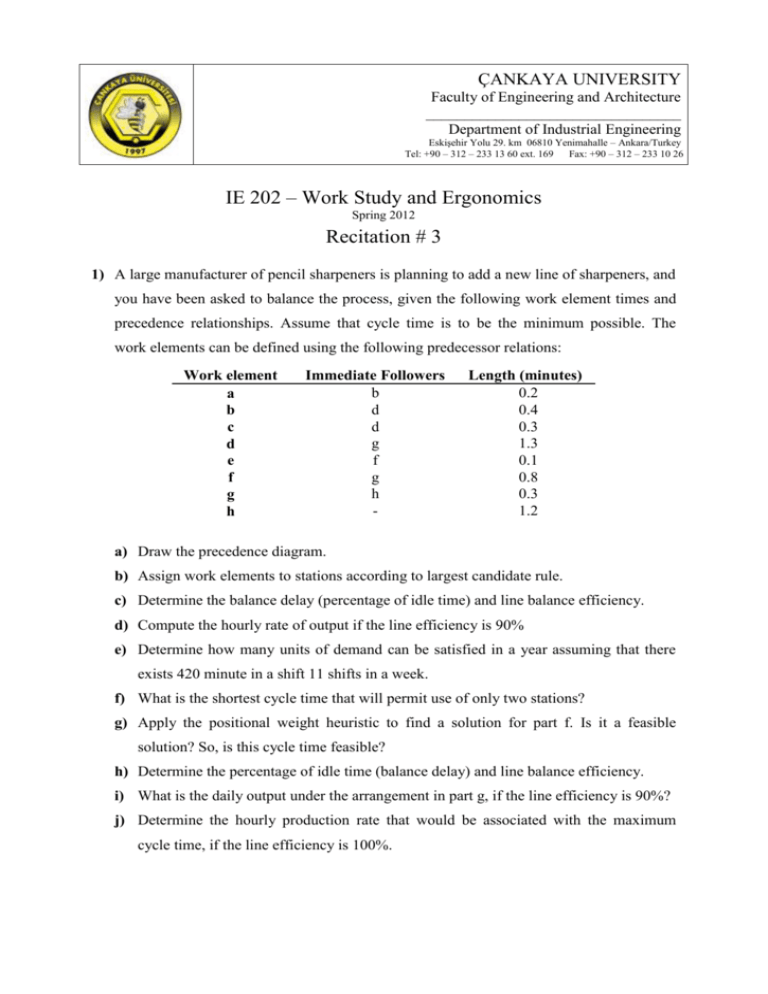

IE 202 – Work Study and Ergonomics

advertisement

ÇANKAYA UNIVERSITY Faculty of Engineering and Architecture _________________________________ Department of Industrial Engineering Eskişehir Yolu 29. km 06810 Yenimahalle – Ankara/Turkey Tel: +90 – 312 – 233 13 60 ext. 169 Fax: +90 – 312 – 233 10 26 IE 202 – Work Study and Ergonomics Spring 2012 Recitation # 3 1) A large manufacturer of pencil sharpeners is planning to add a new line of sharpeners, and you have been asked to balance the process, given the following work element times and precedence relationships. Assume that cycle time is to be the minimum possible. The work elements can be defined using the following predecessor relations: Work element a b c d e f g h Immediate Followers b d d g f g h - Length (minutes) 0.2 0.4 0.3 1.3 0.1 0.8 0.3 1.2 a) Draw the precedence diagram. b) Assign work elements to stations according to largest candidate rule. c) Determine the balance delay (percentage of idle time) and line balance efficiency. d) Compute the hourly rate of output if the line efficiency is 90% e) Determine how many units of demand can be satisfied in a year assuming that there exists 420 minute in a shift 11 shifts in a week. f) What is the shortest cycle time that will permit use of only two stations? g) Apply the positional weight heuristic to find a solution for part f. Is it a feasible solution? So, is this cycle time feasible? h) Determine the percentage of idle time (balance delay) and line balance efficiency. i) What is the daily output under the arrangement in part g, if the line efficiency is 90%? j) Determine the hourly production rate that would be associated with the maximum cycle time, if the line efficiency is 100%. 2) The final assembly of personal computers requires a total of 12 tasks. The assembly tasks can be defined using the following predecessor relations: Task 1 2 3 4 5 6 7 8 9 10 11 12 a) Draw the precedence diagram. Immediate Predecessors 1 2 2 2 2 3,4 7 5 9,6 8,1 11 Time 12 6 6 2 2 12 7 5 1 4 6 7 b) Assuming the firm wants to have 32 computers to be produced in a 8 hour-day shift. Considering that the line efficiency is 100%, assign the tasks to workstations in order of greatest following tasks / most follower (Tiebreaker: greatest processing time) c) Calculate balance delay and line balance efficiency. d) Assign the tasks to workstations in order of greatest positional weight, under the same assumption. e) Calculate balance delay and line balance efficiency.