MHD HEAT TRANSFER IN A LIQUID FILM ON AN UNSTEADY

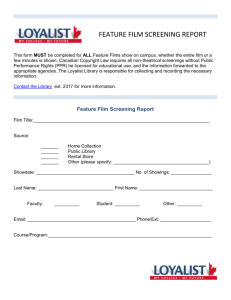

advertisement

SOME EFFECTS OF VISCOUS DISSIPATION AND HEAT SOURCE/SINK ON MHD HEAT TRANSFER OVER AN UNSTEADY STRETCHING SHEET Mamaloukas Ch.a M. Subhas Abelb, Jagadish V. Tawadeb, U.S.Mahabaleshwarc aAthens University of Economics and Business Dept. of Informatics, 76 Patision Str, 10434 Athens, Greece email: mamkris@aueb.gr bGulbarga University, Dept. of Mathematics, Gulbarga- 585 106, Karnataka, INDIA email: msabel2001@yahoo.co.uk (M. Subhas Abel) email: jagadish_maths@yahoo.co.in c Mangalore University, Dept. of Mathematics, Mangalagangothri, Mangalore - 574 199, INDIA email: usmahabalesh@yahoo.co.in Abstract In this paper we present a mathematical analysis of MHD flow and heat transfer to a laminar liquid film from a horizontal stretching surface. Similarity transformations are used to convert unsteady boundary layer equations to a system of non-linear ordinary differential equations. The resulting non-linear differential equations are solved numerically by using efficient numerical shooting technique with fourth order Runge–Kutta algorithm. The effect of Prandtl number Pr and Magnetic parameter Mn on various flow parameters presented through graphs and discussed. Key words: Liquid Film, Unsteady Stretching Surface, Similarity Transformation, Viscous Dissipation, Prandtl number, Magnetic Parameter, Heat source/sink AMS Subject Classification: 35Q30, 35A35 1. Introduction Study of flow and heat transfer within a thin liquid film find applications in extrusion of plastic sheets, polymer, spinning of fibers, cooling of elastic sheets etc. The quality of final product depends on the rate of heat transfer and therefore cooling procedure has to be controlled effectively. If the fluid is very viscous, considerable heat can be produced even though at relatively low speeds, e.g. in the extrusion of plastic, and hence the heat transfer results may alter appreciably due to viscous dissipation. Sarpakaya [1] was the first researcher to study the MHD flow of a non-Newtonian fluid. Prandtl’s boundary layer theory proved to be of great use in Newtonian fluids as NavierStokes equations can be converted into much simplified boundary layer equations which are easier to handle. Crane [2] was the first among others to consider the steady two-dimensional flow of a Newtonian fluid driven by a stretching elastic flat sheet which moves in its own plane with a velocity varying linearly with the distance from a fixed point. Wang [3, 4] have studied 1 the three dimensional flow due to a stretching surface and that due to a stretching surface in a rotating fluid. Dandapat and Ray [7, 8] have studied the thin liquid film flow over a rotating horizontal disk. More recently, Kumari and Nath [9] studied the unsteady MHD film over a rotating infinite disk. Chien-Hsin Chen [11] have studied the effect of viscous dissipation on heat transfer in a non-Newtonian liquid film over an unsteady stretching sheet. Barletta [12] studied the viscous dissipation effect on the fully developed behavior of laminar forced convection for a power-law fluid flowing in a circular tube with a prescribed wall heat flux. Siddheshwar and Mahabaleswar [14] studied analytically the MHD flow and also heat transfer in a viscoelastic liquid over a stretching sheet in the presence of viscous dissipation and radiation. Similarity transformation method was used by Mamaloukas et. al. [13] who studied the problem of second grade fluid flows over a stretching sheet. The influence of heat transfer in an MHD second grade fluid film over an unsteady stretching sheet has been considered by T. Hayat et al [15]. The important observation in this study is, for high values of unsteadiness parameter S reduces the surface temperature which is well in agreement with the results of H. I. Anderson et al [6] and heat sink is one better suited for effective cooling purpose as heat source enhance the temperature in the boundary layer. 2. Formulation of the Problem Consider a thin elastic liquid film of uniform thickness h(t ) lying on the horizontal stretching sheet. The x-axis is chosen in the direction along which the sheet is set to motion. The fluid motion within the film is primarily caused solely by stretching of the sheet. The sheet moves in its own plane with the velocity U x, t bx (1 t ) (1) where b and are both positive constants with dimension per time. The surface temperature Ts of the stretching sheet is assumed to vary with the distance x from the slit as 3 bx 2 2 Ts x, t T0 Tref (1 t ) 2 (2) where T0 is the temperature at the slit and Tref can be taken as a constant reference temperature such that 0 Tref T0 . The flow field is exposed to the influence of an external transverse magnetic field of strength B which is assumed to be of variable kind and is chosen in its special form as 1 B x, t B0 1- t 2 . (3) 2 The velocity and temperature fields of the liquid film obey the following boundary layer equations u v (4) 0, x y u u u 2u B 2 (5) u v 2 0 u, t x y y T T T k 2T u v 2 t x y C p y C p 2 u Q(Ts T0 ). y (6) The pressure in the surrounding gas phase is assumed to be uniform and the gravity force gives rise to a hydrostatic pressure variation in the liquid film. In order to justify the boundary layer approximation, the length scale in the primary flow direction must be significantly larger than the length scale in the cross stream direction. We choose the 1 2 representative measure of the film thickness to be so that the scale ratio is large b x enough i.e., 1 . This choice of length scale enables us to employ the boundary layer 1 b 2 approximations. Further it is assumed that the induced magnetic field is negligibly small. The associated boundary conditions are given by u U , v 0, T Ts at u T 0 at y h, y y dh v at y h. dt y 0, (7) (8) (9) It is noted that the mathematical problem is implicitly formulated only for x 0 . Further it is assumed that the surface of the planar liquid film is smooth so as to avoid the complications due to surface waves. The effect of surface tension is assumed to be u T negligible. The viscous shear stress and the heat flux q k vanish at y y the adiabatic free surface (at y = h). 3. Method of Solution Introducing the stream function x, y, t as defined by u and v , x y (10) 1 2 b the similarity variable 1 t y (11) 3 and 1 b 2 x, y, t x f , 1 t 3 bx 2 T x, y, t T0 Tref 1 t 2 , 2 (12) (13) where f and are dimensionless variables into the equations (4) – (8), we get 2 S f f f ff f Mnf , 2 S Pr 3 (2 f ) f Ec Pr f 2 , 2 (14) (15) It is noted that equation (4) is identically satisfied. The corresponding boundary conditions are reduced to f (0) 1, f (0) 0, f ( ) 0, ( ) 0, S f ( ) . 2 (0) 1, (16) (17) (18) is the dimensionless unsteadiness parameter and the prime indicates b differentiation with respect to . The governing non-linear differential equations (14) and (15) with the appropriate boundary conditions given in (16) to (18) are then solved numerically, using Runge–Kutta fourth order technique along with shooting method ([18], [19]). First of all, higher order non-linear differential equations (14) and (15) are converted into first order differential equations. The problem is reduced to initial value problem, and then it is solved using Runge–Kutta forth order technique applying the shooting technique, to obtain the required solution. Here S 5. Results and discussions The numerical results are obtained for small value of unsteadiness parameter 0 S 2 . It is noteworthy to mention that the solution exists only for 0 S 2 . Moreover, when S 0 the solution approaches to the analytical solution obtained by Crane [2] with infinitely thick layer of fluid ( ). The other limiting solution corresponding to S 2 represents a liquid film of infinitesimal thickness ( 0 ). The step length of h = 0.01 is employed for the computation purpose. The iterative process is terminated until the relative difference between the current and the previous iterative values of f ( ) matches with the 4 S up to a tolerance of 106 . Present results are compared with that of Wang [11] 2 in Table 1 and Table 2. From these tables, we can claim that our results are in excellent agreement with that of Wang [11] under some limiting cases. Some effects of various parameters influencing the dynamics are shown in the figures 2 to 5. Fig.2 shows the variation of film thickness β with the unsteadiness parameter S. It is evident from this plot that the film thickness decreases monotonically when S is increased from 0 to 2. This result concurs with that observed by Wang [11]. . The effects of magnetic parameter Mn, and Prandtl number Pr, on the surface temperature are respectively illustrated in the next figures. The effects of other parameters like, value of Eckert number Ec and heat source/sink parameter on the surface temperature will be illustrated in future research. Clearly, increasing values of magnetic parameter Mn causes the surface temperature to blow-up monotonically. The opposite effect is exhibited in case of Pr i.e., increasing values of Pr decreases the surface temperature. For Prandtl numbers of order unity and below the surface temperature ( ) attains a finite value below 1 and the temperature gradients extend all the way to the free surface. In the limiting case Pr 0 , however, the dimensionless surface temperature tends to unity i.e. the temperature T becomes uniform in the vertical direction and equals Ts . This is consistent with the trivial solution ( ) 1 obtained from the thermal energy equation (15) when Pr = 0. At sufficiently high Prandtl number, i.e. low thermal diffusivity, the surface temperature remained practically equal to zero. Fig.5(a) and 5(b) demonstrate the effect of Prandtl number Pr on the temperature profiles θ(η) for two different values of unsteadiness parameter S. These plots reveals the fact that for a particular value of Pr the temperature increases monotonically from the free surface temperature Ts to wall velocity the T0 as observed by Anderson et al [15]. The thermal boundary layer thickness decreases drastically for high values of Pr i.e., low thermal diffusivity. The effect of Eckert number Ec and heat source/sink on the temperature profile for different values of unsteadiness parameter S will be illustrated in future research similarly. References: 1. L.J. Crane, flow past a stretching plate, Z. Angrew. Math. Phys., 21, (1970), 645-647. 2. H.I. Andersson, K.H. Bech, B.S. Dandapat, Magnetohydrodynamic flow of a powerlaw fluid over a stretching sheet, Int. J. Non-linear Mech., 27, (1992), 929-936. 3. C.Y. Wang, Stretching surface of a rotating fluid, J. Appl. Math. Phys., (ZAMP), 39, (1988), 177-185. 4. C.Y. Wang, Liquid film on an unsteady stretching surface, Quart Appl. Math, 48, (1990), 601-610. 5. C. Wang, Analytic solutions for a liquid film on an unsteady stretching surface, Heat Mass Transfer, 42, (2006), 759–766. 6. H.I. Anderson, J.B. Aarseth, B.S. Dandapat, Heat transfer in a liquid film on an unsteady stretching surface, Int. J. Heat Mass Transfer, 43, (2000), 69-74. 7. B.S. Dandapat, P.C. Ray, Film cooling on a rotating disk, Int. J of Non-linear Mech., 25, (1990), 569-582. 5 8. B.S. Dandapat, P.C. Ray, The effect of thermocapillarity on the flow of a thin liquid film on a rotating disk, J Phys D Appl Phys, 27, (1994), 2041-2045. 9. M. Kumari, G. Nath, Unsteady MHD film flow over a rotating infinite disk, Int. J. Engng. Sci., 42, (2004), 1099-1117. 10. S.D. Conte, C. de Boor, Elementary Numerical Analysis, McGraw-Hill, New York, 1972. 11. Chien-Hsin Chen, Effect of viscous dissipation on heat transfer in a non-Newtonian liquid film over an unsteady stretching sheet, J. Non-Newtonian Fluid Mech., 135, (2006), 128-135. 12. A. Barletta, Fully developed laminar forced convection in circular ducts for power law fluids with viscous dissipation, Int. J. Heat Mass Transfer, 40, (1997), 15-26. 13. C. Mamaloukas, St. Spartalis, Z. Manoussaridis, “Similarity Approach to the Problem of Second Grade Fluid Flows over a Stretching Sheet”, Journal of International Conference on Numerical Analysis and Applied Mathematics 2004, ICNAAM, WILEY-VCH, ESCMSE, Extended Abstracts, (2004), 239-245. 14. P. G. Siddheshwar, U.S. Mahabaleswar, Effects of radiation and heat source on MHD flow of a voscoelastic fluid over a stretching sheet, Int. J. Non-Linear Mech. 40 (2005) 807820. 15. T. Hayat, S. Saif, Z. Abbas, The influence of heat transfer in an MHD second grade fluid film over an unsteady stretching sheet, Physics Letters A, 27 (2008) 1-9. Acknowledgement: The authors are thankful to DST-New Delhi for financial support to pursue this work under DST-Major Research Project (Grant No. SR/S4/MS: 198/03). 6 Tables and Figures Wang [11] Present Results S β f 0 f 0 β f 0 0.4 5.122490 -6.699120 -1.307785 4.981455 -1.134098 0.6 3.131250 -3.742330 -1.195155 3.131710 -1.195128 0.8 2.151990 -2.680940 -1.245795 2.151990 -1.245805 1.0 1.543620 -1.972380 -1.277762 1.543617 -1.277769 1.2 1.127780 -1.442631 -1.279177 1.127780 -1.279171 1.4 0.821032 -1.012784 -1.233549 0.821033 -1.233545 1.6 0.576173 -0.642397 -1.114937 0.576176 -1.114941 1.8 0.356389 -0.309137 -0.867414 0.356390 -0.867416 Table 1: Comparison of values of skin friction coefficient f 0 with Mn = 0.0 Wang [11] Pr Present Results 0 0 0 0.042042 0.351378 1.670913 2.436884 3.027170 0.960438 0.692296 0.097825 0.024869 0.008324 0.042120 0.351920 1.671919 2.443914 3.034915 0.033458 0.304962 1.773032 2.638324 3.279744 0.982312 0.843485 0.286634 0.128174 0.067737 0.033515 0.305409 1.773772 2.638431 3.280329 S = 0.8 and β = 2.15199 0.01 0.1 1 2 3 0.960480 0.692533 0.097884 0.024941 0.008785 0.090474 0.756162 3.595790 5.244150 6.514440 S = 1.2 and β = 1.127780 0.01 0.1 1 2 3 0.982331 0.843622 0.286717 0.128124 0.067658 0.037734 0.343931 1.999590 2.975450 3.698830 Table 2: Comparison of values of surface temperature and wall temperature gradient 0 with Mn = Ec = = 0.0 7 Fig.2. Variation of film thickness β with unsteadiness parameter S with Mn=0.0 Fig.5(a). Variation in the Temperature profiles θ(η) for different values of Pr with S=0.8 Fig.3. Variation of Surface Temperature θ(β) with the Magnetic parameter Mn Fig.5(b). Variation in the Temperature profiles θ(η) for different values of Pr with S=1.2 Fig.4. Variation of Surface Temperature θ(β) with the Prandtl number Pr 8