Institute for Advanced Materials and Renewable

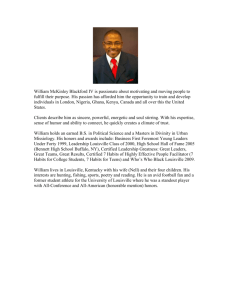

advertisement