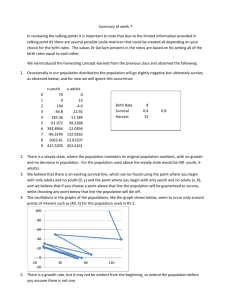

Reaction Simulation Results and Discussion

advertisement

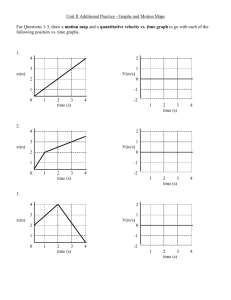

Flow Simulation by 1-D Model A typical set of simulated velocity and holdup profiles for a total cycle time of 80 seconds and LIQUID ON time of 15 seconds are shown in Figure 5.12 and 5.13. The liquid flow rate used is 42 ml/min (1.4 kg/m2s) during LIQUID ON time and 2 ml/min (0.067 kg/m2s) during the rest of the cycle with gas flow of 400 cc/min (0.0192 kg/m2s). The inlet pulse is seen to be sharp with significant spreading as the liquid pulse travels down the reactor. This is observed even with an order of magnitude reduction in spatial and temporal step size and corroborates experimental observations. 0.1 z=0.0 0.09 z=0.25 z=0.45 Liquid Holdup 0.08 z=0.65 0.07 z=0.85 z=1.0 0.06 0.05 0.04 0.03 0.02 0.01 0 0 10 20 time (s) 30 40 Figure 5. 1 Transient Liquid Holdup Profiles at Different Axial Locations in Periodic Flow 0.06 z=0.0 z=0.25 0.05 z=0.45 Liquid Velocity,m/s z=0.65 z=0.85 0.04 z=1.0 0.03 0.02 0.01 0 0 10 20 30 40 time (s) Figure 5. 2 Transient Liquid Velocity Profiles at Different Axial Locations in Periodic Flow Reaction Simulation Results and Discussion The model equations proposed in the previous sub-section are tested here for the alpha-methylstyrene hydrogenation reaction system, for which experimental results are presented in Section 4.3. This reaction system consists of four components, alphamethylstyrene, cumene, hexane and hydrogen. The reactor and catalyst specifications used in the simulation are as tabulated in Section 4.3. Even for a four component system, the number of equations to be solved at each time and axial location can be quite large. For example, for the three pellet apparent rate approach, a set of equations ranging from 92 to 116 needs to be solved, depending upon the wetting conditions (fully wetted pellets: 92 equations, fully dry pellets: 116 equations). These equations originate from the implicit finite difference approximation of the partial differential equations and the nonlinear algebraic equations resulting from the Stefan-Maxwell equations. These are then solved by the multivariable globally convergent Newton method discussed in Section 5.3.4. Typical simulation runs of liquid flow modulation are carried out in two stages. The first stage involves simulation of the reaction to steady state at the mean flow rate to obtain the performance under steady state conditions. This is followed by simulation of one or more cycles with liquid flow ON and OFF (for ON-OFF flow modulation) or with liquid high and low flow (for BASE-PEAK flow modulation). During the first part of the simulation, the inlet velocity and holdup are specified along with the feed concentrations and temperature. The reaction transport equations are solved at each axial location followed by velocity and holdup computation of the entire spatial domain. Figures ___ and ____ depict the development of alpha-methylstyrene concentration profiles at different axial locations with time for a gas limited reaction case (C-MS, feed = 1484 mol/m3 at an operating pressure of 1 atm). Since the rate under these conditions is zero order with respect to alpha-methylstyrene, a linear concentration profile is observed as steady state is reached. Note that the alpha-methylstyrene concentration profiles reach steady state values relatively early as compared to the cumene concentration profiles shown in Figure ____. Cumene concentration profiles reach steady state after about 250 s for this test case as shown in Figure ___. The hydrogen concentration in the liquid phase shows a very interesting behavior as presented in Figure ____. The hydrogen concentration builds to saturation at the exit where low alpha-methylstyrene is present at initial times, whereas at the inlet, it is consumed faster than can be transferred from the gas phase and results in much lower concentration. As liquid reactant (alphamethylstyrene) reaches each point in the vector, the hydrogen concentration drops to its steady state values. 0.005 1.815 5.815 1600 1400 11.853 19.805 Concentration, mol/m3 1200 39.833 1000 74.82 99.93 800 124.817 600 149.811 174.822 400 199.818 200 225.011 250.007 0 0 0.2 0.4 0.6 Axial Location,(z/L) 0.8 1 275.01 299.922 Figure 5.3 Transient alpha-methylstyrene concentration profile development with time (shown in seconds in the legend table) Concentration, mol/m3 0.005 900 1.815 800 5.815 11.853 700 19.805 600 39.833 74.82 500 99.93 400 124.817 300 149.811 174.822 200 199.818 100 225.011 0 250.007 0 0.2 0.4 0.6 Axial Location,(z/L) 0.8 1 275.01 299.922 Figure 5.4. Axial Profiles of Cumene Concentration at Different Simulation Times (shown in the legend table in seconds) Periodic Flow Modulation: Full Cycle Reaction Transport Simulation Several test case simulations were conducted to study the effect of flow modulation to demonstrate the effect of unsteady state operation on species concentration and hence the performance of the trickle-bed. Results of one such test case are presented here to show the effects of flow modulation on reactant and product concentrations over one cycle period. The liquid reactant (alpha-methylstyrene) feed concentration is 1484 mol/m3 and mass velocity is 0.21 kg/m2s (corresponding to an interstitial liquid velocity of 0.009 m/s and feed holdup of 0.03211). The gas superficial velocity used was 3.8 cm/s at 1 atm. operating pressure. The total cycle period () chosen for this case is 60 s with a cycle split () of 0.33. Figure ___ shows supply of alpha-methylstyrene to a previously dry pellet during the liquid ON part of the cycle (0 to 20 s). This is followed by consumption of the alphamethylstyrene by enhanced supply of hydrogen during the liquid OFF part of the cycle (20-60 s). The figure also shows that high alpha-methylstyrene concentrations are also possible at downstream locations when the reactor is operated under unsteady state conditions, which would not be possible in steady state operation. Production rates of cumene are shown in Figure ____ during the same cycle in the same previously dry pellet at different axial locations. At times from 0 to 20 s, cumene production is small due to lower gaseous reactant supply to the pellet, which is followed by high production rates corresponding to enhanced supply of hydrogen to the pellet during the OFF cycle. Figure 5. 5 Intra-catalyst alpha-methylstyrene Concentration Profiles during Flow Modulation for a Previously Externally Dry Pellet at Different Axial Locations Figure 5.6. Intra-catalyst Cumene Concentration Profiles during Periodic Flow Modulation The supply of hydrogen to the catalyst pellet is not easy to show due to its complete consumption as the limiting reactant. Hence, this is shown for a pellet in which reaction rates are low. The hydrogen concentration profile at the beginning of the cycle shows a low concentration (~ 3.5 mol/m3) in the pellet. Hydrogen supply is enhanced due to lower film thickness at high liquid flows. This is followed by significantly higher supply of hydrogen during the OFF part of the cycle, enhancing the reaction rate further, which is reflected in the higher cumene concentration (as shown in Figure ___). Bulk cumene concentration profiles also corroborated the enhanced rate as shown in the Figure ___ for the same set of conditions. This should however not be used in comparison of the steady state profiles since the holdup and velocity changes need to be considered. The correct approach to compare these profiles is to evaluate flow averaged conversion as done in the experimental results. The other rigorous approach is to compare the time averaged reaction rate at each point in the reactor and then to obtain an overall rate (for the cycle) in the entire reactor. This approach is used in the evaluation of simulated reaction rates done in comparison with steady state reaction rates. Cycling Parameter Effects on Performance Several cycling parameters and operating conditions were studied in the experimentally as discussed in Section 4.3. Some of these effects were simulated using the three pellet apparent rate approach for the gas limited case to examine whether the observed trends in the experimental data could be simulated. In all the cases simulated here, the reaction rate constant is set arbitrarily and only the ratio of the unsteady state rate to the steady state rate is considered to estimate the enhancement. Figure ____ shows the effect of space time on the performance enhancement under gas limited conditions at 30 psig operating pressure and feed concentration of 1484 mol/m3. This figure shows higher enhancement at higher space time as observed and discussed in the experimental results discussed earlier in Section 4.3. The enhancement in partial wetting at higher space time causes higher supply of gaseous reactant as discussed earlier and results in reduction of gaseous reactant performance and corresponding higher enhancement over steady state performance. Exact quantitative comparison between this enhancement and the experimentally observed enhancement (depicted in Figure 4.__) is not seen due to several factors such as mass transfer coefficients, thermal effects, assumptions in the apparent rate model, which prevent exact comparison. Due to the large computational time required for each set of data, a sensitivity analysis with respect to above parameters could not be conducted. Hence only quantitative trends are shown in terms of enhancement in rate. Figure ____ shows the total cycle period dependence of the simulated rate at the same operating conditions (P=30 psig, 1484 mol/m3, cycle split = 0.5). The enhancement is seen to decrease with increase in cycle time, implying the extent of liquid reactant starvation can be seen as the decrease in enhancement as the total cycle time is increased. The gaseous reactant starvation and corresponding decrease in performance enhancement observed experimentally is not seen here for the range of cycle times investigated. As discussed above, the exact point at which this phenomenon can be observed depends on the accuracy of the transport parameters. This means that at further lower cycle times such a decrease in enhancement can be expected due to frequent supply of liquid reactants and inadequate time for gaseous reactant supply for complete consumption of the supplied liquid reactant. The influence of cycle split was simulated by setting the same mean flow and varying the liquid ON time to obtain cycle splits of 0.5, 0.33, 0.2 as required. The simulated unsteady state performance shows the expected trend in performance enhancement, i.e., increase in enhancement with a decrease in cycle split. This was observed and explained on the basis of enhanced gaseous reactant access to the catalyst during the liquid OFF time at the same total cycle time of 60 seconds in all the simulations. The extent of enhancement observed is not quantitatively comparable to the experimental enhancement due to factors discussed earlier. The simulation can however be seen to capture the broad trends in the experimentally observed data. Further refinements in the estimation of transport parameters will be able to match the experimentally observed enhancement quantitatively at the expense of large computational effort to obtain exact fits. Enhancement (rate(us)/rate(ss)) 4 3.5 3 P=30 psig, Cfeed=1484 mol/m3, L=0.22 kg/m2s, Cycle time=60 s, split=0.5 2.5 2 1.5 1 0.5 0 300 500 700 Space time, s 900 Figure 5.7 Effect of Mean Liquid Flow (Space time) on Simulated Unsteady State Performance Enhancement (rate(us)/rate(ss)) 3.4 P=30 psig, Cfeed=1484 mol/m3, L=0.22 kg/m2s, split=0.5 3.2 3 2.8 2.6 2.4 2.2 2 0 20 40 60 80 100 120 Cycle Period, s Figure 5.8 Effect of Total Cycle Time on Simulated Unsteady State Performance Enhancement (rate(us)/rate(ss)) 3 P=30 psig, Cfeed=1484 mol/m3, L=0.22 kg/m2s, Cycle time=60 s 2.9 2.8 2.7 2.6 2.5 2.4 2.3 2.2 0 0.1 0.2 0.3 0.4 0.5 0.6 Cycle Split () Figure 5.9 Effect of Cycle Split on Simulated Unsteady State Performance Flow Simulation using CFDLIB (2-D Model) Predicting the complex fluid dynamics in trickle bed reactors is important for their proper design and scale-up. Previous studies have resorted primarily to prediction of overall phase holdup and pressure drop based on an empirical or phenomenological approach (Saez and Carbonnell, 1985; Holub, 1990). Recent advances in understanding of multiphase flow and development of robust codes that can simulate multi-fluid and multi-dimensional problems have made simulation of complex flows such as those observed in trickle beds feasible. Fluid dynamic studies reported in the literature and conducted at CREL (using CFDLIB of Los Alamos) on trickle bed reactors have focussed on predicting steady state phase holdups and velocities to compare with experimental data obtained in steady state operation (Khadilkar, 1997). Recent experimental investigations with unsteady state flow modulation (induced flow modulation or periodic operation) have shown marked improvement in liquid reactant conversion over steady state operation. This is attributed primarily to enhanced supply of liquid reactant to the catalyst for a preset time interval of increased liquid flow rate followed by complete absence of liquid whereby gaseous reactant supply is enhanced. Since CFDLIB is capable of simulating transient multiphase flows (Kashiwa et al., 1994; Kumar 1995), it is the ideal tool for examining the flow distribution under induced flow modulation in trickle bed reactors. The objective of this study is to simulate the effect of induced liquid flow modulation on the time dependent flow distribution inside the trickle bed reactor and to demonstrate that better reactor scale liquid distribution is possible in trickle beds operated under flow modulation. This can validate the hypothesis that maldistribution effects can be nullified by liquid flow modulation. Some modification of the original CFDLIB code is required for simulation of the operation under consideration. These include modification of conventional drag and interfacial exchange terms implemented in CFDLIB using drag formulations developed at CREL or those available in the trickle bed literature. The introduction of interfacial tension term for phasic pressure difference allows computation of the influence of liquid spreading. This test case simulation will serve as a benchmark for comparison with experimental velocity and phase holdup data under unsteady state operation, which have not yet been reported in the open literature. Original Equations: Modeling Interphase Exchange and Interfacial Tension Terms The underlying equations for the CFDLIB code have been discussed in detail in earlier reports by Kumar (1995) and can be found in Kashiwa et al. (1994). CFDLIB developed by Los Alamos National Laboratory, has been used to obtain the results for comparison with the DCM predictions. It is a collection of hydro-codes that share a common numerical solution algorithm, and a common data format. The common solution algorithm is a cell-centered finite-volume method applied to the time-dependent conservation equations (Kashiwa et al., 1994). The governing equations that serve as the basis for the CFDLIB codes are: Equation of continuity: k . k uk k k t (10) Equation of momentum: k u k . k u k u k . k 0 u' k u' k k p k g t [( p0 p) I 0 ]. k 0 u0 k (11) . k 0 k ( p0 p) The special case of one fixed phase (the catalyst bed) has also been incorporated in the code for single and two phase flow simulation. The important terms in simulating trickle bed reactors are the interphase drag term and the influence of phasic pressure difference due to interfacial tension. Phenomenological models developed at CREL by Holub (1990) are incorporated in simulating the drag between the stationary solid phase and each of the flowing phases. The code models the drag force as a product of a user defined exchange coefficient, phase volume fractions, and relative velocity of the two phases k and l as FD( k l ) k l X kl (uk ul ) where the Xkl is modeled by the modified Ergun equation (Holub, 1990; Saez and Carbonell, 1985) with Ergun constants either determined by single phase experiments or using universal values. The exchange coefficient between liquid and solid phase (L-S) and gas and solid phase can then be written as 3 X ( L S) (1 S ) E 1 Re L E 2 Re 2L Lg Ga L | u LS | (1 S ) L Ga L X ( G S) (1 S ) E 1 Re G E 2 Re G2 G g Ga G | u GS | (1 S ) G Ga G 3 For gas-liquid drag, either no interaction is assumed or interaction based on a drag coefficient is used as X ( G L) 0.75L CD |uGL | Ld p For modeling interfacial tension, the well known Leverett’s J function (Dankworth et al., 1990) is used to yield the difference between the gas and liquid pressure calculated in terms of the interfacial tension (), bed permeability (k), and phase fractions as 1 S p L pG k 1/ 2 1 S L 0.48 0.036.ln( ) L The bed permeability (k) is related to Erguns constant E1 and equivalent particle diameter (de) as ((1 S ) / k ) 1/ 2 ( S ) E1 (1 S )d e The simulations are conducted by incorporating the above equation (5) in the pressure calculation step in the code. Test Case Simulation Results and Discussion A test case with a possibility of significant liquid maldistribution was chosen for investigating the effects of induced liquid flow modulation. A two dimensional rectangular model bed of dimensions 29.7 cm x 7.2 cm was considered with pre-assigned porosity values to different cells (33 in the Z direction and 8 in the X direction as shown in Figure 1). Thus 264 values of porosity were generated (with the mean porosity of 0.406 and a variance of 0.04) to form a pseudo random pattern of porosities in the bed (as shown in Figure 1). Liquid flow was introduced at the two central cells at the top of the bed at mean interstitial velocity of 0.1 cm/s, while gas flow was introduced in the rest of the cells at an interstitial velocity of 10.0 cm/s in simulations of both steady and unsteady state operation. Steady state simulation shows evidence of significant maldistribution, particularly at the top and bottom of the reactor (Figure 2a (right) and Figures 3a-3g). Complete absence of liquid is seen in zones near the bottom of the reactor (Figures 2a, 3a, and 3b). Some spreading effect due to surface tension is seen as reported in earlier studies (Khadilkar, 1997), but is not enough to overcome inherent maldistribution effects due to central liquid inlet and the choice of porosity profiles. The liquid flow distribution observed in the above mentioned steady state case was compared with transient simulations carried out with a liquid flow ON time of 15 seconds and a total cycle time of 60 seconds (45 seconds liquid OFF). Snapshots of liquid flow distribution were taken at several time intervals (t= 15, 25, 40, 55 seconds from beginning of liquid ON time) to compare with the steady state liquid holdup data obtained in the earlier simulation of the steady state case. Liquid holdup variation over the reactor cross section is depicted at several axial locations at different times in a typical flow modulation cycle (Figures 3a-3g). These figures clearly demonstrate that unsteady state operation ensures better uniformity in liquid distribution at all locations over that observed in steady state operation. This improved uniformity, although not perfect, does ensure enhanced liquid supply to all locations not previously possible during steady state (in particular, the bottom zones shown in Figures 3a and 3b). These are also plotted as contour plots at t= 15, 25 and 40 seconds shown in Figures 2a, 2b, and 2c, respectively. These clearly show that induced flow modulation results in better liquid spreading and even distribution of liquid over the entire cross section at each axial location at some point in time in the cycle. This also indicates that although the average liquid holdup at each location may not exceed the steady state holdup, the reactor performance may still be enhanced due to higher than steady state holdup for a subinterval of the entire cycle. This time interval of enhanced liquid supply can allow exchange of liquid reactants and products with the stagnant liquid and with the catalyst pellets present in any particular zone. Another observation that can be made from Figures 2a-2c is that for some time interval, all zones in the reactor become almost completely devoid of liquid, and can allow enhanced access of the gaseous reactant to externally dry catalyst during this time interval. Temperature rise and internal drying of catalyst and faster gas phase reaction may also occur in this interval, which can be quenched by the liquid in the next cycle. This demonstrates the possibility of controlled rate enhancement due to induced flow modulation. Title: Creator: TECPLOT Preview : This EPS picture w as not saved w ith a preview included in it. Comment: This EPS picture w ill print to a PostScript printer, but not to other ty pes of printers . Figure 1. Solid Holdup (THE1 = 1.0 - Bed Porsity) Distribution in the Model Trickle Bed (note: lighter areas indicate higher porosity) Title: Creator: TECPLOT Prev iew : This EPS picture w as not s av ed w ith a preview inc luded in it. Comment: This EPS picture w ill print to a Pos tSc ript printer, but not to other ty pes of printers. Figure 2a. Snapshot of Liquid Holdup (THE2) Contours at t =15 s from Start of the Liquid ON Cycle (left) in Comparison with Steady State Holdup Contours (right). (Note: lighter areas indicate higher liquid holdup) Title: Creator: TECPLOT Prev iew : This EPS picture w as not s av ed w ith a preview inc luded in it. Comment: This EPS picture w ill print to a Pos tSc ript printer, but not to other ty pes of printers. Figure 2b. Snapshot of Liquid Holdup (THE2) Contours at t = 25 s from the Start of the Liquid ON Cycle (left) in Comparison with Steady State Holdup Contours (right). (Note: lighter areas indicate higher liquid holdup) Title: Creator: TECPLOT Prev iew : This EPS picture w as not s av ed w ith a preview inc luded in it. Comment: This EPS picture w ill print to a Pos tSc ript printer, but not to other ty pes of printers. Figure 2c. Snapshot of Liquid Holdup (THE2) Contours at t = 40 s from the Start of the Liquid ON Cycle (left) in Comparison with Steady State Holdup Contours (right). (Note: lighter areas indicate higher liquid holdup) 0.120 0.080 0.100 0.060 0.040 0.020 0.080 0.060 0.040 0.020 0.000 Z=1.8 cm from bottom 0.0 1.8 0.000 3.6 5.4 7.2 0.0 1.8 X Location,m 5.4 7.2 (b) 0.120 0.120 Steady State Periodic-t1 Periodic-t2 Periodic-t3 Periodic-t4 Z=9.9 cm from bottom 0.080 Steady State Periodic-t1 Periodic-t2 Periodic-t3 Periodic-t4 Z=18.9 cm from bottom 0.100 Liquid Holdup Liquid Holdup 3.6 X Location,m (a) 0.100 Steady State Periodic-t1 Periodic-t2 Periodic-t3 Periodic-t4 Z=3.6 cm from bottom Liquid Holdup 0.100 Liquid Holdup 0.120 Steady State Periodic-t1 Periodic-t2 Periodic-t3 Periodic-t4 0.060 0.040 0.020 0.080 0.060 0.040 0.020 0.000 0.000 0.0 1.8 3.6 X Location,m (c) 5.4 7.2 0.0 1.8 3.6 X Location,m (d) 5.4 7.2 0.120 0.120 Steady State Periodic-t1 Periodic-t2 Periodic-t3 Periodic-t4 0.080 Steady State Periodic-t1 Periodic-t2 Periodic-t3 Periodic-t4 0.100 Liquid Holdup Liquid Holdup 0.100 0.060 0.040 0.020 0.080 0.060 0.040 0.020 Z=21.6 cm from bottom Z=26.1 cm from bottom 0.000 0.000 0.0 1.8 3.6 5.4 7.2 X Location,m 0.0 1.8 3.6 5.4 7.2 X Location,m (e) (f) 0.120 Steady State Periodic-t1 Periodic-t2 Periodic-t3 Periodic-t4 Liquid Holdup 0.100 0.080 0.060 0.040 0.020 Z=28.8 cm from bottom 0.000 0.0 1.8 3.6 5.4 7.2 X Location,m (g) Figure 3. Comparison of Cross Sectional Liquid Holdup Profiles at Different Axial Locations under Steady and Unsteady State Operation ((a), Z= 0.9 cm; (b), Z= 1.8 cm; (c), Z= 3.6 cm; (d), Z= 18.9 cm; (e), Z= 21.6 cm; (f), Z= 26.1 cm; (g), Z= 28.8 cm)