Soap and Saponification

advertisement

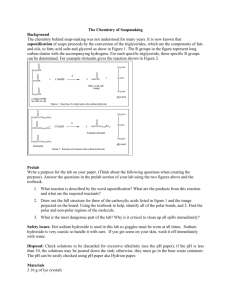

Soap and Saponification Preparation & Chemical Structure One of the organic chemical reactions known to ancient man was the preparation of soaps through a reaction called saponification. Natural soaps are sodium or potassium salts of fatty acids, originally made by boiling lard or other animal fat together with lye or potash (potassium hydroxide). Hydrolysis of the fats and oils occurs, yielding glycerol and crude soap. In the industrial manufacture of soap, tallow (fat from animals such as cattle and sheep) or vegetable fat is heated with sodium hydroxide. Once the saponification reaction is complete, sodium chloride is added to precipitate the soap. The water layer is drawn off the top of the mixture and the glycerol is recovered using vacuum distillation. The crude soap obtained from the saponification reaction contains sodium chloride, sodium hydroxide, and glycerol. These impurities are removed by boiling the crude soap curds in water and re-precipitating the soap with salt. After the purification process is repeated several times, the soap may be used as an inexpensive industrial cleanser. Sand or pumice may be added to produce a scouring soap. Other treatments may result in laundry, cosmetic, liquid, and other soaps. How To Make Soap From Anne Marie Helmenstine, Ph.D., Your Guide to Chemistry. FREE Newsletter. Sign Up Now! These are the instructions for making your own gentle hand or face soap. It's work, but worth the effort! Difficulty: Average Time Required: 1 Day Here's How: 1. If you are using a pure fat, such as coconut oil or olive oil, you can skip to step 5. Coconut oil yields a soft, quick-lathering soap. Olive oil and other vegetable cooking oils yield a soft soap that never completely hardens. 2. Render the tallow by cutting it into chunks, placing it into the large pot, covering it, and heating on medium heat until it is melted. Stir occassionally. 3. Cool the fat to below the boiling point of water. Add a volume of water equal to that of the fat. Bring the mixture to a boil. Cover and remove from heat. Let sit overnight. 4. Remove the fat from the pot. Discard non-fat gunk (scrape it off of the bottom of the fat) and any liquid. 5. Measure 2.75 kg rendered fat. Cut the fat into tennis-ball size chunks and place the pieces into a large bowl. 6. Set up all of your materials. Ventilate the area (or work outside), put on safety gear, and open all containers. 7. Make soap :-) Pour the water into a large glass or ceramic bowl (not metal). Carefully pour the lye into the bowl and mix the water and lye with the wooden spoon. 8. The reaction between water and lye gives off heat (is exothermic) and vapors that you should avoid breathing. The spoon will be somewhat degraded by the lye. 9. Once the lye is dissolved by the water, start adding the chunks of fat, a bit at a time. Keep stirring until the fat is melted. If necessary, add heat (put on a low burner with ventilation). 10. Stir in the lemon juice and fragrance oil (optional). Once the soap is well-mixed, pour it into molds. If you use glass baking dishes for molds, you can cut the soap into bars after it has become firmer (not hard). 11. The soap will harden in approximately an hour. 12. You may wrap the finished soap in clean cotton rags. It can be stored for 3-6 months in a cool, wellventilated location. 13. Wear gloves when washing your equipment, as their may be some unreacted lye remaining. Wash in very hot water to help melt away the residue. Tips: 1. 2. 3. 4. 5. Adult supervision required! Wear gloves and protective eyewear and cover exposed skin to avoid accidental exposure to the lye. Keep out of reach of children! If you get lye on your skin, immediately wash it with lots of cold water. Read the cautions on the container before opening the lye. Don't measure the lye. Instead, adjust the soap recipe to accomodate the container size of the lye. Cooking oils are sensitive to air and light, and soap made from cooking oils will spoil in a few weeks unless it is refrigerated. Volatile fragrance oils or even dried herbs or spices may be added to the soap to scent it. Fragrance is optional. What You Need: 4 kg (9 lb) suet (tallow) 350 g (12 oz) lye 750 ml (3 C) water 500 ml (2 C) lemon juice 7.5 ml (.25 oz) fragrance gloves wooden spoon ventilated work area molds/glass baking dishes Lye to Fat Ratio Table This table is for those of you who want to get a bit more scientific in soap making, or just want to check and see if the person who created the recipe you're planning on using knew what they were doing. Each fat has its own saponification value, or "SAP Value." And because of this, each fat requires a different amount of lye to convert the fat to soap. (Jump to the bottom of the page to learn more about this.) For the soap to be made with no left over lye or fat you must have very accurate measuring equipment. As the same oil from different sources will It's a balancing act... have a slightly different saponification value, we recommend you keep your soap a bit fat heavy to ensure you don't end up with lye in your finished product. In the table below use the 0-4% excess fat columns (red) if you have accurate technical equipment to test for excess fat or lye. Use the 5-8% excess fat columns (green) to make good hand/body soap and the 910% columns (blue) if you want excessively fat heavy soap. This page was written under close consultation by Tina Howard at Majestic Mountain Sage. In fact, the following table was made using her lye calculator, which will automatically calculate the amount of lye you need for a large variety of different fats. You plug into her calculator the fats and quantities and it returns how much lye you'll need. Calculate the amount of lye you need by multiplying the amounts of each fat (including superfatting oil) in your recipe by the number intersected by the fat and your desired excess fat column. Then add the different lye amounts for the different fats in your recipe together. Example: You want to calculate the amount of lye for a recipe that calls for for 16 oz. of lard as it's only fat. You want your finished soap to have 5% excess fat. Intersecting the Lard row with the 5% column, you find the number 0.132. Multiply 16 (fat wt) by 0.132 = 2.1 oz. of lye. Desired Excess Fat In Finished Soap Animal Fat 0% 1% 2% 3% 4% 5% 6% 7% 8% 9% 10% Goat Fat Lanolin Lard Mutton Fat Tallow 0.138 0.075 0.139 0.138 0.140 0.137 0.074 0.137 0.137 0.139 0.136 0.073 0.136 0.136 0.138 0.134 0.073 0.135 0.134 0.136 0.133 0.072 0.133 0.133 0.135 0.131 0.071 0.132 0.131 0.133 0.130 0.070 0.130 0.130 0.132 0.129 0.070 0.129 0.129 0.131 0.127 0.069 0.128 0.127 0.129 0.126 0.068 0.126 0.126 0.128 0.125 0.067 0.125 0.125 0.126 Vegetable Fat 0% 1% 2% 3% 4% 5% 6% 7% 8% 9% 10% Canola Oil Castor Oil Coconut Corn Oil Cottonseed Olive Oil Palm Oil Peanut Oil Safflower Soybean Sunflower 0.137 0.129 0.184 0.136 0.138 0.136 0.142 0.136 0.136 0.136 0.137 0.136 0.127 0.182 0.134 0.137 0.134 0.141 0.134 0.134 0.134 0.135 0.134 0.126 0.180 0.133 0.136 0.133 0.139 0.133 0.133 0.133 0.134 0.133 0.125 0.178 0.131 0.134 0.131 0.138 0.131 0.131 0.131 0.132 0.131 0.123 0.177 0.130 0.133 0.130 0.136 0.130 0.130 0.130 0.131 0.130 0.122 0.175 0.129 0.131 0.129 0.135 0.129 0.129 0.129 0.130 0.129 0.121 0.173 0.127 0.130 0.127 0.133 0.127 0.127 0.127 0.128 0.127 0.120 0.171 0.126 0.129 0.126 0.132 0.126 0.126 0.126 0.127 0.126 0.118 0.169 0.125 0.127 0.125 0.131 0.125 0.125 0.125 0.126 0.125 0.117 0.167 0.123 0.126 0.123 0.129 0.123 0.123 0.123 0.124 0.123 0.116 0.166 0.122 0.125 0.122 0.128 0.122 0.122 0.122 0.123 Weight of water needed = Total weight of fat in recipe times 0.38 Using potasium hydroxide instead of Lye? Multiply the lye by 1.4 - Using the example at the top of the table, 1.4 X 2.1 oz (lye used) = 2.94 oz of potasium hydroxide. Why different oils have their own SAP values: It all has to do with the length of the fatty acid chain. Briefly, it takes the same amount of lye to saponify a short fatty acid molecule as it does to saponify a long fatty acid molecule. The longer a fatty acid molecule is, the more a set number of them weigh. Saying this in another way, the longer chain fatty acids have a higher molecular weight. Hence, it takes less lye to saponify the longer chain fats. You can determine which fats above are the longer chain fats by looking at their SAP values. The higher the SAP number, the shorter the chain. Most of the fats above revolve around 18 carbon chain molecules with the sap value hovering around .136-.140 in the 0% Excess Fat Column. (The reason they are all slightly different is because the mixture of different fatty acids in each fat or oil is slightly different.) On the other hand, coconut oil contains about 47% lauric (C12), 19% myristic (C14), 9.5% palmitic acid (C16) and 20-25% other residues. Because coconut oil has several shorter string molecules, it takes more lye to turn a given weight of them into soap. Coconut's SAP value is .184. The reason for this is: the smaller the molecule, the more you can fit into a given volume. The more you can fit in a given volume, the more saponifiable bonds will be required and the more base you will consume. Speaking of a molar (equal number of molecules) ratio, then it takes an equal level of base to saponify the fat/oil, although the larger molecule will have a larger volume. Chemistry How Does Soap Clean? Soaps Are Emulsifiers Soaps are sodium or potassium fatty acids salts, produced from the hydrolysis of fats in a chemical reaction called saponification. Each soap molecule has a long hydrocarbon chain, sometimes called its 'tail', with a carboxylate 'head'. In water, the sodium or potassium ions float free, leaving a negatively-charged head. Soap is an excellent cleanser because of its ability to act as an emulsifying agent. An emulsifier is capable of dispersing one liquid into another immiscible liquid. This means that while oil (which attracts dirt) doesn't naturally mix with water, soap can suspend oil/dirt in such a way that it can be removed. The organic part of a natural soap is a negatively-charged, polar molecule. Its hydrophilic (water-loving) carboxylate group (-CO2) interacts with water molecules via ion-dipole interactions and hydrogen bonding. The hydrophobic (water-fearing) part of a soap molecule, its long, nonpolar hydrocarbon chain, does not interact with water molecules. The hydrocarbon chains are attracted to each other by dispersion forces and cluster together, forming structures called micelles. In these micelles, the carboxylate groups form a negatively-charged spherical surface, with the hydrocarbon chains inside the sphere. Because they are negatively charged, soap micelles repel each other and remain dispersed in water. Grease and oil are nonpolar and insoluble in water. When soap and soiling oils are mixed, the nonpolar hydrocarbon portion of the micelles break up the nonpolar oil molecules. A different type of micelle then forms, with nonpolar soiling molecules in the center. Thus, grease and oil and the 'dirt' attached to them are caught inside the micelle and can be rinsed away. Although soaps are excellent cleansers, they do have disadvantages. As salts of weak acids, they are converted by mineral acids into free fatty acids: CH3(CH2)16CO2-Na+ + HCl ----> CH3(CH2)16CO2H + Na+ + ClThese fatty acids are less soluble than the sodium or potassium salts and form a precipitate or soap scum. Because of this, soaps are ineffective in acidic water. Also, soaps form insoluble salts in hard water, such as water containing magnesium, calcium, or iron. 2 CH3(CH2)16CO2-Na+ + Mg2+ ----> [CH3(CH2)16CO2-]2Mg2+ + 2 Na+ The insoluble salts form bathtub rings, leave films that reduce hair luster, and gray/roughen textiles after repeated washings. Synthetic detergents, however, may be soluble in both acidic and alkaline solutions and don't form insoluble precipitates in hard water. But that is a different story... Cold Process Soap for One 12 oz Can of Lye Recipe by James Hershberger Ingredients: 1 can (12 oz or 340 grams) 100% lye 21 1/2 oz (605 gms) ice cold or part frozen distilled water 5 lbs, 7 1/3 oz (2.48 kg) lard or all vegetable shortening Equipment: 1 ea, 1-2 quart Pyrex or oven ware bowl 1 ea, 4-6 quart plastic bowl or stainless or cast iron pot 1 ea, plastic, wooden or stainless big spoon 1 ea, shallow cardboard box lined with plastic trash bag Rubber gloves Canning pot (for water bath if you use plastic reaction bowl) Instructions: Prepare the lye water by freezing 1/2 of the water into ice cubes. Put the ice cubes and the rest of the water into the 1 to 2 quart bowl. Using the stirring spoon (known to soap makers as the "crutch"), pour lye slowly into the ice and water, stirring until the lye is all dissolved. Take great care with the lye, it is very caustic and will burn the skin and eyes! Any splatters must be washed off immediately with lots of water! Cover the solution to keep out air and allow to cool (or warm up ) to about 85 degrees F. Melt the fat in the 4-6 quart bowl or pot. Don't use aluminum or galvanized bowls! Plastic ware can be heated in the water bath. When the fat is melted, cool it down to 95 degrees F. Prepare the box with it’s plastic trash bag lining, so the fresh liquid soap can't leak out. When all is ready, begin to stir the liquid fat in a clockwise direction while pouring the lye water into it in a thin steam (pencil size or thinner) until it is all added. Crutch (stir) the mix vigorously, using “S” pattern or use a hand blender alternating with a circular pattern until the mix begins to cool and thicken. At this point do NOT stop or the mix may separate! First the soap will be murky, then creamy, then like heavy cream and finally, like hot cooked pudding and will show traces when you dribble a stream from the crutch onto the surface. This process can take from 10 minutes to 45 minutes, depending on the temperature, weather and purity of your ingredients. Stir vigorously but patiently! With hand blender stir time is cut to 1/10 of the regular time. When your "trace" does not sink back into the surface, the soap is ready to pour into the lined box. Wear rubber gloves and treat the raw soap like you treated the lye water. Wash off all splatters immediately. Have 10% vinegar and water and a sponge to neutralize splatters. After 3-5 hours the soap may be cut into bars with a table knife, NOT a sharp knife. Allow the soap to cure in the box for about a week before breaking it up and handling it, and another month before using it. The old farm ladies carefully "tasted" the fresh soap with the tip of their tongues for the sharp bite of unreacted lye, as I do today. The soap from this recipe makes a bath and facial soap, and if you want old fashioned "Grandma’s Lye Soap," use less fat; about 5 lbs 5 oz instead of the original amount called for in the recipe. Allow this soap to mature in open air for six months. Should you wish to color your soap you may stir in about 20 gms children’s powder tempura paint when the mix reaches the heavy cream stage. Perfumed soap may be made by adding 60 gms (about 2 oz) of essential oil or perfume just before the soap is thick enough to pour. Sometimes I will wait for the unscented soap to cure, and then wrap the soap in muslin, anoint a cloth with perfume and wrap it with the soap in aluminum foil. Set it aside for about six weeks until the perfume has penetrated to the core of the bar. To re-form the bar into a new shape, place some bars into a ziplock bag and warm them up by immersing the closed bag of soap in hot (120degF ) water for 30 minutes. The soap should be soft enough to cut, make into balls or even press into molds. It sets when it has cooled and rested for an hour or so.