Detailed Design Review Agenda w

advertisement

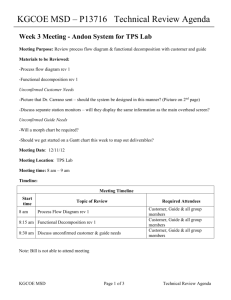

KGCOE MSD Technical Review Agenda Meeting Purpose: Detailed design review of P09711- Automation/Improvement of Packaging on Cookie Line. The objectives of this are to present and receive feedback from others about our final design and bill of materials. Meeting Date: February 13th, 2009 Meeting Location: Building 09 Room 4435 Meeting time: 2:00 – 4:00 PM Timeline: Meeting Timeline Start time Topic of Review 2:00 Project Background Recap 2:10 Design Specifications 2:30 3:00 Required Attendees Overall System- Design, Selection Reasoning & Feasibility Electronics- Design, Selection Reasoning & Feasibility 3:30 Bill of Materials & Risk Assessment 3:55 Wrap Up Discussion KGCOE MSD Prof Kaemmerlen, Dr. Hoople, Mr. Bryan, Scott Young & Chris Isaacson Prof Kaemmerlen, Dr. Hoople, Mr. Bryan, Scott Young & Chris Isaacson Prof Kaemmerlen, Dr. Hoople, Mr. Bryan, Scott Young & Chris Isaacson Prof Kaemmerlen, Dr. Hoople, Mr. Bryan, Scott Young & Chris Isaacson Prof Kaemmerlen, Dr. Hoople, Mr. Bryan, Scott Young & Chris Isaacson Prof Kaemmerlen, Dr. Hoople, Mr. Bryan, Scott Young & Chris Isaacson Page 1 of 25 Technical Review Agenda Project Background Mission Statement: The mission of this project is to create an automated prototype that will separate mini cookies by weight, while preventing cookies from moving on in the process until a specified weight is reached. It will create a clear separation between the sets of cookies that go into each package without substantially slowing down the packaging process. Project Description: Wegmans bakes and packages all of their mini cookies at their bakeshop located here in Rochester on Brookes Avenue. Currently the packaging is done by six or seven people who stand around a conveyor and pull the cookies into the clam-shell packages. This leads to the problem of packing more cookies than needed into a package. The mini-cookie package calls for 397 grams worth of cookies but employees sometimes package up to 450 grams. This is a loss for Wegmans because customers are receiving more cookies than they are paying for. This project will look into building an automated prototype that will separate the cookies into the correct amount by weight, which the employees can then package. KGCOE MSD Page 2 of 25 Technical Review Materials Updated Customer Needs Hierarchy with Importance Ranking Need 1: Separates Products by Weight Need 1.1 Must separate Mini-Chocolate Chip Cookies by weight (9) Need 1.2 Should separate other Mini-Cookies by weight (5) Need 1.3 Should separate Mini-Muffins by weight (3) Need 1.4 Should separate Brownie Bites by weight (3) Need 2: Waste Reduction Need 2.1 Must reduce the amount of excess Mini-Cookies in package (9) Need 3: Separates Products by Count Need 3.1 Want to be able to separate Cookie Chunks by count (3) Need 3.2 Want to be able to separate other products by count that are packaged in that way on this line (3) Need 4: Long Term Solution Need 4.1 Should be adjustable for other products (5) Need 4.2 Must not substantially slow down the process (9) Need 5: Labor/Employee Use Need 5.1 Must be simplistic for employees to use (9) Need 5.2 Must not create a substantial amount of extra labor for employees (9) Need 5.3 Should be repeatable for employees (5) Need 6: Food Environment Restrictions Need 6.1 Production floor ready product must be stainless steel (3) Need 6.2 Production floor ready product must not be painted (3) Need 6.3 Production floor ready product must be water tight (3) Need 6.4 Production floor ready product must meet the NEMA4 level (will take a light water hose spray) (3) Need 7: Budget/Cost Need 7.1 Must not be considered a capital investment (> $10,000) (9) Importance Scale: 9 = These needs have the highest importance and will be the main focus of the project. 5 = These needs are somewhat important and will be the secondary focus of the project if time allows. 3 = These needs are not as important as the rest of the needs and will only be focused on if the main and secondary needs have been satisfied. KGCOE MSD Page 3 of 25 Technical Review Materials Updated Target Specifications Metric No. 1 Need Nos. Need 1.1, 1.2, 1.3, 1.4, 2.1 Metric Importance Units 2 Need 1.1, 2.1 3 Need 6.1, 6.2, 6.3, 6.4 4 Need 4.1, 5.1, 5.2, 5.3 Need 4.1, 4.2, 5.2 Percentage of packages with excess (2 or more) cookies (currently at 95%) Weight of cookie package 9 % 9 grams Follows Wegmans' sanitation standard Requires training that takes X minutes Changeover time 3 Y/N N Y 5 minutes 60 15 5 minutes 20 5 Creates clear separation of product for packaging Throughput 9 Y/N Y Y 7 Need 1.1, 1.2, 1.3, 1.4, 3.1, 3.2 Need 4.2 5 average packages per hour 1500 1700 8 Need 7.1 Cost 9 $ < $10,000 < $5,000 5 6 Marginal Ideal Value value 60% 0% (elimination (elimination of packages of packages with 6 or with 2 or more extra more extra cookies) cookies) 420 397 Importance Scale: 9 = These metrics will be the main focus of this project. 5 = These metrics will be a secondary focus of the project if time allows. 3 = These metrics will not be focused on unless the main and secondary metrics have been addressed. KGCOE MSD Page 4 of 25 Technical Review Materials System Related to Needs and Metrics KGCOE MSD Page 5 of 25 Technical Review Materials Economic Potential KGCOE MSD Page 6 of 25 Technical Review Materials Related Engineering Specifications Metric 1: Percentage of cookies with excess packages (currently 95%) 1. 2. 3. 4. 5. Scale must be capable of measuring 397 +25 grams accurately Scale resolution must be <= 1 gram Scale response time (settling time) must be <=0.5 seconds Drop-chute must switch between weigh stations in < 0.5 seconds Angle of drop-chute must be at a great enough incline in order to prevent backlog of cookies on chute a. Tested at 15, 25, 30, 35 degrees 6. Scale must be able to send signal to board when correct weight is achieved a. Scale has a RS232 output signal Metric 6: Accurately separates product for packaging 1. Chute must have an angle of rotation of >=20 degrees 2. Push-rod must be able to clear the scale in ~ 7.5 seconds 3. Drop-off ramp must have an angle >= 30 degrees Metric 7: Throughput 1. 2. 3. 4. 5. Sifter bar must move at 60 cycles per second Sifter bar must have teeth with width of at least 0.25 inches Sifter bar must have spacing areas of 2.5 inches The funnel must have an angle of 30 degrees or less The chute must have an angle of 30 degrees KGCOE MSD Page 7 of 25 Technical Review Materials Overall System KGCOE MSD Page 8 of 25 Technical Review Agenda Sifting Bar System KGCOE MSD Page 9 of 25 Technical Review Materials Tunnel System KGCOE MSD Page 10 of 25 Technical Review Materials Drop Chute System KGCOE MSD Page 11 of 25 Technical Review Materials Weigh Station System KGCOE MSD Page 12 of 25 Technical Review Materials Material Comparison and Selection Material Densities Density Polycarbonate (g/cm^3)= Density Stainless Steel (g/cm^3)= Density HDPE (g/cm^3)= Density Polypropylene (g/cm^3)= Material Coefficient of Friction Polycarbonate = 0.38 Stainless Steel = 0.35 HDPE = 0.28 Polypropylene = - 1.2 7.85 0.95 0.91 *Data collected from table online with sliding material of Steel Tensile Strength Material psi Polycarbonate = 9000 Stainless Steel = 89900 HDPE = 3250 Polypropylene = 1000 PUSH-ROD WALL DIMENSIONS* 10" x 1.25" x .25 " VOLUME US (in^3) 3.1 Metric (cm^3) 51.2 MATERIAL MASS (g) Polycarbonate 61.5 Stainless Steel 402.0 HDPE 48.6 Polypropylene 46.6 Polycarbonate is the material we chose to use for the drop chute, line chute, sifter bar, sifter motor gear, sifter linkage, pusher, and weight station box. The reason for this is because polycarbonate is easily machined, its lightweight, strong, has a high impact resistance, and has a similar kinetic coefficient of friction as stainless steel. Polycarbonate is also fairly inexpensive compared to other materials, and it can easily be bonded together using methylene chloride, or Weld-On #3 adhesive. SIFTER BAR DIMENSIONS* 13" x 3" x .25" VOLUME US (in^3) 9.8 Metric (cm^3) 159.8 MATERIAL MASS (g) Polycarbonate 191.7 Stainless Steel 1254.2 HDPE Polypropylene 151.8 145.4 DROP CHUTE VOLUME US (in^3) Metric (cm^3) MATERIAL Polycarbonate Stainless Steel HDPE Polypropylene KGCOE MSD 21.1 344.9 MASS (g) 413.9 2707.8 327.7 313.9 V1 V2 V3 V4 V5 Page 13 of 25 in^3 4.0 3.0 5.3 0.8 8.0 cm^3 65.5 49.2 86.9 12.3 131.1 Technical Review Agenda Electronic System Overview KGCOE MSD Page 14 of 25 Technical Review Materials Board Selection Process The board chosen is an Altera DE2-70 University Developmental board (sold through Terasic). This board was chosen for a number of reasons. First being the versatility of the board itself. This board is covered with multiple different interfaces as well as hardware that can handle any task that needs to be performed for this project. The FPGA on this board is the largest in its class and has the highest speed and capacity for its device class. The number of different I/O pins on this device equal 622. These pins are fully customizable to change the output between over 7 different signal types. The different capacities of the ram inside the FPGA, the performance specs, and structure of the memory allow for fast accurate data to be stored, and read off the memory that is structured inside the FPGA. The advantage of this is that there is still more than sufficient room to run multiple programs of which we will not come close to the complexity of. The true advantage of this board is that we will have the two SDRAM devices and Flash memory to use as memory space instead of the so-called “on-chip” (inside the FPGA) memory. This board is flexible enough to be able to add a user interface into the code or even the system, which will include a monitor, and either keyboard or mouse or possibly both. The main purpose in choosing an FPGA over a micro-controller is that an FPGA is easily adaptable and can have; VHDL, Verilog, C or even C++ code run on it. This allows the user to adapt to the environment and be able to configure the code in any way they wish as well as configure the hardware in any way they choose. A second reason for using the FPGA over the micro-controller is because the EE team has used this exact FPGA device previously and has familiar knowledge in this process which will make the coding, debugging, and explaining/teaching of code/process easier. This board is also deigned to be used in a university environment, which means that it provides example code and great support for the user. There is more than sufficient documentation or support through Altera to make sure that use of this device is as easy as possible for any user. In choosing a board that has the most flexibility and the most adaptability, with room to expand the board through its 2 header 40 pin connectors this board surpasses the others. In buying a pre-designed board we are ensuring that all the components work together and that the hardware is working properly. This allows the EE team to focus mainly on the coding and performance process rather than board functionality process. The components chosen on this board have been designed to perform at the maximum rating possible for each part. The memory capacity well exceeds our needs. There is no true metric for the amount of memory required or the speed at which the memory must be at a minimum of. This is due to the fact that it is a prototype in which we are not yet sure of the codes necessities or length or even performance until we write the code. However we have the ability to add to this board anything that we would need because of the I/O headers. This allows us to have the confidence to choose this board knowing there are no bounds or limitations that we have when using this product. The board can even stack multiple boards off of this one to have master and slave configurations allowing endless possibilities for daughter boards. Because this board is 100 percent adaptable and configurable it allows us to choose this board and use it for any application in which we would need it. The output currents and voltages match the requirements of the driver boards for our stepper motors. The current required for the driver device is 20 µamps and the voltage required to drive the logic is 3.3 V. The voltage out of the DE2-70 is 3.3V and the current is around 4mA max. Other boards were considered however none of them had the capability, flexibility, adaptability, or even “bang for their buck” that the DE2-70 board has. KGCOE MSD Page 15 of 25 Technical Review Materials Selected Board Specifications Items that come on the DE2-70 right from the Terasic website USB Blaster (on board) for programming and user API control; both JTAG and Active Serial (AS) programming modes are supported 2-Mbyte SSRAM Two 32-Mbyte SDRAM 8-Mbyte Flash memory SD Card socket 4 pushbutton switches 18 toggle switches 18 red user LEDs 9 green user LEDs 50-Mhz oscillator and 28.63-Mhz oscillator for clock sources 24-bit CD-quality audio CODEC with line-in, line-out, and microphone-in jacks VGA DAC (10-bit high-speed triple DACs) with VGA-out connector 2 TV Decoder (NTSC/PAL) and TV-in connector 10/100 Ethernet Controller with a connector USB Host/Slave Controller with USB type A and type B connectors RS-232 transceiver and 9-pin connector PS/2 mouse/keyboard connector IrDA transceiver 1 SMA connector Two 40-pin Expansion Headers with diode protection DE2-70 kit includes; Altera DE2-70 Board Altera Quartus II DVD with Nios II - Version 7.2 (We provide Quartus II Web Edition software. To learn more about the details please visit Quartus II Software—Subscription Edition and Web Edition Comparison ) 1 USB Cable 1 Adapter DC 12V/2A 6 Silicon Footstands 2 Cables (black- and red-colored) 2 PIN Headers, 1P1N KGCOE MSD Page 16 of 25 Technical Review Materials Currently Selected Scale KGCOE MSD Page 17 of 25 Technical Review Materials Weigh Station Scale Options Quote (for Discussion) ROCHESTER SCALE WORKS, INC. 100 Sherer Street Rochester, NY 14611 Phone (585) 235-5882 Fax (585) 235-5885 www.rochesterscale.com February 10, 2009 RIT / Wegmans 1 Lomb Drive Build 9 Rochester, NY 14623 ATT: Brian Duffy SUBJECT: Electronic Bench Scale Email: brianduffy86@gmail Dear Brian: We are pleased to propose the following for your consideration. One (1) Doran Model 7000XL Stainless Steel Bench Scale. Capacity: 10 lb x 0.001 lb / 4.5 kg x 1 g or 5 lb x 0.001 lb / 2.3 kg x 0.5 g Platform Size: 10” x 10” Features: 6 Digit Red LED display 0.56” high Zero, units and print 304 stainless steel NEMA 4X and IP-69K washdown protection Standard RS-232 PRICE…$1,050.00 less 10% ($105.00) = $945.00 + FOB Factory Optional USB…Add $175.00 KGCOE MSD Page 18 of 25 Technical Review Materials One (1) Doran Model 2200 Stainless Steel Digital Bench Scale. Capacity: 10 lb x 0.002 lb / 4.5 kg x 1 g or 5 lb x 0.001 lb / 2.3 kg x 0.5 g Platform Size: 10” x 10” Features: 6 Digit red LED display 304 Stainless steel construction NEMA 4X and IP-69K washdown protection Standard RS-232 Full numeric keypad PRICE…$1,125.00 less 10% ($112.50) = $1,012.50 + FOB Factory Optional USB…Add $175.00 No additional charge for setup, delivery and calibration. RIT to setup communications. Delivery: Warranty: TERMS: 1 Week from receipt of your order. 1-Year Electronics NET 30 DAYS If this purchase is NYS tax exempt, an exempt certificate must be provided at time of order, otherwise applicable sales tax will be added. Thank you for asking us to quote. Sincerely, Christopher H. Sudore Christopher H. Sudore CHS/lm KGCOE MSD Page 19 of 25 Technical Review Materials Selected Stepper Motor Driver Allegro A3967 data sheet: http://www.sparkfun.com/datasheets/Robotics/A3967.pdf EasyDriver V3 schematic: http://www.sparkfun.com/datasheets/Robotics/EasyDriver-v3Schematic.pdf KGCOE MSD Page 20 of 25 Technical Review Materials Selected Stepper Motor Jamco Valupro Stepper Motor datasheet: http://www.jameco.com/Jameco/catalogs/c291/P74.pdf KGCOE MSD Page 21 of 25 Technical Review Materials Motor Torque Calculations KGCOE MSD Page 22 of 25 Technical Review Materials Bill of Materials Product Number 3005XL Vendor Doran 6007K36 McMasterCarr McMasterCarr McMasterCarr 90631A411 McMasterCarr 99154A390 McMasterCarr N/A Wegmans 57655K34 McMasterCarr 2342K81 97395A525 57655K62 97633A200 7528A13 KGCOE MSD McMasterCarr McMasterCarr McMasterCarr Product Desc. Quantity List Price Total Part Price Lead Time Doran 10"x10"x2" weigh scale Perma-Lube Steel Ball Bearing - ABEC-1 Double Sealed, No. R2 for 1/8" Shaft Dia, 3/8" OD Type 316 Stainless Steel Dowel Pin 3/8" Diameter, 1-1/4" Length Hardened Precision Tubular Shaft 1" OD, .6" ID, 12" Length Znc-Pltd Grade 2 Stl Nylon-Insert Hex Locknut 10-32 Thread Size, 3/8" Width, 15/64" Height 18-8 SS Low Profile Precision Shoulder Screw Slotted Head, 1/4" Shldr Dia, 1/2" L Shldr, 10-32 Thrd Wegmans Mini-Chocolate Chip Cookies 397g Molded Nylon 14-1/2 Deg Angle Spur Gear 32 Pitch, 16 Teeth, 0.5" Pitch Dia, 3/16" Bore Molded Nylon 14-1/2 Deg Angle Spur Gear Rack, 32 Pitch, 3/16" Face Width, 3/16" H O'all, 1'L Black-Phosphate Steel External Retaining Ring for 1/2" Shaft Diameter Weld-on #3 Cement for Acrylics 1 Pint Can 2 $1,000.00 $2,000.00 <2 weeks 6 $12.45 $74.70 <1 week 3 $2.82 $8.46 <1 week 1 $40.50 $40.50 <1 week 1 $2.60 $2.60 <1 week 1 $5.77 $5.77 <1 week 10 $1.30 $13.00 <1 week 2 $3.00 $6.00 <1 week 2 $4.63 $9.26 <1 week 1 $8.56 $8.56 <1 week 2 $12.77 $25.54 <1 week Page 23 of 25 Technical Review Agenda P0304 Terasic Altera DE2-70 Development and Technologies Education Board M-200ROB-08368 8574K55 HWS5012/A Trossen Robotics Jameco Valuepro McMasterCarr McMasterCarr McMasterCarr Arrow Electronics N/A N/A 237472 8585K33 8585K17 EasyDriver V3 Stepper Motor Driver MOTOR,STEP,12VDC/.4A, 2100 GMCM Polycarbonate Round Tube 3-1/2" OD, 31/4" ID, Clear Polycarbonate Round Tube 1-3/4" OD, 11/2" ID, Clear Polycarbonate Sheet 1/4" Thick, 24" X 24", Clear AC/DC Power Supply Single-OUT 12V 4.3A Miscellaneous Components (Resistors, Capacitors, etc.) 1 $599.00 $599.00 <1 week 4 $14.95 $ 59.80 <1 week 4 $21.49 $85.96 <1 week 1 $15.29 $15.29 <1 week 1 $7.66 $7.66 <1 week 6 $33.89 $203.34 <1 week 1 $130.58 $130.58 <1 week 1 $100.00 $100.00 N/A Total $3,396.02 Material Links: Ball Bearing: http://www.mcmaster.com/#2342k81/=iij54 Board: http://www.terasic.com.tw/cgi-bin/page/archive.pl?Language=English&CategoryNo=39&No=226 Gear Motor: http://www.grainger.com/Grainger/items/2L011 Stepper Motor: http://www.jameco.com/webapp/wcs/stores/servlet/ProductDisplay?langId=1&storeId=10001&catalogId=10001&productId=237472& Stepper Motor Driver: http://www.trossenrobotics.com/easydriver-v3-stepper-motor-driver.aspx?feed=Froogle Round Polycarb: http://www.mcmaster.com/#8585k33/=j7qh9 Arrow Electronics: http://app.arrownac.com/aws/pg_webc?s=P KGCOE MSD Page 24 of 25 Technical Review Materials Updated Risk Assessment Risk Team won't have enough time to create to entire prototype Severity Probability Overall Contingency Plan 5 4 20 Create only a fourth of the working prototype Long lead times on ordered parts may push prototype production back 4 3 12 Weighing technology does not meet expectations 4 2 8 Insufficient funds to produce full design 5 1 5 Mechanical and Electrical systems don’t interface well with each other 5 3 15 3 3 9 1 3 3 Cookies get stuck in tunnel section 5 5 25 Weigh station doesn’t push out cookies quickly enough 3 3 9 Chutes don’t switch quickly enough 5 3 15 Settling time is too long 5 3 15 3 3 9 5 3 15 4 2 8 3 5 15 Cookies don’t get pulled by incline gate Incline gate does not switch up Chute doors don’t open/close at right time Conveyor failure Difficulty controlling push rod using motors Force of cookies falling on scale from chute gives a false reading on scale Order parts by week 11, Set up meeting with Wegmans after detailed design review to arrange the ordering of all long lead time materials Extensively research alternative weighing devices, spend more money on improved weighing device Create only a fourth of the working prototype, perform economic analysis to demonstrate the savings that could be realized from investing in this project Be aware of the interface between the two, constant communication between electrical and mechanical engineers Replace incline gate with conveyor Replace incline gate with conveyor Use sifting bar to put cookies into lines which can be more easily handled by the tunnels Use alternative pushing method instead of push rods, use air at a higher pressure Use one weigh station and close chute while cookies back up Purchase scales with a short settling time Prioritize electrical-mechanical interfacing issues Create emergency stop switch Use air compression to control push rod Take an average of the weight samples when deciding when to push cookies out of weigh station Importance Scale: 1= Consequences from risk have little effect on the cookie line’s flow and project’s success 5= Consequences from risk halt the entire cookie line and/or project KGCOE MSD Page 25 of 25 Technical Review Agenda