Workwell Templates

advertisement

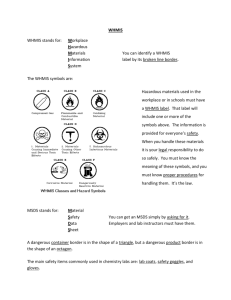

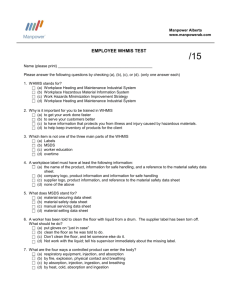

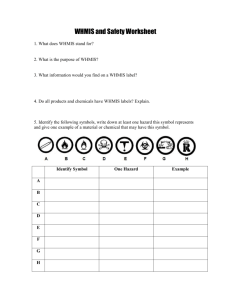

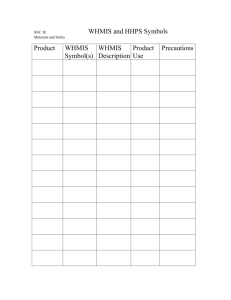

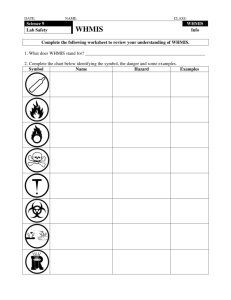

INSERT COMPANY LOGO HERE This is an example only! Title: WHMIS what you could do with each revision/review is to put a revision number i.e.: REV 1.0 Date of Issue: The date of origin Approved by: Owner / management name! Review / Revise Date: every time you revise/review you need to put a date here Location: i.e.: Office / Job Site / Plant / Vehicles/ Warehouse/ Shop PURPOSE: The purpose of this procedure is to review the basic principles of hazardous materials and the principles of Workplace Hazardous Materials Information System in the workplace. LEGISLATION: WHMIS Regulation 860, OHSA Section IV SCOPE: *** This will be the same as the Health and Safety Policy Statement *** NOTE: As with the other Policies, this is an example ONLY! You will need to add the specific Roles & Responsibilities for your company! Where positions are listed i.e. Office Manager, you should make the changes to suit your company! STANDARD / PROCEDURES / POLICY: ***YOUR COMPANY*** will comply with the OHSA and WHMIS Regulation to ensure that all employees are aware of hazardous materials on the jobsite (***list other locations***). All ***YOUR COMPANY*** employees will be required to complete a workplace hazardous materials information system (WHMIS) certificate training course annually. Material Safety Data Sheets (MSDS) will be obtained with all new shipments from suppliers. Employees will not work with new products until the MSDS has been reviewed. Copies of all MSDS sheets will be kept ***location*** for easy access by all employees. Proper storage facilities will be provided for hazardous materials. co name 2007 name of manual Page 1 Proper personal protective equipment will be provided by ***THE COMPANY***, when required All employees will be notified when any new material or products are delivered to the company All employees will be made aware of any new material safety data sheets (MSDS) WHMIS – stands for Workplace Hazardous Materials Information System. It is a Canada-wide system used to provide information about all controlled products (chemicals and compressed gases as an example) used by employees on the job. There are three essential parts / information delivery methods to WHMIS: 1. Labels 2. Material Safety Data Sheets (MSDS) 3. Education and training WHMIS is for your protection. It is your right to know what you are working with and what you might be exposed to. WHMIS describes the danger of materials you may use on the job and tells you how to protect yourself from their hazards. You should know if material has supplier labels and material safety data sheets. Labels All controlled products must have a label that identifies the product and includes, 1. 2. 3. 4. 5. 6. 7. 8. Name of the product WHMIS hazard symbol Classification Risk factor Precautions First Aid instructions MSDS Referral The Supplier Make sure that you can easily identify each product by the label. If labels are missing or defaced, make sure that a workplace label is applied. The ***position*** will develop workplace labels. These labels must be used when a label is missing, product is decanted into non-supplier container or label cannot be read. Material Safety Data Sheets: Gives the following detailed information of a product and its hazards: 1. 2. 3. 4. Product information Hazardous ingredients Physical data First aid measures co name 2007 name of manual Page 2 5. Specific Gravity 6. Fire and explosion data 7. Toxicological properties 8. Reactivity data 9. Preventive measures 10. Preparation date and contact info You can protect yourself by: 1. Practicing safe work habits 2. Being informed 3. Using personal protective equipment – and the right PPE for the job 4. Knowing emergency procedures 5. Following first aid practices In accordance with Ontario WHMIS Regulation 860, ***THE COMPANY*** will do the following: 1 Provide general and specific product training: a. General – CSAO WHMIS b. Specific – for products used every week (***if you have a smaller number of products, you might want to list them here ***) i. First Aid ii. Emergency Response / Spills/ Fire iii. Toxicological properties – health effects iv. Personal Protection Equipment v. Transportation, storage, handling and use 2 ***Name the position of person*** will: a. Locate MSDS for all controlled products b. Copy MSDS for distribution c. Distribute MSDS to: i. company vehicle MSDS binder ii. warehouse iii. ***other location*** d. Check the dates on MSDS – ensure that no MSDS is dated less than three (3) years e. MSDS are sorted alphabetically for insertion into binders 3 General Contractors will provide ***YOUR COMPANY*** with: a. MSDS for products currently being used in the vicinity that ***YOUR COMPANY*** employees will be working b. Any other Information on products likely to be encountered on site co name 2007 name of manual Page 3 Employees are reminded that: 1 Workplace labels are to be placed on products where the supplier label has been removed, illegible, defaced Workplace labels should include: name, safe handling instructions (wear goggles) and location of MSDS (in ***location*** binder) Information on WHMIS is available from the Office Manager Employees share in the responsibility to be familiar with MSDS for the products used 2 3 4 ROLES AND RESPONSIBILITIES: ***position*** will arrange training ***position*** will keep the records on file and update the training matrix The training program will be reviewed on an annual basis with the H & S Rep or JHSC All employees must attend training COMMUNICATION: This Standard and Element will be communicated to all employees via: ***pick the ones that apply to your company or list your own methods *** 1. 2. 3. 4. 5. 6. 7. Joint Health and Safety Committee Minutes Tool Box Talk Payroll Insert Employee Kit Health and Safety Program Orientation Safety Bulletin Board(s) located: office, plant, warehouse TRAINING: 1. *** Those who need to deliver the information i.e.: Orientation need to be trained in the content. They need to understand the information that they are delivering so that questions can be answered **** 2. Training will be arranged by ***owner, management, supervisor etcetera *** 3. Employees will review: a. *** List your methods of communication i.e.: payroll inserts*** 4. Employees will: a. Attend training / Orientation sessions Training will be done by ***name who conducts training *** co name 2007 name of manual Page 4 All employees of ***YOUR COMPANY*** shall take the WMIS course at a registered facility, an employee qualified to do the training or by an outside professional WHMIS trainer. All new employees shall take a WHMIS course as part of their orientation even if they have a valid WHMIS certificate. Each year, WHMIS will be updated and employees are expected to attend annual updating. All new MSDS’s will be posted and discussed at weekly toolbox talks Records will be kept of all training and will be maintained by ***position*** . Notification regarding retraining will be given a minimum of one month prior to training taking place. If training is done internally, the person conducting the training must be qualified to train. A ‘Train the Trainer’ course is required. EVALUATION: ****You cannot start this part of the Element without completing the above Steps! *** 1. All parts of the Standard to be reviewed annually for: a. Suitability / applicability to ***your company*** b. New legislation c. Best practices 2. Employees will receive a written or verbal quiz on a random basis to confirm their knowledge / awareness of this Element 3. The quiz will be conducted by ***Supervisor, lead hand etcetera*** 4. If employee(s) is missing some information (as indicated by the quiz), ***name who *** will review the information with the employee 5. Employee will be quizzed again after ***i.e.: 3 months / 6 months *** Employees will be asked for feedback on the WHMIS training Employees will be asked to report any incident related to materials that have a physical effect on the employee Inspection reports will be monitored for any situation involving hazardous materials Employees will be asked to comment on the training they received Employees will be observed for correct handling of controlled products ACKNOWLEDGE SUCCESS: Annual Safety Meeting Year-End party Summer BBQ Other event ***You must have documentation of what was said with regard to safety *** co name 2007 name of manual Page 5 ***You might consider documenting: what was said, by whom, to whom via memo, email*** You might also consider things like: 1. 2. 3. 4. 5. 6. Tim Horton’s vouchers Chocolate bars Gift cards Safety slogan tool belt apron T-shirts Your company logo golf shirts and jackets Buying pizza or other food items for a team…………..but whatever the item is, keep receipts! On the receipt, indicate: Date Job name or person Why they were given the item Example: Jan 10, 2008 GVCA job PPE compliance ***Acknowledgment of Success also includes you, indicating that you have done a good job in improving safety records at your company*** CONTINUOUS IMPROVEMENT: ***What will you do to this topic for the next year? Did your methods of Communication work properly or not? What changes will you make? *** FORMS: Training Records Copies of Training Certificates and Cards REFERENCE MATERIAL: CSAO OHSA co name 2007 name of manual Page 6 WHMIS Reg Approval signature: Document to be posted: Distribution to: Yes or No Notes: N/A co name 2007 name of manual Page 7