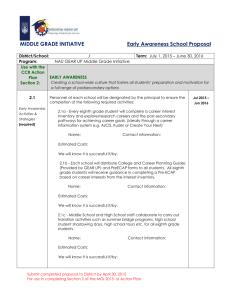

Final Report - CSU Space Grant

advertisement

Mechanical Event Simulation of the Space Shuttle Remote Manipulator System Name: Mark Adrian Miller Date: August 15th, 2003 Title: Mechanical Engineering Student Email:ingunbarrel@hotmail.com Address: 1117 City Park Ave. Appt. E-17 Fort Collins, CO 80521 Phone: 970-215-8656 Table of Contents 1. Introduction Page 2 2. Procedural Overview Page 4 3. Geometry Creation Page 7 4. Analysis Page 10 5. Conclusions Page 32 Mark Miller 3/8/2016 Page 1 1. Introduction The purpose of this study was to use computer aided numerical methods to examine the design and operation of the Space Shuttle Remote Manipulator System. The Space Shuttle Remote Manipulator System modeled and assembled, prescribed joints and drivers to facilitate constrained motion, and the forces acting within the mechanism as a result of the specified motion were solved for. The forces were used to predict structural deflections of the Space Shuttle Remote Manipulator System in a linear FEA solver. Composites were modeled as such. There was also to be an impact survivability analysis done using a non-linear solver to inspect failure modes for the structure. This was to include composite modeling as well, but was also to include the dynamic analysis associated with the collision of the objects. This portion of the study is incomplete to date. Pro\Engineer was used to create the solid model that was to be tested. The various components were modeled as independent entities and brought into an assembly template to be placed. The base of the mechanism was anchored to the operating environment, with successive components being joined either directly to the base or to other components already connected. This created a mechanism whose joints were given different degrees of freedom and whose base is fixed. The model was then transferred to Pro\Mechanica Motion for analysis. The driver definition and placement information was set up. The surfaces that represent gear pairs were constrained to act as such, and the physical properties of the solid material were set. Pro\Mechanica Motion was used to run a mechanical event simulation depicting the unfolding of the arm, and the deployment of an object representative of a satellite. Mark Miller 3/8/2016 Page 2 Forces within the mechanism resulting from the acceleration of the object were plotted against time to identify positions of maximum load in the mechanism. The forces at these positions were transferred into Pro\Mechanica Structure for impartation to the components. The corresponding deflections and stress levels were examined for each part. This helped to verify that the design could handle the predicted loading scenario. Mark Miller 3/8/2016 Page 3 2. Procedural Overview Specifications for the Space Shuttle Remote Manipulator System were obtained from the MD Robotics web page. The site includes a detailed description of the size, weight, construction materials, and degrees of freedom. There is also a diagram of the Space Shuttle Remote Manipulator System, which is shown in Figure 1 below for reference during the overview. This information was used to create a close approximation of the Space Shuttle Remote Manipulator System in Pro\Engineer. Figure 1: Diagram of the Space Shuttle Remote Manipulator System The joints of the Space Shuttle Remote Manipulator System were modeled as simplified versions of the picture shown, and the driving mechanisms were modeled as planetary gear drive systems containing three gears per joint. The shoulder, wrist pitch, and wrist yaw joints were identical to one another. All degrees of freedom were present. The booms were modeled as thin cylinders of an arbitrary thickness, with an additional Mark Miller 3/8/2016 Page 4 surface that represents the mid-surface of the actual composite boom. The thin cylinders were used to provide weight during the calculation of the dynamic forces, and then suppressed during the structural analysis to allow the surface to be assigned the correct shell properties for the composite material. The load was approximated by a five hundred pound object that is attached with a weld joint at the tip of the wrist roll joint. The particular geometry of the load is of little consequence so it was modeled as a fairly simple object. Once modeled the parts were assembled in a convenient fashion, using planes and points to get the orientations right. The actual joint degrees of freedom were specified in Pro\Mechanica Motion. Once assembled the model was analyzed to ensure an accurate representation of the arm. Model mass properties can be examined to ensure the correct weight of the arm. The weight of the upper and lower arm booms are listed individually as well as the total weight of the structure. The booms were modeled to be the correct weights. Then this was subtracted from the total weight, and the remaining weight was evenly distributed to the rest of parts. This was done by calculating the density that corresponds to the remaining weight, for a volume equal to that of the remaining parts. This material property need only be used for the dynamic load calculation and can be changed when the parts undergo structural testing. The model was then transferred into Pro\Mechanica Motion to have the correct degrees of freedom imposed on the joints. Then drivers were assigned to each joint. The drivers either hold the joint still or move it according to a prescribed profile. The gear properties and gear pairs were assigned to the planetary systems, one gear pair for the pinion-planet pair and one gear pair for the planet-orbit pair. The arm was positioned at Mark Miller 3/8/2016 Page 5 maximum extension and all joints except the pinion in the shoulder were set to a constant position of zero. Once in the correct position the driver to move the pinion in the shoulder was set. It was to control the acceleration of the pinion. It consisted of a portion of a sin wave scaled to bring the load from zero velocity to maximum velocity, and back to zero velocity over the course of four seconds. This was meant to be an approximation of a full emergency stop taking place. Once the motion analysis was run, the forces acting in each of the joints were exported to Pro\Mechanica Structure and placed on the individual parts. The joint loads are assigned to exist at a point. To avoid the stress concentrations associated with point loads, the load must be distributed. Once in Pro\Mechanica Structure the forces acting at the joints were distributed to selected surfaces on the model. Each model was constrained at one end and loaded on the appropriate surfaces on the other end. Running the structural simulation allows for the examination of deflections, stresses, and failure indices for each model. These were used to verify the validity of the design based on structural performance in an emergency situation. Mark Miller 3/8/2016 Page 6 3. Geometry Creation 3.1 Lower and Upper Booms The booms were identical except in length, density, and surface property definitions. The upper boom was shorter, denser, and had more layers in the composite lay up. Figures 2 and 3 depict the booms. For the dynamic analysis there was a cylindrical solid extrusion of .5-inch thickness that was given mass properties. This ensured not only the correct weight, but also the correct distribution of weight within the model. An accurate representation of the forces induced by the movements of the arm was achieved. Once the force data was collected the solid protrusions were suppressed leaving only a cylindrical shell. This was defined to have the properties of a composite material, and then loaded with the forces exported from Pro\Mechanica Motion, and used in the structural analysis. Figure 2: Lower Boom Mark Miller Figure 3: Upper Boom 3/8/2016 Page 7 3.2 Planetary Gear System The drive system consisted of three gears and a link. Figure 4 depicts the assembled gear train. The drive and planet gears were identical in size and tooth count, but the drive gear had an extra post for mounting in the joint. The teeth were approximations and did not represent actual tooth geometry, as this is very difficult to achieve. There was a small amount of interference, but this was inconsequential, as the gear pairs in Pro\Mechanica were defined to act along a surface at the pitch radius. Figure 5 shows a picture of the orbit and has a circle running through the middle of the teeth, this is the surface that was used to define the gear pair connections. There were similar circles running through the teeth on the drive and planet gears. All components in the planetary drive system were constructed of Aluminum 6061 T6. Figure 4: Planetary Drive Assembly Mark Miller 3/8/2016 Figure 5: Orbit Gear Page 8 3.3 Shoulder, Wrist, and Elbow Joints The shoulder, wrist yaw, and wrist pitch joints were identical, and consisted of a pair of the joints shown in Figure 6. The elbow consisted of a pair of the joints shown in Figure 7. The circular hole on the face of the joint was the recess for the gear drive system. The other half of these joints had a slightly shallower recess meant to accommodate the link that connected the planet gear to the joint. The load was distributed to the inch wide face inside of the recess. This was meant to be a rough approximation of the actual joints, as a more specific description of the joints was not available. All of the joints were constructed of Aluminum 6061 T6. Figure 6: Shoulder and Wrist Joint Mark Miller 3/8/2016 Figure 7: Elbow Joint Page 9 4. Analysis 4.1 Motion Analysis with Pro\Mechanica Motion 4.1.1 Mechanism Definition Figure 8: Space Shuttle Remote Manipulator System Assembled in Pro\Mechanica Motion Once the arm was modeled and assembled in the correct position, the joints were prescribed to the model, to obtain the correct degrees of freedom. Figure 8 shows the assembled arm in Pro\Mechanica Motion. The base of the arm was prescribed to be welded to the ground body, this was the only ground connection in the model. The orbit Mark Miller 3/8/2016 Page 10 gears were prescribed to be welded into their respective joints. The drive gears were connected to their respective joints with a pin joint. This joint had only a rotational degree of freedom about a central axis. The link for the planet gear was pin jointed to the drive gear, and welded to the other half of the joint. The planet gear was pin jointed to the end of the link. The booms were prescribed to be welded at either end to their respective joints. The load was welded to the end of the wrist roll joint. Gear properties were assigned to the surfaces that represented the gears. The drive and planet gears were defined to be spur gears with a pressure angle of 20 degrees. The orbit was defined to be a ring gear with a pressure angle of 20 degrees. The drive gear was paired with the planet to form the first gear pair. The planet was paired with the orbit to form the second gear pair. Drivers were assigned to all of the pin joints to allow me to control their position and velocity. All but the drive gear driver were set to zero velocity. This completed the assembly of the arm. Mark Miller 3/8/2016 Page 11 4.1.2 Driver Definition Figure 9 is a picture of the acceleration profile that was prescribed to the drive gear pin joint. The joint initially had zero velocity, and was accelerating at a .01299 radians per second squared. The acceleration immediately began to drop off, and two seconds into the simulation the acceleration is zero. The driver then decelerated in an equivalent fashion until zero velocity was reached. Figure 9: Drive Gear Acceleration Curve Mark Miller 3/8/2016 Page 12 Figure 10 is a picture depicting a graph of the load velocity versus time. Point 42 is located where the load meets the wrist roll joint. This was the point that was used to determine how fast the drive gear need turn to produce the maximum loaded operational speed of 2.4 inches per second at the load. The graph peaked at 2.399 inches per second, which was sufficiently similar to the listed value. Figure 10: Load Velocity Mark Miller 3/8/2016 Page 13 4.1.3 Analysis Results Figure 11 shows the total torque occurring in the joints that were used to load the various components. The results are in inch-pounds of torque vs. time. To export the torques and forces to structure the parts were chosen one at a time, a time value of four seconds was specified, and the joint load to be used was selected. Figure 11: Torque Magnitude Plots Mark Miller 3/8/2016 Page 14 Figure 12 shows the total force occurring in the joints that were used to load the various components. The results are in pounds of force vs. time. Figure 12: Force Magnitude Plots Mark Miller 3/8/2016 Page 15 Figure 13 shows the forces and moments developed in the joints at either end of the two booms. Single headed arrows represent force components. The dual headed arrows represent moment components. Double click on the picture to start the movie. Figure 13: Force and Moment Magnitude Animation Mark Miller 3/8/2016 Page 16 4.2 Structural Analysis with Pro\Mechanica Structure 4.2.1 Lower And Upper Booms: Loading Figures 14 and 15 are of the load distributions on the booms. Small magenta arrows represent the magnitude and direction of the load. The load was a function of the total load passing through the weld joint at the far end of each boom. Since the load was prescribed to act at a point, it had to be distributed to the geometry so as to avoid the possibility of stress concentrations occurring in the region of the load. To do this a small section at the end of the boom was selected and specified to have the assigned load act over that region. Pro\Mechanica handles the distribution. The other end of the boom was prescribed to have zero displacement in all directions. This allowed for the loaded end to deflect while the base remains stable. It is at this point that the composite material properties were prescribed to the surfaces. Figure 14: Lower Boom Mark Miller 3/8/2016 Figure 15: Upper Boom Page 17 4.2.2 Lower And Upper Booms: Composite Material Figure 16 is a picture of the material definition dialog box for the composite used in the booms. This describes the properties associated with one layer of the composite. A laminate lay-up of these layers was created to represent the composite. The number of layers in the composite, and what angular orientation the layers are at with respect to one another, was specified when defining the shell properties. The failure criterion was set to allow inspection of the failure indices. This will be discussed in Section 4.2.5. Notice that all of the material properties were specified in three directions. This was to ensure that the anisotropic nature of the material was accounted for when calculating deflections and stresses as a result of loading. Figure 16: Composite Material Definition Mark Miller 3/8/2016 Page 18 4.2.3 Lower And Upper Booms: Deflection Figures 17 and 18 represent the deflection of the booms under load. The scale is in inches, and the maximum is listed on the third line of the text in the upper left hand corner of each picture. The figures indicate that a total displacement of 7.356 inches, at the load, could be expected to occur as a result of the deflection of the booms alone. Figure 17: Lower Boom Deflections Mark Miller Figure 18: Upper Boom Deflections 3/8/2016 Page 19 4.2.4 Lower And Upper Booms: Stress Figures 19 through 22 depict the von Mises stress contours in the booms at full load. They are labeled front and back to differentiate the side in compression and the side in tension. The front side is under tension and the back side is under compression. Because of the nature of the loading and the symmetry of the boom geometry, I would expect the von Mises stress distributions to be the same on both sides of the booms. The color plots show this to be true. This is because von Mises stress is a measure of the total stress in the model, compressive and tensile stresses are both represented as positive quantities. These color plots can be very helpful in determining what areas of the model are experiencing the most stress. But one must be careful when interpreting these plots, as the results may be misleading. If one were to try to determine where the model would fail first, it would be tough to decipher whether it would be the front or the back, as the total stress is the same. For this reason we use failure index color plots to make decisions on if and where the model will fail. Plots of the failure indices for the booms as well as details on the formulation of them appear in Section 4.2.5. Mark Miller 3/8/2016 Page 20 Figure 19: Lower Boom Front Side Stress Figure 20: Lower Boom Back Side Stress Figure 21: Upper Boom Front Side Stress Figure 22: Upper Boom Back Side Stress Mark Miller 3/8/2016 Page 21 4.2.5 Lower And Upper Booms: Failure Figure 23 depicts the failure criterion for the composite. Notice that the user is prompted to enter both the compressive strength, and the tensile strength in two different directions each. This assured that the anisotropic nature of the material was accounted for when predicting the failure indices. Because the strength of a composite will vary tremendously with the direction of loading, one cannot base failure criteria on total stress, as this doesn’t account for direction of loading. The stresses developed in the structure were computed in their component forms for the failure criterion. These stresses included direction as a function of the quantity, negative is indicative of compression. The components were then put into the Tsai-Wu equation, along with the various strengths previously entered, and the failure index was plotted. The index is based around the quantity one; anything above one predicts failure of the structure. Figure 23: Composite Material Failure Definition Mark Miller 3/8/2016 Page 22 Figures 24 through 27 depict the failure index contours in the booms at full load. They are labeled front and back to differentiate the side in compression and the side in tension. The front side is under tension and the back side is under compression. This is where you can really observe the anisotropic nature of composite materials. The areas under compression, Figures 25 and 27, have a much higher failure index than those under tension. This is because the compressive strengths entered in the failure criteria were lower than the tensile strengths. This would lead to a tendency to fail under compression for this particular load. The maximum values achieved were .0256 for the Lower Boom and .0382 for the Upper Boom. Both of these values are substantially lower than one, therefore there should be no reason for the booms to fail under this loading scenario. Mark Miller 3/8/2016 Page 23 Figure 24: Lower Boom Front Side Failure Index Figure 25: Lower Boom Back Side Failure Index Figure 26: Upper Boom Front Side Failure Index Figure 27: Upper Boom Back Side Failure Index Mark Miller 3/8/2016 Page 24 4.2.6 Gear: Displacement, Failure, and Loading Figure 31 depicts the load distribution on the gear. The load magnitude for the gear was obtained by creating a measure of the total force passing through the gear at the pitch radius. Small magenta arrows represent the magnitude and direction of the load. This force acts at a pressure angle of 20 degrees. A small section of a gear tooth face, centered on the pitch radius, was selected and the load was distributed over the surface. The force was prescribed to act over the surface and specified in component and magnitude form to include the pressure angle. This simply requires that the force be specified as having a total magnitude acting in a direction defined component wise in a Cartesian coordinate system. The shaft was prescribed to have zero displacement in all directions. This allows for the loaded end to deflect while the base remains stable. Displacement contours of the gear shown in Figure 28 display a maximum deflection of .00383 inches. Not a significant amount. Stress contours are shown in Figure 29. A problem is revealed in the failure index contours shown in Figure 30. With a maximum value of .7316, it is approaching the upper levels of the failure index. I would speculate that a fatigue analysis of the gear would reveal that repeated cycling would produce an unacceptable tendency towards failure. This high failure index is concentrated in the area where the shaft meets the gear. This problem could be somewhat lessened with the addition of a fillet around the area to decrease the effect of stress concentrations at the sharp corner. Mark Miller 3/8/2016 Page 25 Figure 28: Gear Displacement Contours Figure 30: Gear Failure Index Contours Mark Miller 3/8/2016 Figure 29: Gear Stress Contours Figure 31: Gear Loading Page 26 4.2.7 Shoulder: Displacement, Stress, and Loading Figure 35 depicts the load distribution on the Shoulder. The load was a function of the total load passing through the weld joint collecting the link to the shoulder joint. Small magenta arrows represent the magnitude and direction of the load. Since the load was prescribed to act at a point, it had to be distributed to the geometry so as to avoid the possibility of stress concentrations occurring in the region of the load. To do this a small section in the recess of the joint was selected and specified to have the assigned load act over that region. Pro\Mechanica handles the distribution. The other end of the shoulder was prescribed to have zero displacement in all directions. This allows for the loaded end to deflect while the base remains stable. Displacement contours of the shoulder, shown in Figure 32, display a maximum deflection of 9.266e-5 inches. Not a significant amount. Stress contours are shown in Figure 33. Failure index contours, shown in Figure 34, show a maximum value of .003241, a negligible value. Mark Miller 3/8/2016 Page 27 Figure 32: Shoulder Displacement Contours Figure 34: Shoulder Failure Index Contours Mark Miller 3/8/2016 Figure 33: Shoulder Stress Contours Figure 35: Shoulder Loading Page 28 4.2.8 Elbow: Displacement, Stress, and Loading Figure 39 depicts the load distribution on the elbow. The load is a function of the total load passing through the weld joint collecting the link to the elbow joint. Small magenta arrows represent the magnitude and direction of the load. Since the load was prescribed to act at a point, it had to be distributed to the geometry so as to avoid the possibility of stress concentrations occurring in the region of the load. To do this a small section in the recess of the joint was selected and specified to have the assigned load act over that region. Pro\Mechanica handles the distribution. The other end of the elbow was prescribed to have zero displacement in all directions. This allows for the loaded end to deflect while the base remains stable. Displacement contours of the elbow, shown in Figure 36, display a maximum deflection of 7.559e-5 inches. Not a significant amount. Stress contours are shown in Figure 37. Failure index contours, shown in Figure 38, show a maximum value of .0008096, a negligible value Mark Miller 3/8/2016 Page 29 Figure 36: Shoulder Displacement Contours Figure 38: Shoulder Failure Index Contours Mark Miller 3/8/2016 Figure 37: Shoulder Stress Contours Figure 39: Shoulder Loading Page 30 4.3 Impact Analysis with LS-Dyna Not enough information on the modeling of composites could be gathered to complete the dynamic impact analysis as planned. The software was used to model simple impact scenarios, but not using composites. Mark Miller 3/8/2016 Page 31 5. Conclusion With the exception of the stress concentrations in the gear, the model performed well under the loading conditions. The failure indices on the booms were very low. The maximum deflection experienced during the test may have been slightly misleading. The load the boom was experiencing during the dynamic analysis was a time varying load. The booms only experienced the particular load used in the structural analysis for an instant. This was not long enough for the booms to achieve maximum deflection as a result of it, the load was moving too slowly. The structural analysis simulated a static loading. The load was applied in its entirety and the structure was allowed to come to equilibrium under load. This inaccuracy could be fixed by using a solver capable of solving for the forces and the structural deflections with each iteration. This would allow for the solution at each iteration to be a result of the forces induced by the motion of the deformed shape from the last iteration. Using this method you could inspect the models oscillations as the load came to rest while the structure was deformed, then is sent the other way by the un-deformation of the structure. It is quite possible that ANSYS is capable of this. I feel that the skills acquired throughout the course of this project will prove to be a key factor in my ability to solve complex engineering problems such as this. I will continue to try to improve this simulation so that it includes all of the originally intended features. I have also begun to explore other options for problems that could be solved using these software packages. I have some inventions that could I validate or improved through the process of simulation. I would like to express my appreciation for the opportunity to do this project. The resources that Dr. Sakuri brought to the table proved to be invaluable. His experience in the field of Computer Aided Engineering gave me an insight into the field that broadened the scope of engineering problems that I can hope to solve. Thank you for the opportunity to acquire such a beneficial and horizon broadening skill. Mark Miller 3/8/2016 Page 32