QUALITY THROUGH INCLUSION : CREATING A “HAPPINESS CULT”

advertisement

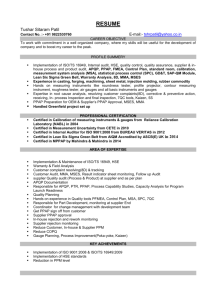

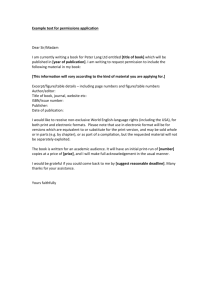

Header Space reserved for Publication CREATING A HAPPINESS CULT : CHALLENGING THE CONSTRAINTS C Sivakumar, CEO, Prabha Engineers, India ABSTRACT With a vision to be the most admired brand in the transportation industry and the most preferred steel component manufacturer for automotive industries, Prabha Engineers grew from 10 employees in 1987 to 550 in 2008, outgrowing the “tiny industry” classification and transforming into a “small enterprise” and finally a “medium” enterprise in record time. Turnover has increased from INR 1.3 million to INR 1400 million, while its locations have multiplied from the single location entity in 1987. The philosophy of the 3 E’s - placing employees above all else, everyday innovation and enabling a culture of entrepreneurship, has been instrumental in charting the company’s extraordinary growth. The vision with which the company operates stresses on the idea of high quality and employee productivity in spite of challenges from dealers, vendors and external agencies. The following write-up elaborates on the 3 Es that the company has engendered to ensure this. Keywords: Happiness Cult, Employee First Philosophy CREATING A HAPPINESS CULT Unconventional has become the corporate watchword of the 21st century. To be able to see opportunities in challenges, meet these and still ensure quality and excellence has become the motto most companies live by. Few companies can claim to have unconventional thinking as the predominant objective in their business planning. Prabha Engineers is one of them. Starting out as an ancillary to truck major Ashok Leyland, meeting their OEM needs in the industrial town at Hosur, Tamil Nadu, Prabha is now a comprehensive manufacturer, becoming the preferred supplier of FES (Front End Structures) to Ashok Leyland, and ensuring customer delight, a credo that the company is extremely committed to. A new plant has been operational at Alwar in Rajasthan since 2007 while a second unit was executed at Hosur with a built-up capacity of 25,000 sq. ft. Beginning its innings as a tiny firm shackled with financial instability and tremendous odds against survival, Prabha Engineers has shown that it can follow the approach of “against the grain” thinking through the 1980s and 1990s – both decades of extreme difficulty in the Indian scenario. If the 80’s were a decade of “license Raj” and governmental bureaucracy, the 90’s were a decade of tremendous transition, with economic liberalization bringing about intense competition, and absolute defeat for many companies that were unable to meet global quality standards, having been forced to compete on a global platform literally overnight. The 21st century has seen the prevalence of foreign direct investment and a spirit of non-linear expansion and progressive thinking, once again creating a fresh set of competitors and new players, all of whom Prabha has been successful in counterbalancing. Indeed, Prabha’s extraordinary growth owes much to the idea of unconventional thinking. To survive conditions of drastic financial instability (Prabha’s annals include days when the purchase of a single light bulb to ensure smooth operations through the night was under scrutiny), to be able to thrive on these challenges and yet stick to one client (Ashok Leyland has been Prabha’s single and most effectively serviced client through the past twenty years), choosing to deepen the arena of services to the firm rather than follow conventional thinking of expanding to multiple clients and to remain a truly Indian firm, despite the temptation of foreign direct investment, have all been instrumental to the firm’s success (see Figure 1a and 1b). Prabha Engineers prides itself on having an employee track record that could well qualify as a record in the region. Till date, they have not fired, charge-sheeted, retrenched or suspended a single employee. Not a single manday has been lost in all these years of rapid expansion and their delivery track record, even in highly mitigating circumstances, is exemplary (near 100% on-time delivery). The number of quality awards that Prabha has obtained (see Figure 2) as well as the fact that they have not logged a single major complaint from their long-time customer, bears testimony to their remarkable achievements. Further more, the focus of Prabha has always been its employees ahead of customers or other stakeholders, an ideal that the company has managed to achieve through multiple means. In an arena where “people centrism” and “employee welfare” has gained rapid currency,. Prabha manages to stay steps ahead by having followed this philosophy even during its lean phases (where the “no employee gets fired” credo was still adhered to). Their formula to achieve this has been to focus on those issues that matter to its people – employees’ children have always been the focus of the company’s human relations operatives, in keeping with the notion that the primary motivation and concerns for the employee focus on the younger generation. By thus shifting the focus, Prabha has ensured a loyalty track record that is difficult to emulate. The idea of innovation has become integral to most companies and their missions. At a time when the Indian economy is on the ascendant, many companies and their stewards have embraced change as a constant in their company policy, adopting new techniques and expanding rapidly. Header Space reserved for Publication The story of Prabha, however, is complex. Understanding that true employee motivation comes from a balance in his/her family rubric (and ensuring that an employee’s child and spouse need greater attention and focus), a balance between emotional health and financial/welfare initiatives and to be constantly unconventional to stay ahead have all contributed to this story (See Figure 2 for “The Prabha Way”), elaborated in the essay that follows. The 3 Es : Employee First The Prabha code for quality comes from two sources : first, a culture of inclusive growth, and a firm belief in placing its people above all else (with the result that the company has maintained 24x7 operations without any mandays lost, without any strikes, lay offs, lockouts or external contingencies) and a series of initiatives that engender “ a cult of happiness”, a commitment to all-round employee growth and motivation. This, above all else, has favoured the company’s commitment to quality. This has been achieved by converting the “management workforce divide” into a “management- workforce team”. This works on the premise that a company that is truly decentralized achieves balanced growth and more out-bound learning. Critical towards the achievement of this are a series of employee-oriented initiatives that are outlined later in this essay (see Figure 3). Social psychologists such as Shelly Chaiken and Yaacov Trope, both researchers at New York University, have expounded on the importance of the dual process to motivation – an emphasis on both structured/logical thinking in addition to emotion-led thinking to achieve maximal productivity. The Indian work ethic combines this knowledge with the idea of a more collectivist approach to decision making, treating the team/group/family above the individual. Prabha has embraced this culture and accordingly, encourages the employee to nurture his/her emotional intelligence at the workplace, in addition to their process-compliance and skill-based training. In keeping with this notion, some of the transformative ideas that have helped ensure employee motivation include outbound training as a mandatory company activity, forcing all employees to stay together as a team for a period of three days every year and truly bond as a family. Critical to this ideal is the notion that the family plays a more critical role in determining an employee’s success than corporate welfare initiatives. In a Maslowian approach, physiological need-fulfillment satisfies an individual’s basic requirements. Prabha, in true counterintuitive fashion, believes that self-actualization for the employee (through a focus on his children and family issues) is a more optimal approach to achieving true emotional-physical balance for each employee, provided base considerations of wage, benefit and incentives are held constant. At an ancillary level, frequent training programmes including the integration of the performing arts (through corporate theatre; See Figure 3 for the list of activities) and exercises in neuro-linguistic programming (NLP). The employee-first philosophy has its roots in the idea that adherence to a core process is most critical. A system that places shareholders above all other stakeholders in a company’s profitability will, at some level, hold dealers, vendors and ultimately the employee to ransom to provide a guaranteed profitability. By definition, this set-up is skewed towards the shareholder. Systemic shocks, external contingencies and other challenges to profitability strain the employee towards achieving a set profitability target, causing widespread employee demotivation. Through a series of initiatives and with a will to correct this assumption, the Prabha philosophy of guaranteed employment, and continued performance-based wages and incentives ensure that the employee is protected from the constant strain of “having to deliver” to a target. Instead, it enables employees to constantly challenge themselves, with a will to win and to push profitability outward. Initiatives are oriented both towards the workday viz. “opening shot”, an every day morning session of positive preparation; “trigger”- the strain drain and positive achievement trigger among others; and those initiatives that are oriented towards employee family health (employees’ parents being sent letters about their ward’s performance and a token monetary contribution every month; home budgeting sessions; GenerationNext that provides a mentoring programme for employees’ children). The Prabha Value Chain Conventional value-chain delineation includes fostering the idea of ownership/intrapreneurship for each employee and then progressing towards optimal manufacturing solutions through the effective use of tools and techniques. At Prabha, the addition to this value chain, which to date contributes to its constant growth and profitability, has been its shift in starting point to “employee well-being” , with family being considered the focus (and particularly the employee’s child), a reversal of the Maslowian pyramid that sets a better base for all the other sections of the value chain (Figure 2). This, in the Indian context, replete with multiple sociocultural and economic uncertainties, has been Prabha’s significant achievement 2 Header Space reserved for Publication Everyday Innovation With a vision to be the most admired brand in the transportation industry and the most preferred steel component manufacturer for automotive industries, the mission at Prabha is two-pronged : first, to build a platform for continuous innovation in the process of manufacturing and second, to harness and constantly reward the human potential of every individual in the organization. The key objectives of the company include constant innovation to reduce waste and lead time, to build TQM competencies through the company and to adopt lean manufacturing techniques to ensure maximum productivity. The innovation continuum at Prabha has ensured a spiraling and stabilized growth from the 1990s and upto 2008 (See Figure 1); and resulted in zero mandays being lost in the past 23 years, a record in the region. Further, the company has never defaulted in its commitment to customers, suppliers, workmen, government agencies and financial institutions. With a focus on total employee involvement (TEI), customer satisfaction was made a priority following the PQCDMS strategy ( Productivity-Quality-Cost-Delivery-Morale-Safety), alongside the adoption of 5S, 3M and 7QC tools. True to Prabha’s unconventional approach, PQCDMS is achieved by a primary focus on “employee concern”, a system by which Prabha starts from the bottom up, periodically checking employee well-being and offering corrective solutions. Some of the key achievements in this regard include the fact that Prabha was the first group to initiate the KANBAN system for FES delivery to their preferred clients, Ashok Leyland. Inventory was brought down from 15 days to 4 hours at the customer end, while ensuring seamless process flow (without line stoppage owing to a transition in Kanban) resulting in the group being awarded the Platinum shield for quality, cost and delivery (See Figure 4). Response time for customer complaints is extremely low in Prabha. Despite the fact that there are multiple external suppliers involved, all of which involve a sizeable risk for variance in standards, adherence to quality and cost, the idea of immediate response has resulted in a stellar customer complaint record – there has been no major customer complaint in the past five years. Further, “pokayoke” was introduced to eliminate quality issues. The innovation continuum has gone ahead to embrace design innovations as well, although design has never been within the scope of the company’s operation. An example includes the bracket at the rear end of the Iraq Load Body that began as a suggestion from Prabha and actually got executed. Significant to the company’s success has been its track record of zero-late deliveries. This is particularly important in an economic set-up that involves multiple insecurities : dealer and vendor inconsistencies, human resource constraints, and frequently, service orders with very high standards. Rewards include the Golden Award in the Supplier Summit (2008, for outstanding QCLDM performance), the NIQR – Susira Award for Outstanding Small Scale Industry (2005), The Employer-Employee Relationship Award (See Figure 4) and the much coveted SME – 1 rating from CRISIL (2008), among others. Enabling a Culture of Entrepreneurship In true Prabha fashion, the unconventional idea of “employee first” has ensured that even workmen on the shop floor have been enabled with the power to make decisions. This has been implemented with the “everyone-becomes-supervisory manager-for-a-week” scheme, where each shop-floor employee gets to make important decisions regarding workflow, human relations and output on a weekly basis. The idea that each employee-producer should periodically conduct a factory audit has fostered an adherence to the highest quality standards. Further, the Prabha “concern” initiative has often resulted in some of the best quality adherence and productivity ideas arising from employee’s intellectual contributions. In a truly democratic fashion, Prabha periodically encourages each employee to profer solutions and implementation ideals (Figure 5). This revolutionary notion has resulted in the accumulation of thousands of workable manufacturing ideas and a culture of constant growth and re-tooling. To illustrate, * This innovation has helped employees obtain individual awards recoganized by the government ( Figure 6). 3 Header Space reserved for Publication Conclusion To follow a culture of conscious differentiation is not an achievement by itself. However, to use this philosophy to achieve continuous yearon-year growth, obtain the highest standards of quality and innovation-led productivity while not compromising on employee well-being has been Prabha’s unique feat. Through successive governments that alternatively curtailed and fostered entrepreneurship, Prabha has managed to foster an ambience of possibilities. By shifting its priorities to employees (ahead of customers), family ( ahead of individual) and decentralization (ahead of topdown management), Prabha has shown its mettle by continuous outward and progressive expansion. Happiness has always been referred to as a state of mind that is idiosyncratic to each individual. Prabha has questioned that definition by making it a cult, fostering and nourishing the ideal through everyday, continuous improvement. Figure 1a : Sales Figures from 1987- Turnover(in INR 100,000s) 13088.35 14000 11627.64 12000 10000 8000 5331.92 6000 4000 2000 0 2839.9 13.21 1990-91 2008 17.23 373.63 1994-95 1999-2000 2004-05 2005-06 Turnover(in INR 100,000s) 4 2006-07 2007-08 Header Space reserved for Publication Figure 1b : Employee Strength 700 602 548 600 460 500 388 400 306 300 194 212 226 2002 2003 200 100 10 22 1981 1991 0 2001 2004 2005 2006 2007 2008 Year Figure 2 : The Prabha Way The Happiness Cult : The Prabha Value Continuum •Family First with focus on Child •“Spark for Suggestions” •Constant well-being *”Become the Manager for a Week” EMPLOYEE WELL BEING •Kaizen •Kanban •PQCDMS •7QCs •5S •3M INTRAPRENEURSHIP & ENTERPRISE TOOLS & TECHNIQUES The Prabha Addition to the Value Spiral 5 •Adherence to quality standards •Zero Complaints MANUFACTURING SOLUTION Header Space reserved for Publication Figure 3 Employee First Initiatives 6 Header Space reserved for Publication Figure 4 Awards and Citations 7 Header Space reserved for Publication Figure 5 SPARK : The Suggestion Scheme for Employees 8 Header Space reserved for Publication Figure 6 Employee Government Award Citation A Government Award for a Prabha Employee whose suggestion in consumables in the grinding area resulted in a cost saving of INR 175,000 9