sectional glass & aluminum overhead doors - Arm-R-Lite

advertisement

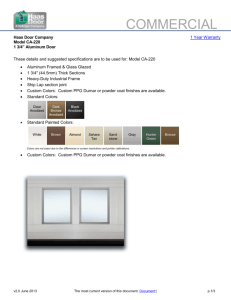

SECTIONAL GLASS & ALUMINUM OVERHEAD DOORS Custom CI 1 PART 1: GENERAL 1.1 SECTION INCLUDES A. operated overhead sectional door (Manual or Motor) B. Aluminum door of rail and stile design. C. Operating hardware and supports 1.2 REFERENCES A. ANSI A216.1-Section Overhead Type Door (NAGDM 102). 1.3 SYSTEM DESCRIPTION A. Sections to be aluminum alloy 6063-T6 B. hardware. operating style with track and (Standard Lift, High Lift, Vertical Lift, or Low Headroom) Track (2” or 3”) 1.4 SUBMITTALS A. Submit shop drawings and product data under provisions of section 01300. B. Shop Drawings: Indicate opening dimensions and required tolerances, connection details, anchorage spacing, hardware locations, installation details. C. Product Data: Provide component construction, anchorage method, and hardware. 1.5 OPERATION AND MAINTENANCE DATA A. Submit under provisions of Section 01700. B. Maintenance Data: Include data for lubrication frequency and spare part sources. 1.7 QUALIFICATIONS A. Manufacturer: Company specializing in manufacturing the Products specified in this section with minimum (20) years documented experience. B. Installer: Company specializing in performing the work of this section with minimum (5) years approved by manufacturer. 1.8 WARRANTY A. 20 YEAR WELDED ALUMINUM FRAME WARRANTY – except for top sections when trolley operated. B. Standard one year warranty applies to the rest of the door. C. Finish Warranty 20-year warranty of finish for clear anodized, dark bronze, stock white, or custom color Duranar® 1-year warranty powdercoat finish 1 PART 2 PRODUCTS 2.1 MANUFACTURERS Standard: For purposes of designating type and quality of work under this Section, Drawings and Specifications are based on products manufactured or Furnished by ARM-R-LITE DOOR MANUFACTURING CO. 2700 Hamilton Blvd. South Plainfield, NJ 07080 800-554-5816 –p 908-754-6522-f info@arm-rlite.com 1. Door Type: CUSTOM CI MODEL by ARM-R-LITE. 2.2 MATERIALS A. Rails and stiles of aluminum alloy 6063-T6 B. finish. (Clear anodized, Dark Bronze anodized, White Enamel, or custom Kynar finish-all 20 year warranty- 1,000’s of colors to choose from, faux wood, powdercoat and textured finishes are also available) 2.3 Panel Construction A. Tubular hollow aluminum shapes to be heli-arc welded in concealed locations. 20 year welded aluminum frame warranty except top sections when trolley operated. B. OPTION: insulated rails and stiles are available in our “Energy Efficiency Package”. C. RAILS AND STILES: .070 Extruded 6063-T6 Alloy 1-3/4” thick Bottom Rail…………..4 1/2” or 7 1/2” tapered or sloping Top Rail………………4 ½” Meeting Rails……….. 3 7/8” Wide per pair End Stiles…………….4 1/2” or 7 1/2” Wide Center Stiles …………3 3/8” Wide D. Sections to contain 2.4 DOOR COMPONENTS A. Hardware: All hinges and fixtures made of 14 gauge galvanized steel. Full floating, ball bearing rollers have hardened steel races, and roller sizes will be adequate for design requirements and limitations. Heavy-duty, fully adjustable roller brackets are attached to each end cap to provide an easy adjustment of the door to the job for proper seal. All hardware is heavy-duty and rust-resistant with galvanized fasteners. Heavy-duty rollers contain steel ball bearings in case-hardened steel races. B. Weather-strip: (Perimeter seal for steel jambs, aluminum door stops for wood jambs) C. Operation (Motor or Manual operation) D. Track: Track is and shall be (2” or 3”) (bracket to wood, angle to wood, or angle to steel E. Torsion Spring with a (tube shaft or an extended solid shaft) F. Sectional Door Assembly: Aluminum door assembly with ship-lap construction To form weather tight joints and provide full-width interlocking structural rigidity. G. Wind load Design: ANSI/AGDM 102 standards and as required by local codes. H. Lock: (Interior slide bolt or keyed cylinder lock or no lock) 2.5 FINISH A. (Clear anodized, Dark Bronze anodize, White enamel, or Custom Kynar finish- all 20 year warranty -1,000’s of colors to choose from, faux wood, powdercoat finish, and textured finishes also available) 2.6 MOTOR OPERATORS Arm-R-Lite Model Motor operators available for every door and track situation. (Trolley operators for standard & low headroom applications) (Jackshaft operators for high lift and vertical lift applications)ALL MOTORS SHOULD HAVE OPTIONS OF CYCLE COUNTERS AND SAFETY REVERSING MECHANISMS 3 PART 3: EXECUTION 3.1 INSPECTION A. Verify that wall openings are ready to receive work and opening dimensions and tolerances are within specified limits. B. Beginning of installation means acceptance of existing surfaces. 3.2 PREPARATION A. Prepare opening to permit correct installation of door unit. 3.3 INSTALLATION A. Install door unit assembly in accordance with manufacturer’s instructions. B. Anchor assembly to wall construction and building framing without distortion or stress C. Secure tracks to structural members only. D. Fit and align door assembly including hardware, level and plumb, to provide smooth operation. E. Coordinate installation of sealant and backing materials at frame perimeter as specified in Section 07900, JOINT SEALERS. F. Install perimeter trim and closures. 3.4 TOLERANCES A. Maintain dimensional tolerances and alignment with adjacent work. B. Maximum variation from Plumb: 1/8 inch. C. Maximum variation from Level: 1/8 inch. D. Longitudinal or Diagonal Warp: Plus or minus 1/8 inch from 10 Ft. straight edge. 3.5 ADJUSTING A. Adjust door assembly to smooth operation. 3.6 CLEANING A. Clean doors, frames and glass. B. Remove labels and visible markings. END OF SECTION- 022814