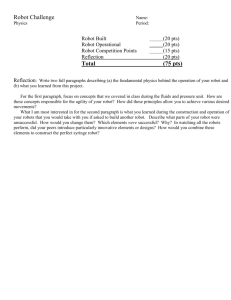

AIM'01 Program - Advanced Intelligent Mechatronics AIM'01

advertisement