Analyzing Sustainability State of Construction Equipment in the

advertisement

Analyzing Sustainability State of Construction Equipment in the State of California

Hakob Avetisyan1 and Miroslaw Skibniewski2

Department of Civil and Environmental Engineering, E­209, 800 N. State College Blvd, California State University Fullerton, CA 92834, U.S.A, havetisyan@fullerton.edu

Department of Civil and Environmental Engineering, Glenn L. Martin Hall 1188, University of Maryland College Park, MD 20742, U.S.A, mirek@umd.edu

2

ABSTRACT Construction equipment are known as highly polluting machines adversely affecting the environment. Management tools are necessary for sustainability assessment of construction equipment fleets to allow contractors to reduce their emissions and comply with local or federal regulations. In addition to management tools there is need for a metrics that will allow companies to accurately assess the sustainability of their construction equipment fleets. In many instances the State of California is adopting the innovative approaches for reducing adverse human impact on the environment. Once successfully implemented the chances are that such practices attract other states for adopting similar approaches. The concept in this paper is based on evaluation of construction equipment fleets and data analysis. Once measured and recorded such results for equipment can be used along with decision­support tools for selection and utilization of construction equipment. The metrics for construction equipment evaluation as well as the tool for sustainable decision­making are developed based on readily available data from manufacturers or maintenance shops without adding extra trouble for contractors or government agencies for their adoption. Developed metrics and decision support tool incorporate logical strategies of supply chain management for optimal selection of construction equipment for any construction site while taking into account the availability, costs, and mobilization related issues as constraints. The metrics and the model can benefit both the government agencies responsible for inspection of fleets and owners of construction companies in their decision­making processes. Cleaner environment is imperative for having healthier future and this goal is feasible.

1

INTRODUCTION

The State of California has been traditionally known for a development and implementation or testing of environmental regulations and policies aimed in providing and promoting sustainable practices. Similar regulations have been developed for construction equipment emission level reductions. Nationwide these regulations were enacted from multi­angle perspectives targeting not only the manufacturers’ side of the problem who were forced to improve engine and filtration technologies by certain percentages over certain time intervals, but also from the perspective of physical limitations enforced on the construction sites (ARB, 2007, 2010a, 2010b).

The State of California was the first state in the nation that in June 26, 2007 adopted a regulation aimed at reducing diesel emissions from construction equipment operating in construction sites (UCSUSA, 2015). By 2020 this rule requires the owners of the off­road equipment like tractors, bulldozers, and forklifts that use diesel to reduce emissions from operation of these equipment pieces. The expected outcome of such requirement is to reduce and eliminate the adverse impact on human health. Such impacts include, but not limited to the premature deaths or asthma attacks, hospitalizations due to heart and/or lung disease, and others. The construction industry adds a significant amount of GHG emissions into the atmosphere. In large part, these emissions are due to the construction equipment, which similar to on­road vehicles depend on fossil fuels as energy source. With continuing demand for fossil fuel, sustained increase in GHG emissions is predicted (EPA 2009a) where the construction industry has its share as the third largest emitter (EPA 2009b). It is known that construction equipment if periodically maintained can last 30 years or more and the adverse effect on the environment needs to be considered in decision­making. During the lifetime of construction equipment the environmental impact can be disturbing if no upgrades with exhaust controls or replacement with new engines applied or equipment fleets not replaced with newer and less polluting equipment pieces. On average the rate of emissions is much greater for construction equipment compared to passenger vehicles. The fuel type (i.e. diesel versus gasoline), engine technology, and horsepower make a significant difference in the amount of emissions generated. For example, a typical excavator produces 454 pounds of carbon dioxide per hour of operation. In contrast a typical medium­size passenger vehicle produces 55 pounds of carbon dioxide per hour of operation. In one year if consider a typical 2000 hours of operation it turns to 454 tons of carbon dioxide equivalents just from one piece of excavator. If an equipment piece is not well maintained, the amount of emissions generated per piece of equipment increases even further. Therefore, it is imperative for any contractor managing a large construction fleet to find problems in advance in equipment management both at operational as well as at corporate levels. Commonly, without even taking into consideration the possibility of improving the system, the equipment manager is likely to concentrate on issues only after the fact that there is something obviously wrong (Fan et al, 2009). As a consequence the contractors face higher and still growing costs and inefficiencies.

In order to understand an overall sustainability state of construction equipment fleets it is important to develop a common measure that can be easily applied and help decision­makers. For this purpose a method that links the age of equipment and horsepower of engine is developed. Next section presents the development and the reasoning of applied approach. 2

SUSTAINABILITY MEASURE

The sustainability state of construction equipment can be assessed in variety of ways. In this paper a Sustainability Index is introduced as one of the ways to analyze the sustainability state of construction equipment. The Sustainability Index is calculated as a result of combination of the age of the equipment and its engine horsepower. These two parameters were found to have a direct impact on the amount of emissions generated from construction equipment. The reason for such linkage between the amount of generated emissions and the age combined with engine horsepower is the engine technology that is being developed year after year.

In order to control the amount of emissions regulations and policies are being developed and implemented on industries. As a result of such movement engine technologies are being developed as well. Stricter regulations and requirements enforced by policy­makers limit the amount of emissions that can be generated by on­road and/or off­road engines and therefore set limits by certain years that should be met by construction equipment manufacturers.

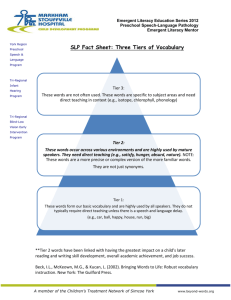

Emission limitations vary by the type of pollutant and the engine power. In 1998 off­road engine regulations were structured as a 3 level tier system. Tiers were phased­in (by horsepower rating) over years. As such, Tier 1 standards were applied on equipment manufactured from 1996 to 2000. Much stricter Tier 2 standards came in effect from 2001 to 2006. Tier 3 standards phased­

in from 2006 to 2008 which were more stringent than Tier 1 and 2. Tier 3 standards were applied only for engines from 37­560 kW. In practice the engine powers is rated by kilowatts per hour, but were also converted to horsepower. Tier 1 to 3 emissions standards are presented in Table 1. Table 1. EPA Tier 1 to 3 Non­road Diesel Engine Emission Standards in g/kWh (g/bhp·hr)

Engine Power

kW < 8

(hp < 11)

8 ≤ kW < 19

(11 ≤ hp < 25)

19≤ kW < 37

(25 ≤ hp < 50)

37 ≤ kW < 75

(50 ≤ hp < 100)

75 ≤ kW < 130

(100 ≤ hp < 175)

130 ≤ kW < 225

(175 ≤ hp < 300)

Tier

Tier 1

Tier 2

Tier 1

Tier 2

Tier 1

Tier 2

Tier 1

Tier 2

Tier 3

Tier 1

Year

2000

2005

2000

2005

1999

2004

1998

2004

2008

1997

CO

8.0 (6.0)

8.0 (6.0)

6.6 (4.9)

6.6 (4.9)

5.5 (4.1)

5.5 (4.1)

­

5.0 (3.7)

5.0 (3.7)

­

HC

­

­

­

­

­

­

­

­

­

­

NMHC+NO

x

10.5 (7.8)

7.5 (5.6)

9.5 (7.1)

7.5 (5.6)

9.5 (7.1)

7.5 (5.6)

­

7.5 (5.6)

4.7 (3.5)

­

NOx

­

­

­

­

­

­

9.2 (6.9)

­

­

9.2 (6.9)

PM

1.0 (0.75)

0.8 (0.6)

0.8 (0.6)

0.8 (0.6)

0.8 (0.6)

0.6 (0.45)

­

0.4 (0.3)

­†

­

Tier 2

Tier 3

Tier 1

2003

2007

1996

5.0 (3.7)

5.0 (3.7)

11.4 (8.5)

­

­

1.3 (1.0)

6.6 (4.9)

4.0 (3.0)

­

­

­

9.2 (6.9)

0.3 (0.22)

­†

0.54 (0.4)

Tier 2

2003

3.5 (2.6)

­

6.6 (4.9)

­

0.2 (0.15)

3

225 ≤ kW < 450

(300 ≤ hp < 600)

450 ≤ kW < 560

(600 ≤ hp < 750)

kW ≥ 560

(hp ≥ 750)

Tier 3

Tier 1

2006

1996

3.5 (2.6)

11.4 (8.5)

­

1.3 (1.0)

4.0 (3.0)

­

­

9.2 (6.9)

­†

0.54 (0.4)

Tier 2

Tier 3

Tier 1

2001

2006

1996

3.5 (2.6)

3.5 (2.6)

11.4 (8.5)

­

­

1.3 (1.0)

6.4 (4.8)

4.0 (3.0)

­

­

­

9.2 (6.9)

0.2 (0.15)

­†

0.54 (0.4)

Tier 2

Tier 3

Tier 1

Tier 2

2002

2006

2000

2006

3.5 (2.6)

3.5 (2.6)

11.4 (8.5)

3.5 (2.6)

­

­

1.3 (1.0)

­

6.4 (4.8)

4.0 (3.0)

­

6.4 (4.8)

­

­

9.2 (6.9)

­

0.2 (0.15)

­†

0.54 (0.4)

0.2 (0.15)

Source: https://www.dieselnet.com/standards/us/nonroad.php There is also Tier 4 standards that has more stringent requirements for NOx emissions, but the requirements are practically indifferent on the amount of CO and PM emissions generated by off­road engines and therefore it is not presented in the form of a table. In a summarized form the requirements for NOx emissions is reduced to 0.4 from 9.2 that should be met by off­road equipment produced between 2011 and 2014 (DieselNet, 2013). The variations in requirements per emission type make it difficult to assess and compare the changes that come with technology developments which may assist in evaluating the sustainability state of equipment fleets. Therefore, a unified method was developed as a combination of equipment age and engine horsepower by averaging the impact of retrofitting. As such the results are presented in Table 2.

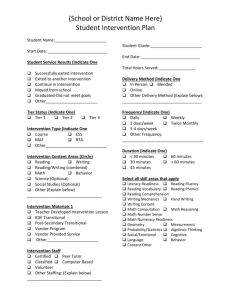

In Table 2 the first column is the year of equipment manufacture followed by a column for age counted based on the benchmarking year of 2015 for the current state. The third column in the table is for horsepower and as a sample case the 750 is used for comparison, which works equally well for any other horsepower ranges. Column titled A&HP represents the combination of the age and the horsepower of the engine. The development of engine technology is not and has never been linear and therefore a square root of A&HP was calculated and then normalized in order to obtain to zero and unit value for extreme value ranges. In fact, if pay attention to the Sustainability Index value for 2015 of 0.82 it means that the improvement potential is not completely achieved. This also matches with the real world situation where the regulations are still enforcing further improvements for emission reductions by engine technology advancements. As such, EU Regulation No 443/2009 sets an average CO2 equivalent reduction for commercial vehicles to 175g per kilometer by 2017 then 145g per kilometer by 2020 a further reduction of 28%. In the US the reductions comparisons from Table 1 indicate that if, for example, the average reduction is calculated for 750 horsepower from years 1996 to 2006 the improvement of 44% can be noticed. This means that another 56% improvement is still possible. Based on the Sustainability Index calculation the year 2006 shows 42% and for 2007 45% meaning that the 55% to 58% improvement can be still anticipated if the 100 percent is ever achievable. 4

Table 2 is considering the age of up to 30 years old equipment, but the same approach can be applied if there is even older piece of equipment under consideration. Table 2. Sustainability Index of Achievements and the Range of Possible Improvements Year of Manufacture

2015

2014

2013

2012

2011

2010

2009

2008

2007

2006

2005

2004

2003

2002

2001

2000

1999

1998

1997

1996

1995

1994

1993

1992

1991

1990

1989

1988

1987

1986

Age

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

Horsepower

750

750

750

750

750

750

750

750

750

750

750

750

750

750

750

750

750

750

750

750

750

750

750

750

750

750

750

750

750

750

A&HP

750

1500

2250

3000

3750

4500

5250

6000

6750

7500

8250

9000

9750

10500

11250

12000

12750

13500

14250

15000

15750

16500

17250

18000

18750

19500

20250

21000

21750

22500

SQRT of NSQRT A&HP

of A&HP

27.39

0.18

38.73

0.26

47.43

0.32

54.77

0.37

61.24

0.41

67.08

0.45

72.46

0.48

77.46

0.52

82.16

0.55

86.60

0.58

90.83

0.61

94.87

0.63

98.74

0.66

102.47

0.68

106.07

0.71

109.54

0.73

112.92

0.75

116.19

0.77

119.37

0.80

122.47

0.82

125.50

0.84

128.45

0.86

131.34

0.88

134.16

0.89

136.93

0.91

139.64

0.93

142.30

0.95

144.91

0.97

147.48

0.98

150.00

1.00

Sustainabilit

y Index

0.82

0.74

0.68

0.63

0.59

0.55

0.52

0.48

0.45

0.42

0.39

0.37

0.34

0.32

0.29

0.27

0.25

0.23

0.20

0.18

0.16

0.14

0.12

0.11

0.09

0.07

0.05

0.03

0.02

0.00

To show the results of the Sustainability Index on a graph the Figure 1is presented. 5

Sustaianbility Index

0.90

0.80

0.70

0.60

0.50

0.40

0.30

0.20

0.10

0.00

0

5

10

15

20

25

30

35

Equipment Age with a 750HP Engine

Figure 1: Graphical representation of Sustainability Index for a 750 HP equipment by year

Figure 1 shows the relationship of the age of an equipment piece that has 750HP engine and the Sustainability Index calculated as described in the discussion of Table 2. In a similar way any horsepower engine at any age can be analyzed that will help in measuring the sustainability state of the construction equipment fleet. Such approach may aid fleet managers and policy­makers in decision­making for more reasonable requirements for construction sites as imposed by Environmental Protection Agency (Avetisyan et al, 2012).

Once the metric for measuring the sustainability state of construction equipment is defined it can be used together with decision support tools and models for deciding what equipment and when to use or purchase for a long term business planning. This approach is applied on a decision support model developed by Avetisyan and Skibniewski (2014) that helps in web­based management of construction equipment. The additions to the model are presented below, but for the details the reader is referred to Avetisyan et al., (2012) and Avetisyan and Skibniewski (2014) for the rest of the constraints and explanation. MATHEMATICAL MODEL

In addition to the existing objective function and constraints a new element is added to the objective function and a constraint to count for the Sustainability Index of equipment and power needed for completion of construction tasks. In many instances the decision for selecting construction equipment is made based on the capacity of the equipment without consideration of power requirements for a particular task. As a result in many cases the equipment can be assigned to a particular task that exceeds the needs for the power more than twice that is necessary to complete the job. One may argue that if the task is not too difficult then the maximum power of the equipment will not be used anyways even if a powerful machine is assigned. In fact there is a difference when using a powerful machine for low capacity task 6

instead of the right power equipment. Even the idling of a powerful machine is more costly than that of a smaller equipment piece.

The objective function and added constraint details in the model and notation are presented next.

The Model

Notation employed in the mathematical formulation of the WB­CEMS’s objective function are defined next.

J

= set of origin sites where the contractor operates

K

= set of destination sites where the contractor operates

X

= {0,1,2,3}, the set of tier levels

Y

= set of equipment types (e.g. excavators, tractors, loaders)

c xyjk

cost of operating (renting, leasing or owning) each type of equipment yY in =

tier xX, at site jk, jJ, kK.

cmxyjk

cost of moving (renting, leasing or owning) each type of equipment yY in tier =

xX, from site j site k, jJ, kK.

g xyjk = GHG emissions rate for equipment type yY, in tier xX, at site jk, jJ, kK, expressed in CO2e

wjkt

= number of working days at site jk, jJ, kK, in period tS

βjkt

=

discounting factor for inflation at site jk, jJ, kK, by period tS

Decision variables

D xyjkt

= quantity of equipment of type y, yY, belonging to tier x, xX, at site jk, jJ, kK, to be used during period tS

Formulation WB­CEMS

Minimize

Z (D xyjkt )

[ Z1 (D xyjkt ), Z 2 (D xyjkt ), Z 3 (D xyjkt )]

(1)

In the objective function each of the Z functions is as the following:

Z1

ª

º

Min¦ « ¦¦¦ ¦ c xyjk D xyjkt » β jkt

tS ¬ xX yY jJ kK

¼

(1a)

Z2

ª

º

Min¦ « ¦¦¦ ¦ w jkt g xyjk D xyjkt »

tS ¬ xX yY jJ kK

¼

(1b)

Z3

ª

º

Min¦ « ¦¦¦ ¦ cmxyjk D xyjkt » β jkt

tS ¬ xX yY jJ kK

¼

(1c)

7

Z3

ª

º

Min¦ « ¦¦¦¦ ( SI xyjk ) D xyjkt »

tS ¬ xX yY jJ kK

¼

(1d)

The set of constraints is not presented in this paper, but conceptually discussed in this paragraph. The first, objective (1a), seeks the selection of equipment so as to minimize the total cost associated with completing the construction tasks over the construction projects. The second, objective (1b), aims to minimize emissions in terms of CO2e released during the construction from all construction sites. The third (1c) objective is minimizing the costs from moving of construction equipment from one site to another. The fourth (1d) objective counts for the Sustainability Index. Objective (1d) maximizes the Sustainability Index, but due to the modeling consistency it is presented as minimization of the negative of the maximization function. The constraints of the model fall into three general categories: those that address construction activity requirements, those that address emissions limitations, and budgetary caps related to the movement of equipment or the operation and ownership costs.

In a similar way a constraint is added to meet the power needs for each task:

¦¦¦¦ EHP

xX yY jJ kK

xyjk

D xyjkt t THPxyjk

tS, iA

(I’)

Where EHPxyjk stands for the equipment horsepower and THPxyjk for task required horsepower.

PRACTICAL APPLICATION To test and evaluate the usefulness of the proposed method a case study was designed, which is currently in progress.

CASE STUDY

To evaluate sustainability state of construction equipment a survey had been designed. The survey is in progress and the results will be populated in future reports and papers. The survey is collecting information about the existing construction equipment fleets and their state. Once this stage is complete the results will be evaluated through the application of Sustainability Index and the outcome will be analyzed through the model with above presented additions. CONCLUSIONS

Solution of the proposed mathematical formulation provides an optimal choice of equipment to be used in each period of a construction project. After the consideration of Sustainability Index in the analysis the outcome is expected to be even more insightful for decision­makers. Similarly, when combined with a web­server such management tools, this approach can benefit contractors in deciding whether to buy, lease or rent equipment for the project. It mostly relies on data that is readily available for any moderate to large construction job. In addition to the readily available data with this approach the decision­maker may need to evaluate how much power is necessary to generate by task category. Power evaluation can be set on a regular excel 8

spreadsheet and be used on every project by task category. Output of the method and the model can help contractors in quantifying the sustainability term for construction fleets as well as understanding the potential value in terms of costs to meet environmental standards or identify requirements for investment for new equipment while reducing project emissions. Also, by including equipment that can be rented or leased in the pool of possible equipment for selection, the tool aids in decisions related to augmentation of an equipment fleet through renting or leasing. Costs considered in the objective function of formulation (WB­CEMS) can account for changes in cost as a function of purchase price, depreciation, terms of lease, rental prices, and tax regulations. Sustainability Index may help policy developments that regulate the industry requirements.

The proposed methodology can aid construction firms in maintaining profitability in a carbon regulated future by facilitating decisions aimed at meeting new regulations or reducing environmental impacts by making changes to its equipment fleet. This can also aid in better positioning a construction firm to receive government­provided incentives for environmental stewardship. 9

REFERENCES

ARB. (2007). “OFFROAD model”. Off­Road Emissions Inventory. California Environmental Protection Agency. available at: http://www.arb.ca.gov/msei/offroad/offroad.htm, accessed on Apr. 14, 2010

ARB. (2010a). “Proposed Amendments to the Regulation for in use Off­Road Diesel­Fueled Fleets and the Off­Road Large Spark­Ignition Fleet Requirements”. California Environmental Protection Agency. available at: http://www.arb.ca.gov/regact/2010/offroadlsi10/offroadisor.pdf, accessed on December 10, 2010

ARB. (2010b). “Carl Moyer Memorial Air Quality Standards Attainment Program”. California Environmental Protection Agency. available at: http://www.arb.ca.gov/msprog/moyer/moyer.htm, accessed on June 8, 2010

Avetisyan, H., Miller­Hooks, E., and Melanta, S. (2012). ”Decision Models to Support Greenhouse Gas Emissions Reduction from Transportation Construction Projects.” J. Constr. Eng. Manage., 138(5), 631–641.

Avetisyan, Hakob and Skibniewski, Miroslaw, (2014). "Web–Based Management System for Construction Equipment Fleets: Global and Local Allocation of Equipment.", Project Management Symposium, MD, College Park. ISSN 2374­9377, pp. 34­43. DieselNet (2013), “Tier 1­3 Emission Standards”, available at: (https://www.dieselnet.com/standards/us/nonroad.php), accessed on January 25th, 2015

Environmental Protection Agency (EPA). (2009a). “Greenhouse Gas Emissions”. Climate Change. available at: http://www.epa.gov/climatechange/emissions/index.html, accessed on Aug. 10, 2009.

Environmental Protection Agency (EPA). (2009b). “EPA NONROAD Model Updates of 2008”. April 2009 International Emission Inventory Conference. available at http://www.epa.gov/ttn/chief/conference/ei18/poster/harvey.pdf, accessed on May 25, 2011

UCSUSA (2015), “California's Clean Construction Regulation”, available at: (http://www.ucsusa.org/our­work/clean­vehicles/california­and­western­

states/californias­clean­construction­regulation#.VOwb93zF­So) , accessed on February 23rd, 2015 10