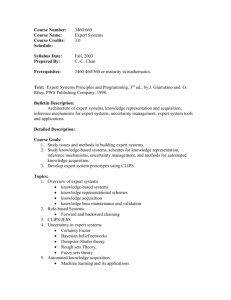

TDTS - USAF Acquisition Process Model

advertisement