bio 221 biomanufacturing-lab course

advertisement

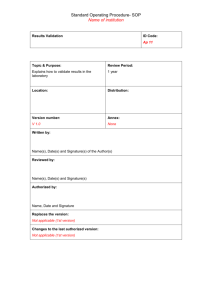

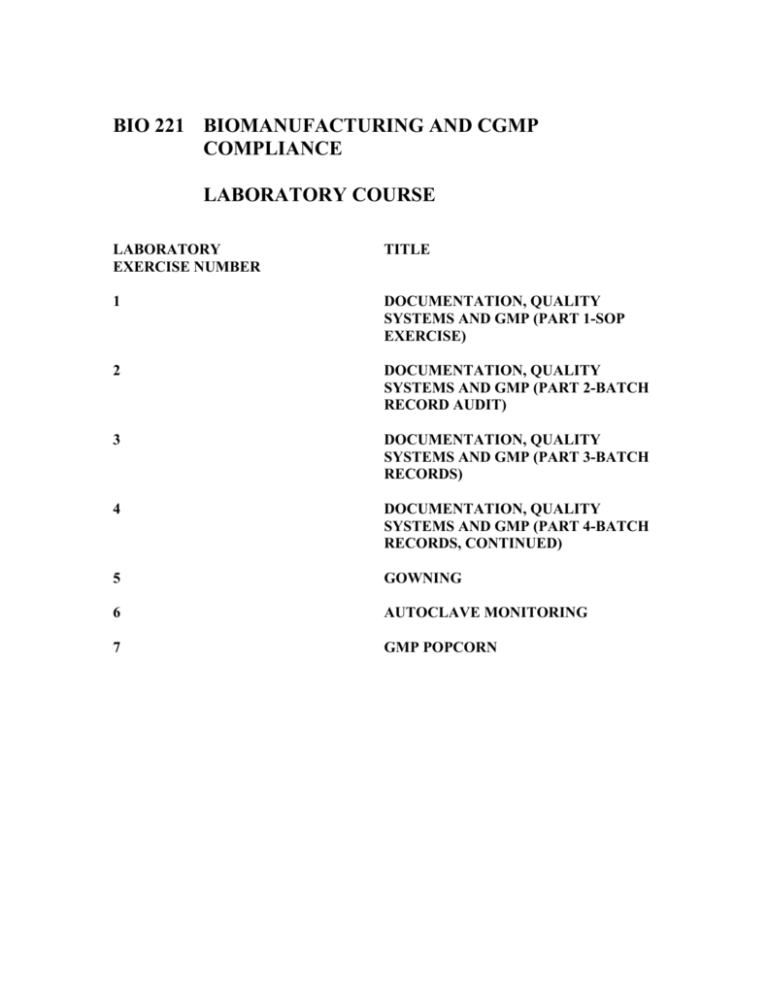

BIO 221 BIOMANUFACTURING AND CGMP COMPLIANCE LABORATORY COURSE LABORATORY EXERCISE NUMBER TITLE 1 DOCUMENTATION, QUALITY SYSTEMS AND GMP (PART 1-SOP EXERCISE) 2 DOCUMENTATION, QUALITY SYSTEMS AND GMP (PART 2-BATCH RECORD AUDIT) 3 DOCUMENTATION, QUALITY SYSTEMS AND GMP (PART 3-BATCH RECORDS) 4 DOCUMENTATION, QUALITY SYSTEMS AND GMP (PART 4-BATCH RECORDS, CONTINUED) 5 GOWNING 6 AUTOCLAVE MONITORING 7 GMP POPCORN DOCUMENTATION, QUALITY SYSTEMS AND GMP Background Good documentation practices are an essential feature of any biotechnology company. A document affirms the following and contains such a statement depending on the purpose of the document: The rules set forth in this document should apply to all personnel in a biotechnology company involved in the holding, transportation, manufacture, testing, support, or packaging of clinical and commercial drugs, whether temporary or regular staff. Biotechnology companies are regulated by the Food and Drug Administration (FDA) as well as by foreign regulatory agencies for products marketed abroad. Strict documentation rules are set to ensure compliance with all regulatory agencies. By placing your signature on a cGMP document, you have proven in the view of the FDA that you have completed a step. cGMP documents and records include, but are not limited to the following: Standard Operating Procedures (SOPs), Manufacturing Procedures (MPs), Specifications, Analytical Methods, Validation Documents, Batch Records, Product and Sample Labels. All cGMP documents may be reviewed by the FDA or other regulatory agencies. Documentation Rules 1. Do When writing in cGMP documents DO: Use only black, indelible, ball-point ink Make all entries legible such that they are readable Initial, unless a signature is required, and date all entries Document each step before moving to the next Write N/A, initial and date spaces if it is not appropriate to fill them in Record numbers less than one with a zero before the decimal point 2. Do Not When writing in cGMP documents DO NOT: Overwrite Use liquid correction fluid Backdate Record data before the action or event has occurred Use ditto marks Leave required data spaces blank Approve, verify or review your own performance 3. Initial/Date All entries to a cGMP document must be accompanied by the identity of the person (initials or signature) and the date that the entry was made. This is required by the Code of Federal Regulations (CFR) and serves as a tracking method to determine that a task was indeed performed and who did the work. Initials are the accepted standard method of identification. However, some operations require a signature. For example, an “Approved By” space must be filled with a signature, not initials. 4. Recording Time Either military time or meridian time is acceptable for recording time. Military time: two (2) digits to indicate the hour (00 to 23) followed by two (2) digits to indicate the minutes (00 to 59). Examples: 0850 1750 Meridian time: One or two digits to indicate the hour (1 to 12) followed by two digits to indicate the minutes (00 to 59), then the morning (AM) or afternoon (PM) designation. Examples: 8:50 AM 5:50 PM 5. Corrections No handwritten changes or corrections may be made to the printed text of an approved cGMP document. Consult with your supervisor if you discover an error. Any changes required to an approved cGMP document shall be implemented through the established quality system. When making a correction to a manually recorded entry on controlled documents perform the following steps: Place a single line through the incorrect entry Initial and date adjacent to the cross-out Enter the correct data near the original entry The mistake must still be legible through the cross-out Date of correction is the date the correction was made, not the date the error was made. 6. Performed By Performance of a step must be documented at the time of completing the step and prior to moving on to the next step. Do not execute a step if the manufacturing procedure is not available for documenting necessary data at the time of execution. The following personnel may initial and date the “Performed By” space: Personnel already proficient in the task performed OR Personnel who are in training under the supervision of their qualified trainer 7. Recorded By The “Recorded By” space is used if the operator is unable to initial and date immediately, due to working in a confined or restricted space, such as a laminar air flow hood. This situation is the only exception to the “Performed By” rule. Data must then be recorded by another person watching the operation. The person recording data must initial and date the “Recorded By” space prior to moving on to the next step. 8. Verified By Verification shall be performed prior to moving on to the next step. Operators executing a task cannot verify their own action. At least one other person must review documentation for accuracy. Personnel may initial or sign and date the “Verified By” space if: They witnessed that a task, operation, or procedure was performed per written instructions and accurately documented AND They are already proficient in the task performed 9. Deviations If you deviate from a written procedure, you must: Notify your supervisor Document the deviation using the appropriate quality system 10. Missing Data If information is not entered at the time of completing the step, the blank entry shall be marked by an asterisk or similar notation. The use of each notation is limited to one per page. Comments explaining the reason information is missing, along with the proper information, e.g. date event actually occurred, shall be documented on the same page of the record. The explanation shall be initialed and dated at the time of recording. 11. Voiding Records On occasion, errors are made in the execution of making an in-process material such as a buffer and all the proper documentation was completed. However, because of the error, the decision is made to scrap the material and start all over with new in-process material. The original document would then need to be voided and attached to the document replacing it. The documents are voided to prevent confusion or mix-ups with the correct document. When voiding a document do the following: Get supervisor and Quality Assurance (QA) approval Write “Void” across the front of the document and include initials and date 12. Recreating and Rewriting Records Recreating or rewriting records should be avoided; however it is sometimes necessary. Supervisor and QA approval is required when recreating records. It is important to identify the recreated document as “Rewrite” and to reference the sources of the information. Records can be recreated only when: Record is illegible Incorrect form or document was used Record was irreparably damaged 13. Rounding Off Rules The following rules apply to rounding off: In a series of calculations, carry the extra digits through the final result, and then round off. If the digit to be removed is <5, the preceding digit remains the same. For example, 1.84 rounds to 1.8. If the digit to be removed is ≥5, the preceding digit is increased by 1. For example, 1.85 rounds to 1.9. GLOSSARY Approved By Backdating Batch Production Record Comment Controlled Documents Cross-out Data Date Document Signature of a qualified individual (supervisor or designee) indicating that the information documented is complete, accurate, and acceptable. Backdating is the practice of going back to a previously completed task that has not been properly initialed and dated and placing the date that the task was completed on the date line, as though filling in the date had been done in a timely fashion. This practice is not allowed in any cGMP document. Collection of records associated with the manufacture of a specific lot of product. Any written additions to a document for informational purposes. All comments must be initialed and dated by the person writing the addition and may require a verification. Written approved documents used in association with cGMPrelated activities to ensure compliance with US and international regulations, as well as company standards. A cross-out indicates a correction has been made. This is accomplished by drawing a single straight ink line through information which has been entered inadvertently or incorrectly. The values and information generated by processing, calculating or transcribing from the raw data. This may include computer printouts. The date is the actual day on which information is entered or printed on a document. A written or printed form which is used to furnish information or Identifiers Initials NA or N/A Overwriting Performed By Quarantine Raw Data Recorded By Reviewed By Signature Video Q002 provide instructions. Information that serves to identify or describe something, such as effective dates, lot number, line number, equipment number, manufacturing or task date, product description, container numbers, specification number and run number. Identifiers can usually be retrieved from another source or document. Consist of the first letter of both the first name and the last name, i.e. surname. Use of the middle initial is optional. Abbreviation for the phrase “Not Applicable”. It is used to indicate that the entering of data into a space provided is not appropriate in that particular case. Overwriting refers to writing over previously recorded information to make a change. Overwriting is never allowed on any cGMP document. Initials or signature of the person executing an operation or task. This is usually the “operator” or “analyst”. The default status for raw materials and packaging components upon receipt from the supplier and for drug products upon completion of processing while awaiting evaluation against identified release criteria. The actual information obtained from an observation, test, measurement or activity. This may include computer or instrument printouts. Initials or signature of a person documenting information, results, or readings of an operation. This may be the “operator”. Initials or signature of the person examining a task, document or record in order to confirm its accuracy and completeness, including checking calculations. Consists of at least the initials of the first name and the complete last name. Corporate Quality Concepts: cGMP Documentation Practices Corporate Quality Concepts: cGMP Documentation Practices Standard Operating Procedures (SOPs) SOPs are documents which detail how staff should undertake particular procedures or processes. These procedures or processes are usually of a general nature, often being independent of any one pharmaceutical product. Many SOPs fall into one of several general categories, including: SOPs detailing step-by-step operational procedures for specific items of equipment, e.g. autoclaves, homogenizers, freeze-dryers, pH meters, product labeling machines, etc.; SOPs detailing maintenance/validation procedures for specific items of equipment or facility areas, e.g. SOPs detailing CDS (cleaning, decontamination and sanitation) of clean rooms; SOPs relating directly to personnel, e.g. step-by-step procedures undertaken when gowning-up before entering a clean room; SOPs relating to testing and analysis, e.g. procedures detailing how to sample properly raw materials or finished products for QC (quality control) analysis, SOPs relating to the routine sampling and testing of WFI from the ring main system, etc. Sections of an SOP: Purpose Scope Responsibilities References Definitions Precautions Materials/Equipment Procedure Attachments History General Word of Caution When Writing SOPs: Keep it general! Only include what is needed so any qualified person can perform the SOP correctly and safely. Do not list specific brand names, unless necessary (example: equipment).Give ranges of times and temperatures if possible. No section should ever be omitted or left blank. An entry of N/A (not applicable) may be included if there is no information to be included in a section. Purpose: Describes why the SOP exists. Scope: Defines to whom and to what the procedure applies. Responsibilities: The person or people responsible for performing and updating the SOP. May also include the person responsible for overseeing the activities of the SOP References: Other documents which were consulted during the writing of the SOP as well as those that should be consulted to perform the SOP. Documents may include manufacturer manuals and other SOPs. Definitions: Describe any words, phrases or abbreviations which are specific to the SOP. Commonly used words, phrases or abbreviations need not be described. For example, do NOT include pH. This is common terminology. Precautions: Describes any hazards associated with the procedure or with materials used in performing the procedure. Materials and Equipment: Any and all materials and/or equipment that are needed to execute the SOP. Procedure: A step by step description of the procedure, organized into subgroups. Attachments: Lists attachments by name and number. Attachments are all documents that are necessary to perform the SOP. Typically these include diagrams and drawings. History: Origin of document. Steps in obtaining an SOP 1. 2. 3. 4. 5. 6. SOP is written. Effective date assigned allowing for time to train personnel. QA (quality assurance) assigns a document number. Circulated for review. Approved and signed by QC, QA, operations, and facilities. QA distributes to authorized personnel. Obsolete versions destroyed. Master copy retained. 7. Document becomes effective. LABORATORY EXERCISE NUMBER 1 DOCUMENTATION, QUALITY SYSTEMS AND GMP (PART 1-SOPs) LABORATORY-WRITING AN SOP Introduction Students will study a generic or template SOP and an actual SOP and. These will be used to write an SOP for use of any piece of equipment with which the students are familiar. Background Following is a generic or template SOP. It starts on the next page. On the next page after the template, and for the next five pages, is an example of an SOP. Study both the generic/template SOP and the SOP example. Company Name: Document Number: Revision Number: Issue Date: Page: Document Title: Supersedes: New Document Originator / Reviser: Signature Dept. __________ Date I have reviewed this document and find it accurate and complete: Date: Date: This document has been approved as a Master Document. Date: Quality Manager This is an OFFICIAL COPY; a true reproduction of the MASTER DOCUMENT. It has been checked for accuracy and approved for use. Date: Issued by: 1.0 PURPOSE: 1.1 2.0 SCOPE: 2.1 3.0 The scope of this document includes… RESPONSIBILITIES: 3.1 4.0 The purpose of this document is to describe in detail the….. It is the responsibility of the Position Title to: REFERENCES (RELATED DOCUMENTS): 4.1 4.2 Refer to DOC# XX-XXX. Refer to DOC#XX-XXX. 5.0 DEFINITIONS: 5.1 Definition 1 … 5.2 Definition 2… 6.0 PRECAUTIONS 6.1 Precaution 1…… 6.2 Precaution 2…… 7.0 MATERIALS AND EQUIPMENT: 7.1 Materials: 7.1.1 Chemical 1….. (Lot #, Product #, handling) 7.1.2 Chemical 2….. 7.2 Equipment: 7.2.1 Hardware 1… 7.2.2 Hardware 2… . 8.0 PROCEDURE: 8.1 Initial Preparation: 8.1.1 Prepare a ………. 8.1.2 Add the ……. 8.1.3 Filter the solution to…. 9.0 8.2 Primary Steps: 8.2.1 Measure the….. 8.2.2 Adjust the pH to …… 8.2.3 Centrifuge at ___ g or _____ rpm and… 8.2.4 Resolubilize the ….. 8.3 Second Treatment to remove remaining contaminants: 8.3.1 The conductivity is …. 8.3.2 Filtration to … 8.3.3 Pass the filtered solution…. 6.3.4 Analyze the pass fraction by SDS-PAGE to determine…. ATTACHMENTS AND EXHIBITS: 9.1 10.0 Attachment or Form #: HISTORY Title Number A Biotechnology Company 123 Bioscience Drive Anywhere, US 0007 Document Number: 1.23 Revision Number: 2 Effective Date: Page 1 of 5 Title: SDS-PAGE SOP Approvals Preparer: _________Your Name________________________ Date ________________ Reviewer: ________His Name _______________________ Date ________________ Reviewer: ________His Name _______________________ Date ________________ 1. Purpose: 1.1. To describe the appropriate operating instructions to perform SDS-PAGE analysis of protein samples. 2. Scope: 2.1. Applies to confirming the presence and purity of two recombinant human proteins (tPA and HSA) produced and purified in the laboratory of A Biotechnology Company. 3. Responsibilities: 3.1. It is the responsibility of the Supervisor to ensure that this SOP is performed as described and to update the procedure when necessary. 3.2. It is the responsibility of the technicians to follow the SOP as described and to inform the Supervisor about any deviations or problems that may occur while performing the procedure. 4. References: 4.1. Invitrogen Novex Gel instructions 4.2. Novex XCell II Mini-Cell Gel Box Operation SOP 4.3. Gel Documentation Instrument SOP 5. Definitions: 5.1. tPA is tissue plasminogen activator. 5.2. HSA is human serum albumin. 6. Precautions: 6.1. Acrylamide is a neurotoxin. Always wear protective gloves when handling the polyacrylamide gels. 6.2. Fixative solution is flammable – keep away from sparks and flames. Dispose in Fixative Hazardous Waste bottle 6.3. GelCode Blue is harmful. Dispose in GelCode Blue Hazardous Waste bottle. 7. Materials: 7.1. Protein Samples 7.2. Protein Standard, 4mg/ml: (2– 8C refrigerator) 7.3. Invitrogen Molecular Weight Marker (2– 8C refrigerator) 7.4. NOVEX Precast Gel Box and Accessories 7.5. Power Supply for Protein Electrophoresis 7.6. NuPAGE 4-12% Bis-Tris Gels (1.0mm x 10 well), 2– 8C refrigerator 7.7. NuPAGE MOPS SDS Running Buffer (20X), room temperature 7.8. NuPAGE Antioxidant, 2– 8C refrigerator A Biotechnology Company 123 Bioscience Drive Anywhere, US 0007 Document Number: 1.23 Revision Number: 2 Effective Date: Page 2 of 5 7.9. NuPAGE SDS Sample Buffer (4X), room temperature 7.10. Reducing Agent (10X), -20C freezer 7.11. Graduated cylinders (1L and 100ml) 7.12. P20, P100 or P200 Micropipettor and tips, including gel loading tips 7.13. Microfuge Tubes 7.14. Microfuge 7.15. Boiling Water Bath 7.16. Staining Trays 7.17. Infors HT Labotron mini rotary shaker 7.18. Gel Fixative Solution 7.19. Pierce GelCode Blue Staining Reagent, 2– 8C refrigerator 7.20. Light Box 7.21. Gel Documentation Instrument 8. Procedure: 8.1. Prepare Running Buffer and Staining Solutions 8.1.1. 1L NuPAGE MOPS SDS Running Buffer (1X) (if needed) 8.1.1.1.Place 50ml NuPAGE MOPS SDS Running Buffer (20X) in a 1 Liter graduated cylinder. 8.1.1.2. Gently add 950ml deionized water by running it down the side of the cylinder to make 1 liter of 1X NuPAGE MOPS SDS Running Buffer. 8.1.1.3. Add a stir bar and gently stir. NOTE: SDS is a detergent and will foam if mixed vigorously. We do not want bubbles. 8.1.2. 200ml NuPAGE MOPS SDS Running Buffer (1X) plus antioxidant (if needed) 8.1.2.1. Separate 200ml of 1X NuPAGE MOPS SDS Running Buffer into a 500ml Erlenmeyer flask. 8.1.2.2. Add 500µl of NuPAGE Antioxidant. 8.1.2.3. Add a stir bar and gently stir. NOTE: SDS is a detergent and will foam if mixed vigorously. We do not want bubbles. 8.1.3. 500ml Fixative Solution (if needed) 8.1.3.1. In a 500ml Wheaton bottle, mix together: 250ml 100% Methanol 215ml deionized water 35ml glacial acetic acid 8.1.3.2. Store at 2– 8C 8.2. Dilute Protein Standards (if needed). 8.2.1.1. Dilute the appropriate protein standard(s) with water to a final concentration of 1mg/ml 8.2.1.2. Label tube with protein name, 1mg/ml, [date], [initials]. Store on ice until ready to use. A Biotechnology Company 123 Bioscience Drive Anywhere, US 0007 Document Number: 1.23 Revision Number: 2 Effective Date: Page 3 of 5 8.3. Prepare Protein Samples and Protein Standards (Do NOT perform this step with the Molecular Weight Marker) 8.3.1. For all the samples and the standards, combine the following in a sterile 1.5ml microfuge tube: 25ul 4x sample buffer 10ul 10x reducing agent 65ul sample 8.3.2. Mix gently with a pipette by aspirating and dispensing at least 3 times 8.3.3. Boil for 3-5 minutes. 8.3.4. Remove from boiling water bath. 8.3.5. Pulse all samples and standards in a microfuge for 30 seconds. 8.4. Prepare Novex Precast Gel Box 8.4.1. Assemble gel box according to its SOP. 8.4.2. Place 200ml NuPAGE MOPS SDS Running Buffer (1X) plus antioxidant in the upper buffer chamber (small chamber between 2 gels or the gel and buffer dam) 8.4.3. Fill the lower buffer chamber with approximately 600ml of 1X NuPAGE MOPS-SDS Running Buffer (large chamber). 8.4.4. Rinse gel wells with micropipettor and buffer from upper buffer chamber. 8.5. Load Samples 8.5.1. Using a micropipettor and disposable tips, load 10ul of the Molecular Weight Marker into one well and up to 50µl of each sample into separate wells. 8.5.2. Load any empty wells with 15µl of diluted 4X Sample Buffer. 8.5.3. Record order of samples and volumes loaded. 8.6. Run NOVEX NuPAGE MOPS SDS Precast Gel Box 8.6.1. Plug electrophoresis chamber into the gel electrophoresis power supply. 8.6.2. Run gel at 200V for 40 – 60 minutes. 8.6.3. Turn off the power supply when the dye reaches 1cm from the bottom of the gel. 8.7. Stain and Photodocument the NOVEX NuPAGE MOPS SDS Precast Gel 8.7.1. Disassemble gel box per SOP and remove gel from plastic cassette. 8.7.2. Rinse gel box well with DI water. Do not use brushes on the gel box, they scratch the surface. Do not immerse top of gel box or electrical components. 8.7.3. Place gel in staining tray. 8.7.4. Wash gel 3 times for approximately 5 minutes with DI water at room temperature on a shaker. 8.7.5. Add enough Fixative solution to cover the gel completely and fix for approximately 15 minutes at room temperature on a shaker. 8.7.6. Discard Fixative Solution into the Fixative Hazardous Waste bottle. A Biotechnology Company 123 Bioscience Drive Anywhere, US 0007 Document Number: 1.23 Revision Number: 2 Effective Date: Page 4 of 5 8.7.7. Wash gel 3 times for a minimum of 5 minutes with DI water at room temperature on a shaker. 8.7.8. Add about 50ml of GelCode Blue and stain for 1-24 hours at room temperature on a shaker. 8.7.9. Decant GelCode Blue into GelCode Blue Hazardous Waste bottle. 8.7.10. Wash gel with DI water for 15 minutes to overnight on a shaker 8.7.11. Remove gel from staining tray and place on visible light box 8.7.12. Identify the protein standards and samples and estimate their molecular weights. See Molecular Weight Diagram. 9. Attachments: 9.1. Molecular Weight Marker Diagram 10. History: Name John Smith A Person Her Name Date 2002 2005 2007 Amendment Initial Release Changed Coomassie stain to GelCode Blue Stain Put into SOP 2005 format A Biotechnology Company 123 Bioscience Drive Anywhere, US 0007 Attachment: Molecular Weight Maker Diagram Document Number: 1.23 Revision Number: 2 Effective Date: Page 5 of 5 SOP Exercise Select any item of laboratory equipment the use of which you are familiar with. It need not be anything complicated. For example a pH meter, a conductivity meter, a balance or even a hot plate and stirrer would be suitable pieces of equipment. Using the above generic or template SOP and the example SOP as guides, write an SOP for operation of the item of laboratory equipment that you have chosen. Once you have obtained all the information you need from the laboratory, this exercise may be completed outside of the laboratory. Write up and print the SOP as if it was the genuine document. Use the format in the generic/template SOP for the preparer and reviewers’ signatures and acceptance of the SOP. This would make the document the best possible and would indicate approval by two reviewers, acceptance by the Quality Manager, and final issuance by the Company. All these features are lacking in the example SOP. Ask classmates to be the two reviewers, the Quality Manager and the issuer. LABORATORY EXERCISE NUMBER 2 DOCUMENTATION, QUALITY SYSTEMS AND GMP (PART 2-BATCH RECORD AUDIT) Introduction Students will gain an understanding of good documentation and cGMPs by the audit of a batch record. Background Each of the Master Batch Production Record (MBPR) and the Batch Production Record (BPR) is a DETAILED step-by-step of the entire production process for a batch of product. It includes: Types and quantities of components and raw materials. Processing parameters such as o Incubation times o Run times o When to add components and in what order, i.e. complete instructions on adding, mixing and sampling for Quality Control Unit (QC) testing o Expected yields Processing quality control parameters such as what QC tests to perform. Environmental control parameters such as the type of clean room required. Specifications for packaging of the product and label(s) that will be used. The Master Batch Production Record is kept and provides the individual Batch Production Records. The Batch Production Record: Accurately follows the Master Batch Production Record. Includes Quality Control Unit review and approval of o Batch Production Record o Cross reference of receiving and Batch Production Records o Any material review and disposition decision o Reprocessing o Release for distribution Is kept for 3 years beyond the date of batch production. Includes, in part, o Batch, lot or control number of product o Identity of equipment and processing lines used o Date and time of the maintenance, cleaning and sanitizing of the equipment and processing lines used o o o o o o o o Incoming shipment lot identifier Identity and mass or measure of each component used Date and initials of persons completing and verifying steps. Date batch produced. Test results. Any material reviews and disposition decisions Documentation that final product specifications are met. Copy(ies) of label(s) used for the packaged product. The batch production record, or more simply batch record, accompanies a product as it is made. The batch record directs the operators in exactly how to make the product – and the operators must follow the batch record instructions just as it is written. Each time a product is to be made, the operators are issued a fresh copy of the current version of the batch record. The batch record also provides blanks that are filled in as the operator performs each task to document that they have done it. For critical steps, a witness watches the operator and signs off as well. By filling in the blanks properly, the operators demonstrate that they have done each task properly. Other points of note for batch records are as follows (some have already been mentioned above). COMPANY NAME: The name of the company should be included on the batch record. TITLE: The title of the batch record is included on each page. ID NUMBER: Each batch record should also contain a unique identification number. It may be listed as the “Batch Record Number.” PAGE NUMBER: Each page of the batch record should be numbered. HAZARD COMMUNICATION: This section warns the operator of any hazards associated with the procedure and any required safety precautions. PROCEDURE: The core of the batch record details what the operator will do in a stepby-step chronological manner. Every batch record has this information. As the operator performs each task, s/he fills in related information to document how that task was done and initials the “operator” blank. The witness initials the “verified by” blank. The date must also be provided for the initials in each case, i.e. for both “operator” and “verified by.” LABEL INFORMATION: Every company will have specific instructions for labeling manufactured products. These instructions must be followed exactly to avoid any mixups. QA REVIEW: Every completed batch record is reviewed by a QA (Quality Assurance) representative to ensure that it is properly filled out. Laboratory Activity On the following page is the front page of a batch record drawn up by a hypothetical company producing small quantities of E. coli media as one of its activities. As part of the company’s quality system you are required to audit this batch record before it is approved and issued to the technicians. Based on the above discussion of batch records, there are at least five omissions in the one below. Draw up and submit a list of these. LABORATORY EXERCISE NUMBER 3 DOCUMENTATION, QUALITY SYSTEMS AND GMP (PART 3-BATCH RECORDS) Introduction Students will practice good documentation and cGMP in two laboratory activities (Laboratory Exercise Numbers 3 and 4) designed as an introduction to manufacturing. Materials and Supplies (To Be Used in Laboratory Exercise Number 4) Bread; peanut butter; jelly; utensils (knives, spoons); aluminum foil; balances Activity Work in groups to develop a company that will manufacture peanut butter and jelly sandwiches. Each group will develop the following in this first activity: Part A 1. Name of Firm. 2. Quality Policy and Mission Statement. 3. Organizational Chart. Part B 1. Specifications for Sandwiches. 2. Raw Materials Needed For Sandwiches. 3. Equipment Requirements. 4. Process Controls. For Part A, use any resources, such as the websites of biotechnology companies manufacturing products, that you believe would be of assistance. Retain all you have developed from above for the second activity, in Laboratory Exercise Number 4. LABORATORY EXERCISE NUMBER 4 DOCUMENTATION, QUALITY SYSTEMS AND GMP (PART 4-BATCH RECORDS, CONTINUED) Introduction This is a continuation from Laboratory Exercise Number 3. Materials and Supplies Bread; peanut butter; jelly; utensils (knives, spoons); aluminum foil; balances Activity Part A 1. Review batch records (batch production records) in Laboratory Exercise Number 2. 2. Each company creates a batch record for the manufacture of its product, viz. peanut butter and jelly sandwiches. Part B 1. Each group gives its batch record to another company for production of its product. 2. Each group manufactures the product and evaluates the batch record during the process. Part C 1. Each group reviews the quality of its product with the group which performed the manufacturing. 2. Discuss the quality of the batch record and any modifications thereof. Report Each group will submit a report containing all the information required in Parts A and B of Laboratory Exercise Number 3. In addition, each group will include in its report batch records from above; one prior to and one after modifications with a discussion of the quality of the batch record in each case. LABORATORY EXERCISE NUMBER 5 GOWNING Introduction In a biomanufacturing facility, gowning requirements for operational areas are set appropriately for the activities that occur within those areas. Appropriate gowning will minimize the number of particulates shed by each operator. This helps a facility maintain the appropriate air classification in each area, which in turn protects the product from potential contamination. Gowning Gowning is the donning of clean room garments to protect the low particle counts required in the processing areas. Different levels of gowning are required, depending on the operations being performed. Code of Federal Regulations 21CFR 211.28(a) states: Personnel engaged in the manufacture, processing, packing, or holding of a drug product shall wear clean clothing appropriate for the duties they perform. Protective apparel, such as head, face, hand, and arm coverings, shall be worn as necessary to protect drug products from contamination. In General General gowning points include the following: Gowning will take place in gowning air locks. Each gowning room will have the maximum number of individuals allowed to gown at one time clearly posted. Choose a gown that is large enough to allow unrestricted movement, but not so large as to interfere with movement. Disposable or Reusable Gowns? In some areas, disposable gowns will be used instead of reusable garments. Disposable gowns should be placed in trash receptacles upon degowning. Reusable garments should be placed in laundry bins upon degowning. Permitted Items The following items are permitted in gowning level 0-3 areas: Earrings Rings Watches Prohibited Items The following items are not permitted in the manufacturing facility at any time: Cosmetics that could shed particles Excessive jewelry that cannot be covered by gowning, for example dangling earrings. Key Concepts The following points are key concepts: In the locker rooms, prior to entering the circulation corridor, shoes should be inspected for mud and debris. If necessary, replace soiled shoes with clean shoes. Tacky mats are usually present near gowning room doors. Whenever moving through a gowning room, always step on the tacky mat to remove debris from the bottoms of your shoes. Prior to donning appropriate level gowning, hands must be sanitized. Hand sanitization stations are available in each gowning room. Safety glasses must be donned prior to entering all processing rooms within the production areas. Safety glasses are required and can be sanitized with ethanol prior to wearing. Safety glasses are not required in non-processing rooms within the production areas. If any gowning garment is found to be defective, it should be tied in a knot for easy identification and placed in the soiled garment bin. While gowning, every effort should be made to minimize garment contact with floor, wall or equipment. When gowning, all zippers and snaps should be completely fastened. If they are not, the gown will not perform as it is designed. At various points in or around the gowning area there are lines of demarcation on the floor. These demarcation lines separate the clean side from the dirty side of the gowning room. Shoe covers and knee-high boots are donned as you step across the line of demarcation from the dirty side to the clean side. If one has stepped back into the dirty side with the intention of returning to the clean side, the shoe covers or boots must be removed, discarded in the soiled garment bin, and replaced with new covers or boots on stepping back into the clean side. To degown, reverse the appropriate level gowning sequence. For areas in which single-use garments are worn, operators may step over the line of demarcation to a lower gown level to remove gown garments. Only one activity, e.g. gowning, degowning, material transfer, environmental monitoring, cleaning, etc., may occur in a gown or degown room at a time. For mechanical space that is accessed from GMP process areas, personnel may be required to don additional gown garments, as posted, and remove those garments upon reentry into a process area. GOWNING LEVELS 0-3 Introduction Appropriate gowning requirements are determined for any given biomanufacturing facility. Gowning levels are presented as an example of gowning for a manufacturing facility. However, they are not a universal industry standard. Gowning Levels 0 Through 3 The following are the minimum requirements for gowning Levels 0 through 3: Level 0 gowning consists of street clothes (clean pants, shirts with sleeves, and clean, close-toed shoes) or plant uniforms and safety glasses. Level 1 gowning consists of items in gowning level 0 plus shoe covers. Level 2 gowning consists of items in gowning level 1 plus a frock, hair cover and facial hair cover, when appropriate. Level 3 gowning consists of items in gowning level 0 plus knee-high boots, hair cover, facial hair cover, when appropriate, and a coverall. Level 0 Gown for Level 0 in the following sequence: Action Inspect shoes for mud and debris. Replace with clean shoes if necessary. Sanitize safety glasses with a disinfectant, such as 70% isopropyl alcohol, or prewetted wipes. Ensure that legs and shoulders are covered and that facility scrubs are available, if necessary. Rationale Depositing debris in the circulation corridor increases the chance of contaminating the processing areas. Removes bacteria and debris that may be carried into the manufacturing areas. This is necessary to minimize particulate shedding within the facility. Level 0 Applicability Refer to the applicable facility gowning Standard Operating Procedure for Level 0 gowning applicability. Level 1 Gown for Level 1 in the following sequence: Action Sanitize hands with Alcare or equivalent. Sanitize safety glasses with a disinfectant, such as 70% isopropyl alcohol, or prewetted wipes. Don shoe covers while stepping across the line of demarcation from the dirty to the clean side of the gowning room. Rationale Clean gowning should be handled with clean hands. Removes bacteria and debris that may be carried into the manufacturing areas. This action ensures that the clean side of the gowning room remains clean. Level 1 Applicability Refer to the applicable facility gowning Standard Operating Procedure for Level 1 gowning applicability. Level 2 Gown for Level 2 in the following sequence: Action Sanitize hands with Alcare or equivalent. Sanitize safety glasses with a disinfectant, such as 70% isopropyl alcohol, or prewetted wipes. Don hair cover and tuck in all hair. Don facial hair cover, if applicable. Don shoe covers while stepping across the line of demarcation from the dirty to the clean side of the gowning room. Don appropriately-sized frock and ensure that all zippers and snaps are completely closed. Rationale Clean gowning should be handled with clean hands. Removes bacteria and debris that may be carried into the manufacturing areas. Hair covers keep hair from shedding. Hair covers keep hair from shedding. This action ensures that the clean side of the gowning room remains clean. Gown will not do its job properly if it is not completely closed. Level 2 Applicability Refer to the applicable facility gowning Standard Operating Procedure for Level 2 gowning applicability. Level 3 Gown for Level 3 in the following sequence: Action Sanitize hands with Alcare or equivalent. Sanitize safety glasses with a disinfectant, such as 70% isopropyl alcohol, or prewetted wipes. Don hair cover and tuck in all hair. Don facial hair cover, if applicable. Don knee-high boots while stepping across the line of demarcation from the dirty to the clean side of the gowning room. Don appropriately-sized coverall and tuck legs into knee-high boots. Rationale Clean gowning should be handled with clean hands. Removes bacteria and debris that may be carried into the manufacturing areas. Hair covers keep hair from shedding. Hair covers keep hair from shedding. This action ensures that the clean side of the gowning room remains clean. Donning boots first keeps the inside of the coverall clean. Tucking ensures that gown legs will not touch the floor and become soiled and keeps particulates from escaping down the gown leg on to the floors. Level 3 Applicability Refer to the applicable facility gowning Standard Operating Procedure for Level 3 gowning applicability. Level 3 gowning is required in areas where processing occurs, with the addition of a mask and gloves when appropriate. It is considered good practice to wear gloves at all times within the processing areas, but gloves are not required for minimum Level 3 gowning. Gloves, however, must be worn whenever equipment is handled within the production areas. If at any time gowning becomes visibly soiled, personnel must move to a degowning room, remove the soiled gown, and reenter the area through the gowning room, donning appropriate clean gowning material. Once inside the processing area, personnel may not unzip their coverall or degown in any way, except in case of emergency. Personnel must move to a gowning room to access cell phones, radios, etc. within the gown. Masks and Gloves When performing certain operations, a mask and/or gloves must be worn in addition to Level 3 gowning: When Handling clean or sanitized labware or product-processing components. Product or processing materials are exposed to the environment. Taking a sample of in-process product. Making aseptic product contact connections. Then Wear clean gloves. All individuals in the clean room must wear masks and clean gloves. Individual taking the sample must wear a mask and clean gloves. Individual making the connections must wear a mask and clean gloves. GOWNING LABORATORY Introduction Students will learn the concepts and skills involved in gowning for both outside and inside an aseptic area (Class 100). Each student will don complete gowning attire in an aseptic manner. Materials and Supplies Hand-sanitizing agent (e.g. Alcare) 70% isopropyl alcohol Wipes Safety glasses Gowns: Frocks and Coveralls Boots Hoods Gloves Masks Beard covers Shoe covers Bouffant caps Activities 1. The laboratory activities will begin with a demonstration of gowning and gloving techniques by the industry instructor. Gowning for both outside and inside the aseptic area of a clean room will be demonstrated. 2. The sequences for degowning will also be demonstrated and performed. 3. Students will perform the gowning and degowning sequences under supervision. 4. Students may critique the performance of each other. LABORATORY EXERCISE NUMBER 6 AUTOCLAVE MONITORING Introduction Autoclaves are large pieces of equipment that are widely used in the biotechnology industry. They contain large compartments capable of sterilizing a wide variety of equipment and labware used in the production process. While disinfectants are used in the sanitization of floors, walls, tabletops and other surfaces, the autoclave is the means by which labware and other pieces of equipment are sterilized for use in applications where sterility is required. The autoclave is capable of sterilizing many pieces of equipment in a relatively short period of time. Equipment and labware are cleaned prior to autoclaving and the autoclave is used to sterilize the equipment. At 121.1°C for a specified length of time, usually 15 to 20 minutes depending on the equipment, microorganisms and their spores are no longer viable. The autoclave, through the injection of clean steam, raises the pressure and temperature of its interior, and therefore its contents, to at least this level. Equipment or labware can be considered sterile and ready for use once it has been sustained at this temperature for the required period of time. Equipment Validation For use in a GMP environment, equipment such as an autoclave would need to be validated. Equipment Validation describes the inspection and qualification of GMP equipment and the associated documentation to verify that predetermined fabrication, installation and operational specifications are met. Equipment Validation ensures that an instrument is appropriate for its intended use. Examples of equipment that must be validated are: Steam autoclaves Dry heat ovens Depyrogenation tunnels Ethylene oxide (ETO) sterilizers Freeze dryers Incubators Refrigerators Pumps HEPA filters Chromatography Fermentors Typical validation phases are: Design qualification (DQ) for setting functional and performance specifications (operational specifications). Installation qualification (IQ) for performing and documenting the installation in the selected user environment. Operational qualification (OQ) for testing the equipment in the selected user environment to ensure that it meets the previously defined functional and performance specifications. Performance qualifications (PQ) for testing that the system consistently performs as intended for the selected application. The validation of a GMP manufacturing facility is a complex operation. Many associated documents require pre- and post-validation approval. Qualified staff must perform the inspections and performance tests in the facility. Good planning, resource allocation and test design are required for the successful deployment of validation activities and the timely completion of reports. Once the initial validation is concluded, the equipment must be monitored to ensure that it remains in a validated state throughout its use, i.e. equipment must be periodically tested to ensure that it is still operating within its pre-determined specifications. Revalidation must be performed after modifications to ensure the same. The steps of validation are: 1. System Documentation 2. SOPs (operation, calibration, maintenance, sampling and testing) 3. Write Documentation (IQ/OQ/PQ) with input from: Engineering Facilities Manufacturing Quality Assurance (QA) Regulatory Affairs (RA) (often as policies) 4. Execution of IQ/OQ/PQ in Facility 5. Review and Approvals of the Validation Technical Reports (by same functions that approved the Validation Protocols) To get validation done: A Validation Protocol needs to be developed. The validation procedures according to the protocols (IQ, OQ, PQ) need to be performed and documented. The Validation Technical Report needs to be signed and issued. A Validation Protocol is an experimental plan intended to produce documented evidence that a system has been validated. Types of Validation Protocols: 1. Installation Qualification (IQ). An IQ is documented verification that all key aspects of the installation adhere to appropriate codes and approved designs and conform to the production department’s and the manufacturer’s specifications. 2. Operational Qualification (OQ). An OQ is documented verification that the equipment performs as intended throughout all anticipated operating ranges. 3. Process Qualification (PQ). A PQ is documented evidence which provides a high degree of assurance that a specific process will consistently produce a product that meets its predetermined specifications and quality attributes. In executing the Validation Protocols: The procedures described in the respective SOP need to be followed carefully and documented fully. The validation work continues until the acceptance criteria are met. If acceptance criteria cannot be met, the suitability of the equipment or of the specified criteria needs to be discussed. In the Technical-Summary Report from the Validation Protocol: The validation study’s goals and approach should be summarized. The results should be summarized. Deviations from the original acceptance criteria should be explained and justified. Approval signatures are required. The monitoring of an autoclave in the present laboratory exercise does not in itself constitute an Operational Qualification (OQ), which would be the pertinent Validation Protocol documenting that that the autoclave operates according to its predetermined specifications. However, this monitoring could provide some of the information necessary for an OQ. Other information would be required such as: SOP and trainer verification Operators’ manual Start-up and shut down Alarms test Instrumentation calibration Integrity of vessel and seals Emergency recovery, after loss of power and/or services Objectives To monitor the saturated steam sterilization cycle at 121°C of an autoclave using a biological indicator. To gain familiarity with a task, i.e. the evaluation of sterilization by an autoclave, that could be used for validation of the operation of the autoclave, i.e. OQ. Materials Autoclave. Raven ProSpore Self-Contained Biological Indicator. Each ampoule contains a suspension of spores of the organism, Geobacillus stearothermophilus, within a growth medium also containing Bromocresol Purple to function as a pH indicator. The acid production associated with growth causes a change in color from purple to or toward yellow. Incubator set at 55-60°C. Procedure 1. Exposure. Add about 50 ml water to a 250 ml beaker. Suspend an ampoule of the Raven ProSpore Biological Indicator in the water contained in the beaker. This is done because sterilization of an item would be less effective if it is in water. If it is functioning correctly, the autoclave would adequately sterilize water and anything contained within it. If the autoclave was not functioning properly it would be detected most markedly with the biological indicator autoclaved in water. Place the beaker of water containing the biological indicator near the drain of the autoclave. This is usually the most difficult location to sterilize and the biological indicator is placed here for the same reason it is placed in water. Run the autoclave cycle. 2. Caution. On completion of the autoclave cycle unlock the autoclave door and open it carefully. Remove the beaker containing the ampoule. Contents of the ampoule are hot and under pressure and therefore it must be handled with care. Allow a sufficient cooling time of 10-15 minutes. Failure to do so may result in bursting of the ampoule. 3. Incubation. Place the processed ampoule in a vertical position in an incubator at 5560°C. Mark a control ampoule, i.e. one that was not autoclaved, and incubate along with the processed ampoule to ensure spore viability. Incubate for 48 hours. 4. Monitoring. Examine the Prospore ampoules daily during incubation. Record your observations. All positive ampoules should be recorded and then disposed of immediately. 5. Interpretation. Control: The control ampoule should exhibit a color change to or towards yellow and/or turbidity. If the control ampoule does not show signs of growth consider the test invalid. Test: A failed sterilization cycle is indicated by turbidity and/or a change in color to or towards yellow. A test ampoule that retains its purple color and is not turbid indicates an adequate sterilization cycle. 6. Results. Record all your observations and state your conclusions in your laboratory report. LABORATORY EXERCISE NUMBER 7 GMP POPCORN Goal Students will make, with adherence to GMP (Good Manufacturing Practices), a batch of popcorn. This must be completed within a fixed time of 2 hours. Objectives To achieve further understanding of the complexity of a GMP process. Simulation of a biomanufacturing facility and the different departments that would interact therein. To be able to complete all the necessary GMP documentation. An appreciation of how working in teams and cooperation between departments are essential features of GMP. To gain insight into the pressures and constraints that one could face while working in industry. This Exercise Could Reflect Industry Frustration could be experienced at times. There may be a feeling of being rushed. There may be a sense of accomplishment once the batch has been made. The actual time for the process, which in industry would be such things as extraction, fermentation, purification, etc., is very small compared to the time it takes to get all GMP documentation in place. Rewards for completion of the task will be in the form of a salary increase and/or stock options. Materials 1. Paper for documentation 2. Approved labels 3. Quarantine labels 4. Box for approved and quarantine 5. Microwave Popcorn 6. Access to microwave oven 7. Water in a squirt bottle 8. Cleaning agent 9. Paper towels 10. Sponge 11. Measuring cups 12. Bags for the finished product Teams A) B) C) D) Material Control: 2 people Quality Control (QC): 2 people Quality Assurance (QA): 2 people Production: 4 people Students should each join a particular team. If numbers are sufficient, distribute yourselves according to the numbers given above. Otherwise ensure that there is at least one person in each team except for production where at least two people are preferred. Documentation Inform the instructor when you have completed production and the product is ready to be shipped. A bonus of $10,000.00 in company stock options (equivalent to 10% on the final grade for this laboratory exercise) for all the members of all the teams will be awarded for every 15 minutes that the product is obtained ahead of schedule with all the documentation completed, i.e. before the end of the 2 hour time limit. A further bonus of a 10% salary increase (equivalent to 10% on the final grade) will be awarded if the product is of good quality. Submit all documentation together with the names of the individuals assigned to each named team.