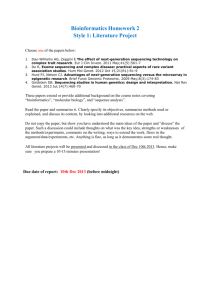

Some Major goals of mixed model production/assembly lines

advertisement

MIXED MODEL PRODUCTION LINES Coimbatore Selvraj Kanagaraj Masters of Science Graduate Student Submitted in Partial Completion of the Requirements of INDEN 5303 Advanced Manufacturing Systems Design This paper was developed to assist students in partial fulfillment of course requirements. No warranty of any kind is expressed or implied. Readers of this document bear sole responsibility for verification of its contents and assume any/all liability for any/all damage or loss resulting from its use. TABLE OF CONTENTS ABSTARCT ....................................................................................................................... 1 Keywords ........................................................................................................................ 1 INTRODUCTION TO MIXED MODEL PRODUCTION LINES.............................. 1 THE EVOLUTION OF SHORT-TERM PRODUCTION PLANNING TECHNIQUES .................................................................................................................. 2 Optimization era ............................................................................................................ 2 Heuristic era ................................................................................................................... 3 Artificial intelligence era ............................................................................................... 3 Interactive schedulers era ............................................................................................. 4 IMPORTANCE OF MIXED MODEL PRODUCTION LINE SEQUENCING ........ 5 SOME MAJOR GOALS OF MIXED MODEL PRODUCTION/ASSEMBLY LINES ...................... 5 PROBLEM STATEMENT .............................................................................................. 7 DESIGN OF AN AUTOMATED SEQUENCING SYSTEM (ASS) ........................................... 8 STEPS FOR SEQUENCING AND LINE CONTROL ................................................................ 9 BENEFITS OF PROPOSED SYSTEM ........................................................................ 10 LIMITATIONS OF THE PROPOSED SYSTEM ....................................................... 10 FUTURE ISSUES ........................................................................................................... 11 CONCLUSIONS ............................................................................................................. 11 BIBLIOGRAPHY ........................................................................................................... 12 LIST OF FIGURES FIGURE 1. ......................................................................................................................... 4 Page i FIGURE 2. ......................................................................................................................... 7 FIGURE 3. ......................................................................................................................... 8 LIST OF TABLES TABLE 1. ........................................................................................................................... 3 Page ii ABSTRACT Mixed model production lines have become more prevalent in today’s manufacturing facilities. The production planning techniques used in optimizing these lines have also developed to fulfill the requirements of the drastically changing manufacturing environment. An overview on the history and development of these techniques is provided. The mixed model production line sequencing is taken into consideration in this paper and its importance and goals are discussed. A production line in a manufacturing line is taken and these techniques are implemented to show the its advantages and benefits in this dynamically changing manufacturing environment. Keywords: Production, Sequencing, Mixed-model production lines. INTRODUCTION TO MIXED MODEL PRODUCTION LINES Due to the unpredictable change in today’s market, manufactures are under a constant pressure to operate their production units having every single line capable of making several different parts for a given period of time. These single lines capable of making several different parts for a given period of time are called as the mixed model production lines. Mixed model production lines are similar to mixed model assembly lines are adopted in many manufacturing facilities today for production flexibility. These production lines help the manufacturing facility to meet the diverse demand of the consumer market. Due to the changes in demand the production lines experience an uneven flow of workload. Hence, it is very essential to keep the load on the production lines equally spread. Processes like scheduling, sequencing and balancing are used to keep the load spread equally in mixed model production lines. Page 1 Single-model lines are used to assemble large numbers of a product whereas multi-model lines are used to assemble different models of the same general product in batches with large lot sizes. Mixed-model lines are used to assemble different models of a product; the models are launched to the line one after another [1]. When some different types of products are manufactured at the mixed-model assembly line and assembly times are significantly different among these product types, the production efficiency usually reduces due to the line stoppage [2, 3]. These mixed model production lines use various production planning techniques to achieve the goals of today’s manufacturing facilities e.g. to function without stoppages. These production-planning techniques use different mathematical equations and formulas and algorithms to deliver the optimal solution. THE EVOLUTION OF SHORT-TERM PRODUCTION PLANNING TECHNIQUES The evolution of short-term production planning techniques followed through four principal eras. These eras are divided as Optimization, Heuristic, Complexity, Interactive schedulers periods [4]. These techniques, which evolved in various periods of time, with their various attributes like control, approach and techniques are represented in the table below Optimization era: The Seventies and Eighties were the ages of Computer Integrated Manufacturing. Its characteristic was strongly a hierarchical top-down control and full automation of manufacturing like integrated optimization. The application of this technique was not a Page 2 great success in the real world due to differences in mono-objective approach and multiobjective approach [4]. Era Control Optimization Approach Hierarchical Automatic Technique Optimization or Heuristic Heuristic Hierarchical Automatic Heuristic Artificial Intelligence Hierarchical Automatic Heuristic Neural Networks Hierarchical Automatic Heuristic Genetic Algorithms Hierarchical Automatic Heuristic Autonomous Agents Hierarchical Automatic Heuristic Interactive Schedulers Distributed Interactive Heuristic + operator Complexity Table 1. Synoptic table of scheduling techniques [4] Heuristic era: Next came the heuristic era, in the Eighties. It concentrated on modeling of reality and an efficient decision support instrument. Due to its static nature and inefficiency in interpreting all possible failures and events the focus was on a more dynamic techniques[4]. Artificial intelligence era: Then came the artificial intelligence era, also known as virtual manufacturing era, extending from the second half of the Eighties to the present. This era has given birth to different techniques like a) Expert systems, b) Neural networks, c) Genetic algorithms, d) Autonomous agent architectures. Page 3 These techniques seem to be the natural (but yet complex) answer to the need of interpreting complex manufacturing systems. The main draw back of this era was the complexity of the systems [4]. Interactive schedulers era: Nineties are the ages of lean/agile/versatile manufacturing. The limitations of CIM paradigm, on one hand and the heuristic approach on the other, have spurred the search of simplicity in short-term production planning system [4]. This is the era of interactive schedulers: they are the simplest kind of scheduling system because the plan is not made by a machine but the planner himself, while the system checks for the feasibility of the decision makers choices [4]. Lowly dynamic techniques Highly dynamic techniques Effectiveness Effectiveness (optimality) (optimality) CIM Artificial intelligence Interactive schedulers Heuristics Efficiency (processing time) Efficiency (processing time) Fig. 1. Short-term production planning techniques [4]. Page 4 Fig. 1 classifies the above-presented techniques according to their dynamism (i.e. the possibility of adapting technique application to the environment evolution) and their trade-off between effectiveness and efficiency [4]. IMPORTANCE OF MIXED MODEL PRODUCTION LINE SEQUENCING Computer-Integrated Manufacturing (CIM) is defined as, “Systems which enable the integrated, rationalized design, development, implementation, operation and improvement of production facilities and their output over the life cycle of the product. These systems identify and use appropriate technology to achieve their goals at minimum cost and effort” [5]. The above definition clearly states the importance design, and improvement of the production facilities role in enabling system to achieve its goals. Here mixed model production lines help in reducing inventories, improving the overall efficiency and increasing profits. The main purpose of mixed models on the production line is to keep the constant usage of every part of the production line. It supports the justin-time (J.I.T) concept of Toyota’s production system. SOME MAJOR GOALS OF MIXED MODEL PRODUCTION/ASSEMBLY LINES Mixed-model assembly lines are widely used in many manufacturing firms to meet diversified demands of consumers without possessing large product inventories. Sequencing products to be manufactured at the mixed-model assembly line is recognized as an important work for improving its performance [6, 7, 8]. The following three different objectives of sequencing of mixed model production lines: Page 5 a) To keep a constant rate of part usages, b) To level the loads (assembly times) at each work station through the line, and c) To keep a constant rate of feeding products into the line [9]. Sequencing for mixed models to be assembled on the conveyor is recognized as an important work for improving the performance of an assembly line or production line. The sequence may vary, depending on the goals of a company [10]. Some of the major goals are 1. The first goal is to level the load (total operation time) at each workstation on the assembly/production line, so as to maximize the operators' efficiency or minimize the risk of stopping the conveyor. This goal has been discussed by, for example, Yano and Rachamadugu [11]. 2. The second goal is to keep the constant usage of every part used in the assembly/production line, which is a good way of fitting the just-in-time (JIT) concept in Toyota production system. This goal was discussed by Bautista, Companys and Corominas [12], Leu, Matheson and Rees [13], Miltenburg and Sinnamon [14, 15, 16], Monden [17], Morabito and Kraus [18], Steiner and Yeomans [19], Sumichrast and Clayton [20], Sumichrast and Russell [21] and Sumichrast, Russell and Taylor [22]. 3. The third goal is to keep the constant feeding of every model fed into the assembly/production line, which is derived from the second goal. This goal has been discussed by, for example, Kubiak [23]. 4. The fourth goal is to minimize the total conveyor stoppage time, which emerged from the autonomation concept in the Toyota production system. This goal has been discussed by, for example, Xiaobo and Ohno [24]. To fulfill these goals in today’s manufacturing industry, many algorithms are developed for scheduling, sequencing, and batching of mixed model production lines. Page 6 PROBLEM STATEMENT In a manufacturing facility, which is involved in fabrication of sheet metals, has a production line consisting a press shop and a surface treatment zone among various other units. Conveyors are used for handling the parts that flow between the press shop and the surface treatment zone. There are six conveyers that run through three baths in the surface treatment zone. The conveyer pauses till the parts in the baths get processed. The manual operation carried out in sequencing the parts according to the demand and process time. Mainly the parts with high demand and low processing times are given priority. The sequencing operation of the parts is done manually. To avoid the manual operation of sequencing between the press shop and the surface treatment process, an automated intelligent sequencing system is designed. Which can sense the type of part arriving and directed it to the surface treatment zone by considering various factors like demand and process time. Processing Lines Bath 1 Automated Bath 2 Sequencing System (ASS) Bath 3 Press Shop Surface Treatment Zone Fig 2. Basic flow of parts Page 7 To accomplish this task, the basic design and an processing steps were borrowed from Choi Wonjoon and Shin Hyunoh [25] and the model was modified to provide a solution to the above manufacturing facility. DESIGN OF AN AUTOMATED SEQUENCING SYSTEM (ASS) As the fabricated sheets finish the de-burring process and gets transported to the surface treatment zone it enters the automated sequencing area. Here, to avoid the manual operation of sequencing between the press shop and the surface treatment process, as well improve the efficiency; an Automated Sequencing System (ASS) is designed. This automated sequencing system is similar to the paint body storage (PBS) system used by Choi Wonjoon and Shin Hyunoh [25]. A system called central production control (CPC) system maintains the parts information. The information in the central production control (CPC) system is updated dynamically every day with respect to the market demand. The automated sequencing system gets information sent by the central production control (CPC) system and compares it with the part data obtained from the sensor placed at the entry point of the system. The parts are sequenced with respect to the data obtained from the central production control system. Central Production Control (CPC) System Towards Surface From Press Shop Treatment Zone Processing lines Programmable Logic Controllers (PLC) Sensor at Exit Sensor at Entry Automatic Sequencing System (ASS) Fig 2. Automatic Sequencing System Page 8 The sequencing process in based mainly on two conditions: 1) Based on the current demand 2) Based on the processing time Programmable logic controllers (PLC) receive the data from the automated sequencing system and direct the parts to the respective process lines. Another sensor is placed at the end of the line, it is used to sense and the number of parts waiting in queue to get processed. The feedback from this sensor is taken to the automated sequencing system for it sequencing process. STEPS FOR SEQUENCING AND LINE CONTROL Most of literature in mixed – model sequencing is for a static problem, that is, the initial creation of the production sequence [17]. An exception is the Toyota’s Goal Coordination Method, which is an extension of the well-known Goal Chasing Method, and was implemented with an expert system [22]. A new dynamic sequencing method is developed to control of the production line [25]. The sequencing and line control algorithm maintains a short list called TDL (To-DoList) which is the linked list of the parts that are already determined to be taken out but still remaining on the process lines. The algorithm tries to keep constant the number of the parts in TOL and the bodies moving to or being accumulated at the entry points of process lines proceeding to the surface treatment zone. Hence, as a part is fed to the assembly line, additional body is appended to TDL [25]. The steps of the output algorithm are as follows: 1) Select the processing line t. 2) Set L, the list of parts, which can be fed to the processing line t now. 3) Select the best part from L. 4) Insert the selected part to TDL. Page 9 At Step 1, the processing line t is the processing line which has smaller 'depletion time.' The depletion time of the processing line i (i=1,2) means the length of interval until all the bodies heading for the assembly line i will be depleted. The depletion time of the processing line i (i=1,2) is calculated as follows: (a) + (b) + (c) . Throughput rate of the assembly line i per hour Where (a) = The number of parts accumulated at the entry point of the Processing line i, (b) = The number of parts of processing line i moving on the output conveyor, (c) = The number of parts of the processing line i in TDL[25]. At Step 2, L consists of the bodies, which are located at the forefront among the bodies not belonging to TDL for each lane. Step 3 is elaborated in the following lines [25]. Since all the parts flowing through the processing lines are of similar dimensions there is no spacing constraint when parts are assigned to the processing lines. So in Step 3 the best part is selected with respect to the criterion explained before. In step 4 the selected part is inserted in the respective processing line, less numbers parts waiting in queue. BENEFITS OF PROPOSED SYSTEM In the current system the sequencing is done manually, but the proposed system works in a more efficiently by using the automated sequencing technique to evenly spreading the load in the system. The proposed system helps to keep a constant rate of part usages. The loads (processing times) at each workstation through the line are leveled or equally distributed and the parts feed into the processing lines are constant, which in turn helps in maximizing the overall efficiency of the system and reducing costs. LIMITATIONS OF THE PROPOSED SYSTEM The current proposed system does not incorporate certain features like variation in the size of parts arriving into the system, since the spacing constraints were already fixed. Page 10 Increasing the system capacity. Adding more processing lines. Are some of the areas where considerable amount of Research & Development remains to be analyzed and accomplished. FUTURE ISSUES The performance analysis of the proposed system can be simulated using simulation packages available in the market. The simulation model can be developed with some experimental conditions and the statistics can be gathered for various conditions. The simulation study might help in studying the capabilities of the present system under various testing conditions. From the data obtained further possibilities in improving and modifying the present system can be analyzed. CONCLUSION The mixed model production lines are the diving force in many manufacturing facilities. Where a variety of models are produced in the same production line [25]. Since there is a lot of variation in the demand level in today’s business environment, the manufacturing facility has to be dynamic in its production efforts and have flexible production lines. An existing production line is taken to find new vistas for improvement. An automated sequencing system in proposed for the above system. The idea is derived from interactive schedulers, because it most efficient technique for today’s dynamic environment. This technique seems to be highly powerful for today’s manufacturing industries. This technique has a good potential for further research and development in near future for its extensive utilization. Page 11 BIBLIOGRAPHY [1] Erdal Erel and Hadi Gokcen “Shortest-route formulation of mixed-model assembly line balancing problem”, European Journal of Operational Research, Volume 116, Issue 1, 1 July 1999, Pages 194-204 [2] L.H. Tsai, “Mixed-model sequencing to minimize utility work and the risk of conveyor stoppage”. Management Science 41 3 (1995), pp. 485¯495. [3] Z. Xlaobo and K. Ohno, “A sequencing problem for a mixed-model assembly line in a JIT production system”. Computer and Industrial Engineering 27 (1994), pp. 71¯74. [4] Maria Caridi and Andrea Sianesi “Multi-agent systems in production planning and control: An application to the scheduling of mixed-model assembly lines”, International Journal of Production Economics, Volume 68, Issue 1, 30 October 2000, Pages 29-42 [5] Nazemetz, W. John, “Hand-Out given in Class,” Lecture No. 1, Fall 2000. [6] J.F. Bard, E. Dar-El and A. Shtub, “An analytic framework for sequencing mixed model assembly lines”. International Journal of Production Research 30 1, INSPEC, pp. 35¯48, 1992. [7] E.M. Dar-El and R.F. Cother, “Assembly line sequencing for model mix”. International Journal of Production Research 13 5 (1975), pp. 463¯477. [8] R.R. Inman and R.L. Bulfin, “Sequencing JIT mixed-model assembly lines”. Management Science 37 7 (1991), pp. 901¯904. [9] W. Kubiak, “Minimizing variation of production rates in just-in-time systems: A survey”. European Journal of Operational Research 66 (1993), pp. 259¯271. [10] Zhao Xiaobo, Zhaoying Zhou and Ainishet Asres. “A note on Toyota's goal of sequencing mixed models on an assembly line”, Computers & Industrial Engineering, Volume 36, Issue 1, January 1999, Pages 57-65 [11] C.A. Yano and R. Rachamadugu, “Sequencing to minimize work overload in assembly lines with product options”. Manage. Sci. 37 (1991), pp. 572¯586. [12] J. Bautista, R. Companys and A. Corominas, “Heuristics and exact algorithms for solving the Monden problem”. Eur. J. Opl. Res. 88 (1996), pp. 101¯113. [13] Y. Leu, L.A. Matheson and L.P. Rees, “Sequencing mixed-model assembly lines with genetic algorithms”. Comput. Ind. Eng. 30 (1996), pp. 1027¯1036. [14] J. Miltenburg and G. Sinnamon, “Scheduling mixed-model multi-level just-intime production systems”. Int. J. Prod. Res. 27 (1989), pp. 1487¯1509. [15] J. Miltenburg and G. Sinnamon, “Algorithms for scheduling multi-level just-intime production systems”. IIE Trans. 24 (1992), pp. 121¯130. [16] J. Miltenburg and G. Sinnamon, “Revisiting the mixed-model multi-level just-intime scheduling problem”. Int. J. Prod. Res. 33 (1995), pp. 2049¯2052 [17] Monden Y. “Toyota production system”. 2nd ed. Institute of Industrial Engineers, Norcross, GA, 1993 [18] M.A. Morabito and M.E. Kraus, A note on “scheduling mixed-model multi-level just-in-time production systems”. Int. J. Prod. Res. 33 (1995), pp. 2061¯2063. [19] G. Steiner and J.S. Yeomans, “Optimal level schedules in mixed-model, multilevel JIT assembly systems with pegging”. Eur. J. Opl. Res. 95 (1996), pp. 38¯52. Page 12 [20] R.T. Sumichrast and E.R. Clayton, “Evaluating sequences for paced, mixedmodel assembly lines with JIT component fabrication”. Int. J. Prod. Res. 34 (1996), pp. 3125¯3143. [21] R.T. Sumichrast and R.S. Russell, “Evaluating mixed-model assembly line sequencing heuristics for just-in-time production systems”. J. Oper. Manage. 9 (1990), pp. 371¯389. [22] R.T. Sumichrast, R.S. Russell and B.W. Taylor, “A comparative analysis of sequencing procedures for mixed-model assembly lines in a just-in-time production system”. Int. J. Prod. Res. 30 (1992), pp. 199¯214. [23] W. Kubiak, “Minimizing variation of production rates in just-in-time systems: a survey”. Eur. J. Opl. Res. 66 (1993), pp. 259¯271. [24] Z. Xiaobo and K. Ohno, “Algorithms for sequencing mixed models on an assembly line in a JIT production system”. Comput. Ind. Eng. 32 (1997), pp. 47¯56. [25] Choi Wonjoon and Shin Hyunoh “A Real-Time Sequence Control System for the Level Production of the Automobile Assembly Line”, Computers & Industrial Engineering, Volume 33, Issues 3-4, December 1997, Pages 769-772 Page 13