* R. L. RICHTER,t and C. W. DlLLt 'Department of Food Science and Nutrition, University of Minnesota, St Paul 55108 tDepartrnent of Animal Science, Texas A&M University, College Station 77843 ABSTRACT Acidified milk samples containing 0.1 to 0.5% guar gum were prepared with concentrations of milk fat from 0 to 20% and SNF from 6 to 12%. The partition coefficients of acetaldehyde, ethanol, and diacetyl were determined by headspace analysis using gas chromatography in samples that were acidified to pH 4.5 at 30 and 50°C. Guar gum did not affect the partition coefficients of the flavor compounds under any experimental condition. At both temperatures, the partition coefficient of acetaldehyde was affected by the concentration of acetaldehyde and the interaction of SNF and acetaldehyde concentration. The lowest partition coefficients of acetaldehyde were observed at 9% SNF under various experimental conditions. The concentration of ethanol and the interaction of milk fat and ethanol concentration affected the partition coefficient of ethanol at both temperatures. The partition coefficient of ethanol increased as ethanol concentration and SNF increased. Milk fat, concentration of diacetyl, and the interaction of SNF, fat, and diacetyl concentration affected the partition coefficient of diacetyl at 30°C. The partition coefficient of diacetyl increased as SNF increased. At 50°C, concentration of diacetyl was the only significant factor. Partition coefficients for ethanol and diacetyl were similar at 30°C; however, at 50"C, the partition coefficient of diacetyl was higher than the partition coefficient of ethanol. The partition coeficient was largest for acetaldehyde at both temperatures. ( Key words: guar gum, partition coefficient, acidified milk products) INTRODUCTION The rapid development of no fat, reduced fat, and "lite" acidified milk products, such as yogurt, sour cream, and buttermilk, has opened new growth areas for cultured milks. This trend is attributed to changes in consumption patterns of consumers because of Received August 7 , 1995. Accepted July 30, 1996. 'To whom correspondence should be addressed 1996 J Dairy Sci 79:2081-2090 nutritional and health concerns. The development of these products frequently involves removal of fat or sugars and the addition of hydrocolloids or starches to achieve desirable rheological characteristics. The effects of these changes on the flavor of the product and on the distribution of flavor compounds are unknown. Factors that might change flavor need to be understood in order to assess the effects of changes in food formulations on perceived flavors. Hydrocolloids are the stabilizers most commonly used in the dairy industry to improve the appearance and viscosity of products. Use of hydrocolloids at concentrations ranging from 0.1 to 0.5% ( 18) is common and does not contribute directly to the taste or odor components of flavor (17, 34). Guar gum, a type of hydrocolloid, is usually used as a stabilizer for acidified milk products because the viscosity of guar gum solutions is not affected by the acid levels found in fermented milk products ( 3 , 10). This neutral polymer, with a molecular mass of about 220,000 ( l o ) , can develop appreciable viscosity even at low concentrations because of swelling and dispersion of the molecular chains in water. In practice, acidified milk products stabilized with guar gum have a slightly shorter body and lower viscosity than do products containing locust bean gum (18). Acetaldehyde, ethanol, and diacetyl are compounds that are critical t o the aroma and flavor of fermented milk products. In proper concentrations, these compounds contribute to the quality of products (11, 121, but excessive or insufficient quantities of any compound cause a flavor defect ( 22 1. Steam-distillation techniques, combined with a colorimetric reaction, have traditionally been used to measure the concentrations of these flavor compounds (2 1, 28). However, these procedures are tedious, and the determined concentration of the volatiles does not provide information that could be used to evaluate the effect of the product matrix on the aroma of the product. In contrast, headspace analysis by gas chromatography is a rapid, uncomplicated procedure that permits quantitation of volatile compounds in the headspace above a sample. Partition coefficients (14, 24, 25), a ratio of concentration of the solute in the gas phase to its concentration in the liquid phase, can be determined 2081 2082 LO ET AL. to define the distribution of flavor compounds in and above a product. Knowledge of partition coefficients would eliminate the requirement of a standard curve for each compound in a product matrix and make it possible to calculate the concentration of a flavor compound in the liquid phase from the concentration measured in the gas phase. Because of the complex nature of food products, most published data about partition coefficients are limited to a single aqueous phase or to simple model food systems. For a better understanding of the distribution of the major volatiles in cultured milk products with reduced fat, the effects of guar gum on the partition coefficients of acetaldehyde, ethanol, and diacetyl were investigated and are reported in this research. MATERIALS AND METHODS Conditions of Gas Chromatography Gas chromatographic analyses were performed with a Tracor GLC (model 540; Tracor Inc., Austin, TX) equipped with a flame-ionization detector. Acetaldehyde, ethanol, and diacetyl were separated and quantitated using a DB-1 Megabore column (30 m x 0.70 mm 0.d. x 0.53 mm i.d., coated with methylsilicone; J&W Scientific Marketing, Floson, CA). High purity hydrogen (30 ml/min) and air (300 mV min) were used for the flame-ionization detector. Ultra-high purity helium a t 7.65 mVmin was used as the carrier gas. The column oven temperature was 40°C. Injector and detector temperatures were 150 and 180°C, respectively. Attenuator settings on the GLC for electrometer input and output were 1. A computing integrator (model SP 4290; SpectraPhysics Inc., San Jose, CA) was used for monitoring and quantitating detector output. The integrator chart speed was 0.5 c d m i n , and attenuation was set at 0.5. Apparatus Preparation A static dilution bottle with a capacity of 2 L (Tekmar Company, Cincinnati, O H ) was used for diluting and standardizing the concentration of acetaldehyde, ethanol, and diacetyl. To minimize surface absorption, the bottle was silanized by careful washing with detergent, followed by rinsing with 5% dimethyldichlorosilane (Supelco, Bellefonte, PA) in toluene. The bottle was then washed with toluene three times, rinsed with anhydrous methanol, and air-dried prior to use. Journal of Dairy Science Vol. 79, No. 12, 1996 Calibration and Identification of Flavor Compounds Diacetyl (Sigma Chemical Co., St. Louis, MO) was fractionally distilled using a Vigreaux column (CMC, Inc., Houston, TX).The fraction with a boiling point of 86°C was collected, and the other fractions were discarded. This sequence was repeated twice to ensure a pure compound. Acetaldehyde and ethanol were from Eastman Kodak Company (Rochester, NY) and Midwest Grain Products Co. (Weston, MO), respectively. Selected amounts (0.02, 0.04, 0.06, and 0.08 pl) of acetaldehyde, ethanol, and diacetyl were injected into the static dilution bottle and equilibrated for 10 min in a 30°C incubator (National Appliance Co., Portland, OR). A 0.5-ml sample was withdrawn from the headspace with a 1-ml gastight syringe (Dynamic Precision Sampling, Baton Rouge, LA) and injected into the GLC. Retention times of the known compounds were determined a t a constant helium flow rate. Calibration curves were prepared to achieve concentrations of 0.004 to 0.016, 0.004 to 0.016, and 0.005 to 0.020 pg/ml of headspace for acetaldehyde, ethanol, and diacetyl, respectively. Regression analysis using mass as the independent variable and peak area as the dependent variable was used to calculate the calibration curve for each compound. The procedure was replicated to ensure accuracy of the calibration. Preparation of Milk Sample Fresh raw cream, raw skim milk, and NDM obtained from the Texas A&M University Dairy Products Laboratory were used to prepare milk samples. Fat and moisture contents were determined in triplicate by the Mojonnier method (26). After analysis, milk samples were stored at 5"C, and the NDM was stored in a plastic container a t room temperature until used. Samples with milk fat concentrations of 0, 10, or 20% at SNF concentrations of 6, 9, and 12% with addition of 0.1, 0.3, or 0.5% guar gum were prepared by mixing calculated amounts of cream, skim milk, NDM, guar gum, and water. Milk samples of 350 ml were pasteurized at 85°C for 30 min in a water bath (Precision Scientific Co., Chicago, I L ) and homogenized with a hand homogenizer (ChaseLogeman Corp., Hicksville, NY). Each milk sample was adjusted to pH 5.3 with 85% lactic acid (Fisher Scientific, Fair Lawn, N J ) . Glucono-&lactone (Sigma Chemical Co. 1 was introduced at a n amount equivalent to 7% of SNF. Thereafter, milk samples were kept at 30°C in a water bath. A Metrohm-Brinkman pH meter (model pH 104; Brinkmann Instruments, Westbury, NY 1, 2083 2083 GUAR GUAR GUM GUM INFLUENCE INFLUENCE ON ON FLAVOR FLAVOR equipped equipped with with an an electrode electrode (Broadley-James (Broadley-James Co., Co., the the gas gas and liquid phases at a t the same temperature, Santa Ana, CA), was used to monitor the pH of respectively. In this research, Santa Ana, CA), was used t o monitor the research, the mass of acetaldeacetaldeethanol, and diacetyl hyde, samples until pH 4.5 ± 0.1 was reached. The samples samples until pH 4.5 0.1 was reached. The samples hyde, ethanol, diacetyl in the liquid matrix was calculated of were 5°C until until used. used. were stored stored at at 5°C calculated by the difference between the quantity of the compounds added into the vials and the quantity the compounds added in the headspace. headspace. Equilibrium Determination Equilibrium Determination for Headspace Analysis for Headspace Analysis Statistical Statistical Analysis Analysis Storage Storage hypo-vials hypo-vials (165 (165 ml; ml; Pierce, Pierce, Rockford, Rockford, IL) IL) The experiment was repeated twice for the three were were used used as as sample sample containers. containers. Each Each vial was concentrations of each compound. compound. All of the data were silanized as described described earlier. earlier. Ten Ten and and 20 20 gg of disdis- concentrations silanized as 27 ) ; tilled at 30°C 30°C were were each each put into into three storage storage split by temperature using a split-plot design ((27); tilled water water at ConSNF, fat, fat, and guar gum were whole-plot factors. Convials, vials, covered covered with with aa septum septum constructed constructed of teflon and SNF, silicon, silicon, and and sealed sealed with with aluminum aluminum crimp-on crimp-on seals seals centration was aa subplot factor. Data were analyzed analysis of variance, and contrast was used for (Pierce). (Pierce). Acetaldehyde, Acetaldehyde, ethanol, ethanol, and and diacetyl diacetyl were by analysis (30), 1, and followintroduced at 0.06, 0.06, 0.06, 0.06, and 0.05 0.05 fLI, p1, respectively, respectively, separation of means using the SAS (30 introduced at ing model: model: using using aa 0.5-fLl 0.5-p1 7000 7000 series series syringe syringe (Hamilton (Hamilton ComCompany, pany, Reno, Reno, NV). NV). The The final final concentration concentration of each Yijklm = fL + Ei + Sj + Fk + (SF)jk + Gl compound (micrograms per compound in in water was was 55 ppm (micrograms gram). The The vials vials were were then agitated agitated by shaking shaking and gram). + (SG )jl + (FG)kl + (SFG )jkl + eijkl The concentration concentration of placed into into incubators incubators at 30°C. The placed + Cm + (SC)jm + (FC)km + (GC)lm acetaldehyde, ethanol, ethanol, and diacetyl diacetyl in the headspace acetaldehyde, + (SFC)jkm + (SGC )jlm + (FGC)klm l-h intervals. intervals. was determined determined by GLC GLC analysis analysis at 1-h was + (SFGC)jklm + Vijklm Equilibration requirements requirements were satisfied when the Equilibration concentration of the the compound in the headspace headspace did concentration change with time. time. The time required for each where not change compound to to reach equilibrium was determined determined in compound p = overall mean, fL = duplicate for for each each sample. sample. Similar Similar analysis was conconduplicate of experiment (i (i = 1 1 and 21, 2), E = effect of 9% SNF, SNF, 0% 0% fat, fat, and 0.3% 0.3% ducted using milk with 9% ducted of SNF ((jj = 6, 9, and 12%), 12%), S = effect of gum as as aa liquid matrix. matrix. guar gum of fat ((kk = = 0, 10, 10, and 20%), 20%), F F = effect of + = Determination of the Partition Partition Determination Coefficient Coefficient Partition coefficients coefficients were determined determined for each at concentrations compound in milk samples compound samples concentrations of 3, 6, 30 and 50°C. 50°C. Temperatures Temperatures of 30 and and 99 ppm at 30 50°C were were selected to ensure efficient liberation of the 50°C volatiles from from the liquid phase during incubation. After the compounds reached equilibrium, equilibrium, a 0.5-ml Mter compounds headspace sample was withdrawn from the vials with headspace sample from a l-ml gastight syringe, without removing the sample a 1-ml syringe, vial from the incubator, and injected into the GLC. vial from incubator, GLC. analyses were made for each vial. The Duplicate analyses syringe was flushed flushed with air between each injection. syringe A partition coefficient was calculated as A Kd = CG - CL [1] 111 where Kd is the partition coefficient of the compound compound between gas and liquid phases, and CG CG and CL are concentrations of the compound the equilibrium concentrations compound in G = effect of guar gum (1 0.3, and 0.5%), ofguar (l = 0.1, 0.1,0.3, 0.5%), of concentration ((nn = 3, 6, and 9 C = = effect of ppm), PPm), eijkl = = error term denoting variations within of which guar gum, the means squares of were used to test guar gum effect and all guar gum interactions, interactions, and Vijklm Vijklm = error term denoting variations within concentration, the mean squares of of which were used to test concentration effect and all concentration interactions. RESULTS AND DISCUSSION Compound Identification Identification and Calibration Calibration Purified compounds were added tto o storage vials, vials, and the headspace in the vials was analyzed by by GLC GLC to determine retention times. The retention retention times times of of acetaldehyde, ethanol, and diacetyl were 1.05, 1.34, and 2.46 min, respectively; only a single peak peak was was detected for each compound. compound. Linear regression regression equaequa). tions were calculated for calibration (Table l1). Journal of of Dairy Science Science Vol. Vol. 79, 79, No. No. 12, 12, 1996 1996 2084 LO ET AL. TABLE 1. Regression equations and coefficients of determination for the major flavor compounds over a range of concentrations tested. Compound Regression equation1 r2 Acetaldehyde Ethanol Diacetyl Y = -191.33 + 156043.43X Y = -44.89 + 142847.34X Y = 26.29 + 174540.51X 0.96 0.99 0.99 ethanol concentration and of SNF, fat, and ethanol concentration affected the partition coefficients of ethanol at 30°C ( P < 0.05). Except for the interaction of SNF, fat, and ethanol concentration, these same A 18.0 1 'Y = Peak area of GLC response; X = mass x 10-3 Equilibrium and Sample Weight Determination Water and milk with 9% SNF, 0% milk fat, and 0.3% guar gum were utilized to determine the equilibration times of acetaldehyde, ethanol, and diacetyl (Figure 1). No difference was found either for water or milk between equilibration times for the partition coefficients of the three volatile compounds when incubation time exceeded 1 h. Therefore, 1 h was chosen as the minimum time required for the samples to reach equilibrium. Partition coefficients were lower for milk than for water, which indicates that the compounds interacted with milk constituents (e.g., protein, milk fat, carbohydrate, or milk salts) and were retained in the milk matrix. The partition coefficients of acetaldehyde, ethanol, and diacetyl in 10 and 20 g of water are compared in Figure 2. The partition coefficients of the three flavor compounds were not affected ( P > 0.05) by the weight of the water. Smith and Van Ness ( 3 1 ) stated that equilibrium time should increase with sample weight, but that was not the case in the current study. Possibly, differences between the sample weights or the amounts of flavor compounds used in this study were not great enough to reflect a difference in equilibration times. Based on these results, a sample size of 10 g was selected for further study. 27.0 Statistical Analysis 24.0 21.0 Results from the analysis of variance of the data are shown in Table 2. Because partition coefficients were dependent on temperature, as they were in studies by Friant (14) and Kieckbusch and King ( 191, the model was split by temperature for appropriate analyses. At 30"C, concentration of acetaldehyde and interactions of SNF and acetaldehyde concentration and of SNF,fat, and acetaldehyde concentration affected ( P < 0.05) the partition coefficient of acetaldehyde. The effects of acetaldehyde concentration and the interaction of SNF and acetaldehyde concentration were significant at 50°C. Concentration of ethanol and interactions of fat and Journal of Dairy Science Vol. 79, No. 12, 1996 0.0 1.o gA 2.0 3.0 Time (h) B 21.0 18.0 0.0 30.0 1.o 2.0 3.0 2.0 3.0 Time (h) -I 18.0 15.0 12.0 9.0 6.0 3.0 0.0 0.0 1 .o Time (h) Figure 1. Equilibration of acetaldehyde ( A ) , ethanol ( B ) , and diacetyl ( C 1 a t 5 ppm in water w ) and in milk ( A) with 9% SNF, 0% fat, and 0.3% guar gum a t 30°C. Kd = Partition coefficient. 2085 GUAR GUM INFLUENCE ON FLAVOR factors were significant when determinations were made at 50°C. Fat, concentration of diacetyl, and the interaction of SNF, fat, and diacetyl concentration affected the partition coefficient of diacetyl at 30°C (P A 18.0 16.0 14.0 12.0 10.0 8.0 6.0 4.0 2.0 0.0 - f - - - - - - - r - - - - - - . - - - - - - , 0.0 2.0 1.0 3.0 Time (h) 44.0 B 40.0 36.0 32.0 28.0 24.0 20.0 16.0 12.0 8.0 4.0 0.0 +-------,,..-------r----., 0.0 1.0 2.0 3.0 Time (h) 135.0 c 120.0 105.0 90.0 75.0 60.0 45.0 30.0 15.0 0.0 -+-----~=====-'--~----­ 0.0 1.0 2.0 3.0 < 0.05). However, diacetyl concentration was the only factor that significantly affected the partition coefficient of diacetyl at 50°C. Higher temperature increased (P < 0.05) the partition coefficient of the flavor compounds. To escape from the liquid phase, volatile molecules must possess a minimum kinetic energy. The higher the temperature is, the greater is the fraction of molecules possessing at least that minimum energy required to escape from the solution (36). Therefore, as temperature increased, molecules in the headspace of a sample also increased. Differences in the binding of flavor compounds by milk components or the solubility of flavor compounds in the water or lipid phase are other possible causes of the differences that were observed at 30 and 50°C (9). The increased volatility of flavor compounds at 50°C might be the reason that the interaction of SNF, fat, and concentration was significant at 30°C but not at 50°C. Saleeb and Pickup (29) reported that the variation of headspace concentration of a given volatile compound is governed by the nature and energy of the interaction of that particular compound with the substrate. Arnold (1) demonstrated that, for nonfood systems, the magnitude of heat of adsorption was the main factor in determining which volatile molecules would be preferentially adsorbed. In our study, the behavior of three flavor compounds was not consistent. For real food systems consisting of various ingredients, different solubilities for different flavor compounds, competition for surface sites, and interactions among absorbents would be expected to have more influence on the distribution of flavor compounds in foodstuffs and headspace. The partition coefficients were dependent on the concentration of the flavor compounds (Table 2). The concentrations used in this research mimicked the concentrations found III real products, which corresponded to the ideal state of infinite dilution at which point Henry's law should be valid. Henry's law states that the partial pressure of the solute in the equilibrium vapor above the solution was directly proportional to the solute concentration in the liquid. Friant (14) and Buttery et al. (6) found that partition coefficients did not change consistently as concentration of volatile compounds changed. In contrast, dependency of the partition coefficient on concentration also was reported (16, 20) as a Freundlich-type behavior (1); at low compound concentration, the primary mechanism is chemisorption on proteins and, at high concentration, solubility in fat. Time (h) Partition Coefficients of Acetaldehyde Figure 2. Comparison of partition coefficients for acetaldehyde (A), ethanol (B), and diacetyl (C) at 5 ppm in 10 g (.) and 20 g (It.) of water at 30°C. Kd = Partition coefficient. Results of the effects of SNF, milk fat, and concentration of acetaldehyde on the partition coefficients at Journal of Dairy Science Vol. 79, No. 12, 1996 2086 LO ET AL. TABLE 2. Analysis of variance for the effect on the partition coefficients for acetaldehyde, ethanol, and diacetyl in acidified milk. Acetaldehyde Source1 ~ S F G SF SG FG SFG C sc FC SFC GC SGC FGC SFGC ~ df ~ 30°C ~ 2 2 2 4 4 4 8 2 4 4 8 4 8 8 16 ~ 0.055 0.828 0.971 0.965 0.979 0.977 0.999 <0.001* 0.015* 0.456 <0.001* 0.653 0.998 0.637 0.824 Ethanol 50°C ~~ 30°C ~ 0.376 0.493 0.998 0.972 0.976 0.715 0.994 <0.001* 0.035* 0.073 0.058 0.966 0.432 0.345 0.959 Diacetyl 50°C ~~ 0.830 0.212 0.682 0.191 0.508 0.831 0.815 <0.001* 0.217 0.004* <0.001* 0.287 0.134 0.267 0.305 ~ 30°C ~ 0.997 0.306 0.770 0.616 0.997 0.991 0.998 <0.001* 0.101 0.004* 0.070 0.513 0.732 0.769 0.727 50°C ~ 0.856 0.008* 0.344 0.058 0.530 0.819 0.972 <0.001* 0.206 0.250 0.003* 0.582 0.515 0.299 0.682 ~ 0.407 0.267 0.428 0.317 0.471 0.563 0.586 0.001* 0.416 0.438 0.300 0.363 0.545 0.383 0.435 1s = SNF a t 6, 9, and 12%; F = fat a t 0, 10, and 20%; G = p a r gum at 0.1, 0.3, and 0.5%; and C = concentration a t 3, 6, and 9 ppm. *Significant ( P < 0.05). different milk fat concentrations at 30°C are shown in Table 3. At 50°C (Table 4), a mean partition coefficient was calculated that corresponded to each acetaldehyde concentration at each concentration of SNF because the only significant interaction was between SNF and acetaldehyde concentration. The effect of SNF on the partition coefficients of acetaldehyde at each concentration of milk fat was consistent but unique. The partition coefficient of acetaldehyde was lowest at 9% SNF under every experimental condition. Three types of flavor interactions are possible in mixtures: synergism, addition, and suppression. Every constituent in the aqueous phase, especially lactose, protein, and hydrocolloids, can affect the results. Lactose and some proteins have been shown to act as a carrier and to bind flavors physically and chemically ( 2 3 ) . However, differences might be explained with a mixed effect that could vary according to the amount, composition, physical state, and the degree of SNF dispersion in other constituents (4,15). In addition, the current system comprised air, fabricated acidified milk, and three different ligands. At the 9% SNF concentration, some specific change in conformation probably increased the number of binding sites, which caused acetaldehyde to remain in the liquid phase. Partition Coefficients of Ethanol Table 5 contains the results of the effects of SNF, ethanol concentration, and milk fat at 0, 10, and 20% on the partition coefficients of ethanol at 3 , 6, and 9 ppm at 30°C. The partition coefficients for ethanol increased as SNF concentrations increased within each concentration of ethanol. This trend was observed at each concentration of milk fat. The effects of TABLE 3. Effects of SNF, milk fat, and acetaldehyde concentration on the partition coefficients ( K d ) of acetaldehyde a t 3, 6, and 9 ppm at 30°C. 0% Milk fat 10% Milk fat 20% Milk fat SNF 3 PPm 6P P ~ 9 PPm 3 PPm 6 P P ~ 9 PPm 3 PPm 6 PPm 9 PPm 6 9 12 4.75a 4.04* 4.09a 2.79a 2.05a 3.64a 3.45a 1.79a 2.93a 4.75a 2.78b 3.68ab 4.01a 2.54a 3.49a 3.89a 1.05b 4.79a 4.90a 3.71a 4.W 4.628 2.75b 4.07ab 4.13a 2.81a 3.89a a,bMeans ( n = 6) in the same column without a common superscript differ ( P < 0.05); degrees of freedom of error terms = 54; standard error = 0.503. Journal of Dairy Science Vol. 79, No. 12, 1996 2087 GUAR GUM INFLUENCE ON FLAVOR TABLE 4. Effects of SNF and acetaldehyde concentration on the partition coefficients ( K d ) of acetaldehyde a t 50°C. SNF 3 PPm 6 PPm 9 PPm 10.3ga 8.25a 10.36a Kd (xlO-3) 8.30a 7.47a 8.88a 8.48a 5.45h 7.52ah (%a) 6 9 12 ~ a,bMeans ( n = 1 8 ) in the same column without a common superscript differ ( P < 0.05); degrees of freedom of error term = 54; standard error = 0.882. milk fat on the partition coefficients of ethanol at 3, 6, and 9 ppm at 50°C are shown in Table 6. The effect of SNF concentration was not included because the interaction of SNF, fat, and ethanol concentration on the partition coefficients was not significant ( P > 0.05). Partition Coefficients of ethanol increased as milk fat concentrations increased. Also, partition coefficients increased as concentration of ethanol increased at each concentration of milk fat. Because lactose and protein are major components in the SNF fraction of milk, effects of their physical and chemical interactions with volatiles on flavor retention should be addressed. Wientjes ( 3 7 1 found that the addition of sugar in a dilute aqueous system produced increased partial vapor pressure for a number of compounds; partial pressure for others decreased markedly. From the results of the current study, we suspected that lactose enhanced the vapor pressure of ethanol, which was more pronounced as the concentration of ethanol increased. Lactose, which is soluble in water, could compete with ethanol for water because ethanol also binds water with a hydrogen bond. A decreased solubility of volatiles in sugar solutions is probably caused by a salting-out effect, which would increase the vapor pressure of flavor compounds. Interactions of flavor compounds with proteins can involve mechanisms such as physical and chemical adsorption by van der Waals interactions, covalent and electrostatic interactions, or penetration into the food interior by diffusion. Even though polar compounds such as alcohols are bound via hydrogen linkages, hydrophobic interactions with nonpolar amino acid residues are considered to be predominant in the binding of volatile compounds of low molecular mass. Several researchers ( 1 3 , 3 3 ) have found that the concentration of volatile compounds was lowered in headspace as concentrations of proteins in the aqueous phase increased. Solms et al. ( 3 3 1 and Solms and Guggenbuehl ( 3 2 1 reported that the binding sites and the amount of bound flavor compound increased as the denaturation of protein increased because more hydrophobic regions were then available for further binding. However, the number of volatile molecules bound per mole of protein could also decrease as the oligomeric protein concentration increased, which might be a result of interactions among proteins ( 8 ). This postulation supported the results of this study, which demonstrated that partition coefficients increased as concentration of SNF increased in a sample matrix. Partition Coefficients of Diacetyl The effects of SNF, milk fat, and concentration on the partition coefficient of diacetyl at 30°C are shown in Table 7. The partition coefficients of diacetyl increased as percentage of milk fat increased at every SNF concentration. At 50°C, mean values of partition coefficients were taken at different concentrations of diacetyl because only the concentration of diacetyl affected partition Coefficients ( P < 0.05). The means of partition coefficients at 3, 6, and 9 ppm of diacetyl were 1.54, 3.50, and 4.82, respectively. Buttery et al. ( 5 ) developed a model system to compare the volatilities of some flavor compounds in model systems using oil or water and oil. Those researchers stated that flavor compounds in those model systems were distributed between the fat and the aqueous phase, following the physical laws of solubility partition ( 33 ) . Fat-soluble compounds had TABLE 5 . Effects of SNF, milk fat, and ethanol concentration on the partition coefficients ( K d ) of ethanol at 3, 6, and 9 ppm a t 30°C. 0% Milk fat 10% Milk fat 20% Milk fat SNF 3 PPm 6 PPm 9 PPm 3 PPm 6 PPm 9 PPm 3 PPm 6 PPm 9 PPm 6 9 12 0.36a 0.4P 0.49a 0.66a 0.69a 0.70a 0.80a 0.85a 1.02a 0.36a 0.54a 0.62a 0.57a 0.65" 0.73a 0.69h 0.93ah 1.22a 0.45a 0.51a 0.55" 0.62" 0.73" 0.74" 0.84b 1.15h 1.79" a,bMeans ( n = 6 ) in the same column without a common superscript differ ( P < 0.05): degrees of freedom of error term = 54; standard error = 0.091. Journal of Dairy Science Vol. 79, No. 12, 1996 2088 LO ET AL. TABLE 6. Effects of milk fat and ethanol Concentration on the partition coefficients ( K d ) of ethanol a t 50°C. gum from 0.1 to 0.5% (data not shown) (Table 2 ) . Samples with 0.310 guar gum were used for the following comparisons. Partition coefficients for Fat 3 PPm 6 PPm 9 PPm acetaldehyde, ethanol, and diacetyl in milk with and Kd (x1O-3) ( 9% ) 0.3% gum using 9% SNF and 0% fat a t 30 without 0 0.92a 1.52" 2.06b 10 1.05a 1.58a 2.28h and 50°C are shown in Table 8 . No significant differ20 1.00a 1.67a 2.82a ences were detected. Burger (4) studied changes in a,bMeans ( n = 181 in the same column without a common super- volatile headspace concentrations in systems of air script differ ( P < 0.05); degrees of freedom of error term = 54; and water upon addition of hydrocolloids. Most standard error = 0.098. hydrocolloids decreased the concentration of a volatile in headspace; however, a decrease was not observed with some hydrocolloids, especially when the concenless volatility in those systems. The acidified milk tration of a flavor compound was low. Mechanisms samples in the current system were composed of three proposed for these effects were restricted diffusion phases with oil, water, and air; the increase in parti- and inhibition of bulk mixing. At high concentrations tion coefficients as milk fat concentration increased of flavor compounds, polymer entanglement was sugwas expected. However, recent work by Ulberth ( 35 1 gested to be the dominant effect that inhibited showed that milk fat content (0.6 to 32.1%) did not replenishment of surface depletion. Direct binding of significantly affect the volatility of fat-soluble aroma flavor molecules to polymers is another possible substances. Because the present system was more mechanism, especially when the formation of struccomplicated than the model system reported by But- tured zones is possible. These zones can be stabilized tery et al. (71, combinations of phase partition, by hydrogen bonds, electrostatic forces, van der Waals specific binding, or transfer effects were likely to oc- forces, and hydrophobic interactions. For many polycur and to affect retention of flavor compounds. saccharides, the formation of structures zones is well Moisture content of the acidified milk samples known in relation to the gel-forming properties of the might have influenced the partition coefficients if the polysaccharides, and these zones can further interact solubility of the compounds was affected. As the con- with flavor molecules. Recent data ( 2 1 described a centration of milk fat increased, less water would be marked decrease of flavor concentration in the headavailable in the milk to solubilize the flavor com- space with increasing coil overlap and entanglement pounds, causing a higher partition coefficient. Also, in flavored aqueous guar gum systems; those results the free fatty acid content of milk possibly increased were an indication of the occurrence of binding efas milk fat concentration increased. Free fatty acids fects. However, those results were obtained when a would lower the surface tension between the aqueous high concentration of the flavor compound was used and air phases, causing a high vapor pressure in the in the system. The comparatively low concentrations headspace. This phenomenon would result in increased concentrations of the volatile compounds in of flavor compounds that were used in the complicated milk system might explain the difference that the headspace. was noted in our study. Partition coefficients of acetaldehyde were higher Effect of Guar Gum than partition coefficients of ethanol and diacetyl. At on Partition Coefficients 30"C, partition coefficients of ethanol and diacetyl No differences between partition coefficients were were similar but lower than the partition coefficient 0.05) with concentrations of guar of acetaldehyde. However, at 50"C, the effect of temsignificant ( P ~~~~~ ~ TABLE 7. Effects of SNF, milk fat, and diacetyl concentration on the partition coefficients of diacetyl at 3, 6, and 9 ppm a t 30°C. ~ ~ 10% Milk fat 0% Milk fat SNF 3 PPm 6 PPm 9 PP* 3 PPm (%) 6 9 12 0 31a 0 34a 0 33.1 0 56" 0 86" 0 75" 1 07'3 1 188 1103 O38a 0 35a 0 456 2 0 4 Milk fat 6 PPm 9 PPm 3 PPm 6 PPm 9 PPm Kd (x10 3 ) 0 65" 0 92a 0 77" 128ah 0 43.1 056.1 0 48" 154'3 0 99b 2 14" 1501, 0 84b 1 67b 120b 1 62a ",bMeans ( n = 6 ) in the same column without a common superscript differ ( P < 0.05); degrees of freedom of error term error = 0.124. Journal of Dairy Science Vol. 79, No. 12, 1996 = 54; standard 2089 GUAR GUM INFLUENCE ON FLAVOR TABLE 8. Partition coefficients of acetaldehyde ( A ) , ethanol ( E ), and diacetyl ( D 1 without and with 0.39 guar gum using 9% SNF and 0% milk fat as liquid phase a t 30 and 5O"C.l Concentration of volatiles (PPm) 3 6 9 "one 0.051. 30°C Gum A E D 5.17 6.38 2.39 2.35 1.72 1.66 0.25 0.29 0.71 0.71 0.83 0.80 Kd ( ~ 1 0 - 3 ) 0.22 11.77 0.21 10.06 0.82 5.38 0.84 5.35 1.27 3.47 1.31 3.29 (%i) 0 0.3 0 0.3 0 0.3 50°C A E D 0.60 0.64 1.22 1.41 1.68 1.52 0.92 0.86 3.21 3.23 4.03 3.99 of the means of partition coefficients comparing with and without guar gum differed ( P > perature on partition coefficients was greater with diacetyl than with ethanol. The partition coefficient of diacetyl increased fourfold, but the partition coefficient of ethanol only increased about twofold, suggesting that the binding of ethanol was probably stronger than the binding of diacetyl in acidified milk systems. CONCLUSIONS Guar gum did not affect the partition coefficients of acetaldehyde, ethanol, or diacetyl; concentrations approximated those encountered in acidified milk products. These results indicated that guar gum in a commercial concentration range of 0.1 t o 0.5% could be used in fermented milk products without changing the distribution of these flavor compounds from that in products without guar gum. The percentage of milk ingredients in acidified milk products can affect the distribution of flavor compounds between the product matrix and the headspace above the product. The effect of milk components was complex, and each flavor compound was affected differently. Interactions between the concentration of the flavor compounds and milk components were significant. These results demonstrate that the effect of milk product composition on the partition coefficients of flavor compounds is dependent upon the physical properties of the flavor compound and on the interactions with the different phases in a milk system. In general, increased temperature of analysis reduced the effect of milk components on the partition coefficients, which must be considered when the purpose of the analysis is to determine the distribution of flavor compounds under the conditions at which the foods will be consumed. ACKNOWLEDGMENT This research was supported by a research grant from Dairy Management, Inc. REFERENCES 1 Arnold, J. K. 1949. Adsorption of gas mixtures, nitrogen-oxygen on anatase. J. Am. Chem. Soc. 71:104. 2 Baines, Z. V., and E. R. Morris. 1989. Suppression of perceived flavor and taste by food hydrocolloids. Page 184 in Food Colloids. 2nd ed. R. 0. Bee, P. Richmond, and J. Mingins, ed. R. Soc. Chem., Cambridge, England. 3 Bassett, H. J. 1983. Use of stabilizers in cultured dairy foods. Cult. Dairy Prod. J. 2:27. 4Burger, J. C. 1982. The influence of hydrocolloids on sensory properties. Prog. Food Nutr. Sci. 6:235. 5Buttery, R. G., D. G. Guadagni, and L. C. Ling. 1973. Flavor compounds: volatilities in vegetable oil and oil-water mixtures. J. Agric. Food Chem. 21:198. 6Buttery, R. G., L. C. Ling, and D. G. Guadagni. 1969. Volatilities of aldehyde, ketones, and esters in dilute water. J. Agric. Food Chem. 17:385. 7Buttery, R. G., L. C. Ling, and D. G. Guadagni. 1973. Some considerations of volatiles of organic flavor compounds in foods. J. Agric. Food Chem. 19:1045. 8Chefte1, J. C., J. L. Cuq, and D. Lorient. 1985. Amino acids, peptides, and proteins. Page 245 in Food Chemistry. 2nd ed. 0. R. Fennema, ed. Marcel Dekker, Inc., New York, NY. 9 Darling, D. F., D. William, and P. Yendle. 1986. Physicochemical interactions involved in aroma transport processes from solution. Page 165 in Interactions of Food Components. G. G. Birch and M. G. Lindley, ed. Elsevier Appl. Sci. Publ.. New York, N y . 10 Francis, P. S. 1961. Solution properties of water soluble polymers. J. Appl. Polym. Sci. 551. 11Frank, J. F. 1984. Improving the flavor of cultured buttermilk. Cult. Dairy Prod. J. 1 9 6 . 12 Frank, J. F., and E. H. Marth. 1988. Fermentation. Page 655 in Fundamentals of Dairy Chemistry. 3rd ed. N. P. Wong, ed. Van Nostrand Reinhold, Co., New York, NY. 13 Franzen, K. L., and J. E. Kinsella. 1974. Parameters affecting the binding of volatile flavor compounds in model food system. I. Proteins. J. Agric. Food Chem. 22:365. 14 Friant, S.L. 1979. Interactive effect of temperature, salt concentration, and pH on headspace analysis for isolation of volatile trace organics in aqueous environmental samples. Anal. Chem. 51:2167. 15 Godshell, M. A. 1988. The multiple roles of carbohydrates in food flavor systems. Cereal Food World 33:913. 16 Halek, G. W., and F. Hatzidimitriv. 1988. Partition coefficient of food package printing ink solvents in soybean oil, chocolate liquor, and a high fat baked product. J. Food Sci. 53568. 17 Igol, R. S. 1982. Hydrocolloid interactions useful in food systems. Food Technol. 3672. Journal of Dairy Science Vol. 79, No. 12, 1996 2090 LO ET AL. 18 Ioanna, S.M., and K. 2. Gregory. 1990. Effect of some stabilizers on textural and sensory characteristics of yogurt ice cream from sheep’s milk. J. Food Sci. 55:703. 19 Kieckbusch, T. G., and C. J. King. 1979. Partition coefficient for acetates in food systems. J. Agric. Food Chem. 27:504. 20Land, D. G., and J. Reynolds. 1981. The influence of food components on the volatility of diacetyl. Page 701 in Flavor. 3rd ed. P. Schreier, ed. Walter de Gruyter & Co., New York, NY. 21Lees, G. J., and G. R. Iago. 1976. Formation of acetaldehyde from threonine by lactic acid bacteria. J. Dairy Res. 4395. 22 Lindsay, R. C., E. A. Day, and L. A. Sather. 1967. Preparation and evaluation of butter culture flavor concentrates. J. Dairy Sci. 50:25. 23 Marrin, J., R. A. Bernhard., and T. A. Nickerson. 1979. Interactions of low molecular weight adsorbates on lactose. J. Dairy Sci. 62:1557. 24Massaldi, H. A., and C. J. King. 1974. Determination of volatiles by vapor headspace analysis in a multi-phase system: d-limonene in orange juice. J. Food Sci. 39:434. 25 McNally, M. E., and R. L. Grob. 1985. A review: current application of static and dynamic headspace analysis: Part I: environmental applications. Am. Lab. 17:106. 26 Milk Industry Foundation. 1959. Methods of Analysis of Milk and Its Products. Milk Ind. Found., Washington, DC. 27 Ott, L. 1988. An Introduction to Statistical Methods and Data Analysis. 3rd ed. PWS-Kent Publ., Boston, MA. 28 Pack, M. Y., E. R. Vedamuthu, W. E. Sandine, and P. R. Elliker. 1968. Effect of temperature on growth and diacetyl production Journal of Dairy Science Vol. 79, No. 12, 1996 by aroma bacteria in single- and mixed-strain lactic cultures. J. Dairy Sci. 51:339. 29 Saleeb, F. Z., and J. G. Pickup. 1978. Flavor interactions with food ingredients from headspace analysis measurements. Page 113 in Flavor of Foods and Beverages. Academic Press, Inc., New York. NY. 30 SAS@User Guide: Statistics, Version 5 Edition. 1985. SAS Inst., Inc., Cary, NC. 31 Smith, J. M., and H. C. Van Ness. 1980. Introduction to Chemical Engineering Thermodynamics. 3rd ed. McGraw-Hill, Inc., New York, NY. 32 Solms, J., and B. Guggenbuehl. 1990. Physical aspects of flavor applications in food systems. Page 319 in Flavor Science and Technology. Y. Bessiere and A. F. Thomas, ed. John Wiley & Sons, Inc., New York, NY. 33 Solms, J., F. Osman-Ismail, and M. Beyeler. 1973. The interaction of volatiles with food components. Can. Inst. Food Sci. Technol. J. 6:AlO. 34 Tobias, J. 1990. Compositional elements affecting flavor of dairy foods: formulated foods. J. Dairy Sci. 73:3657. 35 Ulberth, F. 1990. Headspace gas chromatographic estimation of some yogurt volatiles. J. AOAC 74:630. 36Vitenberg, A. G., B. V. Ioffe, and V. N. Borisov. 1974. Application of phase equilibria to gas chromatographic trace analysis. Chromatographia 7:610. 37 Wientjes, A. G. 1968. The influence of sugar concentrations on the vapor pressure of food odor volatiles in an aqueous solution. J. Food Sci. 33:l.