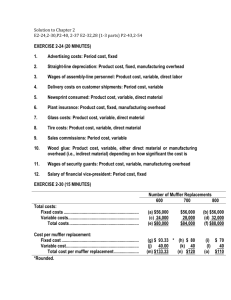

Problem 3-57 (continued)

advertisement