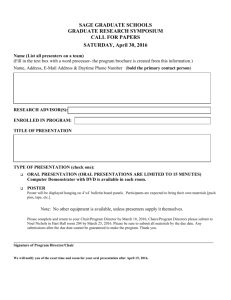

Twin-tub CMOS process

advertisement

● Twin-tub CMOS process 1. Provide separate optimization of the n-type and p-type transistors 2. Make it possible to optimize "Vt", "Body effect", and the "Gain" of n, p devices, independently. 3. Steps: A. Starting material: an n+ or p+ substrate with lightly doped -> "epitaxial" or "epi" layer -> to protect "latch up" B. Epitaxy" a. Grow high-purity silicon layers of controlled thickness b. With accurately determined dopant concentrations c. Electrical properties are determined by the dopant and its concentration in Si C. Process sequence a. Tub formation b. Thin-Oxide construction c. Source & drain implantations d. Contact cut definition e. Metallization ● Balanced performance of n and p devices can be constructed. (Substrate contacts are included in Fig.3.10) 2016/3/7 1 (7~8um) 青玉 or SiO2 (二氧化矽) Anisotropic Etch Form p-island (for n-device) Form n-island (for p-device) 2016/3/7 2 - Grow gate oxide through thermal oxidation - Deposit Doped Polysilicon Etch Polysilicon Step (h): n-implantation for source & drain (self-alignment) Step (i) p-implantation Step (j) - Grow phosphorus glass - Etch glass to form contact cut - Evaporating alumni 2016/3/7 3 3.3 CMOS Process Enhancement (Interconnection) 3.3.1 Metal Interconnect * CMOS circuit = CMOS logic process + Signal/Power/Clock-routing layers - Second-layer of metal (VIA1=M1 to M2) - Note: M1 must be involved in any contact to underlying areas 1. Etch Isolation layer 2.Form a VIA Contact (polysilicon, diffusion) - Process steps for two-metal process (Omitted) 3.3.1.2 Poly Interconnect - Polysilicon layer is commonly used as interconnection of signals. - Reduce resistance of polysilicon → to make long-distance interconnection - Combine polysilicon with a refractory metal (Silicon + Tantalum) 2016/3/7 4 Ω=20-40Ω/square Ω=1-5Ω/square Make long-distance (for interconnect) 3.3.1.3 Local Interconnection - Local Interconnection allow a “direct” connection between ploysilicon and diffusion , alleviating the need for area-intensive contacts and metal - Example: Use of Local Interconnect in SRAM (save 25%) 2016/3/7 5 3.3.2 Circuit elements 1. Resistor - Polysilicon (undoped) – in static memory cell - Resistive metal (Nichrome) to produce high-value, high-quality resistors – in mixed-mode CMOS circuits 2. Capacitors Geometry Process Cross Section - Polysilicon capacitor - Memory capacitor (3-dimensional to increase cap/area) - Example: 1. Trench capacitor (Fig3.18 (a)) 2. Fin-type capacitor (Fig3.18 (b)) 2016/3/7 6 3.4 Layout Design Rules - Function: obtain a circuit with optimum yield in an area as well as possible - Performance ←→ yield * Conservative design rules → Functional circuit → Good yield * Aggressive design rules → Bad yield → Compact circuit/layout for low cost and high speed (A) Line width/spacing Small → open circuit Close → short circuit (B) Spacing between two independent layers - In process: (a) Geometric features for mask-making and lithographical (b) Interactions between different layers (e.g., poly + diffussion) - Rules: a. Micro(μ)-based rules – Industry (submicron) b. Lambda-based rules : e.g.,, 1λ=0.6um for 1.2 um CMOS process) for 4-1.2um Scalable CMOS process. 2λ is the minimum channel length (L). - See Table 3.1 and 3.2 2016/3/7 7 2016/3/7 8 Contact Rules: There are several generally available contacts: - Metal to p-active (p-diffusion) - Metal to n-active (n-diffusion) - Metal to Polysilicon - VDD and VSS substrate contacts - Split (Substrate contacts) 2016/3/7 9 3.4.5 Layer assignment (Table3.4) - CIF: Caltech Intermediate Form - GDSII Format 2016/3/7 10 3.5 Latchup - Latchup : Shorting of VDD and Vss lines → Chip breakdown - Latchup Equivalent Circuit: Vertical : pnp - p = source/drain of p device (Emitter) - n = n-well (Base) - p = p-substrate (Collector) Lateral : npn - n = source/drain of n device (Emitter) - p= p-substrate (Base) - n= n-well (Collector) Rsubstrate, Rwell - Parasitic devices and resistors 2016/3/7 11 2016/3/7 12 Latchup triggering: Transient/Impulse current in start-up A. Lateral triggering: current flows in the emitter of the lateral npn-transistor Vpnp-on →Trigger point : In,trigger = αnpn ˙Rwell - Vpnp,on = 0.7V - αnpn = common base gain of the lateral npn device - Rwell = well resistance B. Vertical triggering: Sufficient current is injected into the emitter of the vertical pnp transistor 3 .5.3 Latchup prevention - Latchup occur (βnpn+1)(IR,sub+IR,wellβpnp) βnpn˙βpnp > 1 + (IDD-IR,sub) VBE,,npn Where IR,sub = Rsub VBE,,npn IR,well = Rsub IDD = total supply current 2016/3/7 13 Observation to prevent latchup: 1. Reduce the resistor values 2. Reduce the gain of the parasitic devices - Approach: 1.Latchup-resistant CMOS process 2.Layout techniques (see section 3.5.4,3.5.5) 3.6 Technology-related CAD tools - Design Rule Check (DRC): On-line and Off-line (Dracula) (3.6.1) - Circuit extraction (Layout Parameter Extraction, LPE) (3.6.2) - CMOS process simulator (Process Input Description Language (PIDL))(sec.3.9) and Supreme by Stanford University. 2016/3/7 14