Chapter 5

advertisement

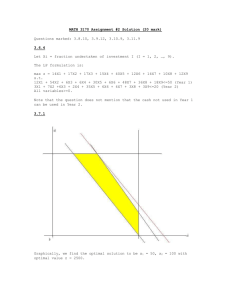

Chapter 5 - Network Modeling : S-41 ————————————————————————————————————————————— Chapter 5 Network Modeling 16. a. 1.012 A1 A2 1.012 1.012 A3 A4 1.012 1.012 1.012 A5 1.035 A6 1.012 1.035 B3 1.035 B1 BB 1.035 1.012 1.035 1.012 1.035 P3 -9999 +50 1.012 B5 1.035 P5 +50 1.058 EB +200 C1 C4 1.058 1.11 D1 b. c. Minimize the total flow from BB (beginning balance) to A1, B1, C1 and D1. See file: PRB5_16.XLS Flow From To $94.985 1 BB 3 B1 $178.673 1 BB 4 C1 $46.676 3 B1 8 B3 $48.309 3 B1 9 P3 $178.673 4 C1 11 C4 $48.309 8 B3 14 P5 $189.036 11 C4 16 EB Total cash required = $273,658 33. Iteration Node Added 1 1 5 2 4 3 3 4 7 5 6 6 2 7 8 8 9 9 Total Cost Cost $0 $85 $20 $25 $30 $20 $30 $35 $25 $270 S-42 : Chapter 5 - Network Modeling ———————————————————————————————————————————————— 5. a. NY 17 Chic. 7 6 +1 18 24 18 95 32 50 LA Denver 27 2 13 30 3 19 5 25 Mem p 24 14 5 35 14 St Lou 35 105 4 San Diego 45 1 -1 b. MIN 5 X12 + 13 X13 + 45 X15 + 105 X17 + 27 X23 + 19 X24 + 50 X25 + 95 X27 + 14 X34 + 30 X35 + 32 X36 + 14 X43 + 35 X45 + 24 X46 + 35 X54 + 18 X56 + 25 X57 + 24 X64 + 18 X65 + 17 X67 ST -X12 - X13 - X15 - X17 = -1 +X12 - X23 - X24 - X25 - X27 = 0 +X13 + X23 + X43- X34 - X35 - X36 = 0 +X24 + X34 + X54 + X64 - X43 - X45 - X46 = 0 + X15 + X25 + X35 + X45 + X65 - X54 - X56 - X57 = 0 + X36 + X46 + X56 - X64 - X65 - X67 = 0 + X17 + X27 + X57 + X67 = +1 Xij 0 c. See file: PRB5_5.XLS The solution is: X13=X36=X67=1 with a minimum total cost of $62. Chapter 5 - Network Modeling : S-43 ————————————————————————————————————————————— 12. a. 35 Cincinnati 5 15 Boston 1 25 Chicago 7 20 Pittsburgh 3 30 5 15 20 5 Memphis 6 15 15 Baltimore 2 25 30 10 Atlanta 4 10 Dallas 8 999 b. c. See file: PRB5_12.XLS The maximum flow is 55 tons. 13. a. +410 Beg Inv 1 +310 +580 $0 D1 $1.50 lb = 0 3 lb = 50 D2 5 +540 +50 $1.50 D3 $1.50 D4 $1.50 lb = 50 7 lb = 50 9 lb = 50 Fin Inv 10 -120 $49 lb = 400 $45 lb = 400 $46 lb = 400 $47 lb = 400 P1 P2 P3 P4 2 4 6 8 -500 -520 -450 -550 note: lb =lower bound b. c. d. See file PRB5_13.XLS Produce 420 in month 1, 520 in month 2, 400 in month 3, 450 in month 4, carry 110 in inventory from month 1 to 2, 50 from month 2 to 3, 140 from month 3 to 4, and 50 at the end of month 4. Total Cost = $83,565. Not much, only $45. S-44 : Chapter 5 - Network Modeling ———————————————————————————————————————————————— 28. a. This is a transportation problem. Note that demand exceeds supply by 20 units. Stores Warehouses 1 +20 2 +25 3 +30 4 +35 5 -30 1 4 6 5 3 6 -30 2 4 4 4 -30 b. 3 3 2 MIN 5 X11 + 4 X12 + 6 X13 + 5 X14 +3 X21 + 6 X22 + 4 X23 + 4 X24 +4 X31 + 3 X32 + 3 X33 + 2 X34 ST -X11 - X12 - X13 - X14 = -30 -X21 - X22 - X23 - X24 = -30 -X31 - X32 - X33 - X34 = -30 +X11 + X21 + X31 + XD1 +20 +X12 + X22 + X32 + XD2 +25 +X13 + X23+ X33 + XD3 +30 +X14 + X24+ X34 + XD4 +35 Xij 0 c. See file: PRB5_28.XLS The optimal solution is: X12 = 25, X14 = 5, X21 = 20, X23 = 10, X34 = 30, XD3 = 20. Minimum total cost = $285. Note that store 3 receives 20 units less than demanded. d. Assign arbitrarily large costs (such as $999) to the arcs representing these flows. The optimal solution is then: X13 = 30, X21 = 20, X24 = 10, X32 = 5, X34 = 25. Minimum total cost = $345. Note that store 2 receives 20 units less than demanded.