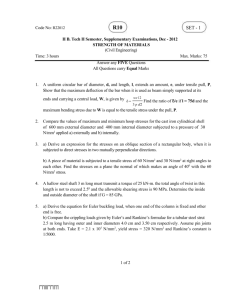

USN SUB CODE - PESIT South Campus

advertisement

Third Semester B.E. 1st IA Test, 2014 solution

PES INSTITUTE OF TECHNOLOGY BANGALORE SOUTH CAMPUS

(Hosur Road, 1KM before Electronic City, Bangalore-560 100)

Department of Mechanical Engineering

Date: 28-08-2014

Subject & code: Mechanics of Materials (10ME34)

Section: A&B

Name of faculty: Mr. Vijay Chandan

Note: Answer any five questions, selecting at least two questions from each part

1) Define

(i) Young’s modulus: When ever a material is loaded, with in its elastic limit the stress is directly

proportional to the strain with in the elastic limit.

For elastic bodies ,the ratio of stress to the strain is constant & is known as Young’s modulus or

modulus of elasticity .E=σ/Ɛ

(ii) Poisson’s ratio: It is the constant ratio between the lateral strain & linear strain, with in the

elastic limit when it is subjected to longitudinal stress & it is denoted by ‘V’

(iii) Principle of super position: Most of machine members are subjected to combination of

various loads. The combined effect of load in the form of stress & strain may be found by using

the principal of superposition .It states that “Total effect of several loads applied on a body is

the sum of effects of individual loads applied separately.

(iv) Modulus of rigidity:It is defined as the ratio of shear stress to shear strain with in the elastic

limit & is usually denoted by G or C

(v) Bulk modulus:When a body is subjected to identical stresses ‘σ’in three mutual

perpendicular directons.The body undergoes uniform changes in three directions without

undergoing distortion of shape.The bulk modulus is defined as the ratio of identical stresses to

the corresponding volumetric strain & denoted by K

2) Derive an expression for the total extension of the tapered circular bar cross-section of diameter

D and d, when it is subjected to an axial pull of load ‘P’.

dl=4pl/πd1d2 { Refer section 1.8, page No. 7 “S S Rattan”}

3) A specimen of steel 25mm diameter with a gauge length of 200mm is tested to destruction. It

has an extension of 0.16mm under a load of 80KN and the load at the elastic limit is 160KN.The

max load is 180KN.The total extension at fracture is 56mm and diameter at neck is 18mm,Find

The stress at elastic limit, Young’s modulus, Percentage elongation, Percentage reduction in

area, Ultimate tensile stress.

Sol: Area=490.874mm2

Stress at elastic limit ‘σ’=325.949N/mm2

Youngs modulus’E’=20371.826N/mm2

%Elongation=28%

%Reduction in Area=48.16%

Ultimate tensile stress=366.693N/mm2

Department of Mechanical Engg.

PESIT, Bangalore South Campus

4) A round bar with stepped portions is subjected to the forces as shown in fig. Determine the

magnitude of forces ‘P’and such that net deformation in the bar does not exceed 1mm.Youngs

modulus E=200GPa and that for aluminum is 70GPa.large end diameter & small diameter of the

tapering bar 40mm and 12.5mm respectively.

Sol: ΔL1=8.73x10-5P mm

ΔL2=1.75 x10-5P mm

ΔL3=3.75x10-5P mm

P=7KN

σs=107.914 N/mm2

σc=55.252 N/mm2

5) Define volumetric strain. A bar of uniform of rectangular section of area ‘A’ is subjected to an

axial load ‘P’,show that the volumetric strain is given by ƐV =P/AE(1-2/m),Where ‘E ‘ is the

young’s modulus & 1/m is Poisson’s ratio.

Refer page 31 “S S Rattan”

6) Derive the relationship between E&G

E=2G(1+𝒗) { Refer sec 1.18, page 37” S S Rattan}

7) A steel bolt of 16mm diameter passes centrally through a copper tube of internal diameter

20mm & external diameter of 30mm.The length of the whole assembly is 500mm.After tight

fitting of the assembly, the nut is over tightened by quarter of turn. What are the stresses

introduced in bolt & tube, if pitch of nut is 2mm.take Es=200GPa & Ec=1.2Gpa.

Sol:

As=201.062mm2

Ac=392.699 mm2

Δ=0.5mm

P=21697.331N

8) A bar of brass 25mm diameter is enclosed in a steel tube of 50mm external diameter & 25mm

internal diameter .The bar & the tube are both initially 1.5m long and are rigidly fastened at the

both ends using 20mm diameter pins. Find the stresses in the two materials when the

temperature rises from 300c to 100oc.Take Es=200KN/mm2,Eb=1000,αs=11.6x10-6/ oc &

αb=18.7x10-6/ oc

SOL:

P=20911.19N

σs=14.2 N/mm2

σb=42.6 N/mm2

Shear stress in pins=33.28 N/mm2

Department of Mechanical Engg.

PESIT, Bangalore South Campus