We EMC(Environmental Management Corporation) as a subsidiary

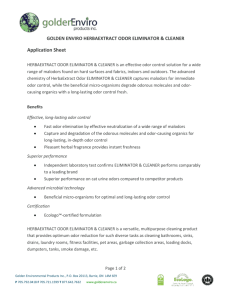

advertisement

Odor control with essential oils and waterless vaporizer □ GE Water Technologies : www.gewater.com KM M Swamy, Regional Technical Support Manager, 65-6267-4882, Singapore Jucheol Heo, Technical Manager 82-52-223-5300, Korea ABSTRACT Almost any manufacturing process can generate odor. Since the Clean Air Act Amendment (CAAA) went into effect, the onus has been placed on industries to reduce their odor emissions. It can cost millions of dollars to companies and shut the facilities if not handled properly. A complete understanding of the odor and the process in which it shall be dealt with are absolutely essential to face any situation that might arise even in the most environment friendly industrial establishment. This paper discusses the eco friendly odor control chemistries, based on essential oils marketed by GE Betz. INTRODUCTION Odors are difficult to define with scientific form compounds that have a strong smell that can affect our olfactory nerves. Bad odors can indicate danger; the addition of mercaptans to natural gas is to insure that any gas leak, however small, is detected even before the odorless LPG causes deaths. ODOR GENERATION AND CONTROL Odor can be generated either by oxidation or reduction. While oxidized odors are distinguished by their musty nature, reduced odors are unique with their 1 putrid and rotten smell. Not all odors are noxious or toxic in nature. Hydrogen Sulfide is the most common odor-causing chemical, followed by mercaptans and much other chemistry. These gases can have lethal consequences when their levels exceed the threshold limits in atmosphere. Concern for public health and safety, improving employee working conditions, property values and governmental legislation are reasons for industrial odor control. Other nonreduced odors, such as those formed by certain compounds containing amines and other groups, also contribute to odor emissions and need to be controlled. The specific need for odor control arises out of the following situations: Odoriferous substances such as Hydrogen Sulfide cause corrosion and thereby machinery or equipment failure. Consumer rejection of consumable goods because of unpleasant odor. Safety concerns that people may be overcome by odor at the workplace and in the neighborhood. Negligence of an odorous area within a working premise typically results in lowered productivity and or development of another unsafe situation. Many chemistries, both inorganic and organic, are available for odor control, specific to the nature of the odor, source and location of concern. The inorganic chemistries are limited by their area of performance, whereas organic chemistries have a wide range of application. PROGRAMS AND SOLUTIONS TO CONTROL ODORS Mechanical solutions such as Scrubbing, Incineration and other traditional methods are quite common in odor control, but they are either too expensive in their capital investment or offer little respite when retrofitted or when the installed capacity is exceeded by the operating capacity. A chemical program 2 will normally have a lower impact on the bottom line than immediate upfront capital expenditures. In addition, the time lapse between odor control conception and installation is shorter. Oftentimes, a chemical program can begin within days of inception. Success of any Odor control program is dependant on three factors: Good understanding of the source of odor, its spread and site conditions under which the odor needs to be combated. A strategic and tactical plan (as there could be unforeseen deviations in process and wind directions, etc) with the site personnel and neighborhood who are potentially affected by odor. Chemistry that is most suited for the abatement of odor at its source or during its spread. At least four chemical means of controlling odors are generally used in the industrial setting: 1. Organic scavenging - Primary amines 2. Chemical oxidation - Chlorination, hydrogen peroxide, permanganate, ozone 3. 4. Precipitation - Iron salts Control by pH - Lime, soda caustic Other solutions that are included in a successful odor control program are: 5. Proprietary organic scavenger 6. Biomodifiers - nitrates and proprietary inhibitors 7. Masking agents 8. Neutralizers Organic scavengers are typically comprised of primary amines that react with reduced sulfur compounds that have acidic protons, as shown in the figure below: H2S ←→ HS- +; H+; HS- ←→ S= + H+ Such nonproprietary compounds are not selective and will react with carbon dioxide as well, and in so doing will have a higher use cost than more selective compounds. 3 Proprietary organic scavengers such as ProSweet™ are more specific in their reaction and will selectively react with the reduced species of sulfur compounds such as hydrogen sulfide and certain mercaptans. These organic scavengers tend to form side reactions; therefore, their use cost will tend to be lower. Of course, proper treatment levels for scavengers depend on many factors such as stream flow rate, temperature, H2S concentration, desired H2S removal efficiency and pH. The benefits of using an organic scavenger include: No pH change Ease of handling and simple feed equipment No sludge generation Biomodifiers such as nitrate are commonly used in facultative and anaerobic lagoons to aid in controlling odors. Anaerobic bacteria use nitrate in preference to sulfate as an electron acceptor during their metabolism of organic substances. When nitrate is present, these sulfide-producing bacteria use it rather than sulfate. Thus the by-product of their activity becomes odorless nitrogen rather than objectionable H2S. Some of the disadvantages of using nitrates are the limitation in effluent waterways and the necessity of significant contact time in order for proper utilization to occur. Masking agents are increasingly being viewed negatively. Primarily, this negativity derives from the fact that in order to mask an odor the masking agent must create a significantly higher odor level. Once done, the perception is that something is being hidden. The masking of odors can present a severe health risk when H2S is being masked. Masking does not mitigate the hazardous health effects of H2S. Oxidizers such as chlorine donating material have safety and handling problems. In addition, chlorine donors may contribute to the formation of carcinogenic tri-halomethanes (THM). Hydrogen peroxide oxidizes H2S, and depending upon the pH of the water system will yield different products as shown below: pH < 8.5 H2O2 + H2S ←→ S + 2H2O 4 pH > 8.5 4H2O2 + S-2 ←→ SO4-2 + 4H2O At pH < 8.5, the stoichiometric H2O2 requirement is 1 gram H2O2 for each 1 gram of H2S. In actual use, however, more H2O2 is required because H2O2 is not selective in what it attacks and therefore oxidizes other materials and organic matter in addition to H2S. Many oxidizers have similar usage characteristics to that of H2O2. Metal salts such as ferric chloride react as follows and precipitate the sulfide from water as ferric sulfide salts. In addition to sludge formation, handling of the iron salts presents a corrosion problem of its own. 2FeCl3 + 3H2S ----> Fe2S3+ 6HCl Neutralizers function in a complex manner. This is because of the makeup of the neutralizers. Those neutralizers that contain essential oils primarily function by capturing odor molecules in a charge film that surrounds the essential oil-water complex. Neutralizers that contain other large organic molecules created by certain fermentation and blending processes function by absorbing odor molecules, by radical reaction, or by condensation reaction between the odor molecules and the neutralizer. Oftentimes, the latter compounds produce a neutralizer reaction product that does not create or leave a detectable odor. Within the neutralizer grouping, the essential oils tend to control a wider range of odors. However, there may be a detectable odor of the essential oil present after odor neutralization The use of chemical neutralizers to control these odors is regarded as an acceptable treatment option because of the minimal amount of capital investment required. Other acceptable technologies, including combustion, oxidation and stripping, are also very efficient, but require considerable capital equipment investment. In many industrial applications odor control methods such as incineration, carbon adsorption, wet scrubbing, source modifications and odor masking may be found. ODOR NEUTRALIZATION WITH ESSENTIAL OILS When it comes to control of non-specific odors from Municipal waste, food 5 industries, pharmaceutical units, automotive lines, flavors and fragrances, nothing works better than neutralizing with essential oils. Essential oils are liquids extracted from plant material by pressing, solvent extraction, or steam distillation. These organic, naturally occurring essential oils are extracted from the seeds, bark, roots, leaves, flowers, wood, balsam, resin, and fruit of plants. The oils are then redistilled or rectified to remove any unwanted materials. Essential oils easily evaporate, infusing the air without leaving an oily residue behind. They are extremely complex organic compounds consisting of hundreds of components and trace elements. Essential oils contain many constituents. The predominant components are terpenes and esters, aldehyde, ketones, phenols, terpenes, oxides, and alcohols but a large number of trace elements are also present. It is these trace elements that give the essential oil its character and enhance its ability to blend with the other oils. The orange peel oil in ProSweet™ OC2533, for example, contains over 200 trace elements at concentrations of less than one percent. As in all natural oils, trace elements provide the delicate, extremely complex nuances that provide the unique odor neutralizing quality. The synergistic effect of trace elements enhances the blending and performance of the odor-neutralizing product. The blended product actually becomes greater in effectiveness and allows for a broader range of applicability than the oils individually. Unlike scavengers, those odor neutralizing products do not REACT with odor-causing chemicals to remove them from the air phase, hence, whatever health hazard related to the odor-causing chemicals, still remains. On the other hand, odor-neutralizing agents are different from masking agents, which covers unpleasant smells with another rather pleasant scent. These oils will behave somewhat like a solvent. The odorous material can be considered the solute. The essential oils are fed to the air in a fashion that would initiate and optimize two physical processes that occur in the vapor phase, Absorption and Adsorption, between the essential oil and the odorous material. Surface area, contact time, particle size, temperature, and concentration of both materials will be important in optimizing the efficiency of the physical processes. The essential oil will physically combine with the odorous material to form a new physical compound. This new combined 6 product will have a net zero odor. Certain odors will be easily neutralized, and certain hydrocarbons (heavy and/or saturated) will be difficult. H2S, most mercaptans, NH3 and most amines can be neutralized. A property of the essential oil is being able to trick the human olfactory system to not smell something that is there. HOW ODOR NEUTRALIZERS WORK: Zwaardemaker in 1900 found that two odors get neutralized if introduced in each nostril. The neutralizing effect was for specific chemical pairs (now called Zwaardemaker pairs or Z-pairs) and was concentration dependent. The exact means of the neutralization reaction between the essential oils and the odiferous compounds is not completely understood. Studies to isolate the exact mechanism are being done. In the process of odor neutralization there is no chemical interaction involved. Neutralization is achieved when no resultant odor, pleasant or unpleasant, is sensed. There exists an optimal concentration of the counter-actant depending on the type and concentration of the pollutant. Examples of Z-pairs include: Butyric acid - Oil of juniper Chlorine - Vanillin Ammonia - Ionone Tobacco odors - Oil of wintergreen Rancid butter, milk fats - Juniper oil ODOR NEUTRALIZATION WITH PROSWEET™ OC2533 AND OC2534 Some site-specific situations offer very few choices other than vapor phase or air contact treatment. GE Betz ProSweet™ OC2533 is a waterless vaporizer that works by air contact. This needs a special equipment to vaporize the chemical into the air, enabling reaction between its many constituents and the odorous gases. This may be in either indoor or outdoor situations, and requires corresponding equipment and technology, depending on the exact situation. GE Betz ProSweet™ OC2534 works by surface contact. It can be sprayed or misted in liquid phase with dilution. 7 The advantages of air ProSweet™ OC2533, waterless vaporizing application are : Can be used anywhere, inside buildings and in open yards compact and portable Immediate impact Covers a wide variety of odors, including H2S up to 10 PPM Completely water-free, hence does not cause any rainy effect. Very effective with ease of operation and application Capital equipment needs are minimal. CASE HISTORY Challenge : A leading refinery in South East Asia experienced noxious mercaptans and non-specific odor from their large light crude storage tanks. The light crude processed while it did not affect the process did emanate odoriferous compounds as vapors while in the crude holding tanks triggering environmental concern from the neighborhood. Legislation on Industrial 8 and Vehicular Emissions forced the refinery to continue to process light distillate crude. Four of these storage tanks were fitted with ring main spraying high-pressure water around the periphery to contain the odor spreading from source. Despite this measure, the odor spread into the nearby community. While the refinery was evaluating other chemistries, the concern from the community was snow balled to a point that there was a serious threat of closure order from the local municipal government. Solution : GE Betz took this challenge and offered a demo on the first day of visit. Neutralizers based on essential oils, vaporizer ProSweet™ OC2533 and ProSweet™ OC2534, a portable misting device proved their might on samples of strong odorous compounds and on odors similar to site conditions. The USDA certification and the eco friendly nature of the chemicals were features the customer was keen with. GE Betz was awarded a month long trial on the existing water misting facility. GE Betz reviewed the engineering aspects and presented a modified misting system with better nozzles that can enhance product performance and save extensively on water consumption. Within a week’s time, one drum of the ProSweet™ product together with a dosing pump was airlifted, delivered, set-up and the trial commenced at the problem location. Results : The refinery has not received a single complaint from the neighborhood on nuisance and noxious odor from the day the trials started with GE Betz ProSweetTM technology. Work environment have as well significantly improved. The number of complaints from neighborhood fell from 32 a week, prior to the commencement of GE Betz’ trial became ZERO since the start of the odor control treatment program. The refinery was likewise pleased, as they were able to apply an environmentally complying true solution to the problem and not a masking agent. The benefit to the plant is that the threat of closure order was eliminated and the Refinery personnel work at a more pleasant working environment what with the removal of the odor. Water consumption was likewise reduced considerably with the completion of installation of the misting nozzles. 9 INTRODUCTION OF GE WATER TECHNOLOGIES GE Water Technologies is the new global platform that brings together GE Betz, GE Osmonics and GE Glegg to create the most comprehensive single source of products and services for the treatment of water and process systems available anywhere in the industry. The integration of these three business components creates a powerful and unified force for helping customers improve performance while reducing operating costs in a broad range of applications. GE Betz is a leading worldwide supplier of specialty chemicals and engineered programs for the treatment of water, wastewater and process systems in industrial, commercial and institutional facilities. Its products are used in plant utilities, such as boilers, cooling towers and wastewater treatment systems, to eliminate problems from corrosion, scale, deposits, foam, odors and microbiological growth, as well as in manufacturing operations to increase productivity, improve product quality, protect assets and meet environmental requirements. GE Betz is also a leading supplier of high-performance chemical treatments, regeneration services and other support programs to increase the efficiency and extend the useful life of membrane separation systems. The primary industries served by GE Betz include automotive, chemical processing, food and beverage processing, metal and plastic finishing, microelectronics, minerals processing, petrochemicals, petroleum refining, pharmaceuticals, power generation and primary metals. GE Osmonics is a leading manufacturer and worldwide marketer of high technology water purification systems; fluid filtration, separation and handling equipment; controls; and replaceable components. The Filtration and Separations Group supplies filtration and separation products for customers in the beverage, municipal drinking water, pharmaceutical, cosmetics, bioengineering, bottled water, laboratory, power generation, food & dairy processing, general industry, electronics manufacturing, acid recovery, wastewater treatment, desalination, petroleum and gas extraction, car wash and wine production businesses. The Process Water Group offers standard and custom-designed reverse osmosis water purification systems and components for the 10 beverage, municipal, pharmaceutical, medical (dialysis), power generation, general industrial and controller/instrument segments. The Household Water Group provides point-of-use filtration and control valve products for residential and commercial markets. GE Osmonics and GE Glegg bring GE Water Technologies a full line of water purification and fluid handling equipment and design services for the industrial, commercial, institutional and household water treatment markets, including cartridge filters; reverse osmosis, nanofiltration, ultrafiltration and microfiltration membranes; filtration lab products; industrial fluid recycling systems; modular RO systems; ion exchange systems; ozone systems, electrodeionization systems; waste neutralizers; degasifiers; clarifiers; valves; controls; instruments and centrifugal pumps. As a division of GE Specialty Materials, GE Water Technologies participates in key GE initiatives for reducing costs, increasing productivity and generating customer value, including disciplined Six Sigma methodology for ensuring quality; digitization to simplify business processes, boundaryless selling and the globalization of personnel and resources. GE Water Technologies is headquartered in Trevose, Pennsylvania, USA, and has worldwide operations. For more information, visit www.gewater.com. 11 APPENDIX : THE RESUME OF THE SPEATER Muthukumaraswamy K M Regional Technical Support Manager, Asia Pacific Industrial & Metals Process GE Betz Singapore Pte Ltd Graduated in 1981 with a First Class degree in Chemistry. Graduated in 1994 with a Diploma in Management. Worked with Petrochemicals and Fertilizers Industry for 13 years before joining Betz in 1995. Experience includes erection, commissioning and operation of medium size petrochemical plants, high-pressure boilers, turbines, utilities, hazardous chemical storage and Hazop study. Worked as a Field Sales & Service Engineer with Betz India Pvt. Ltd., before moving to Singapore in 1999. Over the years, held various positions in Sales, Marketing and Product Management. Won four Technical Excellence awards. Has one global patent and one patent pending technology related to steel industry. Authored technical papers on treatment programs for Sinter Making, Blast Furnaces, Coke oven and By-products plant, BOF practices, Water treatment for Casters that are published in international conferences and within the organization. Currently Technical Support Manager, Asia Pacific with responsibilities for engineering and marketing support in the Industrial & Metals Process applications. Also Championing Odor Control and environmental compliance opportunities within the region. Member of Association of Iron & Steel Engineers and Toastmasters International. 12